Introduction: Navigating the Global Market for fiber laser for cutting metal

In the fast-evolving landscape of industrial manufacturing, sourcing the right fiber laser for cutting metal can be a daunting task for B2B buyers. With numerous options available, organizations must navigate through a complex web of specifications, applications, and supplier offerings to make informed purchasing decisions. This comprehensive guide aims to demystify the fiber laser market by providing insights into various types of machines, their applications across industries, and the critical factors to consider when vetting suppliers. From understanding power capacities and cutting speeds to evaluating the total cost of ownership, this guide equips decision-makers with the knowledge necessary to choose the ideal solution tailored to their specific needs.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany, will find valuable information on the latest advancements in fiber laser technology. By exploring market trends, cost-effective options, and potential ROI from in-house metal cutting solutions, this guide empowers organizations to enhance their operational efficiency and competitive edge. As we delve deeper into this intricate market, our goal is to provide actionable insights that facilitate smarter investments in fiber laser technology, ultimately driving growth and innovation within the metal fabrication sector.

Understanding fiber laser for cutting metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Enclosed Fiber Laser Cutters | Fully enclosed design, enhanced safety, reduced noise, and dust containment. | Aerospace, automotive, and precision parts. | Pros: Safer operation, cleaner environment. Cons: Higher initial cost. |

| Open Bed Fiber Laser Cutters | Open design for larger materials, versatile for various sheet sizes. | Signage, architectural elements, and prototypes. | Pros: Flexibility with sheet sizes, easier access. Cons: Less safe, potential for debris. |

| Flatbed Fiber Laser Cutters | Capability to cut large sheets (up to 5×10 ft), efficient for high-volume production. | Metal fabrication, large signage, and automotive. | Pros: High productivity, low operating costs. Cons: Requires significant floor space. |

| Tube and Pipe Fiber Laser Cutters | Specialized for cutting cylindrical materials, adjustable for various tube sizes. | Furniture, automotive exhaust systems, and pipelines. | Pros: Precision in tube cutting, versatile for different diameters. Cons: Limited to tubular materials. |

| High-Power Fiber Laser Cutters | Power options ranging from 1kW to over 20kW, ideal for thick materials and high-speed cutting. | Heavy industry, shipbuilding, and large-scale fabrication. | Pros: Handles thicker materials, faster cutting speeds. Cons: Higher energy consumption, expensive initial investment. |

What Are Enclosed Fiber Laser Cutters and Their Suitability for B2B Buyers?

Enclosed fiber laser cutters provide a safe and contained environment for metal cutting, reducing noise and dust exposure. These machines are particularly suitable for industries like aerospace and automotive, where precision and safety are paramount. B2B buyers should consider the initial investment versus the long-term benefits of reduced workplace hazards and maintenance costs. The enclosed design can also lead to better material handling and less waste.

Why Choose Open Bed Fiber Laser Cutters for Versatile Applications?

Open bed fiber laser cutters are designed for flexibility, accommodating various sheet sizes and materials. They are ideal for applications in signage and architectural elements, where large pieces are frequently cut. B2B buyers should weigh the benefits of accessibility and versatility against safety concerns, as the open design may expose operators to debris and laser hazards. These machines are typically more affordable than their enclosed counterparts.

How Do Flatbed Fiber Laser Cutters Enhance Production Efficiency?

Flatbed fiber laser cutters are engineered for high-volume production, capable of cutting large sheets efficiently. They are widely used in metal fabrication and automotive industries, where cutting speed and precision directly impact productivity. B2B buyers should consider the machine’s footprint and operating costs, as these units require significant space but can deliver a rapid return on investment through reduced outsourcing and labor costs.

What Are the Advantages of Tube and Pipe Fiber Laser Cutters?

Tube and pipe fiber laser cutters are specialized machines that excel in cutting cylindrical materials with high precision. They are commonly used in furniture manufacturing and automotive exhaust systems. For B2B buyers, investing in this type of cutter means having the ability to handle various tube sizes, but it is essential to recognize that these machines are limited to tubular materials, which may not suit all operations.

Why Invest in High-Power Fiber Laser Cutters for Heavy-Duty Applications?

High-power fiber laser cutters, with capabilities ranging from 1kW to over 20kW, are designed for cutting thick materials at high speeds. They are particularly beneficial in heavy industries such as shipbuilding and large-scale fabrication. While these machines offer significant advantages in terms of speed and material handling, B2B buyers must consider the higher energy consumption and initial costs associated with high-power models, balancing these factors against the potential for increased productivity.

Key Industrial Applications of fiber laser for cutting metal

| Industry/Sector | Specific Application of fiber laser for cutting metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision cutting of automotive panels and components | Enhanced production efficiency and reduced waste | Machine power options, cutting speed, and material compatibility |

| Aerospace | Cutting intricate parts for aircraft components | High accuracy and lightweight designs | Certification standards, material types, and safety features |

| Metal Fabrication | Custom metal fabrication for industrial applications | Flexibility in design and cost savings | Customization options, maintenance support, and ROI analysis |

| Electronics | Cutting of enclosures and brackets for electronic devices | Improved product quality and design versatility | Precision requirements, compatibility with various metals, and after-sales service |

| Jewelry | Intricate designs and custom pieces | Unique offerings and competitive advantage | Laser precision, material types, and engraving capabilities |

How Is Fiber Laser Used in Automotive Manufacturing?

In the automotive industry, fiber lasers are employed for precision cutting of panels and components, significantly improving production efficiency. By utilizing high-powered lasers, manufacturers can achieve intricate cuts with minimal material waste. This technology addresses the challenge of maintaining stringent quality standards while reducing operational costs. Buyers in this sector should consider machine power options and cutting speed, as well as the compatibility of the laser with various metals used in vehicle production.

What Role Does Fiber Laser Play in Aerospace Applications?

Fiber lasers are crucial in aerospace for cutting intricate parts used in aircraft components. This technology enables manufacturers to produce lightweight designs that adhere to strict safety and performance standards. The precision offered by fiber lasers mitigates the risk of defects, ensuring high-quality components that meet regulatory requirements. Buyers in this field must focus on certification standards, the types of materials being processed, and the safety features of the equipment to ensure compliance with industry norms.

