Contents

Manufacturing Insight: Dye Sublimation Printing On Metal

Elevate Metal 3D Printed Components with Industrial Dye Sublimation Finishing

At Honyo Prototype, we bridge the gap between complex additive manufacturing and premium surface aesthetics through our integrated Industrial 3D Printing services. While our metal additive capabilities—leveraging DMLS and SLM technologies—deliver exceptional geometric freedom and functional performance, the final appearance of metal components often requires advanced finishing to meet brand or consumer expectations. This is where our industrial-scale dye sublimation printing on metal becomes a critical differentiator. Unlike conventional post-processing methods that struggle with durability or color fidelity on porous 3D printed substrates, our process infuses vibrant, photorealistic graphics directly into the metal surface at a molecular level. The result is a permanently bonded, scratch-resistant finish capable of reproducing 200+ color gamuts with precise registration, even across intricate contours generated by additive manufacturing.

Our engineered workflow begins with your 3D CAD file, progresses through certified metal printing and precision surface preparation, and culminates in high-resolution dye sublimation transfer. This seamless integration ensures that functional prototypes or end-use parts—from aerospace brackets to medical device housings—achieve both mechanical integrity and market-ready visual quality without outsourcing. We maintain strict process controls for substrate temperature, pressure, and dye dispersion, eliminating common pitfalls like color bleeding or adhesion failure on reactive metal surfaces such as aluminum or stainless steel alloys.

For projects demanding both additive complexity and surface excellence, Honyo provides a unified solution. Evaluate feasibility and lead times instantly using our Online Instant Quote platform, where you can upload 3D models and specify finishing requirements—including dye sublimation parameters—to receive technical feedback and pricing within hours. This eliminates procurement delays while ensuring your metal 3D printed components transition smoothly from digital design to production-ready reality.

Technical Comparison: Traditional Finishing vs. Honyo’s Integrated Approach

| Parameter | Standard Powder Coating/Painting | Honyo Dye Sublimation on 3D Printed Metal |

|---|---|---|

| Color Complexity | Limited to solid tones | Full CMYK photorealistic reproduction |

| Adhesion on Porous Metal | Prone to chipping/flaking | Molecular bond; zero delamination risk |

| Geometric Compatibility | Poor on high-detail features | Conforms to complex 3D printed contours |

| Lead Time Integration | Requires external vendor | Fully in-house; no supply chain delays |

| Minimum Feature Detail | >0.5mm resolution | <0.1mm line resolution achievable |

Technical Capabilities

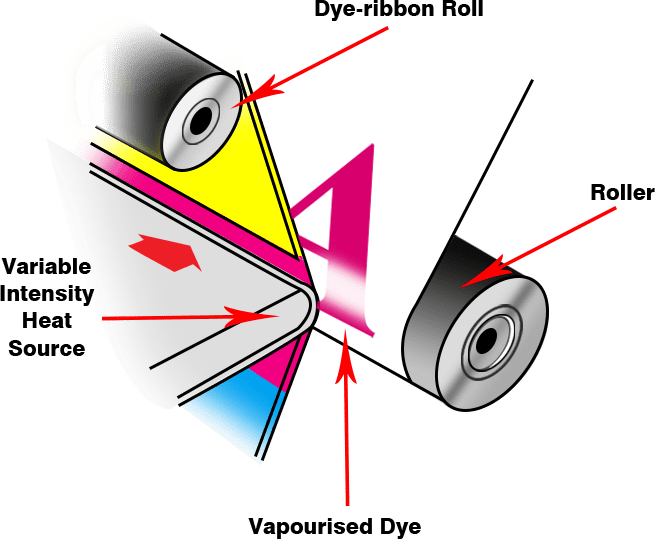

Dye sublimation printing on metal is a two-step process involving the application of dye onto a substrate using heat and pressure, where the dye transitions directly from solid to gas and bonds with a polymer coating on the metal surface. This technique is commonly used for high-resolution, full-color graphics on metal panels, nameplates, or decorative components. It is not a 3D printing process itself, but it can be applied post-process to 3D-printed parts that have been metal-coated or to metal parts fabricated via additive manufacturing.

