Contents

Manufacturing Insight: Electrical Discharge Machining Edm

Precision Beyond Traditional Machining: Honyo Prototype’s Expertise in Electrical Discharge Machining (EDM)

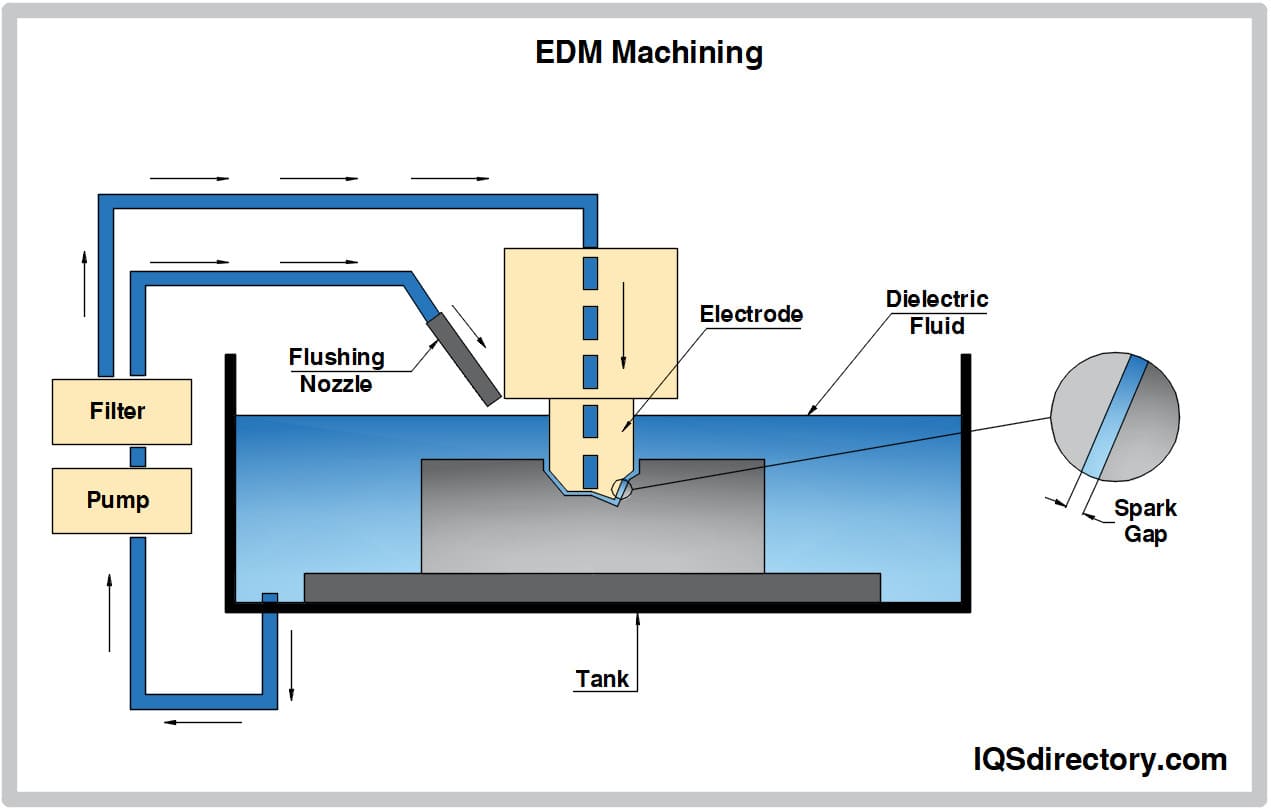

Electrical Discharge Machining (EDM) represents a critical advanced manufacturing process for achieving intricate geometries and exceptional surface finishes in conductive materials that are otherwise difficult or impossible to machine using conventional CNC milling or turning. By utilizing controlled electrical sparks to erode material, EDM excels at producing complex cavities, sharp internal corners, fine details, and tight tolerances in hardened steels, exotic alloys like Inconel or titanium, and other challenging workpieces. This non-contact process eliminates mechanical stress on the part, making it indispensable for high-precision applications across aerospace, medical device manufacturing, tool and die, and complex prototyping where dimensional accuracy and surface integrity are paramount.

Honyo Prototype leverages state-of-the-art CNC-controlled EDM technology, including both Wire EDM and Sinker EDM (Ram EDM) capabilities, to deliver solutions where extreme precision meets demanding material requirements. Our engineering team possesses deep expertise in optimizing EDM parameters for specific materials and geometries, ensuring consistent results with tolerances held to ±0.0001″ (±0.0025 mm) and surface finishes down to Ra 0.1 µm. We understand that EDM is not merely a machining step but an integrated solution requiring material science knowledge, meticulous process planning, and rigorous quality control to overcome the limitations of subtractive methods on hardened components.

