Introduction: Navigating the Global Market for fabrication company names

In today’s competitive landscape, sourcing the right fabrication company names can be a daunting task for international B2B buyers. With diverse markets across Africa, South America, the Middle East, and Europe, businesses must navigate a myriad of options while ensuring that their chosen name reflects their brand’s identity and mission. This guide serves as a comprehensive resource, offering insights into various types of fabrication company names, their applications, and strategies for effective supplier vetting.

Understanding the nuances of naming within the fabrication industry is critical for establishing a strong market presence. In this guide, you’ll discover a wealth of creative and professional name ideas tailored to resonate with your target audience, whether you’re looking to launch a startup or rebrand an existing business. Additionally, we delve into the cost implications of name selection and the significance of domain availability in today’s digital marketplace.

By equipping B2B buyers with actionable insights and a clear framework for evaluating fabrication company names, this guide empowers informed purchasing decisions. It addresses the unique challenges faced by businesses in regions like Nigeria and Saudi Arabia, ensuring that you not only find a name that stands out but also one that aligns with your strategic goals and market demands. As you embark on this journey, let this guide illuminate the path to selecting a name that propels your business forward in the global marketplace.

Understanding fabrication company names Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Descriptive Names | Clearly describe services or products offered. | Manufacturing, construction, metalworks. | Pros: Easy to understand; Cons: May lack uniqueness. |

| Creative Names | Unique, imaginative names that evoke creativity. | Design, art, custom fabrication. | Pros: Memorable and brandable; Cons: May not convey services clearly. |

| Professional Names | Formal and authoritative names that suggest expertise. | Consulting, engineering, and high-end services. | Pros: Builds trust; Cons: Can be perceived as dull. |

| Modern/Tech Names | Names that reflect innovation and modernity. | Tech fabrication, advanced manufacturing. | Pros: Appeals to forward-thinking buyers; Cons: May alienate traditional clients. |

| Fun/Whimsical Names | Light-hearted, playful names that convey a fun approach. | Creative industries, niche markets. | Pros: Engaging and approachable; Cons: May lack seriousness for some clients. |

What Are Descriptive Names and When Are They Suitable for B2B Buyers?

Descriptive names are straightforward and explicitly convey the nature of the services or products offered. They are particularly suitable for buyers looking for clarity and directness in their purchasing decisions, such as those in manufacturing or construction sectors. These names help set clear expectations, making them ideal for businesses that prioritize functionality and reliability. However, while they are easy to understand, they may lack a unique flair, making differentiation in a crowded market challenging.

How Do Creative Names Enhance Brand Identity?

Creative names are imaginative and often evoke a sense of artistry or innovation. They are suitable for businesses involved in design, custom fabrication, or artistic endeavors. Such names can make a brand more memorable and appealing, particularly to clients seeking distinctive solutions. However, the downside is that they may not clearly communicate the services offered, potentially leading to confusion for some prospective buyers.

Why Choose Professional Names for Trust and Authority?

Professional names embody formality and expertise, making them ideal for businesses that operate in consulting, engineering, or high-end fabrication services. These names project reliability and authority, which can be crucial for attracting clients who value professionalism. While they effectively build trust, they can sometimes come across as unexciting or generic, which may not resonate with all target audiences.

What Are the Advantages of Modern/Tech Names in Today’s Market?

Modern or tech names reflect innovation and forward-thinking, making them highly suitable for businesses in advanced manufacturing and technology-driven fabrication. These names can attract clients looking for cutting-edge solutions and signify a commitment to staying current in a rapidly evolving industry. However, they may risk alienating traditional clients who prefer a more established approach, potentially narrowing the customer base.

How Do Fun/Whimsical Names Appeal to Niche Markets?

Fun or whimsical names introduce a playful element to branding, making them ideal for creative industries and niche markets. These names can engage clients on a personal level, fostering a sense of approachability and creativity. Nevertheless, while they can attract attention, they may also be perceived as lacking seriousness, which could deter buyers looking for more conventional or high-stakes services.

Key Industrial Applications of fabrication company names

| Industry/Sector | Specific Application of fabrication company names | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Engineering | Structural Steel Fabrication | Ensures durability and safety in building projects | Compliance with local regulations, material quality, and lead times |

| Automotive Manufacturing | Custom Parts Fabrication | Enhances production efficiency and vehicle performance | Precision manufacturing capabilities and material sourcing options |

| Oil & Gas Industry | Pipeline Fabrication | Supports infrastructure development and maintenance | Safety standards, environmental regulations, and logistical capabilities |

| Aerospace & Defense | Component Fabrication for Aircraft | Guarantees high-performance standards and reliability | Certification requirements, advanced technology, and quality assurance |

| Renewable Energy | Solar Panel and Wind Turbine Components Fabrication | Contributes to sustainable energy solutions | Material sourcing for eco-friendliness and compliance with international standards |

How Are Fabrication Company Names Utilized in the Construction & Engineering Sector?

In the construction and engineering sector, fabrication company names are pivotal for structural steel fabrication. These names convey reliability and expertise, essential for securing contracts and partnerships. Buyers seek companies that can deliver high-quality materials that meet safety and durability standards. International buyers from regions like Africa and the Middle East must consider local compliance regulations, ensuring that the fabrication company can meet specific standards and lead times for projects.