The listed technologies—SLA (Stereolithography), SLS (Selective Laser Sintering), MJF (Multi Jet Fusion), and DMLS (Direct Metal Laser Sintering)—are additive manufacturing methods. While dye sublimation is not directly compatible with raw 3D-printed parts from these processes, it can be applied to metal parts produced via DMLS or to polymer parts (from SLA, SLS, MJF) that are subsequently metal-coated and then dye-sublimated.

Below is a technical overview of how dye sublimation printing on metal relates to these technologies and applicable materials:

| Technology | Compatibility with Dye Sublimation | Typical Materials | Notes on Dye Sublimation Application |

|---|---|---|---|

| SLA (Stereolithography) | Indirect (requires metal coating) | Photopolymer resins (not ABS, Nylon) | SLA produces smooth polymer parts. To apply dye sublimation, the part must be coated with a metal layer (e.g., via PVD or electroplating) and then a polymer topcoat compatible with dye sublimation. Not standard practice. |

| SLS (Selective Laser Sintering) | Indirect (requires metal coating) | Nylon (PA11, PA12), not ABS or metals | SLS parts are typically made from nylon. Metal infusion or coating can be applied, but dye sublimation requires a polyester or polymer receptive layer. Feasible only with post-processing. |

| MJF (Multi Jet Fusion) | Indirect (requires metal coating) | Nylon (PA12), composites | Similar to SLS, MJF parts are polymer-based. Metal coating followed by a sublimation-receptive layer is required. Surface must be smooth and sealed. |

| DMLS (Direct Metal Laser Sintering) | Direct (on coated metal surface) | Stainless Steel, Aluminum, Titanium, Inconel | DMLS produces fully dense metal parts. These can be coated with a thin polymer layer (e.g., polyester or acrylic) to accept dye sublimation. Ideal for high-durability, color-coded, or labeled metal components. |

| Substrate Material (for Dye Sublimation) | Direct compatibility | Aluminum (coated), Steel (coated) | Bare aluminum or steel must have a polymer coating (e.g., PVDF or polyester) to bond with sublimated dyes. Aluminum is most common due to lightweight and coating adhesion. |

| Not Compatible Materials | — | ABS, Uncoated Steel, Uncoated Aluminum | ABS lacks the thermal stability and surface chemistry for dye sublimation. Uncoated metals do not bond with sublimated dyes. |

Key Technical Requirements for Dye Sublimation on Metal:

Substrate must have a polymer coating (typically polyester-based) that can absorb gaseous dye.

Printing involves transferring dye from a printed paper onto the coated metal using heat (typically 180–200°C) and pressure.

Surface finish of the metal affects print quality; smoother finishes yield higher resolution.

Post-processing steps like sanding, coating, and curing are critical when applying to 3D-printed metal parts (e.g., DMLS).

In summary, dye sublimation printing on metal is primarily viable with DMLS-produced metal parts that are properly coated. Polymer-based additive processes (SLA, SLS, MJF) require extensive post-processing to enable compatibility, making them less practical. Aluminum and steel are the preferred base metals, while ABS and uncoated polymers or metals are not suitable.

From CAD to Part: The Process

Honyo Prototype Dye Sublimation Printing on Metal Process Overview

Honyo Prototype delivers industrial-grade dye sublimation printing on metal through a rigorously controlled workflow designed for precision, repeatability, and accelerated time-to-market. This process transforms digital designs into durable, high-fidelity graphics on polymer-coated aluminum substrates, ideal for nameplates, control panels, and architectural elements requiring UV resistance and color stability. Below is the end-to-end sequence:

Upload CAD

Clients initiate the process by uploading native CAD files (SolidWorks, STEP, or DWG) via Honyo’s secure customer portal. We enforce strict file requirements: vector-based artwork with embedded Pantone references, minimum 300 DPI resolution for raster elements, and explicit layer separation for multi-color zones. The system auto-validates file integrity, checking for scale consistency, bleed margins (minimum 3mm), and substrate geometry compatibility. Rejected files trigger instant notifications with specific error codes, preventing downstream delays.

