Contents

Manufacturing Insight: Face Milling Machine

Precision Face Milling Capabilities Within Honyo Prototype’s Advanced CNC Machining Services

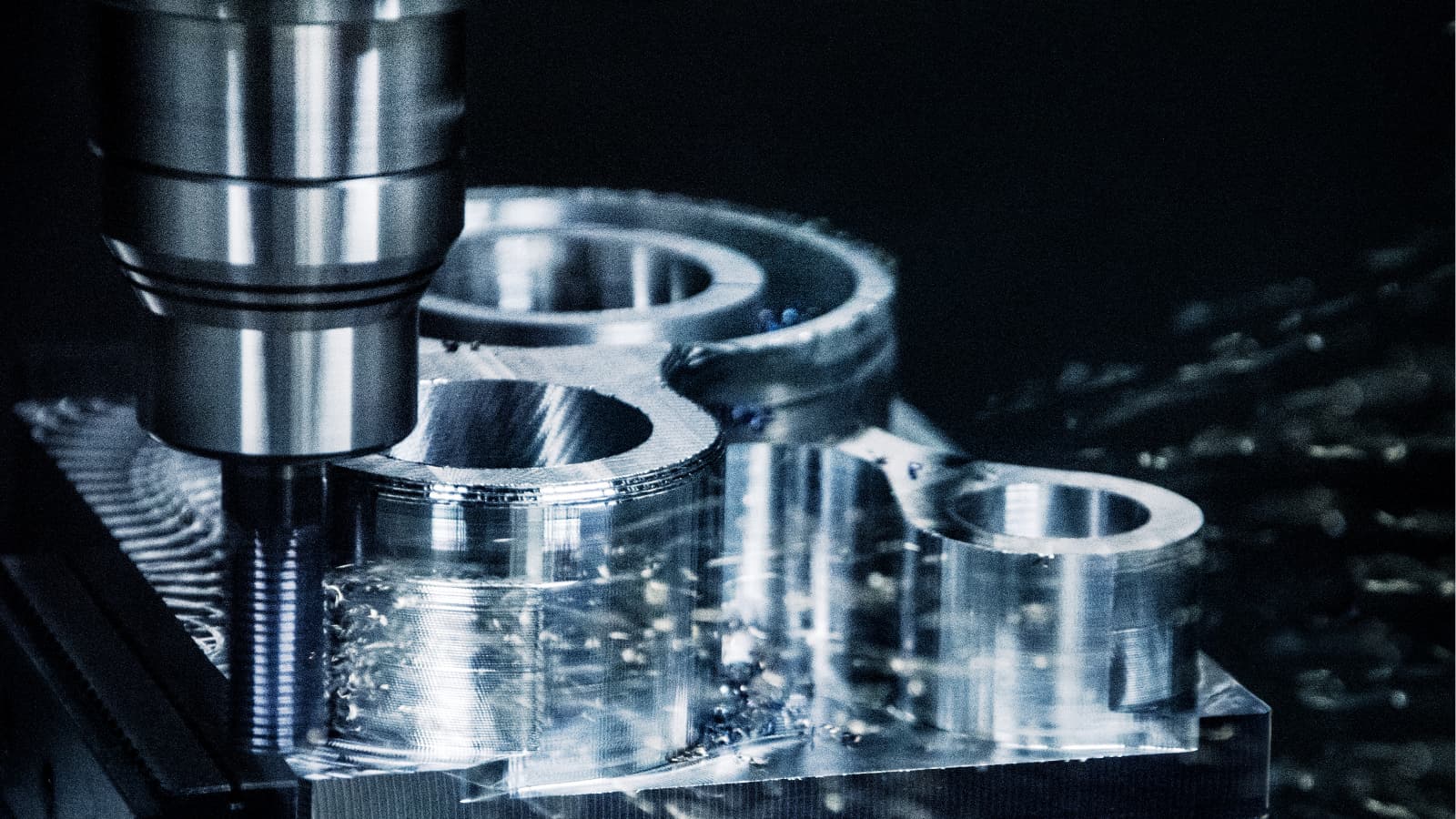

Face milling is a fundamental process for achieving critical flat surfaces, precise datum features, and optimal part interfaces in complex components. At Honyo Prototype, our state-of-the-art CNC machining centers execute high-precision face milling operations with exceptional repeatability, meeting stringent tolerances down to ±0.0002 inches and surface finishes as fine as 32 Ra. Utilizing advanced toolpath strategies, rigid multi-axis platforms, and real-time process monitoring, we ensure geometric accuracy and material integrity across diverse alloys including aerospace-grade aluminum, titanium, stainless steel, and engineered plastics.

