Contents

Manufacturing Insight: Engravable Plastic Sheet

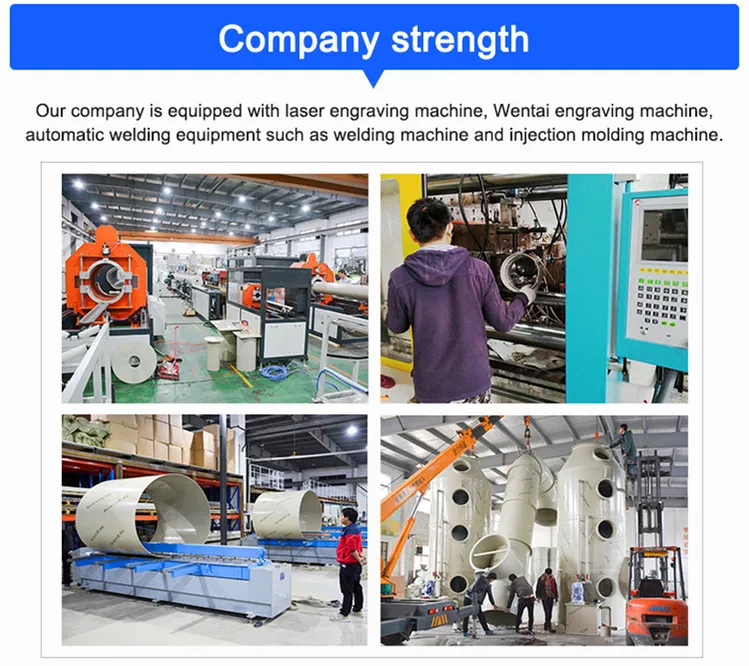

Introducing Precision-Engineered Solutions: Honyo’s Sheet Metal Fabrication Expertise

While Honyo Prototype specializes in high-precision sheet metal fabrication for industrial and commercial applications, we recognize client requirements often extend beyond metallic substrates. It is important to clarify that engravable plastic sheets fall outside our core sheet metal process scope, which focuses exclusively on materials like stainless steel, aluminum, and cold-rolled steel. Our advanced fabrication capabilities—including laser cutting, CNC bending, welding, and finishing—are optimized for metal components demanding tight tolerances, structural integrity, and repeatability.

For clients requiring engravable plastics (e.g., acrylic, polycarbonate, or ABS), we recommend partnering with specialized polymer fabricators. However, when your project demands robust metal enclosures, brackets, chassis, or precision sheet metal parts—even those integrating plastic elements—Honyo delivers end-to-end manufacturing excellence. Our ISO 9001-certified processes ensure dimensional accuracy down to ±0.05mm and seamless scalability from prototypes to volume production.

Leverage our Online Instant Quote platform to accelerate your metal fabrication timeline. Simply upload CAD files (STEP, DWG, DXF) for real-time cost estimation, lead time validation, and DFM feedback—eliminating traditional quotation delays. This digital workflow ensures engineering teams maintain project momentum while benefiting from Honyo’s 35+ years of metallurgical expertise.

| Material Category | Honyo’s Core Capability | Typical Applications |

|---|---|---|

| Sheet Metal (Stainless Steel, Aluminum, CR Steel) | Laser Cutting, CNC Punching, Bending, Welding, Finishing | Enclosures, Brackets, Chassis, Structural Components |

| Plastics (Acrylic, Polycarbonate, ABS) | Not a core service | Engravable Panels, Transparent Shields, Non-Structural Housings |

Partner with Honyo for mission-critical metal fabrication where performance, durability, and precision are non-negotiable. Begin your project today with our instant digital quoting system at honyoprototype.com.

Technical Capabilities

Technical specifications for engravable plastic sheets suitable for laser cutting, bending, and welding processes vary significantly based on material composition. While aluminum and steel are not plastic materials, they are included here for comparative context in hybrid or multi-material fabrication environments. The primary focus remains on industrial-grade thermoplastics such as ABS and Nylon, which are commonly used in prototyping, signage, enclosures, and custom components.