How Does Fiber Laser Enhance Metal Fabrication?

In the metal fabrication sector, fiber lasers are utilized for custom metal fabrication, allowing businesses to create tailored solutions for various industrial applications. The flexibility of fiber lasers enables rapid changes in design, which can lead to significant cost savings and a competitive edge. Buyers should evaluate customization options, the level of maintenance support provided, and conduct an ROI analysis to justify the investment in fiber laser technology.

In What Ways Is Fiber Laser Beneficial for Electronics Manufacturing?

Fiber lasers are increasingly used in the electronics industry for cutting enclosures and brackets for devices. The high precision of fiber lasers ensures that components fit seamlessly, enhancing overall product quality. Furthermore, the versatility of this technology allows manufacturers to experiment with different designs, catering to market demands effectively. Buyers should prioritize precision requirements, the compatibility of the laser with various metals, and the availability of after-sales service when sourcing these machines.

How Is Fiber Laser Transforming Jewelry Production?

In the jewelry industry, fiber lasers enable the creation of intricate designs and custom pieces that stand out in a competitive market. This technology allows jewelers to achieve a level of detail that is often unattainable with traditional cutting methods. The ability to offer unique designs can provide a significant competitive advantage. Buyers should consider the laser’s precision, the types of materials that can be processed, and the engraving capabilities to meet customer demands effectively.

3 Common User Pain Points for ‘fiber laser for cutting metal’ & Their Solutions

Scenario 1: Inconsistent Cutting Quality and Precision

The Problem: Many B2B buyers encounter the challenge of inconsistent cutting quality when using fiber lasers for metal fabrication. This inconsistency often manifests in irregular cut edges, varying kerf widths, and inaccurate dimensions, which can lead to increased waste and rework. Such issues not only compromise the integrity of the final product but can also tarnish a company’s reputation in competitive markets. Buyers may find that they are unable to meet client specifications, leading to delays and potential loss of business.

The Solution: To address this pain point, it’s essential to invest in fiber laser systems equipped with advanced features such as auto-height adjustment and closed-loop feedback systems. These technologies help maintain consistent focal lengths and cutting speeds, ensuring high precision across various materials. Buyers should work closely with suppliers to understand the specific capabilities of different models, ensuring they select a system tailored to their unique needs. Regular maintenance and calibration of the laser system are also crucial; implementing a scheduled maintenance program can help mitigate inconsistencies. Additionally, investing in training for operators on best practices for setup and operation can significantly enhance cutting quality.

Scenario 2: High Operational Costs and Inefficiencies

The Problem: Another significant challenge faced by businesses is the high operational costs associated with running fiber laser systems. This includes expenses related to energy consumption, gas usage, and maintenance. Buyers often find that while the initial investment in fiber laser technology is manageable, the ongoing costs can quickly escalate, impacting overall profitability. Inefficiencies in production processes, such as excessive downtime or slow cutting speeds, can exacerbate these financial burdens.

The Solution: To combat high operational costs, buyers should focus on selecting energy-efficient fiber laser models that offer lower power consumption without sacrificing performance. Systems that utilize nitrogen or oxygen cutting gases efficiently can significantly reduce material costs—some operations report expenses as low as $0.25 per hour. Additionally, optimizing the cutting process through software solutions can enhance workflow efficiency. Implementing a comprehensive training program for staff can help operators maximize the machine’s capabilities, ensuring that cutting speeds and settings are optimized for different materials. Regular performance reviews and audits can identify bottlenecks in the production process, allowing for strategic adjustments to improve overall operational efficiency.

Scenario 3: Difficulties in Scalability and Customization

The Problem: As businesses grow, they often struggle with the scalability of their cutting operations. Many buyers find that their current fiber laser systems are not capable of handling increased production demands or varied material specifications. This limitation can hinder growth opportunities and lead to missed contracts if the equipment cannot adapt to new projects or larger batch sizes.

The Solution: To ensure scalability, buyers should consider modular fiber laser systems that can be easily upgraded or customized. Engaging with suppliers who offer a variety of power options and configurations allows businesses to tailor their equipment to meet changing demands. For instance, investing in a machine that can handle both small parts and full sheets can significantly enhance flexibility. Additionally, incorporating automation solutions, such as robotic arms for loading and unloading materials, can streamline production and reduce labor costs. Buyers should also explore partnerships with equipment manufacturers for ongoing support and upgrades, ensuring that their systems remain relevant and capable of meeting future demands.

Strategic Material Selection Guide for fiber laser for cutting metal

When selecting materials for fiber laser cutting, it is essential to understand the properties, advantages, and limitations of the most commonly used metals. This knowledge helps international B2B buyers make informed decisions that align with their operational needs and market standards.

What Are the Key Properties of Carbon Steel for Fiber Laser Cutting?

Carbon steel is one of the most frequently cut materials using fiber lasers due to its favorable properties. It typically exhibits high strength and excellent machinability, making it suitable for various applications, including automotive parts and structural components. Carbon steel’s melting point ranges from 1425°C to 1540°C, allowing for efficient cutting at high speeds.

Pros: Carbon steel is cost-effective and readily available, making it an attractive option for manufacturers. Its durability and strength contribute to long-lasting products.

Cons: However, carbon steel is susceptible to corrosion if not properly treated or coated, which can limit its use in certain environments. Additionally, the cutting process may produce heat-affected zones that can weaken the material.

Impact on Application: Carbon steel is ideal for applications requiring structural integrity, but it may necessitate additional surface treatments for corrosion resistance, especially in humid or coastal regions.

How Does Stainless Steel Perform in Fiber Laser Cutting Applications?

Stainless steel is another popular choice for fiber laser cutting, known for its corrosion resistance and aesthetic appeal. It has a melting point of approximately 1400°C to 1450°C, making it suitable for high-precision applications.

Pros: The key advantage of stainless steel is its resistance to oxidation and corrosion, making it ideal for food processing, medical devices, and architectural applications. Its polished finish also adds to its appeal in consumer products.