What Role Do Fabrication Company Names Play in Automotive Manufacturing?

In automotive manufacturing, fabrication company names are crucial for custom parts fabrication, which enhances vehicle performance and production efficiency. A strong name can signify innovation and quality, attracting clients seeking precision-engineered components. Buyers need to ensure that the fabrication company has advanced manufacturing capabilities and can source high-grade materials to meet rigorous industry standards, particularly in markets across South America and Europe.

Why Are Fabrication Company Names Important in the Oil & Gas Industry?

For the oil and gas industry, fabrication company names are associated with pipeline fabrication, which is vital for infrastructure development. A reputable name can instill confidence in stakeholders regarding safety and operational efficiency. Buyers must prioritize companies that adhere to stringent safety standards and environmental regulations, especially in regions with specific compliance requirements. Logistics capabilities are also critical, as timely delivery of fabricated components can impact project timelines.

How Do Fabrication Company Names Influence the Aerospace & Defense Sector?

In the aerospace and defense sector, fabrication company names are synonymous with high-performance component fabrication for aircraft. A well-regarded name reflects a commitment to quality and reliability, which are non-negotiable in this field. Buyers must ensure that the fabrication company meets certification requirements and has a robust quality assurance process in place. This is particularly important for international buyers who need to navigate varying standards across different regions, including Europe and the Middle East.

What Significance Do Fabrication Company Names Hold in Renewable Energy?

In renewable energy, fabrication company names are essential for companies producing solar panel and wind turbine components. A name that emphasizes sustainability and innovation can attract environmentally conscious buyers. Buyers must focus on sourcing materials that comply with international standards for eco-friendliness and sustainability. Additionally, understanding the fabrication company’s ability to meet project timelines and quality requirements is crucial, especially for B2B buyers in developing markets like Nigeria and Brazil.

3 Common User Pain Points for ‘fabrication company names’ & Their Solutions

Scenario 1: Navigating Brand Identity Confusion

The Problem: Many B2B buyers struggle to develop a strong brand identity for their fabrication companies due to the vast number of existing names and styles in the industry. This overwhelming selection can lead to confusion about what name will resonate with their target audience. Buyers often face the challenge of finding a name that not only reflects their unique services but also stands out in a competitive marketplace. They risk choosing names that are too generic or similar to competitors, which could dilute their brand identity and make it harder to build recognition.

The Solution: To overcome this challenge, buyers should conduct thorough market research to identify their niche within the fabrication industry. This involves analyzing competitor names and understanding what makes them successful. Once they have this insight, they can brainstorm names that highlight their unique selling propositions (USPs). For example, if a company specializes in eco-friendly materials, incorporating terms like “Green” or “Sustainable” into their name can create a strong brand identity. Additionally, engaging with branding professionals or utilizing naming platforms can provide fresh perspectives and help generate unique name ideas that align with their mission. Regular feedback from potential customers during this process can also ensure the name resonates with their target audience.

Scenario 2: Ensuring Domain and Trademark Availability

The Problem: After selecting a name, buyers often find themselves facing legal hurdles or online visibility issues. A common scenario involves discovering that their chosen name is already trademarked or that the domain name is unavailable, which can lead to costly rebranding efforts and lost momentum. This issue is particularly critical in the fabrication industry, where a strong online presence is essential for attracting clients and partners.

The Solution: To avoid this pitfall, buyers should conduct a comprehensive availability check before finalizing their fabrication company name. This includes searching trademark databases and checking domain registration sites to ensure that the name is not only available but also free from potential legal complications. Tools like the USPTO’s Trademark Electronic Search System (TESS) can help verify trademark availability. Additionally, buyers can use domain registration services to see if their desired domain is available or consider alternative endings, such as .co or .net, if the .com is taken. Securing social media handles that match the business name is also crucial for maintaining brand consistency across platforms. By taking these proactive steps, buyers can confidently move forward with a name that is both legally sound and online-ready.

Scenario 3: Adapting Names for International Markets

The Problem: For B2B buyers looking to expand their fabrication businesses into international markets, a name that works well in one region may not resonate in another. Cultural differences, language barriers, and varying interpretations of words can lead to misunderstandings or negative connotations. This can result in lost business opportunities, as potential clients may feel disconnected from a name that doesn’t align with their cultural context.

The Solution: To effectively adapt a fabrication company name for international markets, buyers should engage in cultural research to understand local language nuances and preferences. This includes consulting with local experts or potential customers to gauge the appropriateness and appeal of the name. Conducting surveys or focus groups can provide valuable insights into how the name is perceived in different cultures. Additionally, it may be beneficial to create a name that is easily translatable or has a universal appeal, thus reducing the likelihood of misinterpretation. A flexible naming strategy, which includes variations of the name for different regions, can help maintain brand integrity while catering to local tastes. By prioritizing cultural sensitivity, buyers can ensure their brand resonates globally, paving the way for successful international expansion.

Strategic Material Selection Guide for fabrication company names

What Are the Key Properties of Common Materials for Fabrication Company Names?

When selecting materials for fabrication company names, it is essential to consider the properties of the materials that align with the brand’s identity and the services offered. Here, we analyze four common materials: steel, aluminum, plastic, and composite materials.

