Contents

Manufacturing Insight: Enclosed Cnc Router

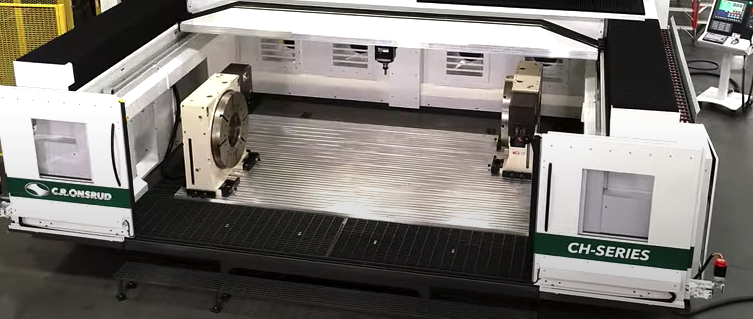

Honyo Prototype delivers precision-engineered components through advanced CNC machining services, leveraging state-of-the-art enclosed CNC router systems to meet demanding industrial requirements. Our enclosed CNC routers provide a controlled machining environment essential for achieving micron-level tolerances and superior surface finishes across diverse materials including aerospace-grade composites, engineering plastics, and non-ferrous metals. The fully enclosed work envelope ensures optimal chip and dust management, critical for maintaining dimensional accuracy in high-mix production runs while enhancing operator safety and prolonging tool life.

These systems form the backbone of our responsive prototyping and low-to-mid volume production capabilities, supporting complex 3-axis and 4-axis machining operations with repeatability conforming to ISO 2768-mK standards. By isolating the machining process from ambient workshop variables, we consistently achieve ±0.005mm positional accuracy and Ra 0.8μm surface quality, directly addressing client challenges in sectors requiring contamination-sensitive or high-reliability parts. Our integrated workflow from CAD model to finished component minimizes handling errors and accelerates time-to-part without compromising on quality validation.

Honyo Prototype’s technical team applies decades of machining expertise to optimize toolpaths, fixturing, and material utilization within these enclosed platforms, ensuring cost-effective production for both one-off prototypes and batch quantities. To streamline your sourcing process, we provide an Online Instant Quote platform where engineers can upload STEP or IGES files for immediate manufacturability feedback and competitive pricing. This digital interface reduces quotation lead times from days to minutes while maintaining the engineering rigor our industrial clients expect from a trusted manufacturing partner. Initiate your next precision component project with validated cost and timeline transparency through our Online Instant Quote system.

Technical Capabilities

Enclosed CNC Router – Technical Specifications

The enclosed CNC router systems offered by Honyo Prototype are engineered for precision machining across multiple axes, supporting complex 3-axis, 4-axis, and 5-axis milling operations, as well as integrated turning capabilities in multi-function models. These systems are designed for tight-tolerance production, ideal for prototyping and low-volume manufacturing in industries such as aerospace, medical, and automotive. The fully enclosed structure ensures operator safety, dust containment, and thermal stability for consistent accuracy.

The machines are optimized to handle a wide range of materials including aluminum, steel, ABS, and nylon, with spindle configurations and tooling selected to maintain surface finish and dimensional precision within ±0.005 mm (±0.0002″) under controlled conditions.

| Specification | Detail |

|---|---|

| Machining Axes | 3-axis standard; optional 4-axis (rotary A or B); full 5-axis simultaneous (A/B or trunnion table configurations) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Spindle Speed Range | 8,000 – 24,000 RPM (air-cooled or liquid-cooled options) |

| Spindle Power | 3.0 kW to 8.0 kW, depending on configuration |

| Control System | Siemens SINUMERIK, Fanuc, or Heidenhain (configurable) |

| Tool Changer | Automatic Tool Changer (ATC) with 8–30 tool capacity (optional) |

| Work Envelope (Max) | 1000 x 600 x 400 mm (X-Y-Z), custom sizes available |

| Linear Guideways | High-precision ground ball screws with THK or HIWIN linear rails |

| Coolant System | Flood coolant, mist coolant, or air blast (material-dependent) |

