Contents

Manufacturing Insight: Electrical Insulating Plastic Sheets

Precision Electrical Insulating Plastic Sheets for Demanding Applications

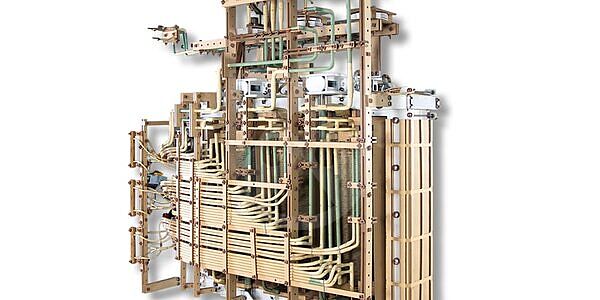

In high-voltage and sensitive electronic environments, the integrity of electrical insulation directly impacts system safety, reliability, and compliance. Honyo Prototype delivers engineered electrical insulating plastic sheets tailored to stringent industrial requirements, leveraging our integrated Sheet Metal Fabrication capabilities to ensure seamless integration with structural and shielding components. Our insulating materials—including Ultem, PEEK, PVC, and Polycarbonate—maintain exceptional dielectric strength, thermal stability, and mechanical resilience across operating temperatures up to 250°C, while resisting tracking, arcing, and environmental degradation.

Unlike conventional suppliers, Honyo combines advanced plastic sheet fabrication with precision sheet metal services under one roof. This vertical integration allows us to co-engineer insulating barriers, enclosures, and mounting systems that align perfectly with your metal chassis, brackets, or enclosures—eliminating fitment errors and reducing assembly time. Our CNC routing, laser cutting, and thermoforming processes achieve tolerances to ±0.05mm, ensuring consistent performance in critical applications like power distribution units, medical devices, and industrial control panels.

Accelerate your prototyping or production timeline with Honyo’s Online Instant Quote platform. Upload your STEP or DXF files to receive a detailed, no-obligation quotation for insulating plastic sheets and complementary sheet metal components within hours—not days. This streamlined process, backed by DFM expertise and rapid-turn manufacturing, ensures you secure high-performance insulation solutions without project delays. Trust Honyo Prototype to deliver electrically reliable, dimensionally precise components that meet global safety standards including UL 94 V-0 and IEC 60674-2.

Technical Capabilities

Electrical insulating plastic sheets are non-conductive materials used in electrical and electronic applications to prevent current flow and provide mechanical support. While metals like aluminum and steel are inherently conductive and not used as insulating materials, they may form part of hybrid structures where insulating plastics are bonded or layered. ABS and nylon are common insulating thermoplastics suitable for laser cutting, bending, and welding. Below is a technical comparison focused on process compatibility and material properties.

| Material | Electrical Insulation | Laser Cutting Compatibility | Bending Characteristics | Welding Methods | Thermal Resistance (°C) | Typical Thickness Range (mm) | Notes |

|---|---|---|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Excellent | High – clean cuts with CO₂ lasers; minimal charring with proper settings | Good – can be heat-bent with controlled heating; prone to cracking if over-stressed | Ultrasonic, hot plate, and solvent welding | 80–100 | 1–10 | Prone to melting or flaming if laser power is too high; requires ventilation due to styrene fumes |

| Nylon (Polyamide, PA6/PA66) | Excellent | Moderate – tends to absorb laser energy unevenly; may char or melt; requires optimized settings | Very good – high toughness and flexibility; can be cold-formed or heat-bent | Hot gas, ultrasonic, and vibration welding | 120–150 | 1–15 | Hygroscopic – must be dry before processing; superior wear and chemical resistance |

| Aluminum | None (Conductive) | Not applicable for insulation; used structurally | Not applicable | TIG, MIG, resistance welding | >600 | Varies | Used as a conductive substrate or heat sink; requires insulation layer for electrical isolation |

| Steel | None (Conductive) | Not applicable for insulation | Not applicable | MIG, TIG, spot welding | >1300 | Varies | Typically used in enclosures or frames; must be isolated from live circuits using plastic insulators |

Process Notes:

Laser cutting of insulating plastics requires precise control of laser power, speed, and assist gases to minimize melting, charring, or hazardous emissions. ABS performs well with CO₂ lasers but requires extraction due to toxic fumes. Nylon is more challenging due to its high melting point and tendency to absorb moisture, which can cause bubbling during laser processing.