Cons: On the downside, stainless steel tends to be more expensive than carbon steel, which can impact budget considerations for large-scale projects. Its higher thermal conductivity can also lead to challenges in maintaining cutting precision.

Impact on Application: Stainless steel is widely used in industries where hygiene and aesthetic quality are paramount, but buyers must consider the cost implications and ensure compliance with relevant standards, such as ASTM A240.

What Are the Benefits of Aluminum in Fiber Laser Cutting?

Aluminum is favored for its lightweight and excellent corrosion resistance, making it a popular choice for applications in aerospace, automotive, and consumer goods. With a melting point of around 660°C, aluminum can be cut efficiently with fiber lasers.

Pros: The primary advantage of aluminum is its low density, which allows for lighter structures without sacrificing strength. Its excellent thermal and electrical conductivity also makes it suitable for various applications.

Cons: However, aluminum can be more challenging to cut due to its reflective properties, which can affect laser efficiency and cutting quality. Additionally, it may require specific settings to achieve optimal results.

Impact on Application: Aluminum is ideal for applications requiring weight reduction, but buyers must ensure their laser systems are equipped to handle its unique cutting challenges.

What Role Does Copper Play in Fiber Laser Cutting?

Copper is less commonly cut with fiber lasers but is gaining traction due to its excellent thermal and electrical conductivity. With a melting point of approximately 1085°C, copper presents unique challenges and opportunities in cutting applications.

Pros: The key advantage of copper is its superior conductivity, making it essential for electrical components and heat exchangers. It also has a high thermal expansion rate, which can be beneficial in certain applications.

Cons: The main limitation of copper is its high reflectivity, which can lead to difficulties in achieving effective laser absorption. This can result in increased operational costs and potential quality issues.

Impact on Application: Copper is ideal for high-performance electrical applications, but buyers must consider the specific requirements and potential limitations of their laser systems when working with this material.

| Material | Typical Use Case for fiber laser for cutting metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components, automotive parts | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, medical devices | Corrosion resistance | Higher cost than carbon steel | Med |

| Aluminum | Aerospace, automotive, consumer goods | Lightweight and excellent conductivity | Challenging cutting due to reflectivity | Med |

| Copper | Electrical components, heat exchangers | Superior conductivity | High reflectivity affects cutting | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them navigate the complexities of fiber laser cutting and make informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fiber laser for cutting metal

What Are the Main Stages of Manufacturing Fiber Lasers for Metal Cutting?

The manufacturing process of fiber lasers for cutting metal encompasses several crucial stages: material preparation, forming, assembly, and finishing. Each of these phases is designed to ensure that the final product meets the high standards expected by B2B buyers.

Material Preparation

The initial phase involves selecting high-quality raw materials, typically including advanced alloys and specialized optical fibers. These materials are meticulously inspected for purity and structural integrity. Suppliers often use laser-cutting techniques to create precise components that will later be assembled into the laser system. This stage is crucial as the quality of the materials directly influences the performance and longevity of the fiber laser.

Forming

In this phase, the raw materials undergo various mechanical processes. Advanced CNC machining is commonly employed to create the intricate parts required for the laser system, such as the laser cavity and the focusing lens. Precision in forming is vital, as any deviation can affect the laser’s performance. Additionally, techniques like stamping or bending may be used for metal housing and structural components, ensuring a robust design capable of withstanding operational stresses.

Assembly

Once the components are formed, they are brought together in a controlled environment. This stage often involves skilled technicians who meticulously assemble the laser systems, ensuring each part fits perfectly. The assembly process may also include integrating electronic components, such as control systems and cooling units. Rigorous checks during this phase help prevent defects, as even minor errors can lead to significant operational issues.

Finishing

The finishing stage involves multiple processes, including polishing, coating, and final inspections. These treatments enhance durability and aesthetics, while also protecting components from environmental factors. For example, laser-cut parts may be anodized to prevent corrosion, especially important for buyers in regions with harsh climates, such as the Middle East and parts of Africa.

How Is Quality Assurance Implemented in Fiber Laser Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process for fiber lasers, ensuring that products meet international standards and customer expectations. Key QA practices include adherence to relevant international standards, systematic checkpoints throughout the manufacturing process, and comprehensive testing methods.

What Are the Relevant International Standards for Fiber Laser Manufacturing?

Compliance with international standards, such as ISO 9001, is essential for manufacturers seeking to establish credibility in the global market. ISO 9001 focuses on quality management systems and emphasizes continuous improvement and customer satisfaction. Additionally, industry-specific certifications, like CE marking for products sold in Europe or API standards for certain applications, are vital for demonstrating compliance with safety and performance regulations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) checks the quality of raw materials before production begins. In-Process Quality Control (IPQC) ensures that manufacturing processes adhere to specified parameters, while Final Quality Control (FQC) involves comprehensive testing of the finished product. These checkpoints help identify and rectify issues early, minimizing costly rework and ensuring consistency.

What Testing Methods Are Commonly Used?

Manufacturers utilize various testing methods to evaluate the performance of fiber lasers. Common tests include beam quality assessment, cutting speed and efficiency evaluations, and thermal performance tests. These tests ensure that the laser systems can meet the demands of different applications, such as cutting thick metals or intricate designs.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those from diverse regions such as Africa, South America, and Europe, must adopt a proactive approach to verify the quality control processes of their suppliers. Several methods can be employed to ensure that the manufacturer adheres to stringent quality standards.

What Role Do Audits and Reports Play in Supplier Evaluation?

Conducting audits is one of the most effective ways to assess a supplier’s quality control measures. Buyers can request access to quality management system documentation, including internal audit reports, corrective action plans, and compliance records. These documents provide insights into the supplier’s commitment to quality and their ability to meet international standards.

How Important Are Third-Party Inspections?

Engaging third-party inspectors can offer an unbiased assessment of the manufacturing processes and quality assurance practices of a supplier. These inspectors can verify compliance with relevant standards and conduct independent tests to confirm product quality. This is particularly beneficial for B2B buyers who may not have the resources to perform extensive in-house evaluations.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers must navigate various quality control nuances when sourcing fiber lasers for metal cutting from international suppliers. Understanding regional standards and expectations is crucial for successful transactions.