The following table outlines key technical properties and process compatibility for each material:

| Material | Type | Thickness Range (mm) | Laser Cutting Compatibility | Bending Characteristics | Welding Method | Engraving Quality | Thermal Resistance (°C) | Chemical Resistance | Notes |

|---|---|---|---|---|---|---|---|---|---|

| ABS | Thermoplastic | 0.5 – 10.0 | Excellent (CO₂ laser, 60–100W) | Good (requires heated jig, 100–130°C) | Ultrasonic, Solvent, Vibration | High (sharp contrast, smooth marks) | 80 – 100 | Moderate (attacked by ketones, esters) | Prone to warping under high heat; emits fumes when laser processed – ventilation required |

| Nylon (PA6/PA66) | Thermoplastic | 1.0 – 15.0 | Moderate (requires controlled power, risk of melting) | Good (annealed bending at 120–150°C) | Hot plate, Vibration, Laser welding | Medium (less contrast, may char) | 120 – 180 | High (resists oils, fuels, many solvents) | Hygroscopic – must be dried before processing; excellent mechanical durability |

| Aluminum | Metal | 0.8 – 6.0 | Poor (reflective, high conductivity – not suitable for standard laser engraving/cutting without fiber laser) | Excellent (CNC or press brake bending) | TIG, MIG, Laser welding | High (with fiber laser or mechanical engraving) | Up to 200 (depending on alloy) | High (forms protective oxide layer) | Not a plastic; used in hybrid assemblies; requires specialized equipment |

| Steel (Mild) | Metal | 0.5 – 12.0 | Poor (requires high-power fiber laser; not typical for plastic engraving systems) | Good (with press brake, springback compensation) | MIG, TIG, Spot welding | High (via fiber laser or mechanical methods) | Up to 400+ | Moderate (prone to rust without coating) | Not a plastic; heavy and conductive; incompatible with standard plastic processing setups |

Process Notes:

Laser cutting of plastics such as ABS and Nylon is best performed using CO₂ lasers (wavelength ~10.6 μm), which are efficiently absorbed by organic materials. ABS provides clean, polished edges when cut with optimized parameters, while Nylon may require slower speeds and assist gas (e.g., compressed air) to minimize charring.

Bending of plastic sheets is typically done using heated bending jigs or strip heaters to locally soften the material. ABS bends smoothly between 100–130°C, while Nylon requires higher temperatures and controlled cooling to prevent cracking.

Welding of thermoplastics is achievable through ultrasonic, vibration, or hot plate methods. ABS welds readily with solvent bonding, whereas Nylon benefits from vibration or laser transmission welding in precision applications.

For engravable applications, ABS offers superior surface engraving results with high contrast and detail, making it ideal for labels, control panels, and user interfaces. Nylon is preferred in high-wear environments due to its toughness and chemical resistance, though engraving contrast is lower without pigment additives.

Aluminum and steel are included for system integration considerations but require fiber lasers and metal-specific tooling, making them incompatible with standard plastic fabrication workflows unless part of a multi-material design.

From CAD to Part: The Process

Honyo Prototype Engravable Plastic Sheet Manufacturing Process

Clients initiate the process by uploading a detailed CAD file via our secure online portal. The file must specify critical parameters including part geometry, engraving depth requirements, font style constraints, and material grade preferences. Acceptable formats are STEP, IGES, or native SolidWorks files with all features fully defined. We require explicit indication of engraving zones and any surface finish specifications to ensure downstream accuracy.

The uploaded CAD data feeds directly into our proprietary AI-driven quoting engine. This system cross-references material databases, historical production metrics, and real-time machine utilization rates to generate a precise cost estimate within 90 minutes. The AI evaluates engraving complexity factors such as minimum feature size, stroke density, and thermal distortion risks specific to plastics like acrylic or polycarbonate. Clients receive a formal quote detailing unit cost, lead time, and any preliminary material recommendations based on functional requirements.

