Introduction: Navigating the Global Market for emerald green powder coat

In the dynamic landscape of global manufacturing, sourcing high-quality emerald green powder coat can be a daunting challenge for B2B buyers. As industries increasingly prioritize durability and aesthetic appeal, understanding the nuances of different powder coat formulations is essential. This guide delves into the various types of emerald green powder coats available in the market, their applications across sectors such as automotive, industrial, and architectural, and the critical factors to consider when selecting a supplier.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique obstacles in navigating product specifications, cost structures, and compliance with local regulations. This comprehensive resource aims to empower businesses by providing insights into effective supplier vetting, pricing strategies, and performance expectations.

By equipping buyers with the knowledge to make informed decisions, this guide ensures that they can confidently procure the right emerald green powder coat that meets both quality and budgetary requirements. From understanding the differences between metallic and non-metallic finishes to evaluating the environmental impact of powder coatings, we will explore all essential aspects to help you thrive in the competitive global market.

Understanding emerald green powder coat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ultra Illusion Green | High gloss metallic finish; requires clear topcoat for activation | Automotive, architectural components | Pros: Unique aesthetic; versatile applications. Cons: Requires additional topcoat for desired finish. |

| RAL 6001 Emerald Green | Smooth medium gloss; excellent durability and corrosion resistance | Structural steelwork, lighting equipment, garden furniture | Pros: Long-lasting; environmentally friendly. Cons: Limited color variations compared to custom options. |

| Misty Emerald | High gloss finish; soft, muted tone | Home decor, furniture, art installations | Pros: Aesthetic appeal; unique color depth. Cons: May not be as durable as industrial options. |

| Polyester TGIC Emerald Green | Thermosetting powder; good chemical and UV resistance | Appliances, automotive parts, agricultural machinery | Pros: High resilience; suitable for various substrates. Cons: Requires precise application for optimal results. |

| Metallic Emerald Green | Shimmering finish with added metallic flakes | Decorative applications, retail displays | Pros: Eye-catching appearance; enhances product appeal. Cons: Higher cost due to metallic components. |

What are the Characteristics of Ultra Illusion Green Powder Coat?

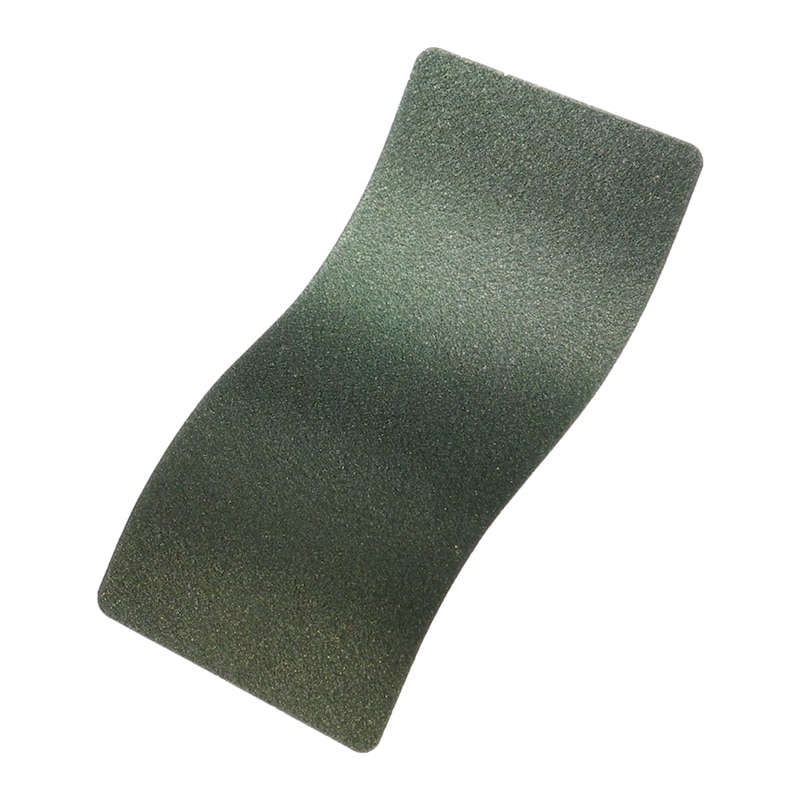

Ultra Illusion Green is a high-gloss, metallic powder coat that transforms its appearance once a clear topcoat is applied. This unique feature allows for a wide range of aesthetic possibilities, making it particularly suitable for automotive and architectural applications. Buyers should consider the requirement for an additional topcoat, which can add to the overall cost and complexity of the application process.

How Does RAL 6001 Emerald Green Stand Out?

RAL 6001 Emerald Green is known for its smooth, medium gloss finish and exceptional durability. This powder coat excels in outdoor applications, providing excellent resistance to corrosion and UV exposure. It is commonly used in structural steelwork and garden furniture. B2B buyers will appreciate its environmentally friendly formulation, but should note that it offers fewer customization options compared to specialty powders.

What Makes Misty Emerald a Unique Choice?

Misty Emerald features a high gloss finish with a soft, muted tone, making it ideal for home decor and artistic applications. Its unique color depth adds aesthetic appeal, which is essential for furniture and art installations. However, buyers should be aware that while it offers a visually striking finish, it may not provide the same level of durability as industrial-grade options.

Why Choose Polyester TGIC Emerald Green?

Polyester TGIC Emerald Green is a thermosetting powder that delivers outstanding chemical and UV resistance, making it suitable for a variety of substrates, including metal and aluminum. Its resilience makes it a preferred choice for automotive parts and agricultural machinery. Buyers should ensure precise application to achieve optimal results, as improper curing can affect the coating’s performance.

