Contents

Manufacturing Insight: Easiest Stainless Steel To Machine

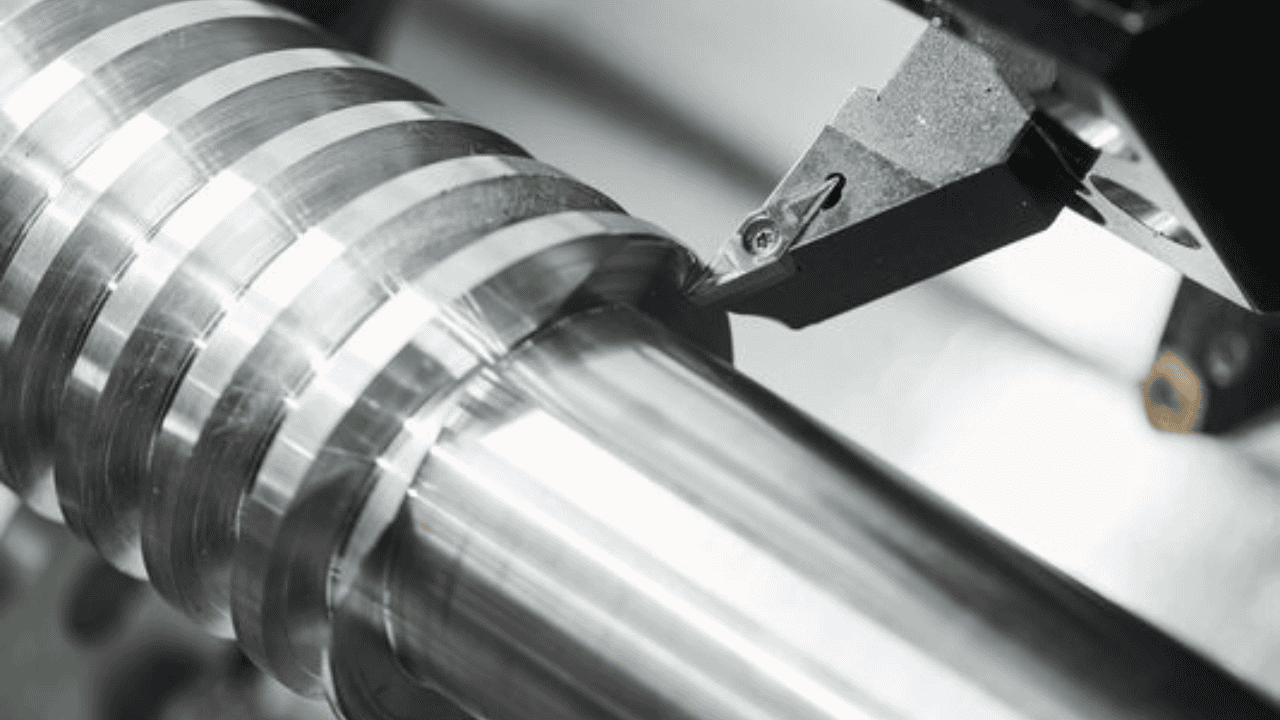

Optimizing Stainless Steel Machinability for Precision Prototyping and Production

Selecting the appropriate stainless steel grade is critical for achieving cost-effective, high-integrity machined components. Among austenitic stainless steels, 303 stainless steel stands out as the easiest grade to machine due to its controlled sulfur and selenium content, which enhances chip breakability and reduces tool wear during CNC operations. This free-machining variant significantly improves productivity for complex geometries in prototyping and low-volume production, though engineers must note its reduced corrosion resistance compared to 304/316—making it ideal for non-critical atmospheric or mild chemical exposure applications like shafts, bushings, and electrical components.

At Honyo Prototype, our CNC machining expertise leverages 303 stainless steel’s machinability advantages through optimized toolpaths, specialized carbide tooling, and rigorous process validation. We consistently achieve tight tolerances (±0.0002″) and superior surface finishes (Ra 0.8 µm) while minimizing cycle times and scrap rates. Our ISO 9001-certified facility handles everything from single-part prototypes to 500-unit runs, ensuring dimensional accuracy and material integrity across milling, turning, and multi-axis operations.