Are There Regional Standards to Consider?

Different regions may have specific regulations and standards that manufacturers must adhere to. For instance, products sold in the European Union must comply with CE marking requirements, while products in the United States may need to meet ANSI standards. Buyers should familiarize themselves with these requirements to avoid compliance issues that could hinder market entry.

What Are the Implications of Quality Control on Supply Chain Management?

Effective quality control processes can significantly impact supply chain management. By ensuring that suppliers maintain high-quality standards, buyers can reduce the risk of defects, minimize downtime, and enhance overall operational efficiency. This is particularly critical for industries with stringent quality requirements, such as automotive or aerospace manufacturing.

In conclusion, understanding the manufacturing processes and quality assurance practices for fiber lasers is essential for B2B buyers aiming to make informed purchasing decisions. By focusing on these aspects, buyers can ensure they select reliable suppliers that will deliver high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiber laser for cutting metal’

Introduction

This practical sourcing guide aims to provide B2B buyers with a comprehensive checklist to facilitate the procurement of fiber lasers for metal cutting. Selecting the right fiber laser is crucial for enhancing productivity, reducing operational costs, and ensuring high-quality output in metal fabrication processes. This guide will help you navigate the complexities of sourcing these advanced machines effectively.

Step 1: Define Your Technical Specifications

Before beginning your search for a fiber laser, it is essential to outline your specific technical requirements. Consider factors such as the types of materials you will be cutting, the thickness of the metals, and the desired cutting speed.

– Power Requirements: Assess the laser power needed (e.g., 1 kW to 22 kW) based on your cutting needs.

– Work Area Size: Determine the maximum dimensions of the materials you plan to process.

Step 2: Research Available Brands and Models

Conduct thorough research on various brands and their fiber laser models. Different manufacturers offer unique features, efficiencies, and price points that can significantly impact your operations.

– Manufacturer Reputation: Look for brands with a strong track record in the industry.

– Model Comparisons: Evaluate models based on specifications, performance, and user reviews to find the best fit for your needs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to perform a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Supplier Credentials: Verify certifications, warranties, and support services offered.

– Past Performance: Ask for customer testimonials to gauge satisfaction levels and reliability.

Step 4: Understand Total Cost of Ownership

When evaluating fiber lasers, consider the total cost of ownership (TCO), which includes not just the purchase price but also operational costs such as energy consumption, maintenance, and consumables.

– Operational Efficiency: Look for machines that offer low running costs, especially regarding energy and gas usage.

– Maintenance Needs: Assess the expected maintenance frequency and costs to avoid unexpected expenses.

Step 5: Request Demonstrations and Trials

Whenever possible, request live demonstrations or trial periods for the fiber lasers you are considering. Seeing the machine in action can provide valuable insights into its performance and ease of use.

– Performance Metrics: Pay attention to cutting speed, precision, and material versatility during the demonstration.

– Operator Experience: Evaluate how user-friendly the machine is, as this will impact training and operational efficiency.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a preferred supplier, engage in negotiations to secure favorable terms and conditions. This includes payment options, delivery timelines, and after-sales support.

– Warranty and Support: Ensure you understand the warranty terms and the level of technical support available post-purchase.

– Flexible Payment Plans: Inquire about financing options or installment plans that can ease the upfront financial burden.

Step 7: Finalize Your Purchase and Plan for Installation

After concluding negotiations, finalize your purchase and prepare for installation. Coordinate with the supplier for shipping and setup to minimize downtime.

– Installation Support: Confirm if the supplier offers on-site installation and training for your team.

– Operational Readiness: Ensure that your facility is equipped to accommodate the new machinery, including power requirements and space.

By following this checklist, B2B buyers can make informed decisions when sourcing fiber lasers for metal cutting, ensuring a successful investment in their manufacturing capabilities.

Comprehensive Cost and Pricing Analysis for fiber laser for cutting metal Sourcing

What Are the Key Cost Components of Fiber Lasers for Cutting Metal?

Understanding the cost structure of fiber lasers for metal cutting is essential for B2B buyers looking to optimize their investments. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The core components of fiber laser systems, including the laser source, optics, and cutting head, play a significant role in the overall cost. High-quality materials can lead to better performance and longevity, which might justify a higher initial investment.

-

Labor: Skilled labor is required for the assembly, testing, and maintenance of fiber lasers. Labor costs can vary significantly based on geographical location and the complexity of the machine.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and indirect labor. Efficient manufacturing processes can help keep these costs lower.

-

Tooling: Custom tooling or attachments may be necessary for specific applications, impacting the overall cost. Buyers should consider the tooling needs when evaluating different models.

-

Quality Control (QC): Rigorous QC processes ensure that each machine meets performance standards. While this adds to the cost, it can reduce long-term operational issues.

-

Logistics: Shipping and handling costs can be substantial, especially for large equipment. International buyers should factor in import duties, shipping insurance, and potential delays.

-

Margin: Suppliers typically apply a profit margin on top of their costs. This margin can vary based on brand reputation, market demand, and competitive pricing strategies.

How Do Price Influencers Impact Fiber Laser Costs?

Several factors influence the pricing of fiber lasers, making it crucial for international buyers to understand these dynamics.

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Negotiating MOQs with suppliers can help buyers achieve better pricing.

-

Specifications and Customization: Customizing a machine for specific cutting needs can increase costs. Buyers should evaluate whether standard models can meet their requirements to avoid unnecessary expenses.

-

Materials Used: The choice of materials significantly impacts price. For instance, lasers that utilize high-quality optics or advanced cooling systems tend to be more expensive but may offer better efficiency.

-

Quality and Certifications: Machines with higher quality and industry certifications often come at a premium. However, the investment can pay off through improved reliability and performance.

-

Supplier Factors: Supplier reputation, service offerings, and geographical location can influence pricing. Established suppliers may charge more due to their reliability and support capabilities.

-

Incoterms: Understanding shipping terms and responsibilities can affect the final cost. Buyers should clarify who bears the costs and risks during transit to avoid unexpected expenses.