What Are the Benefits of Using Metallic Emerald Green?

Metallic Emerald Green adds a shimmering finish with metallic flakes, enhancing the visual appeal of any product. This powder coat is often used in decorative applications and retail displays where aesthetics are paramount. While it can significantly elevate product presentation, buyers should consider the higher costs associated with metallic components, which may impact budget constraints.

Key Industrial Applications of emerald green powder coat

| Industry/Sector | Specific Application of emerald green powder coat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Coating of automotive parts and accessories | Enhanced durability and aesthetic appeal | Ensure compatibility with local regulations and standards |

| Construction & Architecture | Protective coating for structural elements and fixtures | Long-lasting protection against corrosion and UV damage | Verify adherence to environmental regulations and durability standards |

| Agricultural Equipment | Coating for machinery and tools used in agriculture | Improved resistance to harsh weather and chemical exposure | Assess compatibility with agricultural chemicals and rugged use |

| Furniture Manufacturing | Finish for outdoor furniture and fixtures | Aesthetic appeal combined with resistance to fading and wear | Evaluate color consistency and finish quality |

| Lighting Fixtures | Coating for outdoor and indoor lighting solutions | Enhanced visual appeal and durability under various conditions | Consider UV resistance and gloss levels for aesthetic requirements |

How is emerald green powder coat utilized in the automotive industry?

Emerald green powder coat is extensively used in the automotive sector for coating various parts and accessories. Its high durability ensures that components can withstand harsh environmental conditions, while its aesthetic appeal enhances the vehicle’s overall design. International buyers should consider local regulations regarding automotive coatings, ensuring that the powder meets specific compliance standards for safety and environmental impact.

What role does emerald green powder coat play in construction and architecture?

In construction and architecture, emerald green powder coat serves as a protective finish for structural elements like beams, railings, and fixtures. Its excellent resistance to corrosion and UV damage makes it ideal for outdoor applications, ensuring longevity and maintaining visual appeal over time. Buyers in regions with extreme weather conditions, such as parts of Africa and the Middle East, should prioritize coatings that meet rigorous durability standards.

How is emerald green powder coat beneficial for agricultural equipment?

Emerald green powder coat is a popular choice for coating agricultural machinery and tools, providing a robust finish that withstands exposure to harsh chemicals and weather elements. This powder coat enhances the lifespan of equipment, reducing maintenance costs and downtime. When sourcing for agricultural applications, buyers should verify that the coating can endure chemical exposure and is suitable for rugged environments.

In what ways does emerald green powder coat enhance furniture manufacturing?

In the furniture manufacturing sector, emerald green powder coat is used to finish outdoor furniture and fixtures, offering a vibrant aesthetic while ensuring resistance to fading and wear. This makes it an ideal choice for products exposed to sunlight and weather. Buyers should assess the coating’s color consistency and finish quality, as these factors significantly impact customer satisfaction and product appeal.

Why is emerald green powder coat essential for lighting fixtures?

Emerald green powder coat is employed in both outdoor and indoor lighting solutions, enhancing visual appeal while providing a durable finish that can withstand various environmental conditions. Its UV resistance helps maintain color integrity over time, making it suitable for long-term installations. Buyers should consider the gloss levels and resistance properties to ensure the final product meets aesthetic and functional requirements.

3 Common User Pain Points for ’emerald green powder coat’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Color Matching

The Problem: One common challenge faced by B2B buyers of emerald green powder coat is achieving consistent color matching across different batches and suppliers. Variations in formulation, application conditions, and curing processes can lead to discrepancies in the final color, which can be particularly problematic for companies that require uniformity for branding or aesthetic purposes. This issue is especially pertinent in industries such as automotive and architectural design, where color precision is non-negotiable.

The Solution: To ensure consistent color matching, buyers should establish a robust color matching process that involves sourcing from reputable suppliers who provide detailed specifications and quality assurance. It’s crucial to request color swatches before making bulk purchases, as these swatches can provide a more accurate representation of the final product. Additionally, implementing a standardized application process is essential. This includes controlling variables such as powder coating thickness, curing temperatures, and application methods. Buyers can also invest in a color spectrophotometer to measure and compare colors accurately, ensuring that every batch meets the required specifications.

Scenario 2: Concerns Over Durability in Harsh Environments

The Problem: Many B2B buyers are concerned about the durability of emerald green powder coatings, particularly when applied to products exposed to harsh environmental conditions. Industries such as construction, agriculture, and outdoor furnishings often require coatings that can withstand UV rays, moisture, and chemicals. If the powder coat fails to provide adequate protection, it can lead to corrosion, fading, and ultimately increased costs due to repairs or replacements.

The Solution: To address durability concerns, it is essential to select a high-quality emerald green powder coat specifically formulated for exterior applications. Buyers should look for products that feature advanced formulations, such as those with TGIC polyester or hybrid resins, which enhance resistance to UV degradation and environmental factors. Additionally, conducting a thorough review of the product’s technical data sheet can reveal important information regarding salt spray and humidity resistance. For optimal performance, buyers should adhere strictly to the manufacturer’s recommended curing schedules and application techniques to ensure a strong bond and protective finish. Collaborating with experienced applicators who understand the nuances of powder coating can further mitigate risks associated with durability.

Scenario 3: Issues with Application and Coverage

The Problem: Another frequent pain point for B2B buyers is the challenge of achieving even coverage during the application of emerald green powder coat. Inconsistent application can lead to uneven surfaces, missed spots, or excessive build-up, which not only affects the aesthetic but can also compromise the coating’s integrity. This issue is particularly prevalent when dealing with complex shapes or intricate designs.

