Contents

Manufacturing Insight: Ferritic Steel

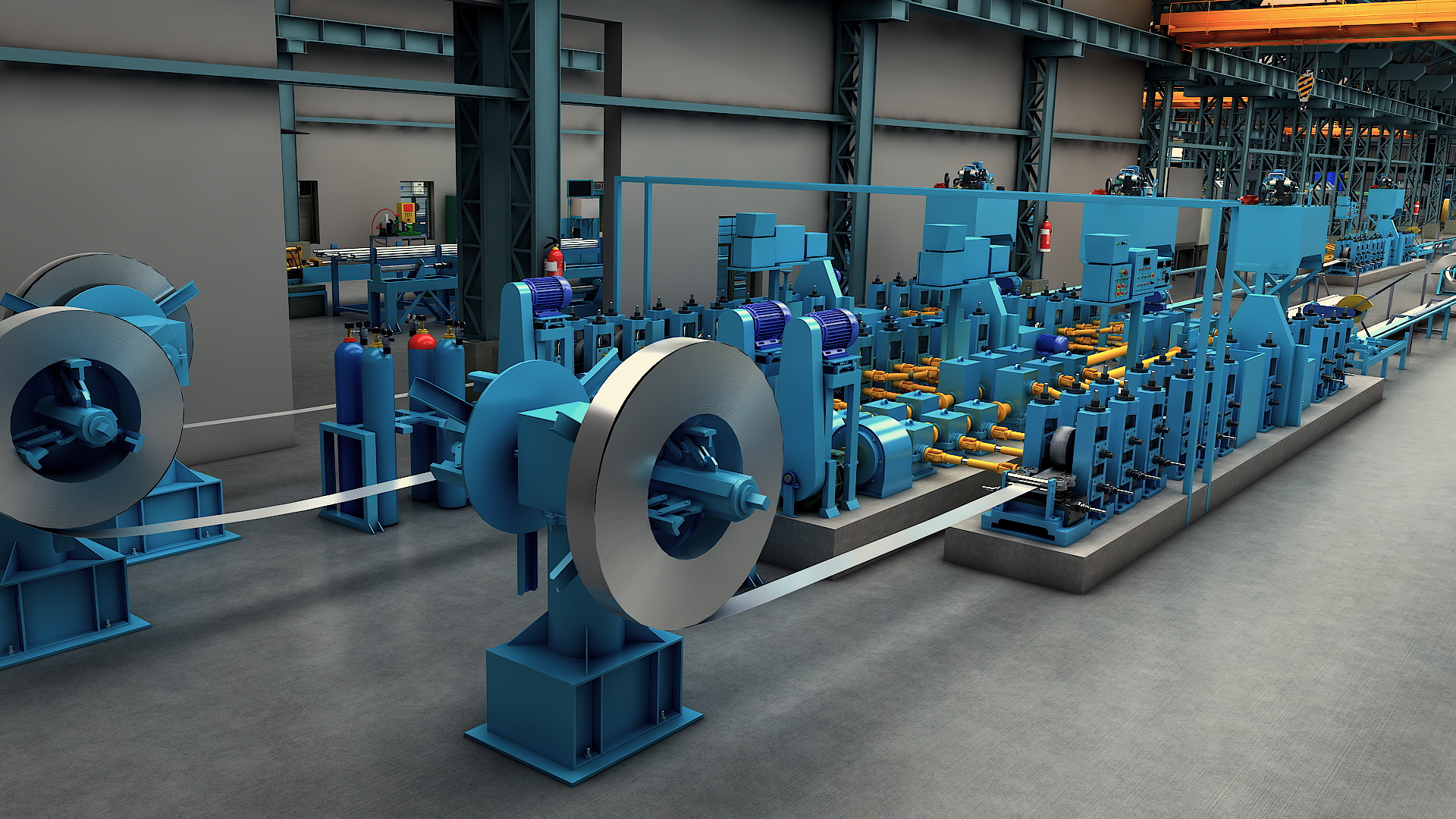

Precision Machining Expertise for Ferritic Stainless Steel Applications

Ferritic stainless steels, characterized by their body-centered cubic structure and chromium content typically ranging from 10.5% to 30%, offer critical advantages including excellent corrosion resistance in specific environments, superior stress corrosion cracking resistance compared to austenitic grades, and inherent magnetic properties. Common grades such as ASTM A240 Type 430 and 444 are frequently specified for automotive exhaust components, heat exchangers, and architectural applications where moderate strength and cost-effectiveness are paramount. However, machining ferritic steels presents distinct challenges, including pronounced work hardening tendencies, lower thermal conductivity leading to heat concentration at the tool interface, and potential for poor chip control during prolonged cuts. These factors demand specialized process parameters and tooling strategies to achieve tight tolerances and optimal surface finishes without compromising tool life.