What Are the Best Negotiation Tips for B2B Buyers of Fiber Lasers?

When negotiating fiber laser purchases, buyers should adopt several strategic approaches to ensure cost-efficiency and favorable terms.

-

Research and Compare: Conduct thorough market research to understand average pricing and features across different suppliers. This information can empower buyers during negotiations.

-

Emphasize Total Cost of Ownership (TCO): Highlight the importance of TCO over initial purchase price. Consider long-term factors like energy consumption, maintenance costs, and expected lifespan.

-

Explore Financing Options: Some suppliers offer financing plans or leasing options, which can alleviate upfront costs. Discuss these alternatives during negotiations to find the best fit for cash flow management.

-

Build Relationships: Establishing a solid relationship with suppliers can lead to better pricing and service. Long-term partnerships often result in loyalty discounts and priority support.

-

Be Clear on Specifications: Clearly define technical requirements to avoid misunderstandings that could lead to additional costs. Detailed specifications also facilitate accurate quotes.

Conclusion: What Should Buyers Consider for International Fiber Laser Purchases?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of fiber laser pricing is crucial. Factors such as regional market conditions, currency fluctuations, and shipping logistics can significantly impact overall costs. Always request detailed quotes and consider potential hidden costs, such as duties and tariffs.

Disclaimer: Prices mentioned are indicative and can vary based on the supplier, specifications, and market conditions. Always verify current pricing directly with manufacturers or suppliers.

Alternatives Analysis: Comparing fiber laser for cutting metal With Other Solutions

When considering cutting technologies for metal fabrication, it is essential to evaluate various alternatives to fiber lasers. Each method offers distinct advantages and disadvantages, making it crucial for B2B buyers to assess which solution aligns best with their operational needs and budget constraints.

| Comparison Aspect | Fiber Laser For Cutting Metal | CO2 Laser Cutting | Plasma Cutting |

|---|---|---|---|

| Performance | High precision with minimal kerf; can cut various metals (up to 25mm) | Good for thicker materials; less precision than fiber lasers | Fast for thick metals; less accurate for thin materials |

| Cost | Higher initial investment, but lower operating costs | Moderate initial investment; higher maintenance costs | Lower initial investment; variable operating costs |

| Ease of Implementation | Requires skilled operators; integration with CNC is common | Easier to use for basic cutting; less training required | Simple setup; requires safety measures for operation |

| Maintenance | Low maintenance; solid-state technology | Higher maintenance due to more moving parts | Moderate; consumables need regular replacement |

| Best Use Case | Ideal for intricate designs and high-volume production | Best for cutting non-ferrous metals and thick sheets | Suitable for heavy-duty cutting and fabrication of large components |

What are the Advantages and Disadvantages of CO2 Laser Cutting?

CO2 laser cutting is a well-established technology that employs a gas laser to cut materials. While it excels at cutting thicker materials, its precision falls short compared to fiber lasers. The initial investment for CO2 systems is generally moderate, making it an attractive option for businesses with budget considerations. However, the maintenance costs can be higher due to the complexity of the machinery and the need for regular upkeep of mirrors and optics. CO2 lasers are particularly effective for non-metal materials and thicker sheets, making them suitable for industries focused on diverse cutting requirements.

How Does Plasma Cutting Compare?

Plasma cutting utilizes an accelerated jet of hot plasma to cut through metals, making it exceptionally fast for thick materials. This method is less accurate than fiber lasers and is not recommended for delicate designs or thin sheets. The initial investment for plasma cutting systems is typically lower, which can be appealing for businesses looking to minimize upfront costs. However, the operating costs can vary significantly based on the type of metals being cut and the frequency of consumable replacements. Plasma cutting is best suited for heavy-duty applications, including construction and heavy manufacturing, where speed takes precedence over precision.

Conclusion: How to Choose the Right Metal Cutting Solution?

Selecting the right metal cutting solution involves a careful evaluation of specific business needs, including production volume, material types, and budget constraints. Fiber lasers offer unparalleled precision and efficiency, making them ideal for high-quality production runs and intricate designs. In contrast, CO2 lasers provide a balance of performance and cost for a variety of materials, while plasma cutting excels in speed and affordability for heavy-duty applications. By aligning operational requirements with the strengths and weaknesses of each technology, B2B buyers can make informed decisions that enhance productivity and profitability in their metal fabrication processes.

Essential Technical Properties and Trade Terminology for fiber laser for cutting metal

What Are the Key Technical Properties of Fiber Lasers for Cutting Metal?

When considering fiber lasers for metal cutting, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications that influence performance, efficiency, and overall return on investment (ROI):

-

Laser Power (kW)

– The power of a fiber laser, measured in kilowatts (kW), directly affects its cutting capabilities. Common power ranges are from 1 kW to 22 kW. Higher power levels enable cutting through thicker materials and achieving faster cutting speeds, which can significantly increase production efficiency. For instance, a 2 kW laser can typically cut up to 12mm of carbon steel, while a 6 kW model can handle even thicker materials, making it crucial for businesses with diverse cutting needs. -

Cutting Speed (m/min)

– This parameter indicates how quickly the laser can traverse the material. Speeds can vary widely based on material type and thickness, with typical maximum speeds reaching up to 25 m/min for thinner sheets. Understanding cutting speed helps businesses estimate throughput and align it with production schedules, ultimately impacting operational efficiency. -

Kerf Width

– The kerf width refers to the width of the material removed during the cutting process. A narrower kerf (typically less than 25 micrometers for fiber lasers) minimizes material waste and can enhance the quality of the finished product. For manufacturers, this is vital for cost control and maintaining competitive pricing. -

Material Compatibility

– Fiber lasers are capable of cutting a variety of metals, including stainless steel, carbon steel, aluminum, copper, and titanium. Knowledge of material compatibility is essential for businesses to ensure that the chosen laser can handle their specific production requirements, which directly affects profitability and operational flexibility. -

Tolerance Levels

– Tolerance indicates the precision of the cut, typically expressed in millimeters. High-tolerance cuts (±0.02 mm) are essential for industries that require meticulous specifications, such as aerospace or automotive manufacturing. Understanding tolerance helps businesses maintain quality standards and customer satisfaction. -

Cooling System

– Efficient cooling systems, often involving refrigerated water chillers, are critical for maintaining optimal operating conditions. Proper cooling prevents overheating, extends the lifespan of the laser, and ensures consistent performance. This is particularly important for high-volume operations where prolonged use can lead to thermal wear.

