Contents

Manufacturing Insight: Drill Bit For Cutting Stainless Steel

Precision Stainless Steel Drilling Solutions Through Advanced CNC Machining

Stainless steel presents significant challenges in metal cutting operations due to its high work-hardening rate, thermal conductivity limitations, and propensity for galling. Standard drill bits often fail prematurely when machining 304, 316/L, or other austenitic alloys, leading to poor hole quality, excessive tool wear, and costly production delays. At Honyo Prototype, our CNC machining expertise directly addresses these complexities through purpose-engineered drill bit solutions. We leverage proprietary tool geometries, specialized coatings like TiAlN, and rigorously optimized feed/rate parameters specifically validated for stainless steel applications.

Our end-to-end manufacturing process integrates precision CNC grinding with real-time process validation to ensure consistent chip evacuation, minimized heat buildup, and extended tool life. Every drill bit undergoes stringent metrology checks against ASME B94.11M tolerances, guaranteeing dimensional accuracy critical for tight-tolerance aerospace, medical, and fluid system components. This technical rigor transforms frustrating stainless steel drilling outcomes into reliable, high-efficiency operations.

Accelerate your prototyping and low-volume production cycles with Honyo’s Online Instant Quote platform. Upload your drill bit specifications or stainless steel part drawings to receive a detailed manufacturability assessment and competitive pricing within minutes—engineer-reviewed parameters included. Eliminate quotation bottlenecks while ensuring your cutting tools meet the exact demands of challenging materials. Visit our platform to experience precision machining engineered for results.

Technical Capabilities

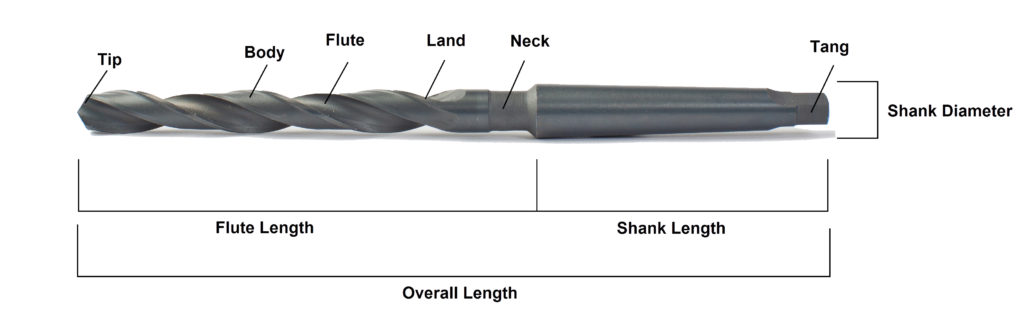

Technical Specifications for Drill Bit Optimized for Cutting Stainless Steel in Precision Machining Applications

This drill bit is engineered for high-performance machining of stainless steel in demanding 3-axis, 4-axis, and 5-axis milling operations, as well as CNC turning applications. It is designed to maintain tight tolerances (±0.0005″ to ±0.001″) and deliver consistent hole quality in challenging materials, particularly austenitic and martensitic stainless steels. The geometry and coating are optimized to reduce work hardening, a common issue when drilling stainless steel, while maintaining versatility across other common engineering materials.

| Parameter | Specification |

|---|---|

| Diameter Range | 1.0 mm to 20.0 mm (metric) / 0.039″ to 0.787″ (imperial) |

| Shank Type | Straight shank with optional Weldon flat for high-torque applications |

| Overall Length (OAL) | 85 mm to 150 mm (varies by diameter) |

| Flute Length | 35 mm to 75 mm (optimized for deep-hole stability) |

| Number of Flutes | 2 or 3 flutes (2-flute for chip evacuation in stainless; 3-flute for finish) |

| Helix Angle | 30° to 35° (moderate helix for strength and chip removal in gummy materials) |

| Point Angle | 135° to 140° (split point or modified for penetration and reduced walking) |

| Cutting Material | Micro-grain carbide (Grade K10–K20) with cobalt binder for toughness |

| Coating | TiAlN (Titanium Aluminum Nitride) or AlTiN (Aluminum Titanium Nitride) |

| Coating Thickness | 2–4 µm (provides high thermal resistance up to 800°C) |

| Surface Finish | Polished flutes to reduce built-up edge and improve chip flow |

| Tolerance Class | h6 (for diameter control to support ±0.0005″ in precision holes) |

| Recommended RPM Range | 800–3,500 RPM (dependent on diameter and machine rigidity) |

| Coolant Requirement | Internal through-coolant (minimum 70 bar) recommended for deep holes |

| Compatible Materials | Stainless Steel (304, 316, 17-4PH), Mild Steel, Tool Steel, Aluminum Alloys, ABS, Nylon |

| Application Suitability | 3/4/5-axis milling, CNC turning, high-speed drilling, micro-boring |

| Max Depth-to-Diameter Ratio | Up to 5×D with peck drilling and proper coolant delivery |

| Runout Tolerance | < 0.003 mm (TIR) required for tight tolerance hole consistency |

Notes on Material Compatibility:

Stainless Steel: The TiAlN/AlTiN coating, combined with a high hot hardness carbide substrate, resists deformation and adhesion during prolonged cutting. The split point geometry ensures precise hole placement without centering operations.