The Solution: To overcome application issues, buyers should invest in training for their applicators and ensure they are equipped with the right tools. Utilizing high-quality spray equipment that allows for precise control over the powder’s flow and application distance can significantly enhance coverage. Buyers should also consider pre-treating surfaces to ensure optimal adhesion, as clean and properly prepared substrates are crucial for achieving a uniform finish. Furthermore, conducting test runs on sample pieces can help identify the ideal settings and techniques for different products, allowing for adjustments before large-scale applications. Regular maintenance of application equipment is also vital to prevent clogging and ensure consistent powder flow. By adopting these practices, businesses can enhance the effectiveness of their powder coating processes and achieve the desired results.

Strategic Material Selection Guide for emerald green powder coat

When selecting materials for emerald green powder coating, it is essential to consider various formulations that can significantly impact the performance, durability, and suitability of the final product. Here, we analyze four common materials used in emerald green powder coatings, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Polyester Powder Coatings?

Polyester powder coatings are widely utilized for emerald green finishes due to their excellent outdoor durability and aesthetic appeal. They typically exhibit high gloss levels and good color retention under UV exposure. Polyester coatings can withstand temperatures of up to 200°C (392°F) during the curing process, making them suitable for various applications.

Pros: Polyester coatings are known for their excellent weather resistance, corrosion protection, and a smooth finish that enhances the visual appeal of coated items. They are also environmentally friendly, as they contain no volatile organic compounds (VOCs).

Cons: However, they may not perform as well in highly corrosive environments compared to other formulations, such as epoxy. Additionally, they can be more expensive than some alternatives.

Impact on Application: Polyester coatings are ideal for outdoor furniture, automotive parts, and architectural elements due to their durability and aesthetic qualities.

International Considerations: Buyers in regions like Africa, South America, the Middle East, and Europe should ensure compliance with local environmental regulations regarding VOC emissions.

How Do Epoxy Powder Coatings Compare for Emerald Green Finishes?

Epoxy powder coatings are another common choice for emerald green applications, particularly when corrosion resistance is a priority. They offer excellent adhesion and durability, making them suitable for industrial applications.

Pros: Epoxy coatings provide superior chemical resistance and are particularly effective in protecting against corrosion and abrasion. They are also relatively cost-effective.

Cons: The downside is that epoxy coatings are less UV resistant than polyester, leading to potential color fading when exposed to sunlight for extended periods. They are typically not recommended for outdoor applications without a topcoat.

Impact on Application: Epoxy coatings are best suited for indoor applications, such as machinery, appliances, and metal furniture that require protection from harsh chemicals.

International Considerations: Compliance with international standards like ASTM and DIN is crucial, especially for buyers in Europe and the Middle East, where regulations on chemical exposure are stringent.

What Advantages Do TGIC Polyester Powder Coatings Offer?

TGIC (Triglycidyl Isocyanurate) polyester powder coatings are a specialized formulation that enhances the durability and performance of standard polyester coatings. They are particularly noted for their enhanced UV resistance and outdoor durability.

Pros: TGIC polyester coatings offer excellent gloss retention and color stability, making them suitable for decorative applications that require a long-lasting finish. They also provide good chemical resistance.

Cons: However, TGIC coatings can be more expensive than standard polyesters and may have specific handling requirements due to their chemical composition.

Impact on Application: Ideal for outdoor applications, TGIC coatings are commonly used in architectural and automotive finishes.

International Considerations: Buyers should verify compliance with local regulations regarding TGIC usage, particularly in regions with strict chemical safety laws.

How Do Acrylic Powder Coatings Enhance Aesthetic Appeal?

Acrylic powder coatings provide a vibrant color palette and excellent gloss levels, making them an attractive option for emerald green finishes. They are known for their ability to produce a smooth, high-gloss finish.

Pros: Acrylic coatings offer excellent UV resistance and color retention, ensuring that the emerald green finish remains vibrant over time. They are also easy to apply and can be used on various substrates.

Cons: The primary limitation is their lower chemical resistance compared to epoxy and TGIC coatings, which may affect their suitability for industrial applications.

Impact on Application: Acrylic coatings are best for decorative applications, such as consumer goods and furniture, where aesthetic appeal is a priority.

International Considerations: Buyers should consider local regulations regarding the use of acrylics, particularly in regions with strict environmental standards.

Summary Table of Material Selection for Emerald Green Powder Coat

| Material | Typical Use Case for emerald green powder coat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor furniture, automotive parts | Excellent weather resistance and aesthetics | Less effective in highly corrosive environments | Medium |

| Epoxy | Industrial machinery, appliances | Superior chemical resistance | Poor UV resistance, not for outdoor use | Low |

| TGIC Polyester | Architectural finishes, automotive applications | Enhanced UV resistance and durability | Higher cost and specific handling requirements | High |

| Acrylic | Decorative consumer goods, furniture | Vibrant colors and excellent gloss | Lower chemical resistance | Medium |

This strategic material selection guide provides a comprehensive overview of the various formulations available for emerald green powder coatings, helping B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for emerald green powder coat

What Are the Key Stages in the Manufacturing Process of Emerald Green Powder Coat?

The manufacturing of emerald green powder coat involves several critical stages, each contributing to the final product’s quality and performance. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: This initial phase is crucial for ensuring the quality of the powder coat. Raw materials, including pigments, resins, and additives, are carefully selected based on their compatibility and performance characteristics. For emerald green powder coats, high-quality pigments are essential to achieve the desired color vibrancy and durability. The raw materials are then mixed in precise ratios, ensuring uniform color distribution.