Our integrated manufacturing ecosystem combines decades of precision machining expertise with cutting-edge technology to deliver components that meet exacting functional and dimensional requirements. Every face milling operation undergoes rigorous in-process inspection and final validation against engineering specifications, minimizing rework and accelerating time-to-assembly for your most demanding applications.

Streamline your prototyping and low-volume production workflow with Honyo Prototype’s Online Instant Quote system. Upload your 3D CAD model, specify materials and finishes, and receive a detailed machining quote within hours—not days—enabling faster project validation and procurement decisions. Experience the efficiency of precision-engineered face milling, backed by Honyo’s commitment to quality and responsive manufacturing support.

Technical Capabilities

Face milling machines are precision machining systems designed for high-accuracy material removal, particularly suited for flat surface generation and complex geometries. At Honyo Prototype, our advanced 3/4/5-axis face milling machines integrate milling and turning capabilities to achieve tight tolerances across a range of engineering materials including aluminum, steel, ABS, and nylon.

These machines support multi-axis simultaneous motion, enabling efficient machining of complex contours and critical features with minimal setup changes. High spindle rigidity, thermal compensation systems, and precision linear guides ensure repeatable accuracy down to ±0.005 mm (±0.0002″) for tight-tolerance applications in aerospace, medical, and industrial components.

Below is a summary of key technical specifications relevant to our multi-axis face milling platforms:

| Specification | Detail |

|---|---|

| Axes Configuration | 3-axis (X, Y, Z), 4-axis (with rotary B or A axis), 5-axis simultaneous (X, Y, Z, A, B) |

| Spindle Speed | Up to 24,000 RPM (high-speed option available for non-ferrous and plastics) |

| Positioning Accuracy | ±0.002 mm (±0.0001″) |

| Repeatability | ±0.001 mm (±0.00005″) |

| Tolerance Capability | As tight as ±0.005 mm (±0.0002″) depending on geometry and material |

| Tool Changer (ATC) | Automatic tool changer, 24–60 tool capacity (depending on model) |

| Control System | Fanuc, Siemens, or Heidenhain CNC with 5-axis interpolation and collision avoidance |

| Work Envelope (Typical) | 800 x 500 x 400 mm (X × Y × Z), customizable configurations available |

| Max Workpiece Weight | Up to 1,000 kg (dependent on table type and machine model) |

| Spindle Power | 22–40 kW (high-torque models for steel and hardened materials) |

| Surface Finish | Achieves Ra ≤ 0.8 µm (32 µin) as-machined; polishable to Ra ≤ 0.2 µm |

| Turning Capability | Integrated milling-turning mode with C-axis contouring and live tooling |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar), optional mist cooling for plastics |

| Materials Processed | Aluminum (6061, 7075), Steel (1018, 4140, stainless), Plastics (ABS, Nylon, PEEK, Delrin) |

| Fixturing Options | Modular vises, vacuum tables, custom fixtures, rotary/tilting tables |

| Probing Systems | On-machine touch probes for in-process inspection and tool presetting |

These machines are optimized for low-volume, high-mix production and prototype development, where precision, material versatility, and complex geometry handling are critical. Our engineering team leverages advanced CAM software (e.g., Mastercam, HyperMill) to program high-efficiency toolpaths that maintain dimensional stability and surface integrity across all supported materials.

From CAD to Part: The Process

Honyo Prototype executes precision face milling operations as part of our rapid CNC machining workflow for metal and plastic prototypes and low-volume production parts. Our process ensures optimal surface finish, dimensional accuracy, and flatness for critical mounting surfaces, sealing planes, or aesthetic features. Below is the detailed technical workflow specific to face milling applications:

CAD File Upload and Geometry Analysis

Customers submit native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system isolates planar surfaces designated for face milling, evaluating surface area, required flatness tolerances (typically ±0.005″ to ±0.0005″ depending on application), and adjacency to critical features. Material selection is cross-referenced against our certified stock database to confirm machinability for the specified operation.