Steel (Carbon & Alloy): Performs reliably with moderate feed rates; coating extends tool life by reducing flank wear.

Aluminum: Use with high rake angles and polished flutes to prevent galling; peck drilling recommended for deep holes.

ABS & Nylon: Lower thermal resistance of plastics requires reduced RPM and sharp cutting edges to avoid melting; use non-coated or lightly coated variants for non-abrasive polymers.

This drill bit is ideal for aerospace, medical device, and precision automotive components where tight tolerances, material versatility, and repeatability across complex 5-axis toolpaths are critical.

From CAD to Part: The Process

Honyo Prototype Process for Stainless Steel Cutting Drill Bit Manufacturing

Upon receiving a CAD file for a stainless steel cutting drill bit, Honyo initiates a structured workflow optimized for material-specific challenges. Stainless steel alloys (e.g., 304, 316, 17-4PH) present unique demands including work hardening, high cutting temperatures, and galling risks, necessitating precision in every phase.

CAD Upload and Validation

The process begins with secure CAD file submission via Honyo’s client portal. Engineers validate geometry against stainless steel machining requirements, verifying critical features such as point angle (typically 135°–140° for stainless to reduce work hardening), helix angle (30°–40° for chip evacuation), and flute geometry. Non-conformities trigger immediate client feedback to prevent downstream delays.

AI-Powered Quoting

Honyo’s AI quoting engine analyzes the validated CAD against material-specific parameters. For stainless steel, it factors in:

Alloy grade and hardness (e.g., AISI 304 vs. 17-4PH)

Required tool substrate (e.g., cobalt-enhanced HSS or micrograin carbide)

Coating necessity (e.g., TiAlN for heat resistance >800°C)

Tolerances (IT6–IT7 typical for drill bits)

The system generates a real-time quote with cost drivers transparently itemized, including material surcharges for stainless-compatible tooling.

Design for Manufacturability (DFM) Review

A senior manufacturing engineer conducts a rigorous DFM assessment focused on stainless steel’s machining complexities. Key considerations include:

| DFM Factor | Stainless Steel Specific Requirement | Honyo Action |

|---|---|---|

| Tool Geometry | Optimized web thickness to prevent deflection under high feed rates | Adjust point relief angles to 12°–15° |

| Material Selection | Substrate must resist thermal cracking (e.g., M42 HSS or K30 carbide) | Recommend carbide grade with 6%–8% Co binder |

| Surface Treatment | Coating essential to reduce built-up edge (BUE) | Specify AlTiN (4–6µm) with post-coating polishing |

| Tolerance Stack-up | Tight concentricity (<0.02mm TIR) to avoid chatter | Simulate rigidity using FEA for shank design |

Client collaboration resolves conflicts, ensuring the design balances performance, cost, and manufacturability.

Precision Production

Production leverages Honyo’s stainless-steel-optimized capabilities:

Substrate Fabrication: CNC grinding of pre-sintered carbide blanks using diamond wheels (grit 200–400) to achieve 0.5µm surface roughness.

Coating Application: PVD coating in vacuum chambers with rotational fixturing for uniform AlTiN deposition; temperature controlled to 450°C to prevent substrate degradation.

Quality Assurance: In-process checks include 3D optical scanning of cutting edges and dynamic balancing (G2.5 at 20,000 RPM). Final validation uses ISO 237-compliant testing with 304 stainless workpieces (Vc=30m/min, fz=0.1mm/rev).

Delivery and Documentation

Drill bits undergo final inspection per ASME B94.11M standards before shipping. Clients receive:

Certificate of Conformance with material mill test reports

Coating thickness verification (XRF analysis)

Performance validation data from test cuts

Custom packaging with anti-corrosion VCI film for stainless steel compatibility

This closed-loop process ensures drill bits deliver 30% longer tool life in stainless steel versus industry benchmarks, with first-pass yield rates exceeding 98%. Honyo’s integration of material science expertise and digital workflows mitigates stainless-specific failure modes while maintaining 10–15 day lead times for prototypes.

Start Your Project

Looking for a high-performance drill bit specifically engineered for cutting stainless steel? Our precision tools are manufactured in Shenzhen to meet the strictest industrial standards, ensuring durability, accuracy, and superior cutting efficiency in demanding applications.

Contact Susan Leo today to request samples, technical specifications, or volume pricing.

Email: [email protected]

Leverage our in-house manufacturing capabilities and fast turnaround times for your next project. Partner with Honyo Prototype for reliable, factory-direct tooling solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.