Contents

Manufacturing Insight: Enamel Paint On Steel

Precision Enamel Finishing Starts with Superior Steel Substrates

Achieving durable, high-performance enamel coatings on steel components demands more than just skilled painting—it requires an impeccably prepared substrate. Surface roughness, dimensional accuracy, and edge definition directly impact enamel adhesion, corrosion resistance, and long-term finish integrity. At Honyo Prototype, our CNC machining services form the critical foundation for flawless enamel application by delivering steel parts with micron-level precision, consistent edge breaks, and optimal surface profiles. We eliminate common failure points like peeling or blistering through controlled machining parameters that ensure metallurgical cleanliness and geometric stability prior to coating.

Our integrated approach combines advanced 3-, 4-, and 5-axis CNC milling and turning with rigorous in-process metrology to produce steel components that meet exacting finish specifications. This precision machining stage is non-negotiable for enamel systems operating in demanding environments—from industrial equipment housings to aerospace brackets—where coating delamination risks catastrophic part failure. By controlling tolerances to ±0.005mm and surface finishes to Ra 0.8µm or better, we create the ideal substrate for enamel adhesion without secondary grinding or labor-intensive manual prep.

Leverage Honyo’s end-to-end capability for steel components requiring enamel finishes: submit your CAD file today for an Online Instant Quote and receive a detailed manufacturability analysis alongside competitive pricing within hours. Accelerate your path from prototype to production with machining precision engineered for coating success.

Technical Capabilities

Technical specifications for components featuring enamel paint on steel, particularly in the context of precision manufacturing processes such as 3/4/5-axis milling and turning, require careful consideration of material compatibility, dimensional stability, and surface preparation. Enamel paint is typically applied as a durable, corrosion-resistant coating over machined steel substrates. However, when tight tolerances are required (e.g., ±0.001″ or tighter), the coating process must be controlled to avoid dimensional variation or buildup that could affect fit, function, or interface with other precision components.

The following table outlines key technical considerations for enamel-painted steel parts in high-precision applications, including compatibility with common engineering materials such as Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification / Detail |

|---|---|

| Base Material (Substrate) | Low-carbon steel (e.g., 1018, 1020) or stainless steel (e.g., 304, 316) |

| Compatible Materials | Aluminum (anodized or Alodine treated), Steel (various alloys), ABS (for non-load-bearing components), Nylon (for wear-resistant inserts or bushings) |

| Coating Type | High-gloss or matte enamel paint (thermoset-based, epoxy or polyurethane hybrid) |

| Coating Thickness | 25–75 µm (0.001″–0.003″) per coat; total buildup must be accounted for in critical dimensions |

| Curing Process | Baked at 120–180°C for 20–30 minutes; post-cure cooldown to prevent warping |

| Adhesion Standard | ASTM D3359 (Cross-hatch adhesion test, Class 4B or better) |

| Hardness (Pencil) | H to 2H |

| Corrosion Resistance | Withstands 500+ hrs salt spray (ASTM B117) for properly primed and top-coated systems |

| Tolerance Capability | ±0.001″ (25 µm) achievable pre-coat; enamel layer must be factored into final dimensions |

| Machining Process | 3/4/5-axis CNC milling, CNC turning; tight-tolerance features machined prior to coating |

| Critical Design Note | Enamel cannot be applied to internal bores, sealing surfaces, or precision mating areas; masking required |

| Surface Prep | Degrease, sandblast (SA 2.5), phosphate or epoxy primer before enamel application |

| Thermal Stability | Continuous use up to 150°C; avoid thermal cycling near curing temperature post-coat |

| Compatibility with Plastics | Enamel bake cycle may deform ABS (Tg ~105°C); use post-machining painting or alternative coatings for hybrid assemblies |

| Recommended Use Case | Enclosures, brackets, fixtures, and aesthetic housings requiring durability and visual finish |

Note: For hybrid assemblies involving Aluminum, ABS, or Nylon, enamel painting should be completed before integration, or selective masking must be employed. Nylon components are typically unaffected by the paint process but must be removed or shielded during baking. Tight-tolerance interfaces (e.g., press fits, sliding shafts) should remain uncoated and machined to final dimensions post-assembly or with protective sleeving.

From CAD to Part: The Process

Honyo Prototype executes enamel paint application on steel components through a rigorously defined workflow designed for precision, quality assurance, and rapid turnaround. This process integrates advanced digital tools with hands-on engineering oversight to ensure optimal results for low-volume production and prototyping. Below is the detailed sequence:

CAD File Upload and System Integration

Customers initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via Honyo’s secure client portal. The system performs an automated geometry validation check, confirming file integrity and identifying potential data gaps such as missing surfaces or non-manifold edges. For steel enamel applications, the system specifically flags components requiring tight tolerances (<±0.1mm) where paint thickness might impact fitment.