What Are the Common Trade Terms Associated with Fiber Laser Cutting?

Familiarizing yourself with industry jargon can streamline communication and enhance business negotiations. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for reliable suppliers or partners in the fiber laser market. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for budgeting and inventory management, especially for international buyers who may face different MOQs based on supplier policies. -

RFQ (Request for Quotation)

– An RFQ is a document issued by potential buyers requesting price quotes from suppliers for specific products or services. For B2B buyers, effectively issuing RFQs can lead to competitive pricing and better negotiation outcomes. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping costs, risks, and responsibilities, which is critical for smooth international operations. -

Lead Time

– Lead time is the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for planning and ensuring that production schedules align with supply chain capabilities. -

Watt Density

– This term refers to the distribution of laser power across the cutting area, influencing the quality and speed of the cut. Higher watt density typically allows for faster cutting speeds and cleaner edges, making it a crucial factor for performance evaluation.

Understanding these technical properties and trade terminology will empower B2B buyers to make informed decisions regarding fiber lasers for metal cutting, ensuring alignment with their operational needs and financial objectives.

Navigating Market Dynamics and Sourcing Trends in the fiber laser for cutting metal Sector

What Are the Key Trends Shaping the Fiber Laser Cutting Metal Market?

The fiber laser cutting metal market is experiencing a transformative phase, driven by advancements in technology and shifting buyer preferences. A significant global driver is the increasing demand for precision and efficiency in metal fabrication processes. Businesses are seeking solutions that not only enhance production speed but also reduce operational costs, leading to a surge in the adoption of fiber laser technology. This trend is particularly pronounced in regions like Europe and the Middle East, where industries such as automotive and aerospace are heavily investing in automation and smart manufacturing.

Emerging technologies, such as artificial intelligence and machine learning, are being integrated into fiber laser systems, enhancing their capabilities in predictive maintenance and operational efficiency. Moreover, international B2B buyers are increasingly focusing on customizable solutions that cater to specific production needs, as seen in the rise of tailored fiber laser machines with varying power capacities. This customization trend empowers manufacturers to optimize their production lines and reduce waste.

Additionally, the market dynamics are shifting toward sustainability. Buyers are becoming more aware of the environmental impact of their production processes and are actively seeking suppliers that prioritize eco-friendly practices. This focus on sustainability is influencing sourcing decisions, compelling suppliers to adopt greener technologies and materials.

How Is Sustainability Influencing B2B Sourcing in the Fiber Laser Sector?

Sustainability is emerging as a pivotal factor in the sourcing decisions of B2B buyers in the fiber laser cutting metal sector. The environmental impact of manufacturing processes, particularly in terms of energy consumption and waste generation, is prompting companies to seek solutions that align with their sustainability goals. Fiber laser systems are inherently more energy-efficient compared to traditional cutting technologies, consuming less power and generating less heat, which translates to lower operational costs.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for suppliers who demonstrate a commitment to ethical sourcing and transparent practices. This includes ensuring that materials used in fiber laser cutting, such as metals and gases, are sourced responsibly, minimizing negative environmental impacts. Certifications for green practices, such as ISO 14001 for environmental management, are becoming essential for suppliers aiming to attract discerning buyers.

Furthermore, initiatives aimed at reducing carbon footprints are influencing product development. Manufacturers are innovating to create machines that use less energy while maintaining high performance, thus appealing to buyers who prioritize both efficiency and sustainability in their operations.

What Is the Historical Context of Fiber Laser Technology in Metal Cutting?

The evolution of fiber laser technology in the metal cutting sector has been marked by significant advancements since its inception in the late 20th century. Initially, CO2 lasers dominated the cutting landscape; however, the introduction of fiber lasers in the 2000s revolutionized the industry. Fiber lasers offered superior beam quality, efficiency, and operational longevity, quickly gaining traction among manufacturers.

The shift towards fiber lasers was driven by their ability to cut a wider variety of metals with higher precision and lower operating costs. Over the years, continuous improvements in fiber laser technology, such as enhanced cooling systems and automation capabilities, have solidified their position as a preferred choice for metal fabrication. Today, fiber lasers are not only integral to traditional manufacturing sectors but are also gaining prominence in emerging industries, including renewable energy and aerospace, reflecting their adaptability and efficiency.

As the market continues to evolve, international B2B buyers must stay attuned to these trends and historical developments to make informed sourcing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of fiber laser for cutting metal

-

How do I choose the right fiber laser cutting machine for my business needs?

Selecting the right fiber laser cutting machine involves evaluating several factors, including the types of materials you will be cutting, the thickness of these materials, and your production volume. Consider the power capacity of the machine (typically ranging from 1 kW to 20 kW), as higher wattage can cut thicker materials more efficiently. Additionally, assess the cutting area size to ensure it fits your operational requirements. It’s advisable to consult with manufacturers for customization options tailored to your specific applications. -

What is the best fiber laser cutting machine for small to medium metal fabrication shops?

For small to medium metal fabrication shops, machines like the 1500W or 2000W fiber laser cutters are often the best fit. These models strike a balance between performance and cost, making them ideal for cutting materials such as stainless steel, aluminum, and carbon steel. Look for machines that offer programmable features and easy maintenance to enhance operational efficiency. Additionally, consider options with a compact footprint to save space in your workshop. -

What are the typical payment terms for purchasing fiber laser cutting machines internationally?

Payment terms for international purchases of fiber laser cutting machines can vary widely among suppliers. Common terms include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer financing options or extended payment plans, especially for larger orders. Always clarify terms in the purchase agreement, including any currency considerations and potential fees for international transactions, to avoid misunderstandings. -

How can I ensure the quality and reliability of the fiber laser cutter I plan to buy?