How Does Steel Influence Fabrication Company Names?

Steel is renowned for its high strength and durability, making it a preferred choice in various industries, including construction and manufacturing. It typically has excellent temperature and pressure ratings, which is crucial for applications like structural components and machinery. However, steel is susceptible to corrosion unless treated, which can limit its application in certain environments.

Pros and Cons: Steel’s durability ensures long-lasting products, but its weight can complicate manufacturing and transportation. Additionally, while steel is generally cost-effective, the need for protective coatings can increase overall expenses.

Impact on Application: Steel is compatible with a wide range of media, including water, oil, and gas, making it versatile for many applications. However, international buyers must consider compliance with local standards like ASTM or DIN, particularly in regions with stringent regulations.

What Role Does Aluminum Play in Fabrication Company Names?

Aluminum is lightweight and resistant to corrosion, making it ideal for applications where weight savings are critical, such as in the aerospace and automotive industries. Its excellent thermal and electrical conductivity also enhances its appeal for electrical components.

Pros and Cons: The primary advantage of aluminum is its lightweight nature, which facilitates easier handling and installation. However, it is generally more expensive than steel and can have lower strength in certain applications, which may limit its use in heavy-duty contexts.

Impact on Application: Aluminum’s corrosion resistance makes it suitable for outdoor applications, particularly in coastal regions. Buyers from Africa and the Middle East should ensure that the aluminum grades used meet local environmental conditions and standards.

How Do Plastics Affect Fabrication Company Names?

Plastics are versatile materials used in various applications, from consumer goods to industrial components. They can be engineered to provide specific properties such as chemical resistance, flexibility, and lightweight characteristics.

Pros and Cons: The primary advantage of plastics is their low cost and ease of manufacturing, which allows for rapid prototyping and production. However, they may not offer the same level of durability as metals, and their performance can degrade under high temperatures or exposure to UV light.

Impact on Application: Plastic components are commonly used in applications that require chemical resistance, such as in the food and beverage industry. International buyers should be aware of compliance with regulations like FDA standards for food safety.

What Are the Benefits of Composite Materials in Fabrication Company Names?

Composite materials combine two or more constituents to achieve superior properties, such as enhanced strength-to-weight ratios and improved corrosion resistance. They are increasingly used in aerospace, automotive, and construction applications.

Pros and Cons: The key advantage of composites is their ability to be tailored for specific applications, providing excellent performance characteristics. However, they can be more expensive and complex to manufacture compared to traditional materials.

Impact on Application: Composites are ideal for applications requiring lightweight and high-strength materials, such as in aircraft and high-performance vehicles. Buyers should consider the specific certifications and standards applicable to composites in their region, as these can vary significantly.

Summary Table of Material Selection for Fabrication Company Names

| Material | Typical Use Case for fabrication company names | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, machinery | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Aerospace, automotive parts | Lightweight and corrosion-resistant | Higher cost, lower strength | High |

| Plastic | Consumer goods, industrial components | Low cost and ease of manufacturing | Less durable under extreme conditions | Low |

| Composite | Aerospace, high-performance vehicles | Tailored properties for specific applications | Higher manufacturing complexity | High |

This analysis provides B2B buyers with essential insights into material selection for fabrication company names, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for fabrication company names

What Are the Main Stages of Manufacturing in Fabrication Companies?

The manufacturing processes in fabrication companies typically consist of four primary stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers, as they directly impact the quality, cost, and lead time of the final product.

How Is Material Preparation Conducted in Fabrication?

Material preparation is the initial step where raw materials, such as metals, plastics, or composites, are selected and processed to meet specifications. This may involve cutting materials to size, treating them to enhance properties, or inspecting them for defects. For instance, steel may undergo processes such as annealing or tempering to improve its strength and workability. Buyers should ensure that suppliers have robust material sourcing and preparation practices, as the quality of raw materials significantly influences the overall product quality.

What Forming Techniques Are Commonly Used in Fabrication?

The forming stage involves shaping the prepared materials into the desired form. Common techniques include bending, welding, machining, and stamping. Each technique has its advantages depending on the material and design requirements. For example, welding is often used for creating strong joints in metal fabrication, while CNC machining provides precision for complex geometries. B2B buyers should inquire about the specific forming techniques employed by their suppliers, as this will affect the strength, durability, and precision of the final products.

How Is Assembly Performed in the Fabrication Process?

Assembly is the next step where individual components are joined to create a complete product. This could involve mechanical fastening, welding, or adhesive bonding. The assembly process must be carefully managed to ensure that all parts fit together correctly and function as intended. Quality assurance during assembly is crucial, as errors can lead to product failures. Buyers should assess the assembly capabilities of potential suppliers, including their technology, workforce skills, and quality controls in place during this phase.

What Finishing Processes Are Essential for Fabricated Products?

Finishing processes enhance the appearance and performance of the fabricated products. Techniques include surface treatment, painting, coating, and polishing. These processes not only provide aesthetic value but also improve resistance to corrosion and wear, which is particularly important for products used in harsh environments. Buyers should confirm that suppliers use appropriate finishing techniques that meet their specific industry standards and requirements.

What Are the Quality Assurance Measures Used in Fabrication?