Forming: Once the raw materials are prepared, they undergo a process called extrusion. The mixture is heated and forced through a die to create a continuous strand of powder. This powder is then cooled and broken down into smaller particles through a process known as grinding. The particle size is critical; it affects the application properties and final finish of the powder coat. For emerald green powder coats, achieving a consistent particle size enhances the coating’s flow characteristics and finish.

Assembly: In this stage, the powder is packaged for distribution. Quality control measures are implemented to ensure that the product meets specific standards before it is sent to customers. This includes checking for any contamination and verifying that the packaging is secure to prevent moisture ingress, which can affect the powder’s performance.

Finishing: The final stage involves applying a surface treatment to enhance the powder’s properties. For emerald green powder coats, this may include the application of a clear topcoat to improve gloss and protect against UV degradation. This process is vital for achieving the desired aesthetic appeal and durability.

How Is Quality Assurance Implemented in Emerald Green Powder Coat Production?

Quality assurance (QA) in the production of emerald green powder coat is paramount to ensure consistency and reliability. Manufacturers typically adhere to international standards such as ISO 9001, which provides a framework for quality management systems. This compliance assures B2B buyers that the manufacturer is committed to continuous improvement and customer satisfaction.

International Standards Compliance: Adhering to standards like ISO 9001 means that the manufacturing process is regularly reviewed and optimized. Furthermore, industry-specific standards such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply, particularly for applications in construction, automotive, and oil and gas sectors.

Key Quality Control Checkpoints:

-

Incoming Quality Control (IQC): This checkpoint verifies the quality of raw materials upon arrival. Suppliers must provide documentation, including safety data sheets and quality certifications, to ensure the materials meet the necessary specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, various parameters such as temperature, humidity, and particle size are monitored. Regular sampling and testing are conducted to detect any deviations from established standards.

-

Final Quality Control (FQC): Before packaging, a final inspection is performed to assess the product’s color consistency, gloss levels, and overall appearance. This may involve physical tests, such as adhesion and impact resistance, to ensure the powder coat meets performance expectations.

What Testing Methods Are Commonly Used for Quality Assurance in Powder Coating?

Several testing methods are employed to ensure the quality and performance of emerald green powder coats. These tests are vital for verifying that the product meets the required specifications and industry standards.

-

Adhesion Testing: This test assesses how well the powder coat adheres to the substrate. A common method is the cross-hatch test, where a grid is cut into the coating, and adhesive tape is applied to determine the amount of coating that comes off when the tape is pulled away.

-

Gloss Measurement: The gloss level of the powder coat is measured using a gloss meter. This ensures that the final product achieves the desired aesthetic properties.

-

Durability Testing: To evaluate the powder coat’s resilience, manufacturers conduct tests such as salt spray testing (ASTM B-117) and humidity resistance testing (ASTM D-1735). These tests simulate environmental conditions to assess corrosion resistance and overall durability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential for ensuring product reliability.

-

Supplier Audits: Conducting regular audits of suppliers can help assess their manufacturing processes and quality control measures. This can be done through on-site visits or by requesting documentation that details their quality management systems.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their testing methodologies, results, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control practices. These inspections can be particularly valuable for B2B buyers who may not have the resources to conduct thorough audits themselves.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing emerald green powder coats. Understanding these factors can enhance procurement strategies and ensure compliance with regional regulations.

-

Regulatory Compliance: Different regions may have specific regulations regarding chemical compositions and environmental standards. B2B buyers should be aware of these regulations and ensure that suppliers comply with local laws.

-

Cultural and Communication Differences: Effective communication is vital when dealing with international suppliers. Cultural differences may affect negotiation styles and expectations. Establishing clear communication channels can mitigate misunderstandings and foster stronger supplier relationships.

-

Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chain, including sourcing of raw materials and production processes. This transparency can enhance trust and ensure that the product meets the buyer’s quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance measures for emerald green powder coat not only helps in making informed purchasing decisions but also strengthens partnerships with suppliers. By focusing on quality control practices and compliance with international standards, B2B buyers can ensure they receive a product that meets their performance and aesthetic requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’emerald green powder coat’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to source emerald green powder coat effectively. Understanding the nuances of powder coating materials, their applications, and supplier evaluations is crucial for making informed purchasing decisions that align with project requirements.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical specifications. This includes understanding the desired gloss level, finish type (e.g., matte or high gloss), and any specific durability requirements, such as chemical resistance or UV stability. Defining these parameters ensures that you can communicate your needs effectively to potential suppliers.

Step 2: Research Industry Standards

Familiarize yourself with relevant industry standards for powder coatings, such as ASTM and ISO certifications. These standards provide benchmarks for quality and performance, helping you to gauge whether a supplier’s products meet necessary criteria. Additionally, understanding regional regulations can help you avoid compliance issues later.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from other clients, particularly those in similar industries or geographic regions. Evaluate their product range, quality assurance processes, and customer service responsiveness to ensure they align with your business needs.

Step 4: Request Samples for Testing

Always request samples of the emerald green powder coat before placing a bulk order. Testing samples allows you to assess color accuracy, finish quality, and adhesion properties on your specific substrates. This step is crucial to ensure that the product meets your aesthetic and functional requirements.

Step 5: Compare Pricing and Terms

Conduct a thorough comparison of pricing and terms among different suppliers. Look for volume discounts, shipping costs, and payment terms. It’s essential to balance cost with quality; the cheapest option may not always provide the best value in terms of performance and durability.

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier has the necessary certifications, such as ISO 9001 or other relevant quality management systems. Certifications indicate a commitment to quality and can provide assurance that the supplier adheres to best practices in manufacturing and environmental management.