Honyo Prototype EDM Service Capabilities Overview

| Process Type | Key Strengths | Typical Applications |

|---|---|---|

| Wire EDM | High precision cutting of complex 2D/3D profiles, tight tolerances, excellent surface finish on through-cuts | Punches, dies, extrusion tooling, medical components, intricate prototypes |

| Sinker EDM (Ram EDM) | Creation of complex 3D cavities, internal features, blind holes, textured surfaces | Injection molds, forging dies, aerospace turbine components, micro-features |

Partnering with Honyo Prototype for your EDM and broader CNC machining needs provides access to a seamless, integrated manufacturing ecosystem. Our facility combines EDM with complementary high-speed CNC milling, turning, and precision grinding, enabling comprehensive part realization from concept to final inspection under one roof. Crucially, we recognize that speed in prototyping and low-volume production is non-negotiable. To eliminate procurement delays, Honyo Prototype offers an Online Instant Quote system specifically engineered for complex processes like EDM. Upload your CAD file, specify material and requirements, and receive a detailed, accurate quote within hours – not days – accelerating your path from design to functional part. Leverage our precision EDM capabilities and rapid quoting to solve your most demanding manufacturing challenges efficiently.

Technical Capabilities

Electrical Discharge Machining (EDM) is a non-traditional manufacturing process that removes material using electrical discharges (sparks) between an electrode and a conductive workpiece. It is particularly effective for machining complex geometries, hard materials, and achieving tight tolerances where conventional milling or turning may face limitations. While EDM is not used for non-conductive materials such as ABS or Nylon, it excels in precision machining of conductive metals like aluminum and steel. Below is a technical specification summary focused on EDM capabilities in the context of 3/4/5-axis operations, turning compatibility, tight tolerance performance, and applicable materials.

| Parameter | Specification / Detail |

|---|---|

| Process Type | Electrical Discharge Machining (EDM) – Sinker (Ram) and Wire EDM |

| Axis Configuration | Typically supports 3-axis (X, Y, Z); 4-axis (indexing or rotary) and 5-axis (advanced sinker EDM with tilt/rotate electrodes) available in high-end systems |

| Turning Compatibility | Not applicable – EDM is not a turning process; used as a complementary process for intricate features post-turning or milling |

| Positioning Accuracy | ±0.001 mm (±0.00004 in) |

| Repeatability | ±0.0005 mm (±0.00002 in) |

| Surface Finish (Ra) | 0.1 – 1.6 µm (4 – 64 µin), depending on finish pass and material |

| Minimum Feature Size | Wire EDM: down to 0.02 mm (0.0008 in) kerf width; Sinker EDM: electrode-dependent |

| Material Compatibility | Conductive materials only: Aluminum, Steel (including hardened tool steels), Titanium, Copper, Brass, Graphite (electrode material) |

| Non-Compatible Materials | ABS, Nylon, and other plastics (non-conductive thermoplastics cannot be machined via EDM) |

| Typical Tolerances Achieved | ±0.005 mm (±0.0002 in) standard; up to ±0.002 mm (±0.00008 in) with fine finishing |

| Electrode Materials | Graphite, Copper, or Copper-Tungsten (selected based on wear resistance and finish needs) |

| Applications | Mold cavities, micro-features, deep ribs, sharp internal corners, hardened part machining |

| Key Advantages | No mechanical force on part, ability to machine hardened materials, high precision, fine detail reproduction |

| Limitations | Slower material removal rate, high electrode wear, limited to conductive materials |

Note: While 3/4/5-axis milling and turning refer to traditional CNC subtractive processes, EDM integrates with these workflows—especially in mold and aerospace industries—where tight tolerance features (such as vent holes, internal contours, or hardened inserts) are completed using EDM after primary milling or turning operations. For non-conductive materials like ABS and Nylon, alternative processes such as CNC milling or injection molding are recommended.

From CAD to Part: The Process

Honyo Prototype Electrical Discharge Machining Process Overview

Honyo Prototype implements a structured, technology-driven workflow for Electrical Discharge Machining (EDM) projects, designed to optimize precision, reduce lead times, and ensure manufacturability. Our process begins with client-supplied CAD data and progresses through integrated digital and engineering stages to certified delivery. Below is a detailed explanation of each phase, reflecting our commitment to advanced manufacturing standards.

CAD Upload and Initial Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs automated geometry validation, checking for unit consistency, surface integrity, and feature compatibility with EDM capabilities. Files requiring clarification trigger immediate notifications to the client, preventing downstream delays. This stage ensures the digital model aligns with EDM’s fundamental constraints, such as minimum feature sizes and electrode accessibility.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes geometric complexity, material properties, tolerances, and surface finish requirements. The algorithm cross-references historical production data, machine utilization rates, and material costs to generate a technically accurate quote within 2–4 hours. Unlike manual quoting, our AI identifies high-risk geometries early (e.g., deep cavities with narrow aspect ratios) and suggests preliminary process optimizations, providing clients with transparent cost drivers and realistic lead time estimates.