| Enclosure Features | Full steel enclosure with safety interlocks, dust extraction ports, viewing window |

| Materials Supported | Aluminum (6061, 7075), Steel (mild, stainless), ABS, Nylon (PA6, PA66), Delrin, and other engineering plastics |

| Surface Finish Capability | Ra ≤ 0.8 µm (32 µin) achievable with finishing passes |

| Tolerance Range | ±0.01 mm (±0.0004″) standard; tight-tolerance mode down to ±0.005 mm with thermal compensation |

| Integrated Turning (Optional) | Live tooling with C-axis control for mill-turn operations on select 4/5-axis models |

| Software Compatibility | Compatible with Mastercam, Fusion 360, HyperMill, and Siemens NX via standard post-processors |

These enclosed CNC routers are built for repeatable, high-accuracy material removal, supporting both soft and hard materials with optimized feed and speed parameters. The environmental enclosure helps maintain stable operating conditions, critical when holding tight tolerances in long-run or high-precision jobs.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for enclosed CNC router fabrication, designed to ensure precision, manufacturability, and on-time delivery for complex electromechanical assemblies. Our process begins when a client uploads a complete 3D CAD model through the secure Honyo Portal. This model must include all structural components, mounting interfaces, and critical tolerances for the enclosure frame, dust management system, and router spindle integration.

The AI Quote engine immediately analyzes the CAD geometry, material specifications, and finish requirements against Honyo’s real-time production database. This proprietary system evaluates machine time, material utilization, and historical defect rates for similar geometries—particularly critical for enclosed systems requiring precise panel alignment and vibration damping. Within 90 minutes, clients receive a formal quotation detailing cost breakdowns, lead time, and any preliminary material constraints. Typical quotation accuracy exceeds 95% due to AI calibration against 12,000+ historical CNC enclosure builds.

Design for Manufacturability (DFM) review follows quote acceptance, conducted by senior mechanical engineers specializing in motion control systems. This phase focuses on enclosure-specific challenges: verifying adequate thermal clearance around spindle motors, confirming accessibility for maintenance panels, assessing gasket compression zones for dust sealing, and validating structural rigidity to minimize harmonic resonance. Engineers utilize GD&T analysis to identify tolerance stack-ups in multi-panel assemblies. Clients receive a formal DFM report within 24 business hours, highlighting required modifications—such as chamfer additions for acrylic window assembly or reinforcing rib placement—to prevent warpage during machining. Common enclosure material considerations include:

| Material | Typical Use Case | Key DFM Consideration | Max Panel Size (mm) |

|---|---|---|---|

| 6061-T6 Aluminum | Structural frames | Minimize pocket depth to prevent flex | 1200 x 2400 |

| Polycarbonate | Viewing windows | 0.5mm draft angles required | 1000 x 2000 |

| Steel (A36) | Base plates | Stress-relief holes for welding | 1500 x 3000 |

Approved designs move to production where enclosed router assemblies undergo strict phase-gated processing. All aluminum enclosure frames are machined on dual-pallet 5-axis DMG MORI centers with in-process probing for critical mounting surfaces. Acrylic/polycarbonate panels receive anti-static coating pre-machining to prevent chip adhesion. Each subassembly undergoes dimensional verification against the original CAD using FARO Arm metrology before final hardware installation. Dust collection ducting and cable management channels are pressure-tested at 1.5x operational specs.

Final delivery includes comprehensive documentation: CMM inspection reports for critical interfaces, assembly sequence videos for field technicians, and a serialized traceability log linking each component to raw material certs. Enclosures ship in custom foam-in-place packaging rated for 150G impacts, with delivery typically occurring within 10–15 business days post-DFM signoff for standard configurations. Honyo maintains ISO 9001-certified processes throughout this workflow to guarantee repeatability for clients requiring multiple unit deployments.

Start Your Project

Explore our enclosed CNC router solutions engineered for precision, safety, and efficiency in demanding production environments. Designed for professional workshops and rapid prototyping applications, these systems offer robust performance with integrated dust and noise containment.

For detailed specifications, pricing, or custom configuration support, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring high-quality build standards and streamlined logistics for global delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.