Contents

Manufacturing Insight: Files For Cnc Router

Optimizing Your Design for Precision CNC Routing at Honyo Prototype

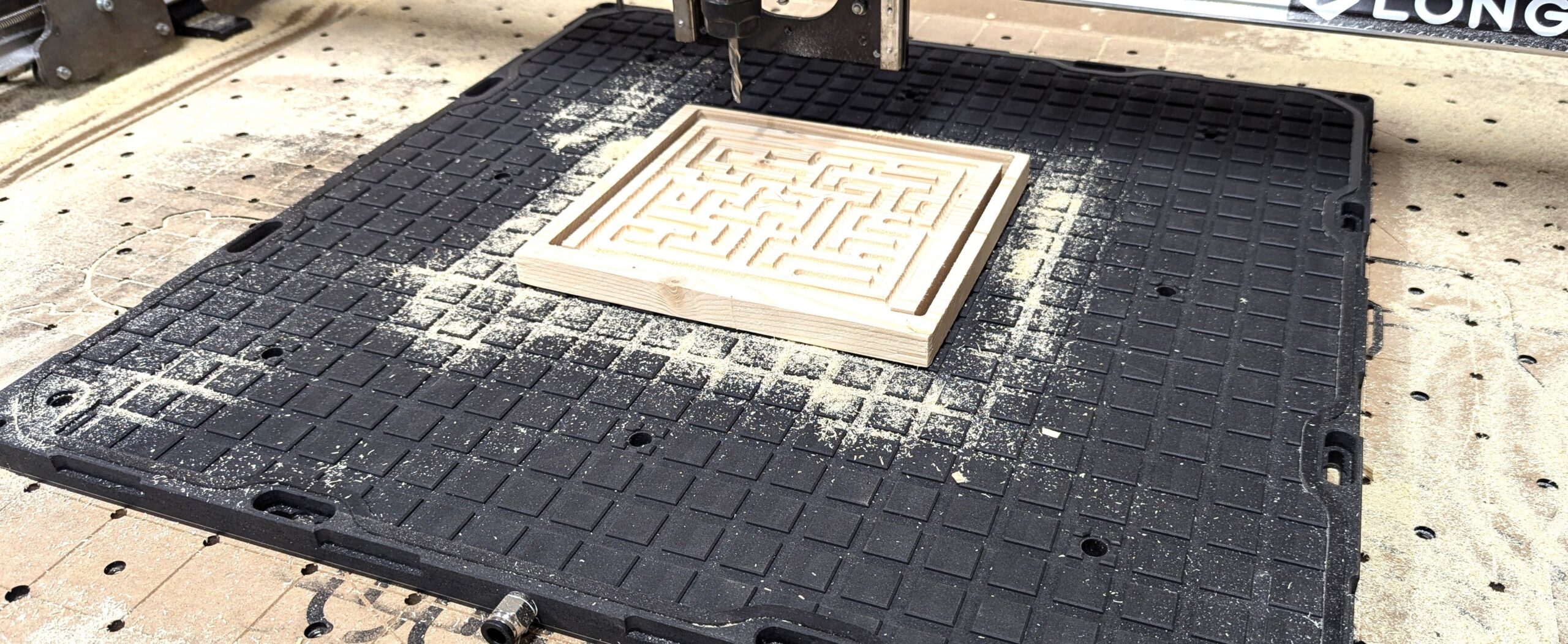

At Honyo Prototype, we understand that the foundation of a successful CNC routing project begins long before the spindle engages the material. The quality, completeness, and manufacturability embedded within your design files directly determine the precision, efficiency, and cost-effectiveness of the final prototype or low-volume production part. Our advanced CNC machining services are engineered to transform your digital concepts into high-fidelity physical components, leveraging state-of-the-art 3-, 4-, and 5-axis routing capabilities for complex geometries in wood, plastics, composites, and non-ferrous metals.

