Contents

Manufacturing Insight: Fathom Machining

Precision Realized Through Fathom Machining at Honyo Prototype

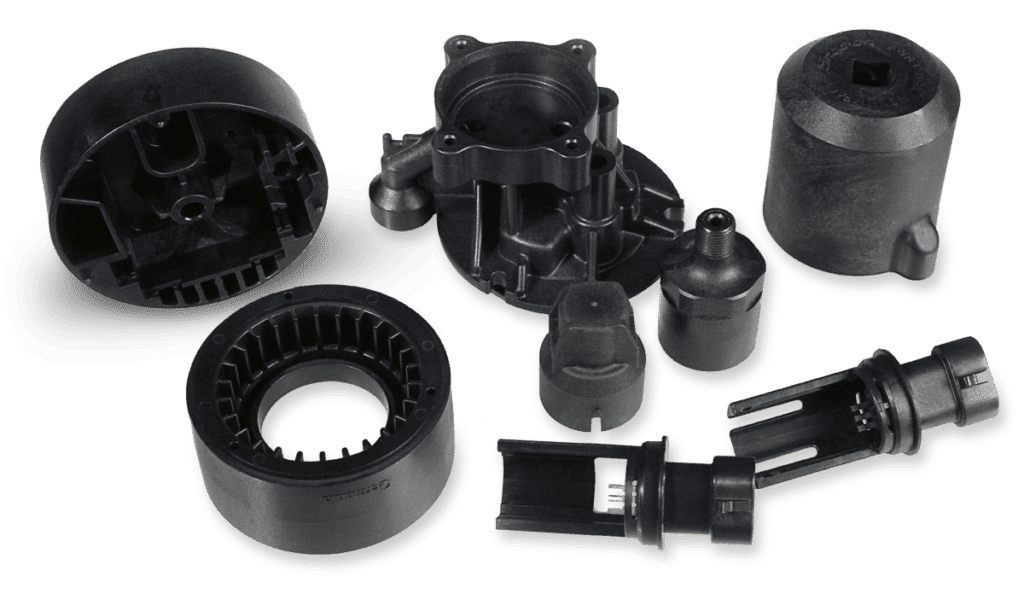

At Honyo Prototype, we define Fathom Machining as the deep engineering comprehension and flawless execution required to transform complex design concepts into high-integrity physical components. This philosophy underpins our comprehensive CNC Machining services, where advanced manufacturing capability meets rigorous process discipline. We specialize in delivering precision-machined prototypes and low-volume production parts across demanding industries including aerospace, medical devices, and robotics, where dimensional accuracy and material integrity are non-negotiable.

Our technical foundation leverages a modern fleet of multi-axis CNC milling and turning centers, capable of achieving tight tolerances down to ±0.0002 inches across diverse materials such as titanium alloys, aluminum 7075-T6, PEEK, and engineered plastics. Every process, from initial material selection through meticulous in-process inspection using CMM and optical comparators, is governed by our AS9100D and ISO 13485 certified quality management system. This ensures consistent part conformance, structural reliability, and full traceability – critical factors for applications where failure is not an option.

Accelerating your development cycle begins with seamless accessibility. Honyo Prototype leverages its Online Instant Quote platform to provide rapid, transparent pricing and manufacturability feedback within hours, not days. Simply upload your CAD file to immediately assess lead times, identify potential design optimizations, and initiate a technically qualified partnership. This digital gateway eliminates procurement friction, allowing engineering teams to focus on innovation while we handle the precision execution. Partner with Honyo to experience Fathom Machining: where deep technical insight drives every cut.

Technical Capabilities

Fathom Machining is a precision manufacturing service specializing in advanced CNC machining processes, including 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. The service supports tight tolerance requirements and a wide range of engineering-grade materials, including aluminum, steel, ABS, and nylon. Below are the technical specifications for Fathom’s machining capabilities.

| Feature | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis turning centers) |

| Tolerance Capability | Standard Tolerance: ±0.005 in (±0.13 mm); Tight Tolerance: ±0.001 in (±0.025 mm) achievable with process control and inspection |

| Positioning Accuracy | ±0.0002 in (±0.005 mm) per axis on high-precision 5-axis platforms |

| Repeatability | ±0.0005 in (±0.013 mm) across production runs |

| Surface Finish | Typical: 32–64 μin (Ra); fine finishes down to 16 μin (Ra) with polishing or post-processing |

| Maximum Work Envelope | Milling: Up to 2000 mm × 1000 mm × 800 mm (78.7 in × 39.4 in × 31.5 in); Turning: Max diameter 500 mm (19.7 in), length up to 1000 mm (39.4 in) |

| Spindle Speed | Milling: Up to 24,000 RPM; Turning: Up to 6,000 RPM (varies by machine configuration) |

| Tooling | High-speed steel (HSS), carbide, and diamond-coated tools; automatic tool changers (ATC) with 24+ tool capacity |

| Control Systems | Fanuc, Siemens, or Heidenhain CNC controls with full tool path verification and probing |

| Inspection Support | In-process and final inspection using CMM, optical comparators, and laser scanning |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS (I400, MC801), Nylon (6, 6/6) |

| Material Forms | Bar stock, plate, block; stock sizes up to 6 in (152 mm) diameter or thickness |

| Coolant Systems | Flood coolant, mist cooling, and dry machining (for plastics to avoid warping) |

| Fixturing | Custom and modular fixturing; vacuum, mechanical, and zero-point systems for 5-axis work |

| Lead Time | Prototype: 3–7 days; Production: 7–14 days (depending on complexity and volume) |

