Contents

Manufacturing Insight: Electronics Cnc Machining

Electronics-Specific CNC Expertise for Precision Components

The electronics industry demands components with exceptional dimensional accuracy, complex geometries, and material integrity to ensure optimal performance in high-stakes applications. From intricate heat sinks and EMI shielding enclosures to micro-connector housings and sensor mounts, Honyo Prototype delivers CNC machining solutions engineered specifically for the challenges of modern electronics manufacturing. Our advanced multi-axis milling and turning capabilities achieve tolerances down to ±0.0002 inches, utilizing certified engineering-grade materials including aluminum alloys, stainless steels, PEEK, and specialized composites that meet stringent thermal, electrical, and regulatory requirements.

Accelerate Prototyping and Production with Instant Quoting

Honyo Prototype eliminates traditional quoting delays with our proprietary Online Instant Quote platform, designed for engineering teams requiring rapid turnarounds. Upload your STEP or IGES file, specify materials and finishes, and receive a detailed technical quote with manufacturability feedback in seconds—not days. This seamless integration provides immediate cost transparency and lead time visibility, enabling faster design validation and production scheduling without compromising on the rigorous quality standards expected in electronics assembly. Partner with Honyo to transform complex electronic component designs into precision-machined reality, from prototype to high-volume production.

Technical Capabilities Overview

| Feature | Specification | Electronics Application Benefit |

|————————|—————————————-|—————————————–|

| Tolerance Range | ±0.0002″ to ±0.001″ | Ensures signal integrity in RF components |

| Max Work Envelope | 22″ x 16″ x 12″ (5-axis) | Accommodates multi-cavity enclosures |

| Material Expertise | Aluminum 6061/7075, PEEK, PTFE, Brass | Thermal management & EMI shielding |

| Surface Finishes | Anodizing, Plating, Bead Blasting | Corrosion resistance & aesthetic needs |

| Lead Time (Prototype) | As fast as 3 business days | Accelerates NPI cycles |

Technical Capabilities

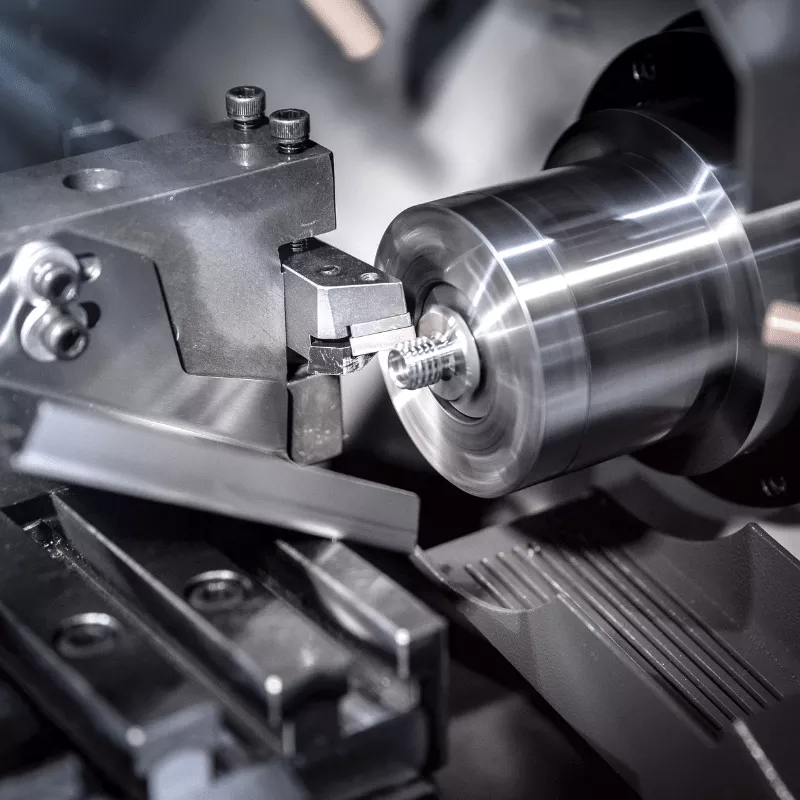

Electronics CNC machining involves precision manufacturing processes used to produce complex components for electronic enclosures, heat sinks, connectors, brackets, and housings. These parts require tight tolerances, excellent surface finishes, and dimensional accuracy to ensure proper fit and function within sensitive electronic assemblies. The most common CNC methods employed are 3-axis, 4-axis, and 5-axis milling, as well as CNC turning for rotational components.

Multi-axis milling allows for complex geometries to be machined in a single setup, reducing error and improving repeatability. 5-axis machining is especially valuable for intricate electronic housings with undercuts or compound angles. CNC turning is used for cylindrical components such as connectors or shafts. Tight tolerances down to ±0.001″ (0.025 mm) are routinely maintained, with critical features inspected via CMM or optical comparators.