Quality assurance (QA) is a critical aspect of the fabrication industry, ensuring that products meet specified standards and customer expectations. Various international standards and industry-specific certifications guide QA processes.

Which International Standards Should B2B Buyers Look For?

ISO 9001 is one of the most recognized quality management standards globally. It provides a framework for consistent quality assurance across manufacturing processes. Many fabrication companies also comply with additional industry-specific standards such as CE marking for construction products in the European Union or API specifications for the oil and gas sector. Buyers should seek suppliers that demonstrate compliance with these standards, as they reflect a commitment to quality and reliability.

What Are the Key Quality Control Checkpoints in Fabrication?

Quality control checkpoints are essential throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet quality standards.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A thorough examination of the finished product before shipment to ensure it meets all specifications.

Implementing these checkpoints helps prevent defects and ensures that products are delivered to buyers without issues.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps:

-

Conduct Audits: Regular audits of suppliers can provide insights into their quality assurance processes. Buyers should request access to audit reports and certifications.

-

Request Quality Reports: Suppliers should provide documentation that details their quality control processes and results from various checkpoints.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s manufacturing and quality assurance practices.

-

Ask for References: Buyers can request references from other clients to understand the supplier’s reliability and quality history.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Each region may have specific regulatory requirements and standards that affect quality assurance practices.

How Do Regional Standards Impact Quality Assurance?

Different countries and regions may have varying standards for quality assurance. For example, European buyers may prioritize CE certification, while Middle Eastern buyers might focus on local regulatory compliance. It is essential for buyers to familiarize themselves with the specific requirements of their region and the regions where their suppliers operate.

What Should B2B Buyers Know About Cultural Differences in Quality Control?

Cultural attitudes towards quality and manufacturing practices can vary significantly between regions. For instance, some cultures may prioritize rapid production over stringent quality checks, while others may adopt a more meticulous approach. B2B buyers should consider these cultural factors when evaluating suppliers, as they can influence quality outcomes.

Conclusion: Ensuring Quality in Fabrication Partnerships

In summary, understanding the manufacturing processes and quality assurance measures in fabrication is crucial for B2B buyers. By being informed about material preparation, forming, assembly, and finishing stages, as well as relevant quality control measures and international standards, buyers can make informed decisions when selecting fabrication partners. Ensuring that suppliers adhere to rigorous quality standards not only protects buyers’ investments but also fosters long-term, successful partnerships in the fabrication industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabrication company names’

Introduction

Choosing the right name for your fabrication company is a pivotal step in establishing your brand identity and market presence. A well-crafted name not only conveys your business’s mission and values but also resonates with your target audience. This guide provides a practical checklist to help B2B buyers navigate the process of selecting an impactful fabrication company name.

Step 1: Conduct Market Research

Understanding the competitive landscape is essential for choosing a unique and effective name. Analyze existing fabrication companies in your target regions—Africa, South America, the Middle East, and Europe—to identify naming trends and common themes. This research will help you avoid names that are too similar to competitors, reducing the risk of brand confusion.

Step 2: Define Your Brand Identity

Before brainstorming names, clarify your brand’s identity. Consider the values, mission, and personality you want to communicate. Is your brand innovative and cutting-edge, or is it more traditional and reliable? A clear understanding of your brand will guide you in crafting a name that aligns with your overall vision.

Step 3: Brainstorm Creative Names

Gather a diverse team to brainstorm potential names, encouraging creativity and open dialogue. Aim for names that are catchy, memorable, and reflective of your brand identity. Use techniques like word association and mind mapping to generate a variety of ideas, and don’t hesitate to think outside the box.

Step 4: Evaluate Name Availability

Once you have a shortlist of potential names, check for their availability. This includes:

– Domain Name Availability: Ensure a matching domain is available for your online presence.

– Trademark Registration: Conduct a trademark search to avoid legal issues down the line.

A unique name is only valuable if it can be legally owned and effectively marketed.

Step 5: Test Your Top Choices

Before finalizing a name, test your top choices with a sample of your target audience. Gather feedback on the names’ appeal, memorability, and perceived relevance. This step is crucial as it provides insight into how potential customers might perceive your brand.

Step 6: Consider Localization

If you plan to operate in multiple regions, consider how your name translates across different languages and cultures. A name that works well in one country may carry unintended connotations in another. Ensure that your chosen name is culturally appropriate and resonates positively with diverse audiences.

Step 7: Finalize and Register Your Name

After thorough evaluation and testing, choose the name that best represents your brand. Once selected, proceed to register your business name and domain, ensuring all legal protections are in place. This final step solidifies your brand’s identity and prepares you for marketing and operational activities.

By following this checklist, you can strategically navigate the process of selecting a fabrication company name that will serve as a strong foundation for your brand in the competitive marketplace.

Comprehensive Cost and Pricing Analysis for fabrication company names Sourcing

What Are the Key Cost Components for Sourcing Fabrication Company Names?

When sourcing fabrication company names, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: This pertains to the resources required for branding, such as logos, trademarks, and digital presence assets. The cost can vary significantly based on the complexity and uniqueness of the design.

-

Labor: Labor costs encompass creative input from designers and branding experts. Depending on the region, labor costs can fluctuate, impacting overall pricing.

-

Manufacturing Overhead: This includes the indirect costs related to the branding process, such as utilities, rent for office space, and equipment maintenance.