Step 7: Establish a Clear Communication Channel

Establishing a clear communication channel with your supplier is vital for a successful partnership. Discuss expectations regarding delivery timelines, order modifications, and support for any technical issues that may arise during application. A supplier that values communication can help facilitate smoother transactions and resolve potential challenges quickly.

By following this checklist, B2B buyers can navigate the sourcing process for emerald green powder coat with greater confidence, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for emerald green powder coat Sourcing

What Are the Key Cost Components in Sourcing Emerald Green Powder Coat?

When sourcing emerald green powder coat, it is essential to understand the various cost components involved. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The quality of raw materials significantly influences the price. For instance, high-quality resins and pigments used in the production of emerald green powder coatings can range from $21.77 to $24.64 per pound, depending on the supplier and specifications.

-

Labor: Labor costs vary by region and the complexity of the coating process. In regions with higher labor rates, like parts of Europe, the overall labor cost will be higher, impacting the final price.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, equipment maintenance, and facility costs. Efficient production processes can help lower these costs.

-

Tooling: If custom tooling is required for specific applications, this can add to the initial investment. Buyers should consider whether standard tooling can be used to reduce costs.

-

Quality Control (QC): Ensuring that the powder coat meets specific standards and certifications can also add to the cost. Products with certifications for environmental safety and durability may carry a premium.

-

Logistics: Shipping costs vary greatly depending on the distance and mode of transport. International buyers, particularly from Africa and South America, should account for additional costs related to customs and duties.

-

Margin: Suppliers typically include a margin in their pricing, which can be influenced by their market positioning, brand reputation, and customer service levels.

How Do Price Influencers Affect Emerald Green Powder Coat Costs?

Several factors can influence the pricing of emerald green powder coats, which buyers should consider when negotiating:

-

Volume/MOQ: Purchasing in larger quantities often results in lower per-unit costs. Suppliers may have minimum order quantities (MOQ) that can affect pricing.

-

Specifications and Customization: Custom colors, finishes, or additives can significantly increase costs. Buyers should clearly specify their needs to avoid unexpected charges.

-

Materials and Quality: The choice between standard and premium materials can alter pricing. Understanding the differences in quality and the potential impact on performance is crucial.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence price. Established suppliers may charge more due to their reliability and quality assurance processes.

-

Incoterms: The terms of delivery (Incoterms) play a vital role in logistics costs. For example, ‘FOB’ (Free On Board) might mean lower transportation costs for the buyer, while ‘DDP’ (Delivered Duty Paid) includes all shipping costs, potentially raising the upfront price.

What Are the Best Buyer Tips for Cost-Efficiency in Emerald Green Powder Coat Sourcing?

To optimize costs when sourcing emerald green powder coat, consider the following tips:

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially for bulk orders. Highlighting long-term business potential can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Don’t just focus on initial pricing; consider the TCO, which includes durability, maintenance, and potential reapplication costs. Higher upfront investments in quality materials can lead to lower long-term costs.

-

Research Market Prices: Understand the market dynamics and average pricing in different regions. This knowledge can strengthen your negotiation position.

-

Seek Out Multiple Suppliers: Obtaining quotes from several suppliers can provide leverage in negotiations and help identify the best value options.

-

Stay Informed on Regulations: Be aware of local regulations in your target markets, as compliance requirements can impact overall costs and pricing structures.

Disclaimer on Prices

The prices mentioned in this analysis are indicative and can vary based on supplier, region, and market conditions. It is advisable for buyers to conduct thorough research and obtain updated quotes directly from suppliers before making purchasing decisions.

Alternatives Analysis: Comparing emerald green powder coat With Other Solutions

Introduction to Alternatives in Powder Coating Solutions

When considering surface finishing options, particularly for industrial applications, emerald green powder coat emerges as a popular choice due to its durability and aesthetic appeal. However, buyers should also evaluate other viable alternatives that might better suit specific project requirements. This analysis will compare emerald green powder coat with two alternative solutions: liquid paint and anodizing. Each option has its unique attributes that could influence a buyer’s decision based on performance, cost, and application context.

Comparison Table

| Comparison Aspect | Emerald Green Powder Coat | Liquid Paint | Anodizing |

|---|---|---|---|

| Performance | High durability, UV resistance, and corrosion protection | Moderate durability, less UV resistance | Excellent corrosion resistance, wear protection |

| Cost | $21.77 – $24.64 per lb | Generally lower cost per gallon | Higher initial cost due to process complexity |

| Ease of Implementation | Requires specialized equipment for application | Easier application with standard tools | Requires specialized anodizing equipment |

| Maintenance | Low maintenance, long-lasting finish | Moderate maintenance, may require touch-ups | Low maintenance, but can wear over time |

| Best Use Case | Structural steel, automotive parts, decorative applications | General metal surfaces, interior applications | Aluminum components, architectural features |

Detailed Breakdown of Alternatives

Liquid Paint

Liquid paint is a conventional surface finishing method that provides a smooth finish and is generally easier to apply than powder coatings. It can be applied using spray guns or brushes, making it accessible for smaller projects or on-site applications. However, liquid paint often lacks the durability of powder coatings, particularly in outdoor environments where UV exposure and corrosion are concerns. While it typically has a lower upfront cost, the need for frequent maintenance and touch-ups can increase long-term expenses.

Anodizing

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant anodic oxide finish. This method is particularly effective for aluminum, enhancing its natural properties. Anodizing provides excellent resistance to corrosion and wear, making it ideal for architectural components and products exposed to harsh environments. However, the process requires specialized equipment and can be more expensive upfront compared to both emerald green powder coating and liquid paint. Additionally, while anodized surfaces are low maintenance, they can wear down over time and may require refinishing.