AI-Powered Quoting with Process Validation

Our proprietary AI engine generates an initial quote within 2 hours, analyzing face milling parameters including cutter diameter selection (typically 50-100mm for production efficiency), stepover values (15-25% of tool diameter for Ra 32-63 μin finishes), and spindle speed/feed rate ranges based on material hardness. This is not an automated approval; Senior Manufacturing Engineers validate all AI outputs against machine capabilities (e.g., Haas VF-2SS with 1,200 IPM rapids and 0.0001″ positioning accuracy) and geometric complexity.

Engineering-Driven DFM for Face Milling Operations

During Design for Manufacturability review, our engineers specifically address face milling considerations:

Verifying sufficient surface area for stable chip evacuation to prevent recutting

Recommending minimum corner radii (0.5mm typical) to avoid tool deflection on interrupted cuts

Adjusting flatness tolerances based on workpiece size (e.g., ±0.001″ achievable on 300x300mm surfaces)

Flagging thin-wall sections requiring adaptive toolpaths to minimize vibration

Confirming workholding strategy to prevent flexure during high-torque face milling

This phase includes collaborative feedback with the client within 24 hours if design modifications would improve yield or reduce cycle time by >15%.

Precision Production Execution

Face milling operations occur on our climate-controlled CNC vertical machining centers with the following protocol:

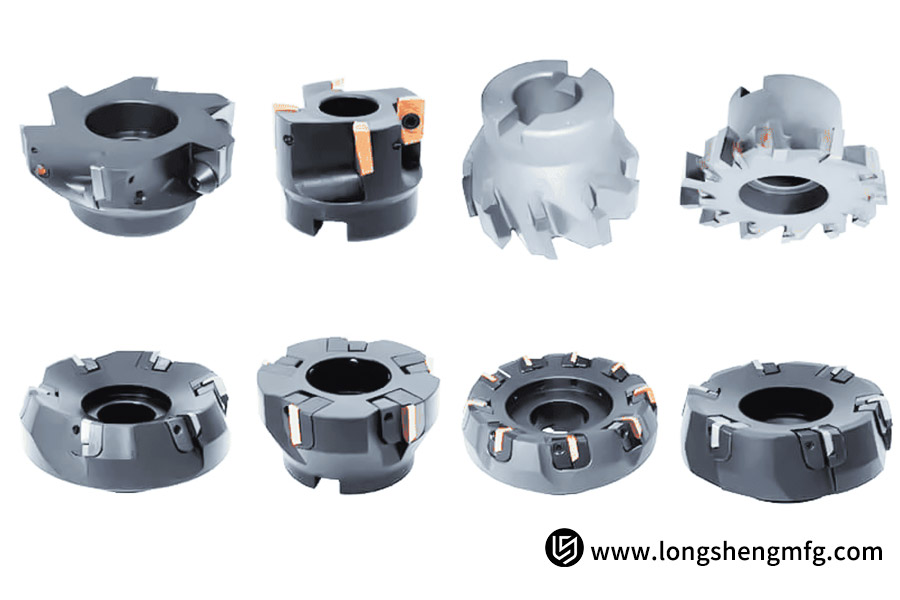

Tooling: Carbide indexable face mills with polished inserts (e.g., Sandvik CoroMill 200) for aluminum or ISO S-grade inserts for stainless steel

Process: Two-pass strategy (roughing at 0.010″ DOC, finishing at 0.002-0.005″ DOC) with climb milling to optimize surface finish

Verification: In-process height gauge checks after roughing; final surface validated via CMM flatness measurement (per ISO 1101)

Environment: Strict temperature control (20±1°C) to minimize thermal growth effects on critical flatness

Quality-Controlled Delivery

All face-milled components undergo our Triple-Check Protocol before shipment:

1. Dimensional inspection of milled surface against print tolerances (report includes flatness, parallelism, and surface roughness data)

2. Visual verification under 10x magnification for chatter marks or tool witness lines

3. Material certificate traceability matching

Standard lead time for face-milled components is 5-7 business days from DFM approval, with expedited 72-hour options available. Every shipment includes a First Article Inspection report documenting surface profile measurements per ASME Y14.5, ensuring compliance with the customer’s functional requirements for sealing, assembly, or optical performance.

Start Your Project

For high-precision face milling solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures tight tolerances, fast turnaround, and consistent quality for your production needs. Reach out today to discuss your project requirements and discover how our face milling capabilities can support your engineering goals.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.