-

Tooling: For fabrication companies, tooling costs can include the expenses associated with creating molds or templates necessary for producing branded materials.

-

Quality Control: Ensuring that the branding aligns with industry standards and meets customer expectations is essential. This may involve additional costs for testing and certification.

-

Logistics: This includes the distribution of marketing materials and branded items, which can vary based on the destination and method of shipping.

-

Margin: The profit margin that suppliers include in their pricing can vary widely depending on their market positioning and competitive strategy.

How Do Price Influencers Affect Fabrication Company Name Sourcing?

Several factors influence the pricing for sourcing fabrication company names, particularly for international buyers.

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Buyers should consider Minimum Order Quantities (MOQs) that can impact overall pricing.

-

Specifications and Customization: Custom designs typically incur higher costs due to the additional time and resources required. Buyers should weigh the benefits of bespoke solutions against their budget.

-

Materials Used: The choice of materials for branding (e.g., digital assets, printed materials) directly affects costs. Premium materials may lead to higher quality but also increased expenses.

-

Quality and Certifications: Brands that offer certified quality may charge a premium, but this can ensure compliance with international standards, which is particularly important for buyers in regulated markets.

-

Supplier Factors: Supplier reputation, experience, and geographical location can influence pricing. Sourcing from established suppliers in regions with lower labor costs may yield more competitive pricing.

-

Incoterms: Understanding Incoterms is essential for international transactions. These terms define responsibilities and costs related to shipping, insurance, and customs, affecting the total cost of ownership.

What Tips Can Buyers Use to Ensure Cost-Efficiency When Sourcing Fabrication Company Names?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips to ensure cost-efficiency:

-

Negotiate Terms: Buyers should engage in negotiations not just on price but also on payment terms, delivery schedules, and after-sales support. This can lead to better overall pricing structures.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial price, consider all associated costs over the product’s lifecycle. This includes maintenance, potential rebranding costs, and the value of customer perception.

-

Research and Compare Suppliers: Conduct thorough research to compare multiple suppliers. Look for reviews, case studies, and testimonials to gauge reliability and quality.

-

Leverage Local Knowledge: Buyers from specific regions should leverage local contacts and market knowledge to identify reputable suppliers who understand the local context and can offer competitive pricing.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing strategies based on economic conditions, currency fluctuations, and cultural factors. Understanding these nuances can aid in better negotiation and decision-making.

Conclusion

In summary, sourcing fabrication company names involves a complex interplay of costs and pricing influencers. By understanding these elements and employing strategic approaches, international B2B buyers can enhance their sourcing efficiency and overall value. Always remember to consider the total cost of ownership and leverage local insights to navigate the global marketplace effectively.

Alternatives Analysis: Comparing fabrication company names With Other Solutions

Exploring Viable Alternatives to Fabrication Company Names

When establishing a brand in the fabrication industry, the name you choose plays a crucial role in your market positioning. However, there are various alternatives to simply creating a traditional fabrication company name. This analysis compares ‘fabrication company names’ with other branding strategies, such as using descriptive business names and adopting a tech-driven approach through digital platforms.

| Comparison Aspect | Fabrication Company Names | Descriptive Business Names | Tech-Driven Branding Solutions |

|---|---|---|---|

| Performance | Creates a unique identity and evokes brand values. | Provides clear understanding of services offered. | Engages customers through interactive platforms. |

| Cost | Low cost for naming; potential trademark fees. | Similar low cost; may require additional marketing. | Higher initial investment for development and maintenance. |

| Ease of Implementation | Straightforward naming process; creative brainstorming needed. | Simple if the service is clear; may require market research. | Complex setup; requires technical expertise and ongoing management. |

| Maintenance | Minimal once established; requires occasional rebranding. | Low maintenance; may need updates based on service changes. | High maintenance; needs regular updates and technical support. |

| Best Use Case | Ideal for businesses focused on brand personality and differentiation. | Best for straightforward service offerings and clarity. | Suited for businesses aiming for innovation and tech-savvy customers. |

What Are the Advantages and Disadvantages of Descriptive Business Names?

Descriptive business names offer a clear picture of the services provided, which can be highly beneficial for customer understanding and immediate recognition. For instance, a name like “Precision Metal Works” directly communicates the nature of the business. However, while this clarity can attract customers initially, it may lack the distinctiveness necessary to stand out in a crowded market. As competition grows, businesses may struggle with brand recall if the names are too generic.

How Do Tech-Driven Branding Solutions Compare?

Tech-driven branding solutions, such as interactive websites or mobile applications, leverage technology to create a more engaging customer experience. These platforms can showcase fabrication capabilities through virtual tours, project galleries, and customer feedback mechanisms. While the initial costs can be significantly higher due to development and maintenance needs, the potential for increased customer engagement and loyalty can yield long-term benefits. However, this approach requires continuous innovation and technical support, which may pose challenges for smaller businesses without dedicated IT resources.

Conclusion: How to Choose the Right Solution for Your Fabrication Business?