For engineering teams prioritizing speed-to-prototype without compromising quality, Honyo’s Online Instant Quote platform delivers precise pricing and lead times in under 60 seconds. Simply upload your STEP or IGES file to receive a manufacturability analysis alongside a formal quotation—enabling faster procurement decisions and seamless transition from design to precision-machined reality.

Material Performance Comparison for Key Applications

| Grade | Machinability Rating | Typical Use Cases | Corrosion Resistance | Honyo Production Lead Time (Prototype) |

|——-|———————-|——————-|———————-|————————————–|

| 303 | Excellent (80-85%) | Shafts, fittings, non-critical hardware | Moderate (not for marine/salt) | 3-5 business days |

| 304 | Fair (45-50%) | Food processing, architectural | High | 5-7 business days |

| 17-4PH | Poor (25-30%) | Aerospace, high-strength fixtures | High | 7-10 business days |

Leverage 303 stainless steel’s machining efficiency with Honyo’s precision capabilities—where material science meets scalable manufacturing execution. Initiate your project with a real-time quote today.

Technical Capabilities

The term “easiest stainless steel to machine” typically refers to free-machining stainless steel grades that offer improved machinability due to the addition of elements like sulfur or selenium. Among stainless steels, Type 303 is widely recognized as the most machinable due to its sulfur content, which enhances chip breaking and reduces tool wear. While it sacrifices some corrosion resistance compared to 304 or 316, 303 is preferred in high-volume precision machining such as 3/4/5-axis milling and turning operations requiring tight tolerances.

Below is a comparative overview of materials commonly used in precision CNC manufacturing, including the easiest-to-machine stainless steel (303) alongside other frequently machined materials like aluminum, carbon steel, ABS, and nylon. This table focuses on key technical properties relevant to multi-axis machining and tight tolerance production.

| Material | Type/Grade | Machinability Rating (Relative) | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Best Suited For Tight Tolerance Applications? | Notes for 3/4/5-Axis Machining |

|---|---|---|---|---|---|---|---|---|

| Stainless Steel | 303 (Free Machining) | 70–75% (Excellent for stainless) | 580–700 | 180–220 | 15 | Good | Yes | Best stainless choice for complex geometries; low built-up edge; excellent chip control |

| Stainless Steel | 304 | 45% | 505–700 | 150–200 | 16 | Excellent | Yes, but harder to machine than 303 | Higher tool wear; not ideal for high-volume precision work |

| Stainless Steel | 316 | 40% | 570–690 | 150–200 | 15 | Excellent | Yes, with proper tooling | Poor chip breaking; requires coolant and sharp tools |

| Aluminum | 6061-T6 | 90–100% (Excellent) | 310 | 95 | 167 | Good (with oxide layer) | Yes | Minimal tool wear; high MRR; ideal for complex 5-axis parts |

| Carbon Steel | 12L14 | 85% (Excellent) | 540 | 170 | 52 | Poor | Yes | Free-machining due to lead addition; common for turned components |

| Engineering Plastic | ABS (Acrylonitrile Butadiene Styrene) | 80% (Good) | 40 | 80 (Rockwell M) | 0.2 | Excellent | Yes, with dimensional stability controls | Low melting point; requires sharp tools, low heat buildup; vacuum hold-down recommended |

| Engineering Plastic | Nylon 6/6 | 70% (Moderate) | 80 | 85 (Rockwell M) | 0.25 | Excellent | Yes, with moisture conditioning | Hygroscopic; pre-dry before machining; low friction aids chip removal |

Key Takeaways for High-Precision Machining:

Type 303 stainless steel is the optimal choice among stainless steels for 3/4/5-axis milling and turning when tight tolerances (±0.0005″ or better) and high repeatability are required. Its free-machining characteristics reduce cycle times and improve surface finish compared to standard austenitic grades.

However, for maximum machinability and throughput in tight tolerance applications, aluminum 6061-T6 and free-machining carbon steel 12L14 outperform all stainless steels. Plastics like ABS and nylon are also easily machined but require environmental and handling adjustments due to thermal sensitivity and moisture absorption.

