Contents

Manufacturing Insight: Fabricacion De Piezas De Plastico Por Inyeccion

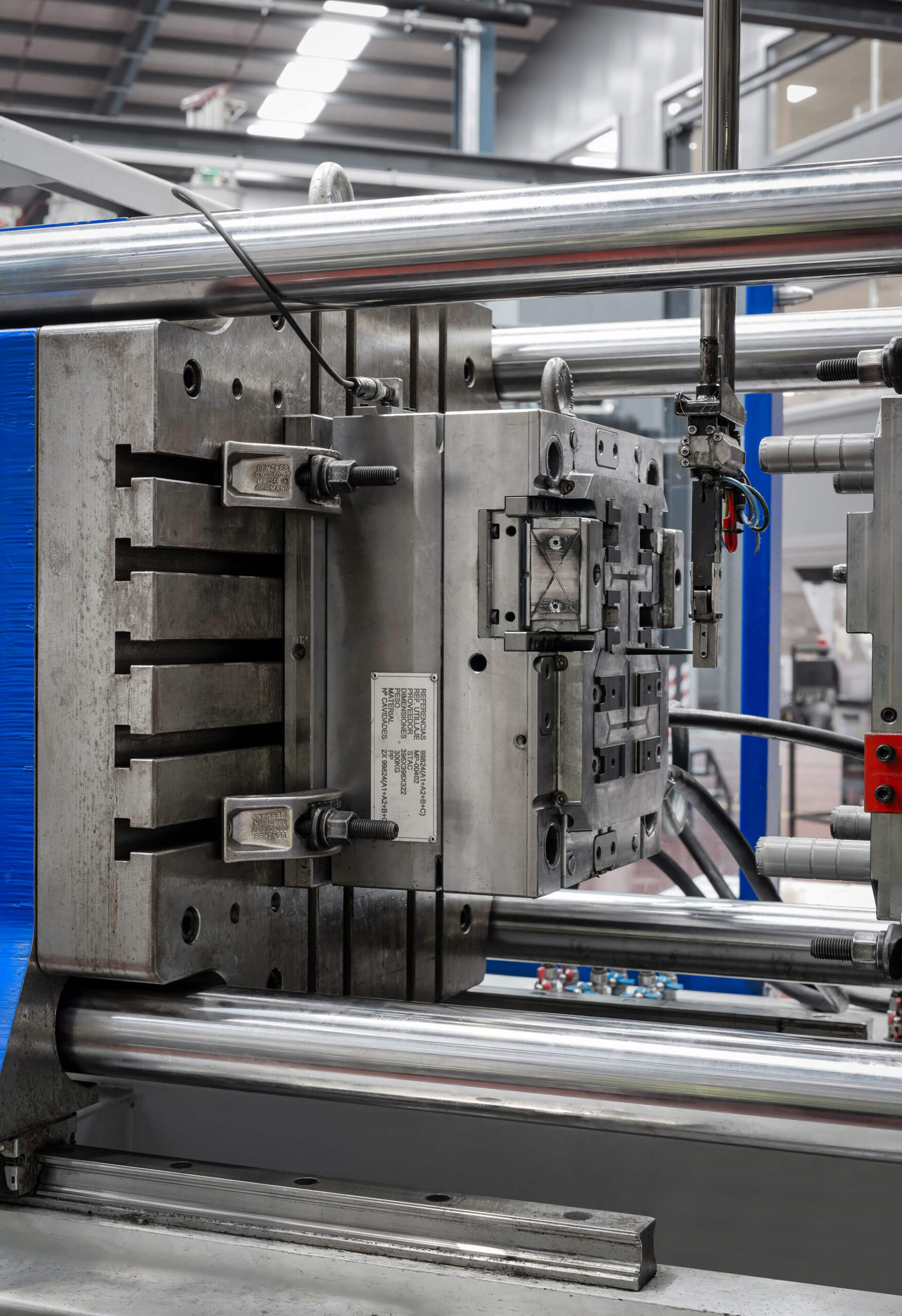

Precision Plastic Injection Molding Development Supported by Honyo’s Advanced CNC Capabilities

For manufacturers requiring high-integrity plastic injection molded components, the foundation of success lies in precision tooling and rapid prototyping validation. While Honyo Prototype excels in end-to-end plastic injection molding solutions, our integrated CNC machining services are critical enablers throughout the development lifecycle. We leverage state-of-the-art 3-, 4-, and 5-axis CNC machining centers to produce injection molds, cavities, and cores with micron-level accuracy, ensuring optimal part geometry, surface finish, and cycle time efficiency. This capability is equally vital for creating functional prototypes directly from engineering-grade thermoplastics, allowing clients to validate form, fit, and function before committing to full mold fabrication.

Our technical approach bridges design intent with manufacturability, minimizing iteration delays and costly mold revisions. All CNC-machined elements undergo rigorous in-process metrology using calibrated CMMs and optical comparators, guaranteeing compliance with ISO 2768-mK or client-specific tolerances. For projects demanding accelerated timelines, Honyo’s Online Instant Quote system provides immediate, transparent pricing and lead time estimates for both CNC machining and injection molding services. Simply upload your 3D model to receive a formal quotation within hours—streamlining procurement and accelerating your path from concept to certified production.