Common materials include aluminum for lightweight and thermally conductive enclosures, stainless or tool steel for high-strength components, and engineering plastics like ABS and nylon for insulative or wear-resistant parts.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning |

| Typical Tolerances | ±0.001″ (0.025 mm); tighter tolerances achievable with inspection (±0.0005″) |

| Surface Finish | 32 to 64 μin (Ra) standard; optional polishing or anodizing for aluminum |

| Materials – Metals | Aluminum 6061-T6, 7075-T6; Stainless Steel 303, 304, 17-4 PH; Tool Steel (e.g., A2, D2) |

| Materials – Plastics | ABS (Acrylonitrile Butadiene Styrene), Nylon 6/66 (PA6/PA66), PEEK, PTFE |

| Max Work Envelope (Milling) | 20″ x 16″ x 12″ (508 x 406 x 305 mm) typical; larger with multi-setup |

| Max Work Envelope (Turning) | Up to 2″ (50 mm) diameter bar stock, 12″ (305 mm) length |

| Tooling | Carbide end mills, drills, boring tools; high-speed spindles (up to 24,000 RPM) |

| CNC Control Systems | Fanuc, Siemens, Heidenhain, or Haas; compatible with STEP, IGES, and native CAD files |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, micrometers, bore gauges |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, engraving, plating |

These technical capabilities ensure that electronic components meet strict performance, thermal, and EMI/RF shielding requirements while maintaining compatibility with PCBs and other sub-assemblies.

From CAD to Part: The Process

Honyo Prototype Electronics CNC Machining Workflow

Honyo Prototype executes electronics CNC machining through a rigorously defined, technology-driven workflow designed for precision, speed, and manufacturability assurance. This process begins with CAD upload and concludes with certified delivery, integrating AI and engineering expertise at critical decision points.

CAD Upload and Initial Validation

Customers initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate validation checks for file integrity, unit consistency, and geometric completeness. For electronics-specific components, we verify critical attributes such as PCB mounting hole tolerances, heat sink fin geometries, and EMI shield clearance zones against baseline electronics manufacturing standards. Invalid files trigger automated feedback detailing required corrections before proceeding.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which cross-references Honyo’s real-time machine availability, material stock levels, and historical process efficiency metrics. The AI analyzes part geometry complexity, feature criticality (e.g., press-fit pins, waveguide cavities), and material properties (e.g., aluminum 6061-T6 for RF enclosures, FR-4 for prototype PCB substrates) to generate a technically accurate quote within 2 hours. Quotes include explicit cost drivers such as secondary operations (tapping, anodizing), tolerance-driven machining time multipliers, and NRE charges for custom fixtures.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by Honyo’s electronics-specialized manufacturing engineers. This phase focuses on electronics-specific risk mitigation:

Verifying minimum wall thickness for thermal management components against material thermal conductivity limits

Assessing drill aspect ratios for high-density interconnect (HDI) substrate prototypes

Confirming chamfer requirements on connector mounting surfaces to prevent PCB delamination

Flagging non-standard fastener thread forms requiring custom tooling

The DFM report provides actionable recommendations with engineering rationale, such as modifying internal corner radii to match standard end mill sizes or adjusting tolerance stacks for multi-part assemblies. Customers receive a collaborative portal to approve, discuss, or revise designs before release to production.

Precision Production Execution

Approved designs move to production in our climate-controlled electronics machining cell. Key protocols include:

Material handling under ESD-safe conditions with <10^9 ohm surface resistance workstations

Machine-specific process plans leveraging 5-axis milling for complex enclosures and Swiss-type lathes for precision connector pins

In-process CMM verification of critical features (e.g., coaxial port alignment within ±0.025mm) using calibrated Zeiss equipment

Real-time SPC monitoring of surface roughness (Ra ≤ 0.8µm for RF surfaces) and dimensional drift

All electronics components undergo post-machining ultrasonic cleaning and visual inspection under 10x magnification to detect micro-burrs on signal paths.

Certified Delivery and Traceability

Final parts ship with comprehensive documentation:

First-article inspection reports (FAIR) per AS9102 standards for aerospace electronics

Material test certificates (MTC) with batch traceability

Conformal coating compatibility verification (if applicable)

Serialized work order logs linking each component to machine operators, tooling batches, and inspection timestamps

Standard lead time from CAD upload to delivery is 5–7 business days for single-part prototypes, with expedited 72-hour options for validated designs.

Typical Process Timeline

| Stage | Duration (Business Days) | Key Output |

|———————–|————————–|———————————————|

| CAD Upload & Validation | 0.25 | Validated geometry file |

| AI Quote Generation | 0.5 | Costed technical quotation |

| DFM Analysis | 1.0 | Actionable manufacturability report |

| Production | 3.0–4.0 | FAIR-certified components |

| Delivery | 0.25 | Traceable shipment with full documentation |

This workflow ensures electronics components meet stringent functional requirements while minimizing time-to-prototype. Honyo’s integration of AI efficiency with domain-specific engineering oversight delivers first-pass yield rates exceeding 98.5% for complex electronics hardware.

Start Your Project

Looking for precision CNC machining services for your electronics components? Honyo Prototype offers high-accuracy, low-to-medium volume production tailored to the demanding requirements of the electronics industry. From enclosures and heat sinks to connectors and structural parts, we deliver tight-tolerance machined components with fast turnaround.

Our state-of-the-art CNC machining facility is located in Shenzhen, China—strategically positioned for efficient manufacturing and global logistics. We specialize in aluminum, copper, brass, and engineering plastics commonly used in electronic devices, ensuring optimal performance and reliability.

Contact Susan Leo today to discuss your project specifications, request a quote, or learn more about our capabilities. Email us at [email protected] and experience responsive, expert support from a trusted partner in electronic component prototyping and production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.