When selecting a naming strategy or branding approach for your fabrication business, consider your target audience, operational capabilities, and long-term goals. If your priority is to create a memorable brand that resonates emotionally with customers, a unique fabrication company name may be the best choice. On the other hand, if clarity and straightforward communication of services are vital, a descriptive name could serve your business better. For those looking to innovate and connect with a tech-savvy audience, investing in tech-driven branding solutions could set you apart from competitors. Ultimately, aligning your branding strategy with your business model and market needs is essential for success in the fabrication industry.

Essential Technical Properties and Trade Terminology for fabrication company names

Understanding the technical properties and trade terminology in the fabrication industry is crucial for international B2B buyers. This knowledge not only facilitates better communication but also aids in making informed decisions when selecting a fabrication partner.

What Are the Key Technical Properties Relevant to Fabrication Company Names?

1. Material Grade

Material grade refers to the classification of materials based on specific characteristics, such as strength, durability, and corrosion resistance. In fabrication, common materials include steel, aluminum, and plastics, each with distinct grades that determine their suitability for different applications. For B2B buyers, knowing the material grade helps in assessing the quality and performance of fabricated products, ensuring they meet industry standards and project requirements.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension or measured value. In fabrication, tighter tolerances often imply higher precision and quality. Understanding tolerances is essential for buyers, as it directly impacts the functionality and safety of the final product. When evaluating potential fabrication companies, buyers should inquire about their capability to meet specific tolerance requirements.

3. Surface Finish

Surface finish describes the texture and smoothness of a material’s surface after fabrication. Different finishes can affect aesthetic appeal, corrosion resistance, and adhesion properties. Buyers must consider the required surface finish for their projects, as it can influence both the performance and longevity of the fabricated item. Companies specializing in specific surface treatments may be more suitable for certain applications.

4. Load Capacity

Load capacity refers to the maximum weight or force a fabricated component can safely support. This property is particularly important in structural applications, where inadequate load capacity can lead to failure. B2B buyers should assess the load capacity specifications provided by fabrication companies to ensure that their products can withstand operational demands.

5. Weldability

Weldability indicates how easily a material can be welded. This property is critical for fabrication processes that involve joining different components. Understanding a material’s weldability helps buyers select appropriate fabrication methods and ensures the integrity of the final assembly. Buyers should inquire about the welding processes used and their compatibility with the materials specified.

Which Trade Terms Should B2B Buyers Understand in Fabrication?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fabrication, understanding OEM relationships can be crucial for buyers looking for specific components that must meet original specifications and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it affects pricing and inventory management. Knowing the MOQ helps businesses plan their purchases and avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. For fabrication companies, responding to RFQs accurately and promptly can enhance their chances of securing contracts. Buyers should provide detailed specifications in their RFQs to receive precise quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is essential for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transportation. Buyers should familiarize themselves with relevant Incoterms to negotiate favorable shipping terms.

5. CAD (Computer-Aided Design)

CAD refers to the use of software to create precise drawings and technical illustrations. In fabrication, CAD is essential for designing components and ensuring they meet specified dimensions and tolerances. Buyers should consider whether a fabrication company uses advanced CAD technology, as it can significantly improve accuracy and reduce lead times.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions when selecting fabrication partners, ultimately leading to better project outcomes and long-term business success.

Navigating Market Dynamics and Sourcing Trends in the fabrication company names Sector

What Are the Current Market Dynamics and Key Trends in the Fabrication Industry?

The fabrication industry is currently experiencing a transformative phase driven by several global factors. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for customized and innovative fabrication solutions. Key drivers include rapid urbanization, increasing infrastructure development, and the growing need for sustainable manufacturing practices. Furthermore, advancements in technology, such as automation, robotics, and 3D printing, are reshaping sourcing strategies, enabling companies to enhance efficiency and reduce lead times.

Emerging trends in B2B sourcing within the fabrication sector highlight the importance of digital transformation. Companies are increasingly adopting online platforms for procurement, allowing for real-time tracking and better supplier relationship management. Additionally, data analytics is being utilized to predict demand patterns, optimize inventory, and streamline operations, thereby reducing costs and improving service delivery. For international buyers, understanding these dynamics is crucial for leveraging competitive advantages in their respective markets.

How Are Sustainability and Ethical Sourcing Influencing the Fabrication Sector?

Sustainability has become a cornerstone in the fabrication industry, driven by regulatory pressures and consumer demand for environmentally responsible practices. The environmental impact of fabrication processes, including waste generation and carbon emissions, has prompted companies to reevaluate their supply chains. Ethical sourcing is gaining traction, as buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This includes the use of recycled materials, energy-efficient processes, and adherence to labor rights.

Moreover, certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for fabrication companies aiming to establish credibility in the market. Buyers are now more inclined to collaborate with manufacturers who are committed to sustainability, as this not only enhances brand reputation but also aligns with the growing trend of corporate social responsibility. Consequently, the demand for “green” materials and processes in fabrication is likely to rise, presenting opportunities for businesses that can meet these criteria.

What Is the Historical Context of the Fabrication Industry?

The fabrication industry has evolved significantly over the decades, transitioning from traditional craftsmanship to highly automated processes. Initially, fabrication focused on manual techniques and small-scale production. However, the advent of industrialization in the 19th century marked a pivotal shift, introducing mass production and mechanization. This transformation continued into the 20th century with the rise of advanced materials and technologies, including welding and machining.