Material selection should balance machinability, mechanical performance, environmental exposure, and post-processing requirements. For prototype and low-volume precision components, 303 stainless remains a top-tier option where stainless properties are mandatory.

From CAD to Part: The Process

Honyo Prototype’s Streamlined Process for Machining Stainless Steel Components

Honyo Prototype optimizes stainless steel machining efficiency by focusing on grades with superior machinability, primarily AISI 303 (free-machining due to sulfur addition) and AISI 304 (standard grade with balanced properties). While no stainless steel is inherently “easy” to machine compared to materials like aluminum or brass, these grades minimize tool wear, chip control issues, and cycle times when processed correctly. Our end-to-end workflow ensures precision, cost control, and rapid turnaround:

CAD Upload & Validation

Clients initiate the process via our secure online portal, uploading native CAD files (STEP, IGES, Parasolid) or industry-standard 2D drawings. Our system performs automated geometry validation, checking for unit consistency, manifold errors, and manufacturing feasibility. Invalid submissions trigger immediate client notifications with specific correction guidance, preventing downstream delays. All data is encrypted per ISO 27001 standards, with revision tracking for auditability.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, trained on 15+ years of machining cost databases. The algorithm analyzes part geometry, material selection (defaulting to 303/304 for stainless steel requests), tolerances, and surface finish requirements. It cross-references real-time machine availability, tooling costs, and labor rates to generate a binding quote within 2 hours. Critical outputs include:

Detailed cost breakdown (material, machining, finishing)

Lead time estimation (typically 5–10 business days for stainless steel prototypes)

Risk flags for features exceeding standard capabilities (e.g., aspect ratios >10:1)

Engineer-Verified DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our in-house manufacturing engineers. This phase identifies cost-saving optimizations without compromising function. For stainless steel, common DFM interventions include:

| Common Issue | Recommended Fix | Impact on Cost/Lead Time |

|---|---|---|

| Thin walls (<1.5mm) | Suggest local reinforcement or alternative geometry | Reduces chatter/vibration; avoids 30% scrap risk |

| Non-standard tolerances (e.g., ±0.001″ on non-critical faces) | Propose relaxed tolerances per ISO 2768-mK | Cuts machining time by 25% |

| Sharp internal corners | Recommend 0.02″ radius for tool clearance | Prevents tool breakage; eliminates secondary EDM |

Clients receive a formal DFM report with annotated visuals and justification for each suggestion. Approval or revision occurs within 24 hours.

Precision Production

Approved orders move to our climate-controlled CNC facility. Stainless steel components are machined on Haas ST-30Y or DMG MORI CTX beta 1250 machines with:

Carbide tooling optimized for 303/304 (e.g., uncoated or TiN-coated drills for chip control)

High-pressure coolant systems to manage heat and prevent work hardening

In-process CMM verification for critical features (e.g., ±0.0005″ bores)

Material traceability is maintained via laser-etched heat numbers, with full batch certification (mill test reports) included in delivery. Secondary operations (deburring, passivation, laser marking) follow ASME B46.1 standards.

Quality-Controlled Delivery

Final inspection includes first-article reporting per PPAP Level 2, with full FAI documentation. Parts are packaged in anti-tarnish VCI film with desiccant, secured in crush-resistant containers labeled with serialized tracking IDs. Real-time shipment updates via FedEx API provide ETA accuracy within 2 hours. Typical delivery is 7 business days from DFM approval for simple stainless steel prototypes, with expedited 3-day options available.

This integrated process reduces stainless steel prototype lead times by 40% versus industry averages while maintaining <0.5% defect rates. By prioritizing machinability-optimized materials and embedding DFM rigor early, Honyo minimizes waste and ensures clients receive production-ready parts on schedule.

Start Your Project

Looking for the easiest stainless steel to machine for your next project? Discover superior machinability and consistent quality with materials engineered for precision and performance.

Contact Susan Leo today at [email protected] to learn more about our stainless steel solutions and how we can support your manufacturing needs.

Honyo Prototype – Your trusted partner with a state-of-the-art factory in Shenzhen. Fast turnaround, expert technical support, and reliable supply for prototyping and low-volume production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.