Upon quote acceptance, our engineering team conducts a rigorous Design for Manufacturability (DFM) review. We analyze the CAD model for engraving-specific challenges including wall thickness transitions near engraved areas, potential stress concentrations, and optimal fixturing points to prevent vibration-induced errors. Critical checks involve verifying minimum engraving depths against material thermal properties to avoid melting or charring during laser processing. We provide actionable feedback within 24 hours, suggesting geometric modifications if necessary to achieve ±0.05mm depth tolerance while maintaining structural integrity.

Production begins only after DFM sign-off. Engravable sheets undergo CNC laser processing using calibrated fiber or CO2 laser systems depending on material composition. For acrylic, we employ 30W fiber lasers with nitrogen assist gas to achieve clean, polished engraved edges; polycarbonate utilizes lower-power CO2 lasers with pulsed settings to minimize thermal stress. Each batch includes first-article inspection against the CAD model, with surface roughness measurements (Ra) documented to ensure engraving clarity meets ISO 25178 standards. Secondary operations like edge polishing or masking application occur as specified.

Final delivery includes serialized parts packaged with anti-static protection and humidity control. We provide a comprehensive quality report containing engraved depth verification data, surface roughness certificates, and material traceability documentation. Standard lead time is 5–7 business days from DFM approval, with expedited 72-hour options available for qualified projects. All shipments include real-time tracking and comply with UN3481/PI903 shipping requirements for plastic components.

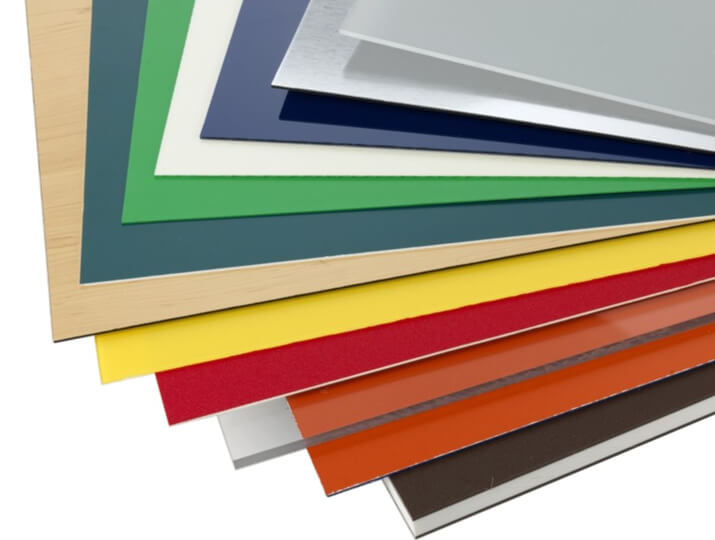

Common Engravable Plastics and Properties

| Material | Laser Type | Max Engraving Depth | Surface Roughness (Ra) | Key Applications |

|—————|————|———————|————————|—————————|

| Acrylic (PMMA)| Fiber | 3.0 mm | 0.8–1.2 μm | Control panels, signage |

| Polycarbonate | CO₂ | 1.5 mm | 1.5–2.0 μm | Aerospace labels, medical |

| ABS | CO₂ | 1.0 mm | 2.0–2.5 μm | Industrial nameplates |

| PETG | Fiber | 2.0 mm | 1.0–1.5 μm | Electronic enclosures |

Start Your Project

Looking for high-quality engravable plastic sheets for your next project? Honyo Prototype offers precision-manufactured solutions tailored to your specifications. With our state-of-the-art facility located in Shenzhen, we ensure fast turnaround times and consistent quality for both prototypes and production runs.

For inquiries or custom orders, contact Susan Leo at [email protected]. Let us support your design and manufacturing needs with reliable, expert service.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.