Conclusion: How to Choose the Right Solution for Your Needs

In choosing the right surface finishing solution, B2B buyers should consider the specific requirements of their projects, including the environment in which the product will be used, budget constraints, and the desired aesthetic appeal. Emerald green powder coat offers superior durability and a vibrant finish, making it suitable for a wide range of applications. However, for projects with tighter budgets or simpler application processes, liquid paint may be a more viable option. On the other hand, anodizing presents a robust choice for aluminum products requiring high corrosion resistance. Ultimately, understanding the trade-offs between these alternatives will enable buyers to make informed decisions tailored to their operational needs and long-term goals.

Essential Technical Properties and Trade Terminology for emerald green powder coat

What Are the Key Technical Properties of Emerald Green Powder Coat?

Emerald green powder coat is characterized by several essential technical properties that significantly impact its application and performance in various industries. Understanding these properties is crucial for B2B buyers making informed purchasing decisions.

1. Material Grade

Emerald green powder coat typically falls under the polyester or epoxy polyester categories. These materials are chosen for their durability and resistance to environmental factors. The material grade affects the coating’s performance in terms of adhesion, flexibility, and long-term durability, making it vital for applications in sectors like automotive, architecture, and industrial equipment.

2. Gloss Level

The gloss level of emerald green powder coat can range from matte to high gloss. Gloss levels are measured using gloss units, with higher numbers indicating a shinier finish. For instance, a gloss level of 80-85 units indicates a semi-gloss finish, while levels above 85 denote high gloss. This property is important for aesthetic appeal and can influence customer perception in retail or decorative applications.

3. Cure Temperature

The recommended cure temperature for emerald green powder coatings generally falls between 350°F to 400°F (about 177°C to 204°C). Proper curing is essential to achieve optimal hardness and durability. B2B buyers must ensure that their application processes can meet these temperature requirements to avoid issues like poor adhesion or compromised finish quality.

4. Chemical and UV Resistance

Emerald green powder coat is designed to resist various chemicals and UV radiation. This property ensures that coated surfaces maintain their color and integrity over time, even when exposed to harsh environments. For industries such as automotive and construction, where materials face significant exposure, chemical and UV resistance are critical specifications.

5. Salt Spray and Humidity Resistance

A quality emerald green powder coat can endure salt spray for up to 1,000 hours, as per ASTM standards. Similarly, it should resist humidity for an equivalent duration. These tests indicate how well the coating can withstand corrosive environments, making them essential considerations for B2B buyers in coastal regions or humid climates.

What Are Common Trade Terms Related to Emerald Green Powder Coat?

Navigating the B2B landscape requires familiarity with specific trade terms that can influence procurement and project planning.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications for emerald green powder coat is crucial for buyers who require coatings that meet specific performance standards for their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For emerald green powder coat, MOQs can vary significantly based on supplier policies. Buyers should consider MOQs to ensure they are making cost-effective purchases without overcommitting to inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of products. B2B buyers should issue RFQs for emerald green powder coat to gather competitive pricing and service terms, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs and risk. Familiarity with relevant Incoterms is essential for B2B buyers, especially when sourcing emerald green powder coat from international suppliers.

5. Lead Time

Lead time is the time taken from placing an order to receiving the product. In the context of emerald green powder coat, understanding lead times can help buyers plan their production schedules and manage customer expectations effectively.

6. Color Matching

Color matching refers to the process of ensuring that the powder coat meets specific color standards or customer specifications. This is especially important for brands requiring consistency across products. Buyers should consider this aspect when selecting suppliers to ensure that the emerald green powder coat matches their desired aesthetic.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring emerald green powder coat, ensuring that they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the emerald green powder coat Sector

What Are the Key Trends Driving the Emerald Green Powder Coat Market?

The emerald green powder coat sector is witnessing significant growth, driven by a combination of aesthetic demand and functional performance across various industries. One of the key trends is the increasing preference for eco-friendly coatings, aligning with global sustainability initiatives. Buyers are particularly focused on products that offer low volatile organic compounds (VOCs) and high durability, making emerald green powder coatings a popular choice for applications in automotive, architectural, and industrial sectors.

Emerging technologies, such as advanced color-matching systems and automated application processes, are also reshaping the sourcing landscape. These innovations enhance precision and reduce waste, appealing to international B2B buyers who prioritize efficiency and cost-effectiveness. Moreover, the rise of e-commerce platforms has simplified procurement, allowing buyers from diverse regions like Africa, South America, the Middle East, and Europe to access a broader range of products and suppliers.

Market dynamics are influenced by regional preferences as well. For example, in Brazil and Saudi Arabia, there is a growing inclination towards customized solutions that cater to local aesthetic and functional requirements. This demand is supported by suppliers who are increasingly offering tailored services, such as color matching and technical support, which facilitate smoother transactions and foster long-term partnerships.

How Is Sustainability Shaping Sourcing Practices in the Emerald Green Powder Coat Sector?

Sustainability is becoming a cornerstone of sourcing practices in the emerald green powder coat sector. The environmental impact of coatings, particularly regarding their lifecycle and waste management, is a growing concern for B2B buyers. As such, there is a strong emphasis on sourcing from manufacturers that adhere to stringent environmental standards and demonstrate a commitment to sustainable practices.

Ethical supply chains are also gaining traction, with buyers increasingly interested in suppliers that provide transparency in their sourcing processes. Certifications such as ISO 14001 for environmental management and other ‘green’ labels can enhance a supplier’s credibility and appeal to international buyers. These certifications not only indicate compliance with environmental regulations but also signal a commitment to reducing ecological footprints, which is an essential consideration for companies operating in regions with strict environmental laws.