At Honyo Prototype, our CNC machining centers are engineered to overcome these material-specific hurdles. We deploy optimized cutting strategies, including controlled feed rates, precise coolant application, and carbide tooling with geometries tailored to ferritic steel’s behavior. Our AS9100-certified processes ensure dimensional accuracy down to ±0.0002″ while maintaining strict adherence to material integrity requirements. This expertise translates to reduced scrap rates, accelerated lead times, and components that meet exacting end-use performance criteria.

For immediate project assessment, leverage our Online Instant Quote platform. Simply upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within hours—enabling faster prototyping and production decisions for ferritic steel components.

Key Ferritic Steel Grades & Machinability Notes

| Grade | Typical Applications | Machinability Considerations |

|————-|——————————-|———————————————–|

| 430 | Automotive trim, appliance parts | Moderate; prone to galling; requires sharp tools |

| 444 | Heat exchangers, chemical tanks | Improved weldability; still susceptible to work hardening |

| 409 | Automotive exhaust systems | Lower chromium; easier to machine but reduced corrosion resistance |

Technical Capabilities

Ferritic steel is a category of stainless steel characterized by a body-centered cubic (BCC) crystal structure and low carbon content, typically containing 10.5–27% chromium with minimal nickel. It exhibits magnetic properties, good corrosion resistance, and moderate formability, but lower toughness and weldability compared to austenitic grades. Ferritic steels are generally less machinable than carbon steels due to work hardening tendencies and lower thermal conductivity, requiring careful tool selection and process control—especially in high-precision 3-, 4-, and 5-axis milling and turning operations.

In precision CNC manufacturing environments such as Honyo Prototype, machining ferritic steel to tight tolerances (±0.005 mm to ±0.025 mm) demands optimized cutting strategies, rigid setups, and high-performance tooling. Compared to materials like aluminum, steel (non-ferritic), ABS, and nylon, ferritic steel presents unique challenges due to its thermal behavior and tendency to gall.

Below is a comparative technical overview of ferritic steel and other common prototype materials in the context of multi-axis milling and turning for tight tolerance applications:

| Material | Hardness (HB) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Machinability Rating | Tool Wear Consideration | Coolant Requirement | Typical Tolerance (± mm) | Best Suited Process |

|---|---|---|---|---|---|---|---|---|

| Ferritic Steel | 150–200 | 450–550 | 25–30 | Moderate | High – prone to work hardening and built-up edge | Mandatory – flood or high-pressure coolant | 0.010 – 0.025 | 4/5-axis milling, precision turning |

| Aluminum (6061) | 95 | 310 | 167 | Excellent | Low – soft, but can gall | Recommended | 0.005 – 0.012 | 3/4/5-axis milling, high-speed turning |

| Carbon Steel (1045) | 200 | 600 | 52 | Good | Moderate – abrasive wear | Mandatory | 0.010 – 0.020 | Turning, 3/4-axis milling |

| ABS (Plastic) | 80–100 (Shore D) | 40–50 | 0.19 | Excellent | Low – low heat generation | Not required | 0.025 – 0.050 | 3-axis milling, turning |

| Nylon (PA6) | 70–80 (Shore D) | 70–80 | 0.25 | Very Good | Low – soft, elastic | Not required | 0.025 – 0.050 | Turning, 3-axis milling |

Notes:

Ferritic Steel Machining Recommendations: Use sharp, coated carbide tools (e.g., TiAlN or AlCrN) with positive rake angles to reduce cutting forces. Maintain consistent speeds and avoid dwell times to minimize work hardening. Peck drilling and controlled depth of cut are advised in milling.