To ensure the quality and reliability of a fiber laser cutter, start by researching the manufacturer’s reputation and customer reviews. Request certifications that demonstrate compliance with international standards, such as ISO or CE. Inquire about warranty terms and after-sales support, including maintenance and troubleshooting services. If possible, arrange for a demonstration of the machine to assess its performance firsthand before making a purchase. -

What factors should I consider when vetting suppliers of fiber laser cutting machines?

When vetting suppliers, consider their experience and track record in the industry, as well as their customer service responsiveness. Check for certifications and compliance with international quality standards. Ask for references from previous clients, particularly those in your region, to gauge satisfaction levels. Additionally, evaluate their ability to provide support and spare parts after the sale, as this can significantly affect your operational continuity. -

What are the common lead times for fiber laser cutting machine delivery?

Lead times for the delivery of fiber laser cutting machines can vary depending on the supplier and the level of customization required. Typically, standard machines may have a lead time of 4 to 12 weeks, while customized solutions can take longer, often exceeding 12 weeks. It’s essential to discuss timelines during the ordering process and factor in potential delays due to international shipping and customs clearance. -

Are there minimum order quantities (MOQ) for purchasing fiber laser cutting machines?

Most manufacturers do not impose a minimum order quantity (MOQ) for fiber laser cutting machines, as each machine is usually a significant investment. However, some suppliers might offer bulk discounts for purchasing multiple units or additional equipment. It’s advisable to inquire about any MOQ requirements when discussing your order, especially if you’re considering a customized machine. -

What logistics considerations should I keep in mind when importing a fiber laser cutting machine?

When importing a fiber laser cutting machine, consider shipping methods, customs regulations, and potential tariffs or duties that may apply in your country. Ensure that the supplier provides the necessary documentation for customs clearance. It’s also important to plan for the machine’s installation and setup upon arrival, which may require specialized handling or local technicians. Coordinate with logistics providers to ensure timely and safe delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Fiber Laser For Cutting Metal Manufacturers & Suppliers List

1. OMTech – Fiber Laser Cutting Machines

Domain: omtechlaser.com

Registered: 2020 (5 years)

Introduction: Best Fiber Laser Cutting Machine for Metal Fabrication

– OMTech Fiber Laser Metal Cutting Machines:

– FC22 1500W Enclosed Fiber Laser Cutting Machine: As low as *$828/MO (Price Match Guarantee)

– FC22-C 1500W Open Metal Laser Cutting Machine: As low as *$767/MO (Price Match Guarantee)

– FC-105 Fiber Laser Cutting Machine: As low as *$1,081/MO (Price Match Guarantee)

– FC-44 Fiber Laser Cu…

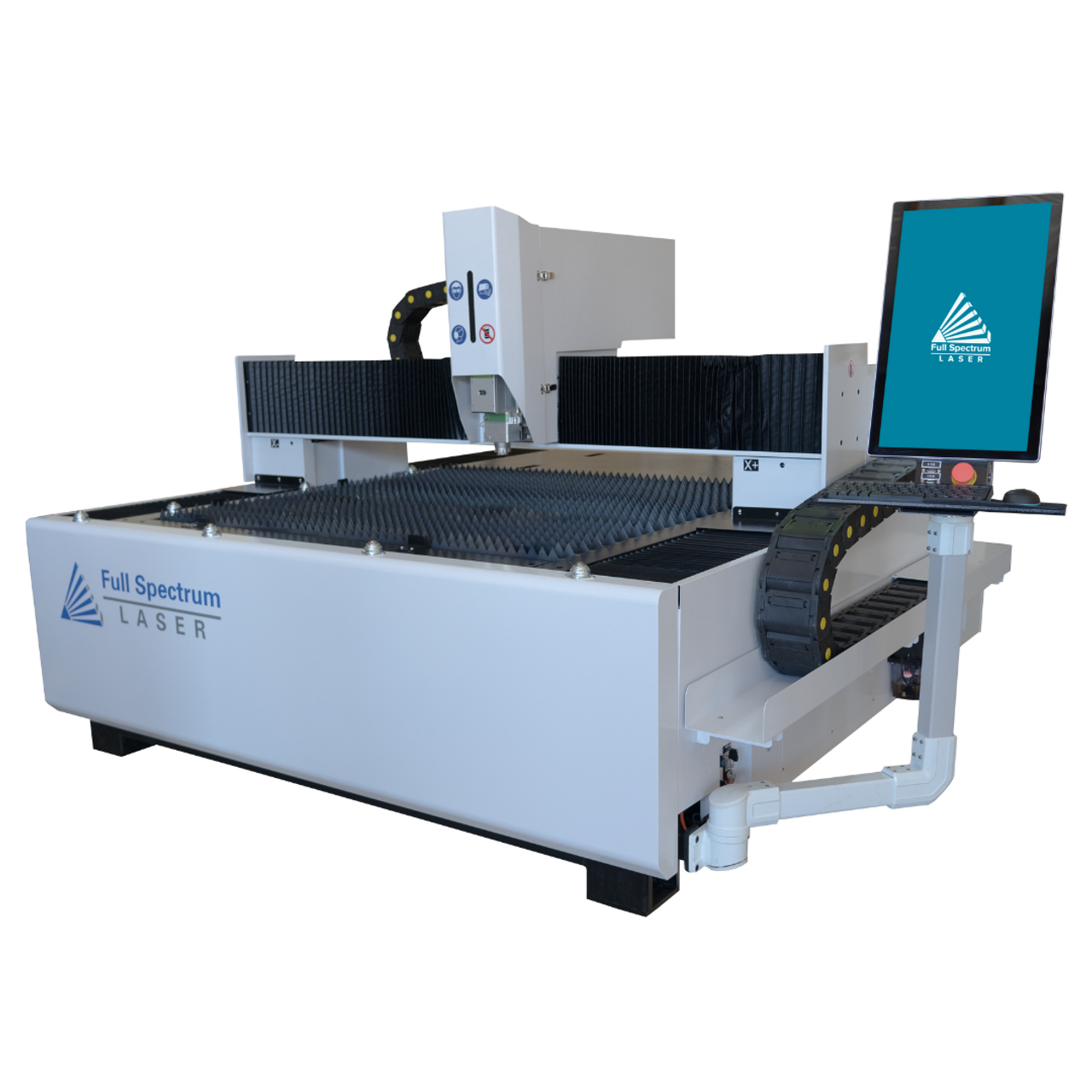

2. Atlas Alloy – Flatbed Metal Cutting Fiber Laser

Domain: fslaser.com

Registered: 2010 (15 years)