Providing well-prepared files—typically DXF, DWG, STEP, or IGES formats with clear toolpath definitions, accurate dimensions, and specified material requirements—is critical for seamless manufacturing execution. Suboptimal files often lead to extended lead times, unforeseen revisions, and compromised part functionality. Honyo’s engineering team specializes in rigorous file analysis and manufacturability feedback, ensuring your design is optimized for CNC routing efficiency without sacrificing design intent. We proactively identify potential issues like undercuts, thin walls, or non-standard tool requirements, enabling faster iteration and first-article success.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload your CAD files directly to our platform for an immediate, transparent cost estimate based on real-time machine availability, material costs, and geometric complexity. This eliminates traditional quoting delays, allowing you to make informed decisions and initiate production within hours, not days. Trust Honyo Prototype to bridge the gap between your digital design and precision-engineered reality, where file readiness meets manufacturing excellence.

Technical Capabilities

Technical specifications for CNC router files depend on the machining process, material properties, and required tolerances. Below is a summary of key considerations for 3/4/5-axis milling and turning operations, focusing on file requirements, compatible materials, and achievable tolerances.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Typical File Formats | STEP, IGES, STL, DWG, DXF (for 2.5D) | STEP, IGES, Parasolid | STEP, IGES, Parasolid, SolidWorks Part/Assembly | STEP, IGES, DWG |

| Model Type Recommended | Solid or Surface (preferred) | Solid (for complex rotational features) | Solid (full 3D geometry required) | Solid (axisymmetric geometry ideal) |

| Tolerance Capability | ±0.005″ (±0.13 mm) standard; ±0.001″ (±0.025 mm) tight | ±0.005″ standard; ±0.001″ achievable | ±0.002″ standard; ±0.0005″ (±0.013 mm) with precision tooling | ±0.001″ (±0.025 mm) standard; ±0.0005″ with fine tuning |

| Surface Finish (Typical) | 125–32 μin (Ra) | 125–32 μin (Ra) | 125–16 μin (Ra), up to mirror finish with polishing | 32–16 μin (Ra), down to 8 μin with grinding |

| Common Materials | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon | Aluminum, Steel, ABS (for prototypes) | Aluminum (aerospace grades), Stainless Steel, Titanium, Engineering Plastics | Aluminum, Steel, Stainless Steel, Brass, ABS, Nylon (limited) |

| Material Considerations | Aluminum: easy to machine; Steel: requires rigid setup; ABS/Nylon: low melting point, require sharp tools and lower feed rates | Same as 3-axis; additional rotary fixturing considerations | High-speed machining common; tool clearance and collision avoidance critical in programming | Ductile materials like Aluminum and Steel ideal; thermoplastics require reduced heat buildup |

| Fixturing Complexity | Low to moderate (standard vices, clamps) | Moderate (rotary indexer required) | High (multi-angle access, custom fixtures) | Moderate (chucks, collets, steady rests) |

| Programming Software | Fusion 360, Mastercam, SolidCAM | Fusion 360, Mastercam (with 4-axis module) | Mastercam, Hypermill, PowerMill | Mastercam, GibbsCAM, Esprit |

| Lead Time Influence | Fast (standard setups) | Medium (setup and alignment) | Long (programming and verification) | Fast to medium (depending on part complexity) |

Notes on Tight Tolerances:

Achieving tolerances tighter than ±0.001″ requires thermal stability, high-precision tooling, and calibrated equipment.

Multi-axis milling (4/5-axis) reduces setup steps and improves accuracy for complex geometries.

For Aluminum and Steel, use of coolant and proper tool paths minimizes thermal expansion.

Plastics like ABS and Nylon require reduced spindle speeds and sharp cutters to prevent melting or burring.

Ensure all CAD models are watertight, with correct units (inches or mm), and include geometric dimensioning and tolerancing (GD&T) where applicable for critical features.