Technical Capabilities

Technical specifications for plastic injection molding parts fabrication involve a combination of precision machining processes such as 3/4/5-axis milling and turning, especially when producing molds or prototypes requiring tight tolerances. These processes ensure high accuracy in cavity and core dimensions, surface finish, and part consistency. Below is a detailed summary of the technical specifications, including applicable materials and capabilities.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling for complex mold geometry; CNC turning for cylindrical mold components such as cores, ejector pins, and bushings |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical mold features; ±0.025 mm (±0.001″) typical for non-critical dimensions |

| Surface Finish | Mold cavities: Ra 0.1–0.8 µm (mirror polish to textured finishes); Plastic parts: As molded or post-processed |

| Materials – Mold Tooling | Aluminum (e.g., 7075-T6, 6061-T6) for rapid tooling; Steel (e.g., P20, H13, S136) for production molds requiring high wear resistance and longevity |

| Materials – Plastic Parts | ABS (impact-resistant, medium heat), Nylon (high strength, wear-resistant), and other engineering thermoplastics compatible with injection molding |

| Part Complexity | High complexity supported via 5-axis milling for undercuts, freeform surfaces, and internal features without manual repositioning |

| Tooling Accuracy | Full GD&T compliance; CMM inspection reports available; First Article Inspection (FAI) per AS9102 or customer requirement |

| Production Volume Support | Prototype (1–100 shots), bridge tooling (100–10,000 shots), and full production molds (100,000+ cycles) |

| Secondary Operations | EDM (for fine details), polishing, texturing, heat treatment (for steel molds), and assembly of mold components |

This technical capability enables Honyo Prototype to deliver high-precision injection molds and molded plastic components suitable for industries such as automotive, medical, and consumer electronics, where dimensional stability and repeatability are critical.

From CAD to Part: The Process

Honyo Prototype executes plastic injection molding projects through a rigorously defined workflow designed for speed, precision, and manufacturability assurance. Our process begins with secure CAD file ingestion via our customer portal, accepting industry-standard formats including STEP, IGES, and native SOLIDWORKS files. Upon upload, proprietary AI algorithms initiate an automated quote generation system that analyzes geometric complexity, part volume, material requirements, and projected cycle times to provide an instant preliminary cost estimate and lead time range within minutes. This AI-driven quote serves as a foundational assessment but is never the final commercial offer.

The AI-generated quote triggers mandatory Design for Manufacturability (DFM) engineering review. Our senior manufacturing engineers perform a comprehensive technical validation against 47 critical plastic injection molding parameters. This phase is where Honyo adds significant value through human expertise that transcends algorithmic analysis. Key DFM checkpoints include:

| DFM Parameter Category | Critical Checks Performed | Honyo Engineering Action |

|---|---|---|

| Wall Thickness & Transitions | Uniformity, sink risk zones, draft angles | Recommend geometry modifications, suggest rib redesigns |

| Gate Location & Type | Flow analysis, weld line prediction, ejector pin placement | Propose optimal gate strategies, modify ejection system design |

| Material Suitability | Resin flow properties, shrinkage rates, thermal stability | Validate material selection or recommend alternatives |

| Tool Steel & Lifespan | Cavity pressure, wear zones, cooling efficiency | Specify appropriate mold steel grade and hardened components |

Following DFM approval, our production team initiates concurrent tooling fabrication and process validation. We utilize P20 or H13 tool steel molds with conformal cooling channels manufactured in-house on Makino machining centers. Every mold undergoes 72-hour dry cycles and scientific molding validation before first-article production. All parts are produced under ISO 9001-controlled conditions with in-process dimensional checks at 30%, 60%, and 100% production milestones using calibrated CMM equipment. Material certificates (UL, FDA, or automotive grade) accompany every shipment with full lot traceability.

Delivery encompasses final inspection reporting per AS9102 or customer-specific FAIR requirements, precision packaging to prevent transit damage, and global logistics coordination. Standard lead time from DFM sign-off to delivery is 15-20 business days for single-cavity tools, with expedited options available. Customers receive digital access to real-time production dashboards showing mold status, QC results, and shipment tracking through our secure client portal. This integrated workflow ensures zero surprises from digital model to certified physical part.

Start Your Project

Si necesita fabricación de piezas de plástico por inyección con altos estándares de calidad y entrega rápida, confíe en Honyo Prototype. Contamos con una moderna planta de producción en Shenzhen, China, especializada en la fabricación precisa y eficiente de componentes plásticos mediante procesos de moldeo por inyección, ideal para prototipos y producciones en serie.

Para obtener una cotización o consultar sobre sus necesidades técnicas, comuníquese con Susan Leo al correo [email protected]. Nuestro equipo está listo para apoyarle con soluciones personalizadas, tiempos de entrega competitivos y soporte continuo durante todo el proceso de manufactura.

Ubicación del taller: Shenzhen, corazón del sur de China, con acceso logístico global y control riguroso de calidad en cada etapa del proceso.

Datos de contacto

Nombre: Susan Leo

Correo: [email protected]

Ubicación: Shenzhen, China

Servicio: Fabricación de piezas plásticas por inyección – Desde prototipos hasta producción en volumen

Trabajamos con materiales de alta resistencia, acabados personalizados y moldes de precisión para cumplir con los requisitos más exigentes de su proyecto.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.