Today, the fabrication sector is characterized by its integration of cutting-edge technologies and sustainable practices. As global markets expand, the industry is increasingly interconnected, with international buyers seeking reliable partners that can provide innovative solutions tailored to specific needs. Understanding this historical context helps B2B buyers appreciate the current landscape and anticipate future developments in the fabrication market.

Frequently Asked Questions (FAQs) for B2B Buyers of fabrication company names

-

How do I choose a unique fabrication company name that stands out in the market?

To select a unique fabrication company name, start by researching existing names in your industry to avoid duplication. Focus on terms that reflect your core values and the services you provide. Consider using evocative language or creative combinations of words to convey your brand’s personality. It’s also essential to ensure that the name is easy to pronounce and remember. Finally, check domain availability to support your online presence. -

What are the key factors to consider when vetting fabrication suppliers internationally?

When vetting fabrication suppliers, consider their reputation, experience, and client reviews. Verify their certifications and adherence to industry standards. Assess their production capabilities and technology used, as well as their ability to meet your specific requirements. Additionally, inquire about their logistics, lead times, and flexibility in handling changes or customizations. Establishing direct communication can help gauge their reliability and customer service approach. -

What customization options should I expect from a fabrication company?

Most fabrication companies offer a range of customization options, including material selection, design alterations, and specific dimensions. You can often request tailored solutions to meet your project’s unique requirements, such as finishes or assembly techniques. It’s crucial to communicate your needs clearly and ask for samples or prototypes to ensure the final product aligns with your expectations. -

What is the typical minimum order quantity (MOQ) for fabrication services?

Minimum order quantities (MOQs) can vary significantly between fabrication companies and depend on the type of product being manufactured. Typically, MOQs may range from a few units to several hundred, depending on production costs and materials used. When sourcing suppliers, inquire about their MOQ policies and whether they offer flexibility for smaller orders, especially if you are testing a new product line or entering a new market. -

What payment terms are standard in international fabrication contracts?

Payment terms for international fabrication contracts commonly include options such as upfront deposits, milestone payments, or payment upon delivery. Terms can vary based on the supplier’s policies and your relationship with them. It’s essential to negotiate terms that work for both parties and consider using letters of credit or escrow services for added security. Always ensure that the payment terms are clearly outlined in the contract to avoid misunderstandings. -

How can I ensure quality assurance in my fabrication orders?

To ensure quality assurance in your fabrication orders, request certifications and quality control processes from your supplier. Many companies follow international standards such as ISO 9001 for quality management. It’s advisable to conduct factory visits or audits, if feasible, and ask for samples before placing large orders. Additionally, implementing regular inspections during production can help catch any issues early in the process. -

What are the logistics considerations when importing fabricated goods?

When importing fabricated goods, consider shipping costs, lead times, and customs regulations specific to your destination country. Understand the Incoterms that define responsibilities for shipping, insurance, and tariffs. It’s also wise to work with a logistics provider familiar with international trade to navigate potential challenges and ensure timely delivery. Proper documentation, including invoices and certificates of origin, is crucial for smooth customs clearance. -

How do I handle disputes with international fabrication suppliers?

Handling disputes with international fabrication suppliers requires a clear communication strategy. Start by addressing the issue directly with the supplier, providing detailed evidence of the problem. If informal resolution fails, refer to the contract’s dispute resolution clause, which may outline arbitration or mediation steps. Maintaining a professional tone and being open to compromise can facilitate a more amicable resolution. Additionally, consider involving legal counsel if necessary to protect your interests.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