From CAD to Part: The Process

Honyo Prototype maintains a rigorous, client-centric workflow for CNC router projects designed to ensure precision, efficiency, and seamless project execution. Our standardized process for handling “files for CNC router” follows five distinct phases, each optimized for manufacturability and client transparency.

Upload CAD

Clients initiate the process by uploading native CAD files (preferred formats: STEP, IGES, DWG, DXF, or native SolidWorks/ Fusion 360) through our secure online portal. We explicitly require geometrically accurate 3D models or 2D vector files with complete dimensional data. File validation occurs immediately upon upload, checking for unit consistency, closed profiles, and layer integrity. Non-native formats (e.g., PDF, JPEG) trigger an automated notification requesting corrected source files to prevent interpretation errors inherent in image-based data.

AI Quote

Validated CAD files enter our proprietary AI-driven quoting engine, which analyzes geometric complexity, material requirements, and machine time estimates. The system cross-references real-time shop floor data including router spindle availability, tooling libraries, and material stock levels. Within 90 minutes, clients receive a preliminary quote detailing cost breakdowns, lead time projections, and material recommendations. This AI estimate is explicitly labeled as provisional; final pricing requires engineering validation during DFM to account for nuanced manufacturability factors the AI cannot fully assess.

DFM (Design for Manufacturability)

All projects undergo mandatory engineering-led DFM review by our CNC specialists. This phase focuses on router-specific constraints:

Material grain direction optimization for wood/composites

Minimum feature size validation against tool diameter (e.g., 3mm end mills cannot cut 2mm internal corners)

Pocket depth-to-width ratio analysis to prevent tool deflection

Nesting efficiency assessment for sheet materials

Kerf compensation adjustments for vector paths

Key CNC router DFM checks include:

| Parameter | Standard Tolerance | Critical Risk if Ignored |

|---|---|---|

| Internal Corner Radius | ≥ Tool Radius | Tool breakage, incomplete cuts |

| Thin Wall Thickness | ≥ 2x Material Thickness | Vibration-induced chatter, part failure |

| Through-Cut Kerf | +0.1mm per side | Misaligned assemblies, fit issues |

| Undercut Features | Requires specialized tooling | Non-manufacturable geometry |

Engineers provide actionable feedback within 4 business hours via annotated markups, offering specific redesign suggestions to eliminate non-value-added operations. Client approval of DFM recommendations is required before proceeding.

Production

Approved designs move to production on our CNC router fleet (including 5-axis and high-speed machining centers). We implement:

Material verification per client specifications (e.g., FSC-certified plywood, aerospace-grade aluminum)

Digital toolpath simulation to prevent collisions and verify cut sequences

In-process inspections at critical stages using calibrated CMMs for dimensional verification

Batch processing optimization where multiple client parts are nested on a single sheet to reduce waste and cost

All router programs include adaptive toolpath strategies to maintain consistent chip load and surface finish, with real-time spindle power monitoring to detect anomalies.

Delivery

Completed parts undergo final QA per AS9102 standards, including first-article inspection reports for quantities over 50 units. Parts are cleaned, deburred, and packaged with anti-static protection for sensitive materials. Delivery includes:

Dimensional conformance report against original CAD

Material certification documentation

As-machined 3D scan data (optional, client-requested)

Digital work package with revised CAM files

Standard lead time from DFM approval to shipment is 5-7 business days for prototypes and 10-12 days for small production runs, with expedited options available. All deliveries include tracking with real-time shop floor progress visibility via our client portal. This integrated workflow ensures CNC router projects achieve target quality while minimizing iteration cycles and cost overruns.

Start Your Project

Need precision files for your CNC router project? Get in touch with Susan Leo at [email protected] to request technical specifications, file formats, and manufacturing support.

Our factory in Shenzhen ensures fast turnaround and high-accuracy production tailored to your design requirements.

Contact:

Susan Leo

Email: [email protected]

Location: Shenzhen, China

Let’s streamline your prototyping process with optimized CNC-ready files.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.