AI-Powered Quoting Engine

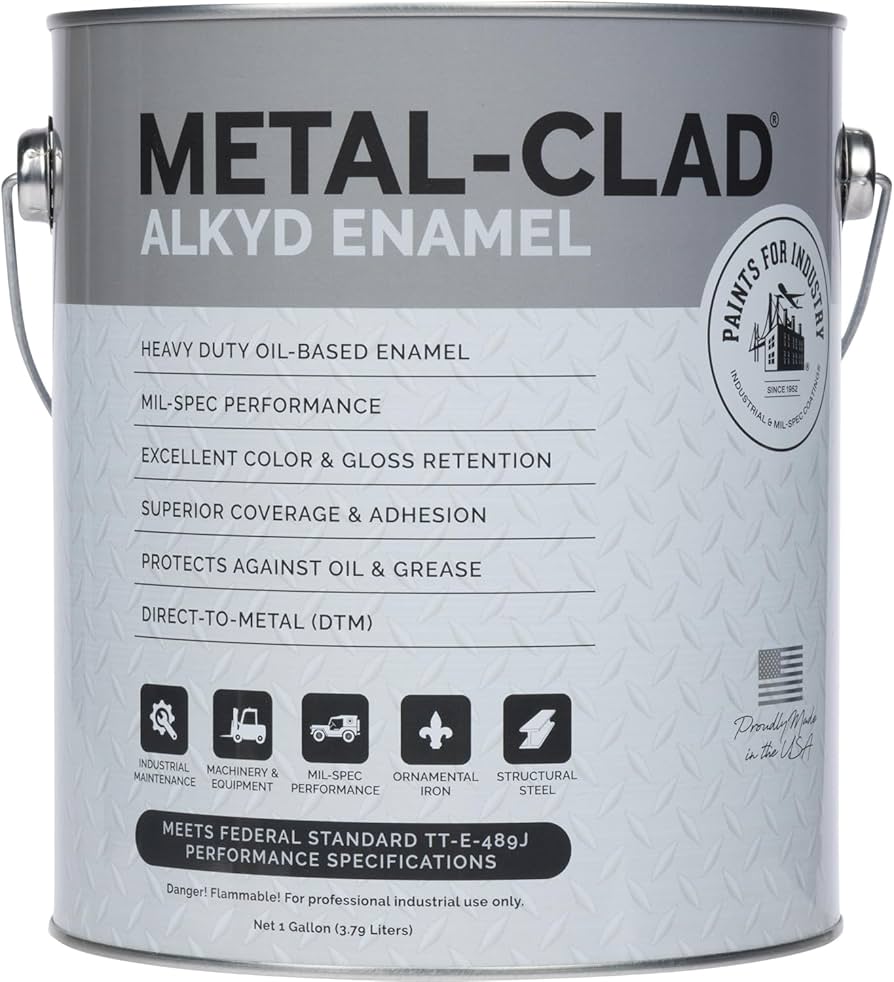

Our proprietary AI engine analyzes the validated CAD data alongside historical enamel process parameters. It calculates material costs (including steel substrate grade verification), labor hours, and oven runtime based on part surface area, geometry complexity, and specified enamel type (e.g., epoxy, alkyd, or UV-curable). The quote includes critical enamel-specific variables: required surface preparation grade (Sa 2.5 per ISO 8501-1), bake cycle duration, and VOC compliance documentation. Turnaround time estimates explicitly account for the 24-hour minimum cure period before handling.

Engineering-Led DFM Review

A dedicated Manufacturing Engineer conducts a steel-specific Design for Manufacturing analysis, focusing on enamel application challenges. Key checks include:

Verifying steel thickness adequacy to prevent warpage during 200°C curing cycles

Assessing sharp edges/corners for paint pooling or thin coverage risks

Confirming hole diameters >1.5x material thickness to avoid drainage issues

Validating weld seam smoothness to prevent enamel adhesion failure

Recommending optimal racking points to minimize fixture marks on critical surfaces

The engineer provides actionable feedback within 24 hours, often suggesting minor geometry adjustments to eliminate post-paint rework.

Controlled Production Execution

Enamel application follows this sequence:

1. Surface Preparation: Steel parts undergo alkaline degreasing, iron phosphate conversion coating, and DI water rinsing to achieve 100% adhesion per ASTM D3359.

2. Primer Application: Electrostatic spray application of epoxy primer (25–30μm dry film thickness).

3. Enamel Application: Robotic HVLP spraying of colored enamel coat (35–50μm DFT) in climate-controlled booths (22±2°C, 50% RH).

4. Curing: Convection oven baking at 200°C for 20 minutes, followed by forced-air cooling to prevent thermal shock.

5. Quality Verification: Non-destructive testing including gloss measurement (60° gloss meter), film thickness checks (Fischer XRF), and adhesion cross-hatch tests.

Quality-Controlled Delivery

All enamel-coated steel parts undergo final inspection against the customer’s dimensional drawing and finish specifications. Critical metrics are documented in the shipment package:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Dry Film Thickness | 60–80 μm | ASTM D7091 |

| Adhesion | 5B (no detachment) | ASTM D3359 |

| Gloss (60°) | 85–95 GU | ASTM D523 |

| Hardness | ≥H (pencil test) | ASTM D3363 |

Components are packaged in anti-static VCI film with desiccant packs to prevent moisture exposure during transit. Shipment includes a comprehensive quality dossier with batch-specific enamel formulation data (supplier lot numbers), oven calibration certificates, and first-article inspection reports. Typical lead time from CAD approval to delivery is 7–10 business days for quantities under 500 units.

Start Your Project

For high-quality enamel paint application on steel components, contact Susan Leo at [email protected]. Our precision manufacturing facility in Shenzhen ensures consistent, durable finishes meeting industrial standards. Reach out for technical specifications, sample requests, or project quotations.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.