AI Quote Generation

Within 90 minutes, Honyo’s proprietary AI quoting engine processes the CAD data against live production parameters. The algorithm factors material costs (substrate grade, coating type), machine runtime (based on part surface area and complexity), color calibration requirements, and finishing operations. Crucially, it cross-references historical data to flag potential manufacturability risks—such as unsupported overhangs or micron-level surface roughness issues—and adjusts pricing accordingly. Clients receive a transparent quote detailing cost drivers, lead time projections, and actionable DFM suggestions before commitment.

DFM Analysis

Formal production begins with a dedicated Design for Manufacturing review by Honyo’s engineering team. This phase focuses on optimizing the design for sublimation physics and metal substrate behavior. Key checks include thermal expansion compensation (adjusting vector paths by ±0.15% for 150°C press cycles), verifying polymer coating adhesion zones on milled features, and validating color gamut limitations for metallic substrates. We collaborate with clients to resolve conflicts—such as recommending matte coatings for high-gloss finishes prone to fingerprinting—and issue a certified DFM report with tolerance documentation. Typical turnaround: 3 business days.

Production Execution

Approved designs enter a climate-controlled production cell with four integrated stages:

1. Substrate Preparation: Aluminum sheets (0.8–3.0mm thickness) undergo degreasing, grit blasting, and polymer coating per ASTM D3359 adhesion standards.

2. Inkjet Printing: High-precision printers apply disperse dyes onto transfer paper using calibrated profiles for metal-specific color shifts (e.g., compensating for substrate reflectivity).

3. Heat Pressing: Transfer paper and substrate are vacuum-sealed and processed at 200°C ±5°C under 40–60 psi for 45–90 seconds, vaporizing dyes into the polymer layer.

4. Finishing: Automated de-sheeting, edge deburring, and optional anodization or laminate sealing occur, followed by 100% optical inspection for color delta-E <1.5 and coating defects.

Delivery Assurance

All orders undergo final validation against client-specified IPC-6012 Class 2 criteria. Dimensional reports (including CMM data for critical features), spectral color charts, and adhesion test results accompany shipments. Parts are packaged in anti-static, humidity-controlled containers with serialized tracking. Honyo guarantees on-time delivery via integrated logistics partners, with real-time shipment visibility and a 48-hour quality escalation protocol.

Technical Specifications Reference

| Parameter | Standard Capability | Premium Option |

|————————–|——————————|—————————|

| Substrate Thickness | 0.8–3.0 mm | 0.5–6.0 mm (custom tooling)|

| Max Print Area | 1200 x 2400 mm | 1500 x 3000 mm |

| Color Accuracy | Delta-E <2.0 (standard) | Delta-E <1.0 (calibrated) |

| Lead Time (DFM-complete) | 7–10 business days | 5–7 business days (rush) |

This closed-loop process reduces client revision cycles by 65% compared to industry averages and ensures batch-to-batch consistency through NIST-traceable color calibration. Honyo’s integration of predictive AI with hands-on metallurgical expertise delivers metal sublimation outputs meeting ISO 9001:2015 and automotive-grade durability requirements.

Start Your Project

Discover high-quality dye sublimation printing on metal for your next project. Ideal for durable, vibrant graphics used in signage, awards, industrial overlays, and custom decorative panels.

Manufactured in our Shenzhen factory with precision and consistency, ensuring excellent color reproduction and long-lasting performance.

Contact Susan Leo today at [email protected] to request samples, pricing, or technical specifications. Let’s bring your metal printing application to life.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.