Fathom’s 5-axis milling capabilities allow for complex geometries with minimal setup, reducing error potential and improving dimensional accuracy. Tight tolerance machining is supported through thermal compensation, on-machine probing, and strict process validation. Material selection is optimized for machinability, strength, and end-use performance—aluminum and steel for high-strength metal components, ABS for functional prototypes, and nylon for wear-resistant, non-conductive parts.

From CAD to Part: The Process

Honyo Prototype Fathom Machining Process Overview

Honyo Prototype’s proprietary “Fathom Machining” workflow integrates AI-driven efficiency with rigorous engineering oversight to deliver high-precision machined prototypes and low-volume production parts. This end-to-end process minimizes lead times while ensuring manufacturability and quality. Below is a technical breakdown of each phase, reflecting our standardized B2B operational protocol.

CAD Upload and Initial Processing

Customers initiate the workflow by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo formats) via our secure client portal. Our system performs an automated geometry validation check, flagging potential issues such as non-manifold edges, missing datums, or unit inconsistencies. File integrity verification occurs within minutes, with immediate notification if resubmission is required. All data is encrypted per ISO 27001 standards, and intellectual property is protected under signed NDAs.

AI-Powered Quoting Engine

Validated CAD files enter our AI quoting module, which leverages a neural network trained on 12+ years of historical machining data from 250,000+ projects. The algorithm analyzes geometric complexity, material utilization, feature tolerances, and setup requirements against real-time shop floor capacity. It cross-references material costs from vetted suppliers and applies predictive machining time calculations based on machine-specific feed-rate optimization models. Quotes—including detailed cost breakdowns by operation, material, and finishing—are generated in under 2 hours for 95% of submissions. Critical parameters like minimum wall thickness or hole depth-to-diameter ratios trigger automatic escalation to engineering review.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by Honyo’s AS9100-certified manufacturing engineers. This phase is iterative and collaborative:

Engineers identify non-optimal features (e.g., internal radii smaller than standard tooling, excessive part repositioning needs) using tolerance stack-up simulation.

A formal DFM report is issued within 24 hours, proposing actionable modifications to reduce cost or lead time without compromising functional intent.

Customers receive annotated 3D markups via the portal and may schedule video consultations for complex redesigns. Zero-cost DFM revisions are permitted pre-approval.

Precision Production Execution

Approved designs move to production in our climate-controlled facility, featuring:

Material Procurement: Sourced from ISO 9001-certified mills with full material test reports (MTRs).

Machining: Performed on Haas, DMG MORI, and Makino CNC centers (3-axis to 5-axis mill-turn) with in-process probing for first-article validation.

Quality Control: Real-time SPC monitoring; critical dimensions verified via Zeiss CMMs per ASME Y14.5.

Typical production timelines by complexity tier:

| Complexity Tier | Features Included | Standard Lead Time |

|---|---|---|

| Tier 1 | <5 critical tolerances (±0.05mm), no undercuts | 3–5 business days |

| Tier 2 | 5–10 critical tolerances (±0.025mm), shallow cavities | 7–10 business days |

| Tier 3 | Tight tolerances (±0.005mm), deep cavities, multi-axis features | 12–18 business days |

Logistics and Delivery Assurance

Completed parts undergo final QA sign-off, including surface roughness validation (per ISO 25178) and dimensional certification. Packaging uses static-dissipative materials with humidity indicators for sensitive alloys. Shipments include:

Traceable lot numbers linked to MTRs and CMM reports in the client portal.

Real-time FedEx/UPS tracking with ETAs updated via API integration.

Customs documentation pre-validated for global shipments (ITAR-compliant where required).

Standard delivery is DDP (Delivered Duty Paid) globally, with 99.2% on-time fulfillment rate across 2023 Q1–Q4. Expedited options (air freight, 24-hour production) are available at quoted premiums.

This closed-loop process ensures technical rigor at every stage while maintaining the agility expected in rapid prototyping. All phases are monitored through our digital twin platform, enabling clients to track progress via live dashboards without engineering overhead.

Start Your Project

Interested in precision Fathom Machining services? Contact Susan Leo at [email protected] to discuss your project requirements. Our advanced manufacturing facility in Shenzhen ensures high-quality, on-time production with strict quality control and rapid turnaround. Let Honyo Prototype be your trusted partner for reliable, cost-effective machining solutions. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.