Engineering-Led DFM Analysis

Following quote acceptance, Honyo’s manufacturing engineering team conducts a rigorous Design for Manufacturability (DFM) review. This is not a passive checklist but an active collaboration: engineers evaluate electrode strategies, fixturing requirements, and potential thermal distortion risks. For sinker EDM, we simulate electrode wear and flushing dynamics; for wire EDM, we assess kerf compensation and taper management. Clients receive a formal DFM report with actionable recommendations—such as modifying radii to reduce machining time or adjusting tolerances to avoid over-engineering—ensuring the design is optimized for cost-effective, high-precision production.

Precision EDM Production

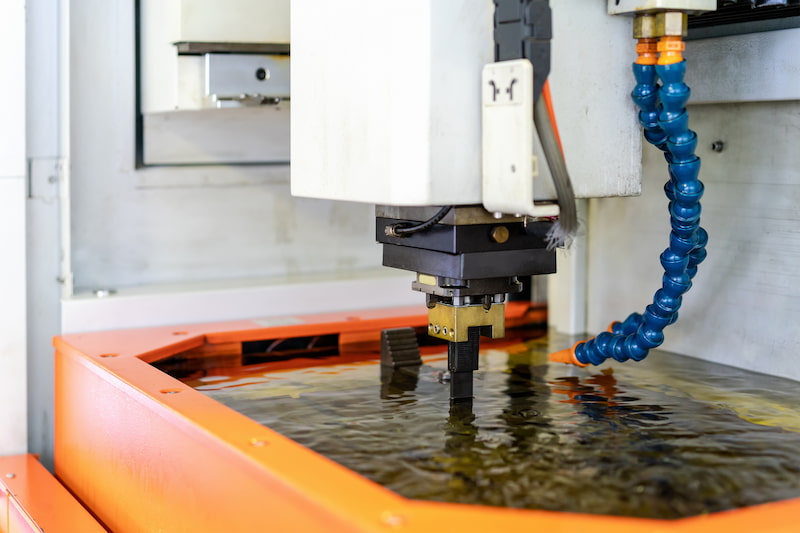

Approved designs move to our climate-controlled EDM facility, equipped with Makino, AgieCharmilles, and Sodick machines. Production follows a documented workflow:

Wire EDM: Used for through-cut profiles and tight-tolerance contours. Machines operate with ±2µm accuracy, utilizing deionized water for flushing and multi-axis taper cutting.

Sinker EDM: Employed for complex 3D cavities, leveraging graphite or copper electrodes. Our process includes adaptive roughing and fine-finishing cycles to achieve Ra ≤ 0.4µm.

All operations adhere to ISO 9001:2015 protocols, with real-time monitoring of gap voltage, current, and dielectric fluid quality. Critical dimensions undergo in-process CMM verification to preempt deviations.

Certified Delivery and Traceability

Upon completion, parts undergo final inspection per AS9102 or client-specific standards. Dimensional reports, material certifications, and process validation data are compiled into a digital package accessible via our client portal. Parts ship with serialized tracking and anti-static packaging for delicate EDM surfaces. Honyo’s delivery includes full process documentation, enabling traceability from CAD to shipment—a requirement for aerospace, medical, and automotive sectors where our clients operate.

Process Performance Metrics

Key outcomes from our integrated EDM workflow are quantified below:

| Phase | Typical Duration | Key Quality Control Measure | Client Benefit |

|---|---|---|---|

| CAD to Quote | < 4 hours | Geometry validation accuracy > 99.5% | Eliminates quoting errors; accelerates RFQ |

| DFM | 1–2 business days | Reduction in non-conformities by 35–50% | Lowers NRE costs; avoids rework |

| Production | 3–10 days* | First-pass yield > 92% | Predictable lead times; high repeatability |

| Delivery | 24–72 hours post-inspection | 100% documentation compliance | Audit-ready traceability; seamless integration |

*Varies by complexity; e.g., simple wire-cut dies vs. multi-electrode mold cavities.

This end-to-end process exemplifies Honyo’s fusion of AI efficiency and engineering expertise, transforming complex EDM requirements into certified, production-ready components while mitigating traditional prototyping risks. Clients gain visibility at every stage, ensuring alignment with stringent industry demands.

Start Your Project

For precision electrical discharge machining (EDM) solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures tight tolerances, high-quality surface finishes, and fast turnaround for complex geometries. Trust Honyo Prototype for reliable EDM services tailored to your prototyping and production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.