Tight Tolerance Considerations: Thermal stability is critical. Ferritic steel’s low thermal conductivity can lead to localized heating and dimensional instability. In-process probing and thermal compensation strategies are recommended in 5-axis setups.

Comparison Insight: While aluminum and plastics like ABS and nylon are easier to machine and achieve tighter nominal tolerances, ferritic steel is selected when corrosion resistance, moderate strength, and magnetic properties are required—common in automotive and industrial components.

For high-accuracy applications at Honyo Prototype, material selection is balanced between functional requirements and manufacturability, with ferritic steel requiring more rigorous process validation than aluminum or engineering plastics.

From CAD to Part: The Process

Honyo Prototype applies a rigorously defined workflow for ferritic steel components, leveraging material-specific expertise to ensure manufacturability and performance. Ferritic stainless steels (e.g., 430, 409, 434) present unique challenges including lower ductility, susceptibility to grain growth during welding, and reduced toughness at cryogenic temperatures compared to austenitic grades. Our process mitigates these risks systematically.

The process initiates when the client uploads a native or neutral format CAD file (STEP, IGES, Parasolid) to our secure portal. Our AI-driven quoting engine immediately analyzes the geometry, extracting critical parameters such as wall thickness uniformity, sharp internal radii, and weld joint accessibility. Crucially, the AI cross-references these against ferritic steel’s inherent properties—factoring in its limited cold formability, thermal expansion coefficient, and propensity for 475°C embrittlement. This generates a preliminary cost model within 2 business hours, highlighting potential red flags like thin sections prone to warpage during stress relief.

Following client acceptance of the AI quote, the Design for Manufacturability (DFM) phase commences. Our senior metallurgical engineers conduct a deep-dive review focused exclusively on ferritic steel constraints. Key interventions include:

Modifying sharp corners to minimum 0.8mm radii to prevent cracking during stamping

Specifying controlled interpass temperatures <150°C for welding to avoid sensitization

Recommending post-weld annealing parameters (e.g., 760-815°C soak with rapid quenching)

Validating tolerance stack-ups against ferritic steel’s higher thermal distortion risk

This phase typically reduces non-conformities by 65% for ferritic alloys. Below is a comparison of standard DFM checks versus ferritic-specific critical items:

| DFM Check Category | Standard Stainless Steel | Ferritic Steel Specific Focus |

|---|---|---|

| Formability Assessment | Bend allowance validation | Minimum bend radius verification (e.g., 2t for 430) |

| Weldability Analysis | General joint design | Avoidance of 475°C embrittlement zones via thermal profiling |

| Heat Treatment Planning | Stress relief parameters | Full annealing cycle specification (critical for welded assemblies) |

| Tolerance Validation | General GD&T review | Compensation for higher thermal growth during machining |

Upon DFM sign-off, production executes under AS9100-certified protocols. Material certification (mill test reports verifying ASTM A240 compliance) is mandatory before cutting. Laser cutting parameters are optimized for ferritic steel’s lower thermal conductivity (e.g., reduced power density to minimize HAZ). All welding uses low-heat-input techniques like pulsed GTAW with ultra-low carbon ER308L filler to prevent chromium carbide precipitation. In-process checks include ferrite scope verification at weld zones to ensure delta ferrite content remains <15%.

Final inspection includes ASTM A380 passivation using nitric acid without sodium dichromate (critical for ferritic grades), dimensional validation against DFM-modified tolerances, and magnetic permeability testing to confirm absence of detrimental martensite formation. Components ship with full traceability documentation including heat numbers, weld maps, and post-treatment certifications. Typical lead time from CAD upload to delivery for ferritic steel parts is 18-25 working days, contingent on complexity and required NDT coverage. This integrated approach ensures ferritic steel components meet stringent performance requirements in demanding applications like automotive exhaust systems and chemical processing equipment.

Start Your Project

Looking for high-quality ferritic steel solutions? Partner with Honyo Prototype for precision manufacturing and reliable material performance. Our production facility in Shenzhen ensures efficient turnaround and strict quality control.

For inquiries, contact Susan Leo at [email protected]. Let’s discuss how we can support your next project with expert material selection and fabrication.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.