Introduction: Atlas Alloy Flatbed Metal Cutting Fiber Laser up to 20kW

– Model Options: 4’x8′ 1000W, 4’x8′ 1500W, 4’x8′ 2000W, 5’x10′ 3000W, 5’x10′ 6000W

– MSRP: $55,000.00

– Cutting Area: 47″ x 95″ (1100 mm x 2400 mm) or 59″ x 118″ (1500 mm x 3000 mm)

– Machine Dimensions: 4’x8′: 173″ x 90″ x 55″ (4.4m x 2.3m x 1.4m); 5’x10′: 197″ x 89″ x 75″ (5010 mm x 2260 mm x 1900 mm)

– Weight: 4’x8′: 6024 lbs (2732 kg); 5…

3. Hytek Tools – Fiber Laser Cutting Solutions

Domain: hytektools.com

Registered: 2015 (10 years)

Introduction: [{‘model’: ‘2025 FIBERTEK™ Model DE’, ‘size’: ‘5×10’, ‘power’: ‘2000w-30,000w’, ‘price’: ‘from $145,650.00’}, {‘model’: ‘ROBOTUBE™ MODEL RT2’, ‘type’: ‘Fiber Laser Metal Tube Cutter’, ‘price’: ‘from $182,000.00’}, {‘model’: ‘2025 FIBERTEK™ MODEL SE’, ‘size’: ‘5×10’, ‘power’: ‘2000W-12000W’, ‘price’: ‘from $122,000.00’}, {‘model’: ‘2025 FIBERTEK™ MODEL D’, ‘size’: ‘5×10’, ‘power’: ‘1000W-6000W’, ‘p…

4. Laser Cutter – Compact Precision for Metals

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking to purchase a home/small business laser cutter for cutting thin metals (max 3mm), specifically brass and aluminum. Budget of £7k. Size is a major limiting factor as it will be used at home (upstairs). Need high level of accuracy. Research indicates that cutting 3mm is difficult with non-industrial machines, with most capable of cutting less than 1mm. Interested in wattage and toxicity of m…

5. Boss Laser – 2kw AccuCut

Domain: shop.bosslaser.com

Registered: 2012 (13 years)

Introduction: Laser Machines – Boss Laser offers a variety of laser cutting, engraving, and marking machines including CO2 lasers, UV & fiber laser markers, and industrial fiber cutters. Key products include the 2kw AccuCut priced at $57,997, and various models in the LS-Series, HP-Series, FC-Series, FM-Series, and UV-Series. The machines can cut and engrave a wide range of materials including acrylic, aluminum…

6. Laguna Tools – Fiber Lasers

Domain: lagunatools.com

Registered: 1996 (29 years)

Introduction: Fiber Lasers from Laguna Tools are designed for exceptional precision and efficiency, suitable for cutting materials such as carbon steel, stainless steel, aluminum, titanium, brass, bronze, and copper. They are ideal for industries like aerospace, automotive, and metal fabrication. Key features include:

– Laser Power: Ranges from 1KW to 30KW depending on the model.

– Working Area: Options inclu…

7. MechMate – Fiber Laser Cutting Solutions

Domain: mechmate.com

Registered: 2005 (20 years)

Introduction: This company, MechMate – Fiber Laser Cutting Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Cloudray – Laser Tools

Domain: cloudraylaser.com

Registered: 2017 (8 years)

Introduction: [{‘name’: ‘Cloudray Raytools BT210S’, ‘power’: ‘0-1.5kW’, ‘price’: ‘$985.00 USD’}, {‘name’: ‘Cloudray Raytools BT240S’, ‘power’: ‘0-3kW’, ‘price’: ‘$1,125.00 USD’}, {‘name’: ‘Cloudray Raytools BM111’, ‘power’: ‘0-3.3kW’, ‘price’: ‘From $2,645.00 USD’}, {‘name’: ‘Cloudray Raytools BM06K’, ‘power’: ‘0-6KW’, ‘price’: ‘From $3,370.00 USD’}, {‘name’: ‘Cloudray Raytools BS06K’, ‘power’: ‘0-6KW’, ‘price’…

9. Gweike – 50W Fiber Laser

Domain: forum.lightburnsoftware.com

Registered: 2017 (8 years)

Introduction: Gweike 50w fiber laser; Cutting 1 mm metal; Engraving in 1-1.5 mm thick sheets of brass; Cutting settings: Layer is a line; Power: 100%; Speed: 1 mm/sec to 1000 mm/sec; Frequency: 30; Passes: 5 to 50; Suggested techniques: Wobble enabled, intermittent cleaning passes, aiming for highest material removal rate at lowest thermal input, material test in line mode.

Strategic Sourcing Conclusion and Outlook for fiber laser for cutting metal

In the competitive landscape of metal fabrication, strategic sourcing of fiber laser cutting technology is paramount for businesses aiming to enhance operational efficiency and reduce costs. Investing in fiber laser systems, which offer superior precision and lower operating expenses, can lead to significant returns on investment. For instance, the ability to cut various materials with minimal kerf and at lower energy costs positions these machines as not just tools, but essential assets for modern manufacturing.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe evaluate their sourcing strategies, the customization options available in fiber laser cutters allow for tailored solutions that meet specific production needs. This adaptability is crucial for maintaining competitiveness in diverse markets.

Looking ahead, the demand for advanced metal cutting solutions will continue to rise, driven by innovation and the need for high productivity. Businesses are encouraged to leverage the benefits of fiber laser technology, not only to optimize their operations but also to explore new growth opportunities. Engaging with reputable suppliers and seeking expert consultations will ensure that buyers are well-equipped to make informed decisions that align with their long-term business objectives.