Furthermore, the use of recycled materials in the production of emerald green powder coatings is becoming more common. This trend not only supports sustainability but also aligns with the growing consumer demand for environmentally friendly products. Buyers can benefit from sourcing eco-conscious products, which can enhance their own sustainability narratives and provide a competitive edge in their respective markets.

What Is the Historical Context of Emerald Green Powder Coatings in B2B Applications?

Emerald green powder coatings have evolved significantly since their inception in the mid-20th century. Initially developed as a durable and aesthetically pleasing alternative to traditional liquid coatings, powder coatings quickly gained popularity due to their superior performance characteristics, including resistance to chipping, fading, and scratching.

As industries expanded and diversified, so did the applications of emerald green powder coatings. Their use transitioned from mainly industrial applications to encompass a wide range of sectors, including automotive, architectural, and consumer goods. The introduction of advanced formulations, such as those with enhanced UV resistance and lower environmental impact, has further solidified their position in the market.

Today, as B2B buyers seek innovative and sustainable solutions, emerald green powder coatings stand out as a versatile option that meets both functional and aesthetic needs. This historical evolution reflects a broader trend within the coatings industry towards sustainability and performance, which continues to shape sourcing decisions for international buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of emerald green powder coat

-

How do I ensure the quality of emerald green powder coat before purchasing?

To ensure the quality of emerald green powder coat, request samples or swatches from suppliers. Evaluate the color consistency, gloss level, and texture. Additionally, review the supplier’s technical data sheets and safety data sheets to understand the product’s specifications and performance. Look for certifications or compliance with international standards, such as ASTM or ISO. Engaging in discussions with other clients about their experiences can also provide insights into the supplier’s reliability and product quality. -

What is the best emerald green powder coat for outdoor applications?

For outdoor applications, consider using RAL 6001 Emerald Green powder coat, known for its excellent exterior durability and chemical resistance. This thermosetting powder coating is specifically formulated to withstand harsh weather conditions, UV rays, and corrosion. It is ideal for structural steelwork, garden furniture, and agricultural machinery. Always verify the product’s performance characteristics and ensure it meets your specific application needs before making a decision. -

What are the minimum order quantities (MOQ) for emerald green powder coat?

Minimum order quantities (MOQ) for emerald green powder coat can vary significantly among suppliers, often ranging from 25 to 200 pounds. It is advisable to check with multiple suppliers to find one that aligns with your purchasing needs. Some suppliers may offer flexibility in MOQs based on your specific requirements or establish a long-term partnership. Keep in mind that larger orders often lead to better pricing per unit. -

What payment terms should I expect when sourcing emerald green powder coat internationally?

Payment terms for international purchases of emerald green powder coat typically include options like advance payment, letters of credit, or payment upon delivery. Most suppliers will provide a pro forma invoice outlining the payment structure. It’s crucial to negotiate terms that suit your cash flow while ensuring the supplier is comfortable with the arrangement. Always confirm the payment methods accepted, as some may offer discounts for early payments. -

How do I vet suppliers for emerald green powder coat effectively?

Vetting suppliers involves assessing their credibility, product quality, and service reliability. Start by researching the supplier’s history, customer reviews, and industry reputation. Request references and contact previous clients to gather feedback. Additionally, evaluate their manufacturing capabilities, certifications, and compliance with industry standards. A reliable supplier should also provide clear communication and timely responses to inquiries. -

What logistics considerations should I keep in mind when importing emerald green powder coat?

When importing emerald green powder coat, consider shipping methods, customs regulations, and local delivery logistics. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your timeline and budget. Understand the import duties and taxes applicable in your country to avoid unexpected costs. Collaborate with experienced freight forwarders or customs brokers who can navigate the complexities of international shipping on your behalf. -

Can I customize the shade or finish of emerald green powder coat?

Yes, many suppliers offer customization options for emerald green powder coat, allowing you to select specific shades, finishes, or gloss levels. Be sure to communicate your exact requirements and request color samples to ensure the final product meets your expectations. Some manufacturers may also provide color matching services if you have a specific color reference. It’s essential to discuss these options early in the sourcing process to ensure timely production. -

What are the common applications for emerald green powder coat in various industries?

Emerald green powder coat is widely used in industries such as automotive, architectural, and industrial equipment. Its aesthetic appeal and durability make it suitable for decorative items, garden furniture, and agricultural machinery. Additionally, it is often utilized in the manufacturing of lighting fixtures and structural components due to its resistance to corrosion and UV damage. Understanding the common applications can help you identify the right product for your specific needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Emerald Green Powder Coat Manufacturers & Suppliers List

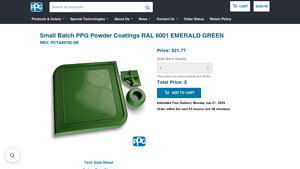

1. PPG – RAL 6001 EMERALD GREEN

Domain: powdercoatings.ppg.com

Registered: 1990 (35 years)

Introduction: {“Product Name”: “RAL 6001 EMERALD GREEN”, “SKU”: “PCTA49102-SB”, “Price”: “$21.77 USD”, “Small Batch Quantity”: “Up to 25 lbs”, “Appearance”: “Smooth”, “Gloss Level”: “80 @ 60”, “Durability”: “Ultra-Durable”, “Exterior Durability”: “Excellent”, “Chemical Resistance”: “Good”, “Salt Spray Resistance”: “1000 hours pass (ASTM B-117)”, “Humidity Resistance”: “1000 hours pass (ASTM D-1735)”, “Recommend…