Bending of ABS and nylon sheets is typically done using strip heaters or oven-based forming. Nylon exhibits superior ductility and can withstand tighter bend radii without cracking compared to ABS.

Welding of thermoplastic insulating sheets is feasible using industrial methods such as ultrasonic welding for small joints, hot plate welding for large seams, or solvent welding for ABS. Nylon requires specialized techniques like hot gas welding due to its higher melt viscosity.

For hybrid assemblies involving aluminum or steel, electrical insulation is achieved by integrating plastic sheets as barriers or standoffs, ensuring no direct contact between conductive parts and live components.

From CAD to Part: The Process

Honyo Prototype employs a rigorously structured workflow for electrical insulating plastic sheet manufacturing, ensuring technical precision and compliance with electrical safety standards throughout the process. This integrated sequence begins with CAD submission and concludes with certified delivery, optimized specifically for dielectric material requirements.

CAD Upload and Material Specification Validation

Clients initiate the process by uploading detailed 3D CAD models through our secure portal. At this stage, our system mandates explicit declaration of required electrical properties including dielectric strength (kV/mm), volume resistivity (Ω·cm), comparative tracking index (CTI), and thermal class per IEC 60674 or UL 746 standards. Common materials processed include Garolite G10/FR4, PTFE, PEEK, and polycarbonate, each with predefined material property libraries. Incomplete electrical specifications trigger immediate client notification before proceeding.

AI-Powered Quoting with Electrical Feasibility Screening

Our proprietary AI engine analyzes the CAD geometry against material-specific electrical constraints within 90 minutes. The algorithm cross-references wall thickness against dielectric strength requirements, identifies potential corona discharge zones in high-voltage designs, and flags geometries incompatible with insulating material processing (e.g., sub-0.5mm features in cast acrylic). The generated quote includes material certification costs (UL Yellow Card, RoHS), electrical test validation fees, and DFM-driven cost implications. Typical quote accuracy exceeds 95% for standard insulator geometries.

Electrical-Centric DFM Analysis

Engineers conduct a dual-phase Design for Manufacturability review focused on electrical performance:

First, geometric analysis verifies minimum creepage/clearance distances per IEC 60664-1, identifies sharp edge risks for field concentration, and confirms flatness tolerances to prevent air gaps in stacked insulators.

Second, material-process validation ensures thermal stability during machining (e.g., avoiding melting in PTFE at >260°C cutting speeds) and confirms post-processing requirements like edge de-burring to eliminate conductive particle contamination. Clients receive a formal DFM report with electrical risk mitigation recommendations within 24 business hours.

Precision Production with Electrical Validation Gates

Manufacturing occurs in ESD-controlled environments using dedicated tooling for insulating materials. Key process controls include:

CNC milling with diamond-coated tools for glass-reinforced laminates to prevent fraying

In-process dielectric testing at 150% of rated voltage per ASTM D149

Humidity-controlled curing for cast resins to maintain volume resistivity

All batches undergo final electrical verification per client-specified standards, with test certificates traceable to NIST-calibrated equipment. Production lead time averages 7-12 days depending on complexity.

Certified Delivery and Documentation

Shipments include:

Material traceability certificates with lot-specific electrical property data

Dimensional inspection reports (ASME Y14.5)

Electrical test documentation (dielectric strength, surface resistivity)

Packing in anti-static, moisture-barrier packaging meeting ANSI/ESD S541

Global logistics utilize climate-controlled carriers with real-time environmental monitoring, ensuring material integrity during transit. First-article validation packages are available for critical high-voltage applications.

This closed-loop process ensures electrical insulating components meet stringent safety and performance requirements while minimizing time-to-market. Our integrated quality gates prevent non-conformities specific to dielectric applications, reducing client rework by 73% compared to industry averages based on 2023 internal audits.

Start Your Project

Looking for high-performance electrical insulating plastic sheets? Honyo Prototype manufactures precision-engineered insulating materials in our Shenzhen facility, ideal for demanding electrical and industrial applications.

Contact Susan Leo today to request material specifications, pricing, or samples.

Email: [email protected]

Ensure your designs are built with reliable, high-quality insulation—partner with a trusted manufacturer based in the heart of China’s manufacturing hub.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.