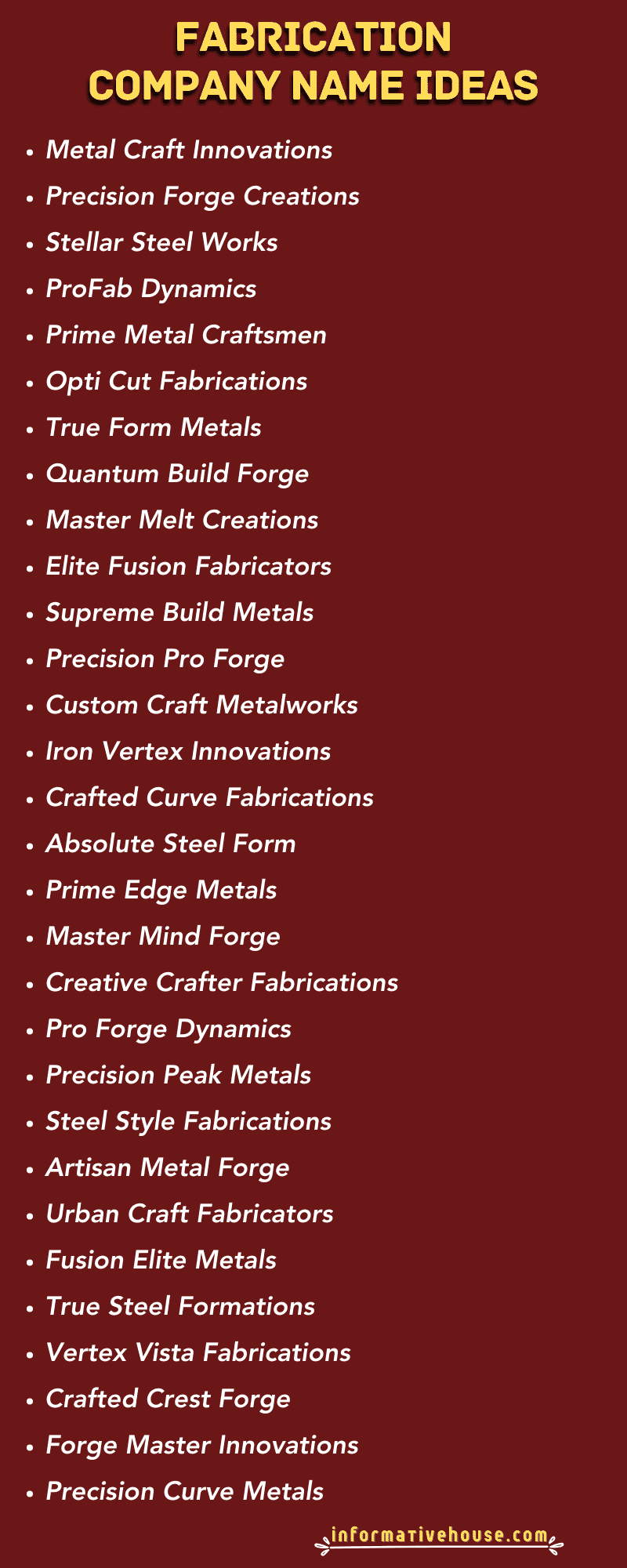

Top 7 Fabrication Company Names Manufacturers & Suppliers List

1. Fabrication – Creative Business Name Ideas

Domain: brandbucket.com

Registered: 2007 (18 years)

Introduction: 80+ Creative Fabrication Business Name Ideas, including categories such as High Value Names, Short Names, Catchy Names, Clever Names, Classic & Elegant Names, Modern & Trendy Names, International & Global Names, Creative Business Names, Evocative & Suggestive Names, Feminine & Female Names, Masculine & Male Names. Industry-specific name ideas for sectors like Agriculture & Farming, Art & Design, C…

2. Fabrication Shop Names – Industry Insights

Domain: mobile-cuisine.com

Registered: 2010 (15 years)

Introduction: 400+ Fabrication Shop Name Ideas, Metal fabrication industry expected to reach over $21 billion by 2024, business name ideas for fabrication shops including categories like Aluminum Fabrication Shop Names, Welding Fabrication Shop Names, Steel Fabrication Shop Names, and Machine Shop Names.

3. Home Welding Solutions – MIG & Plasma Cutting Services

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user is looking to start a welding business from home, focusing on small jobs due to limited space and equipment. They have experience with MIG welding, plasma cutting, and casting, and have been gifted a plasma cutter and a small MIG welder.

4. Manufacturing – Name Generator

Domain: atom.com

Registered: 1995 (30 years)

Introduction: Manufacturing Company Name Generator offers over 5,584 unique manufacturing name ideas, including classic and innovative options. The platform provides expert-curated brand names with matching domains, and users can generate names quickly or browse premium options. It features a crowdsourced naming platform, allowing users to start naming contests for unique ideas, and offers managed contests for …

5. Namesnack – Fabrication Industry Overview

Domain: namesnack.com

Registered: 2019 (6 years)

Introduction: The fabrication industry includes plastic, metal, and wood fabrication, covering processes from mining to welding. Key product details include:

1. Metal fabrication (e.g., Craft Heat & Hammer, Steel City Joinery, The Metal Tap)

2. Wood fabrication (e.g., The Woodwork Haven, The Timber Kiln)

3. Plastic fabrication (e.g., Chemic Mining)

4. General fabrication (e.g., A Fabricated Effect, The Industri…

6. Machining Design – Business Naming Strategies

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: The discussion revolves around naming a business related to machining and design work. Key considerations include using personal names, initials, or descriptive terms that reflect the services offered. Suggestions include avoiding overly broad names and ensuring the name represents the business’s capabilities without misleading customers. Examples of names discussed include ‘EWL Custom Tool Design…

7. Eng-Tips – Structural Steel Solutions & Software Development

Domain: eng-tips.com

Registered: 1997 (28 years)

Introduction: 1- Engineering Services for Structural Steel. 2- Software Development (Mainly for Steel Designer and Fabricators).

Strategic Sourcing Conclusion and Outlook for fabrication company names

In today’s competitive fabrication industry, the significance of strategic sourcing cannot be overstated. By selecting a compelling name for your fabrication business, you not only enhance brand recognition but also establish a strong market presence that resonates with your target audience. A well-chosen name reflects your company’s values and can set you apart in a crowded marketplace, especially as you expand operations in diverse regions like Africa, South America, the Middle East, and Europe.

International buyers should prioritize names that convey trust, innovation, and quality to appeal to local markets. As you consider potential names, remember to research your competition and ensure uniqueness to avoid legal pitfalls. Furthermore, aligning your name with your brand identity will strengthen your marketing efforts and customer engagement.

As you move forward, take the time to brainstorm and evaluate names that capture the essence of your fabrication business. The right name will not only enhance your brand image but also foster connections with clients around the globe. Embrace this opportunity to define your brand’s future and make a lasting impression in the fabrication industry.