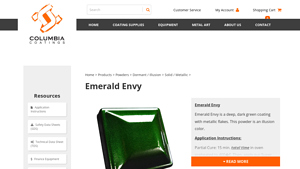

2. Columbia Coatings – Emerald Envy

Domain: columbiacoatings.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Emerald Envy”, “item_number”: “U4193027”, “price_per_pound”: {“1-9”: “$24.03”, “10-24”: “$22.45”, “25-43”: “$21.60”, “44-87”: “$20.37”, “88+”: “$19.93”}, “description”: “Emerald Envy is a deep, dark green coating with metallic flakes. This powder is an illusion color.”, “application_instructions”: “Partial Cure: 15 min. total time in oven preheated to 400°F. Then, apply our Super…

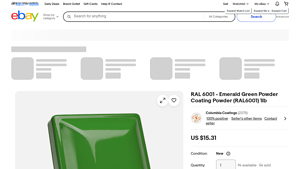

3. Columbia Coatings – RAL 6001 Emerald Green Powder Coating

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “RAL 6001 – Emerald Green Powder Coating Powder (RAL6001)”, “Weight”: “1lb”, “Condition”: “New”, “Color”: “Green”, “Type”: “Powder Coat”, “Seller”: “Columbia Coatings”, “Feedback”: “100% positive feedback”, “Price”: “$15.31”, “Shipping”: “$12.24”, “Estimated Delivery”: “Mon, Jul 21 – Thu, Jul 24”, “Quantity Sold”: “54”, “Available Quantity”: “94”, “Item Number”: “222861027479”, “D…

4. Cool Tools – Misty Emerald Powder Coating

Domain: cooltools.us

Registered: 2004 (21 years)

Introduction: Powder Coating – Misty Emerald – High Gloss

5. The Powder Coat Store – Transparent Candy Green Powder Coating Paint

Domain: thepowdercoatstore.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Transparent Candy Green Powder Coating Paint”, “weight”: “1 LB”, “price”: “$21.99”, “packaging_options”: [“Heavy Duty Resealable Bag”, “Reusable Plastic Container”, “1/2 LB Sample and Blank Panel Combo”, “1 LB Chrome & 1 LB Candy Green”], “description”: “This is an extremely popular, super smooth candy green powder. This is a candy top coat so a silver or chrome basecoat is neede…

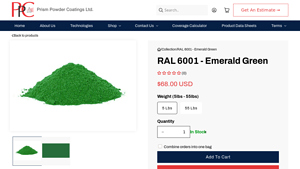

6. Prism Powder Coatings – RAL 6001 Emerald Green

Domain: prismpowder.com

Registered: 1998 (27 years)

Introduction: {“product_name”:”RAL 6001 – Emerald Green”,”brand”:”Prism Powder Coatings Ltd.”,”price”:”$68.00 USD”,”weight_variants”:[{“weight”:”5 Lbs”,”price”:”$68.00″},{“weight”:”55 Lbs”,”price”:”$333.00″}],”description”:”RAL 6001 ‘Emerald Green’ PPC Code PG-1101-H High Gloss Powder Coating. Superior protection against corrosion for both interior and exterior applications. Safe to use and nontoxic. Can be app…

7. Nortek Powder – RAL 6001 Emerald Green

Domain: nortekpowder.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “RAL 6001 Emerald Green”, “sku”: “P9SG121”, “price_range”: “$49.75 – $261.80”, “package_sizes”: [5, 10, 15, 20, 44], “category”: [“6000 Series”, “Green”, “RAL”], “description”: “RAL 6001 Emerald Green polyester powder coating in various package sizes.”, “manufacturer”: “Nortek Powder Coating”, “established”: 2005, “contact”: {“address”: “5900 Success Drive, Rome, NY 13440, USA”, “…

8. Crosslink – RAL 6001 Emerald Green Powder Coating

Domain: crosslinkpaints.com

Registered: 2019 (6 years)

Introduction: {‘name’: ‘RAL 6001 Emerald Green Powder Coating Powder’, ‘price’: ‘$14.50’, ‘part_number’: ‘RAL-POW-LBS-6001’, ‘availability’: ‘Call For Availability’, ‘application’: ‘Metals’, ‘paint_type’: ‘Polyester TGIC’, ‘size’: ‘1 LBS’, ‘gloss_level’: ‘Standard Full Gloss 75-85%’, ‘color’: ‘RAL 6001 Emerald Green’, ‘quantity_pricing’: {‘1-4’: ‘$14.50’, ‘5-24’: ‘$13.50′, ’25-49’: ‘$12.50′, ’50+’: ‘$11.50’}, ‘…

Strategic Sourcing Conclusion and Outlook for emerald green powder coat

Emerald green powder coatings, such as RAL 6001 and Ultra Illusion Green, offer exceptional durability and aesthetic appeal, making them a preferred choice across various industries, from automotive to architectural applications. The strategic sourcing of these coatings is vital for B2B buyers aiming to ensure consistent quality, adherence to environmental standards, and competitive pricing. By partnering with reliable suppliers, businesses can leverage the unique properties of emerald green powder coats, such as excellent UV resistance and chemical durability, to enhance their product offerings.

As the demand for sustainable and visually striking coatings grows, international buyers—especially those in Africa, South America, the Middle East, and Europe—should prioritize sourcing strategies that not only meet regulatory requirements but also align with market trends. Consideration of local suppliers can lead to reduced lead times and better support, while global partnerships can expand product variety and innovation.

Looking ahead, the market for emerald green powder coatings is poised for growth, driven by increasing applications in various sectors. Now is the time for B2B buyers to explore these opportunities, ensuring they remain competitive and responsive to evolving customer preferences. Engage with suppliers today to secure high-quality emerald green powder coatings that will elevate your product line.