Contents

Manufacturing Insight: Double Cuts Sheet Metal

Double Cuts Sheet Metal: Precision Fabrication for Complex Geometries

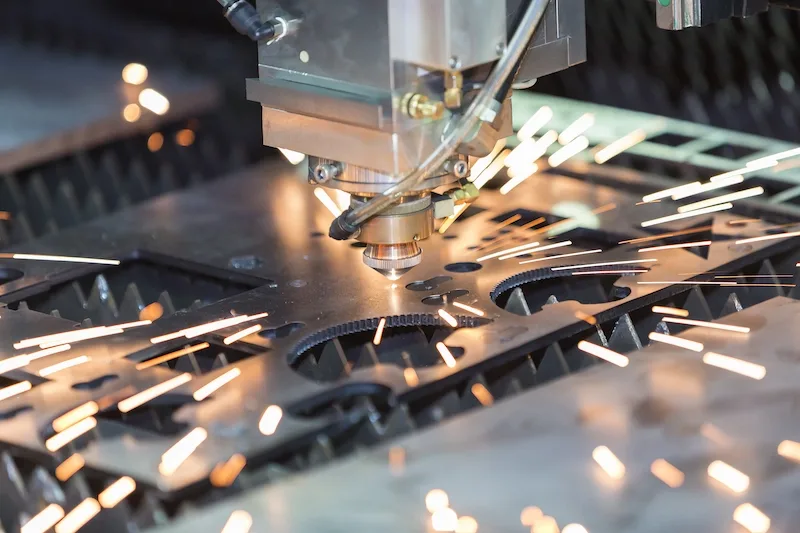

Achieving exacting tolerances in sheet metal components featuring dual or sequential cut features demands advanced process control and engineering expertise. Honyo Prototype delivers superior double cuts sheet metal fabrication, leveraging state-of-the-art CNC punching, laser cutting, and multi-stage bending capabilities to ensure dimensional accuracy down to ±0.05mm. Our integrated manufacturing workflow eliminates cumulative errors common in multi-operation setups, critical for applications requiring tight alignment of secondary features such as mounting tabs, interlocking joints, or precision apertures.

Engineers trust Honyo for complex sheet metal assemblies where conventional fabrication risks misalignment or material deformation. We utilize real-time in-process metrology and proprietary nesting algorithms to optimize material yield while maintaining geometric integrity across all cut sequences. This precision extends to secondary operations including tapping, countersinking, and finishing, ensuring fully functional prototypes and low-volume production parts meet stringent design specifications on schedule.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload your STEP or DXF file to receive a detailed manufacturability analysis and competitive pricing within minutes—no manual RFQ delays. Our system automatically validates critical parameters like bend reliefs, kerf allowances, and feature spacing for double-cut geometries, providing actionable feedback before order placement. Experience seamless integration from design validation to certified production, backed by ISO 9001-certified processes and dedicated engineering support.

Request your instant quote today to validate feasibility and cost for precision double cuts sheet metal components.

Technical Capabilities

Double cut sheet metal refers to a manufacturing process where a sheet metal part undergoes two distinct cutting operations, typically to achieve higher precision, complex geometries, or to separate nested components. This process is commonly performed using laser cutting, followed by secondary operations such as bending and welding to form complete assemblies. Below are the technical specifications related to laser cutting, bending, and welding for common materials used in double cut sheet metal fabrication, including Aluminum, Steel, ABS, and Nylon.

| Parameter | Aluminum (e.g., 5052, 6061) | Steel (e.g., Mild Steel, 304 SS) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|

| Laser Cutting | ||||

| Recommended Laser Type | Fiber laser | Fiber or CO₂ laser | CO₂ laser | CO₂ laser |

| Typical Thickness Range | 0.5 – 6.0 mm | 0.5 – 10.0 mm | 1.0 – 5.0 mm | 1.0 – 4.0 mm |

| Cut Tolerance | ±0.1 mm | ±0.1 mm | ±0.2 mm | ±0.2 mm |

| Edge Quality | Smooth, minimal dross | Smooth, slight oxidation on carbon steel | Clean, slight melting at edges | Slight melting; may require post-process |

| Bending | ||||

| Bend Radius (Min) | 1 × material thickness | 1 × material thickness (carbon steel) | 1.5 × material thickness | 2 × material thickness |

| Springback Consideration | Moderate (varies by alloy) | Low to moderate | High | High |

| Tooling Requirement | Precision press brake with V-dies | Standard press brake | Low-tonnage brake; soft tooling | Low-tonnage brake; soft tooling |

| Welding | ||||

| Suitable Methods | TIG, MIG, Laser Welding | MIG, TIG, Spot Welding, Laser | Not weldable via traditional methods | Ultrasonic, Vibration, Hot Plate |

| Joining Alternative | Mechanical fasteners, adhesives | Welding standard | Adhesives, snap fits | Adhesives, mechanical interlocks |

| Heat Sensitivity | Moderate (risk of warping) | High heat input tolerated (steel) | High (melts/deforms easily) | High (creep and thermal expansion) |

| General Notes | Non-ferrous, lightweight, corrosion resistant | Durable, magnetic (carbon steel), weldable | Thermoplastic; used for enclosures, not structural | High wear resistance; used in moving parts |

Notes:

Double cut processes often involve a first cut to separate the blank, followed by bending and a second cut to remove support tabs or achieve final feature accuracy.

Aluminum and steel are primary candidates for integrated laser cutting, bending, and welding workflows.

ABS and nylon are non-metallic materials typically used in hybrid assemblies; they are generally not bent like sheet metal and require specialized joining techniques.

Thermal management is critical during laser cutting and welding to avoid distortion, especially in thin sheets and thermoplastics.

From CAD to Part: The Process

Honyo Prototype’s double cut sheet metal process refers to manufacturing operations where a single sheet undergoes two distinct cutting sequences to produce nested or interdependent parts. This is commonly required for complex assemblies, shared tooling features, or parts needing secondary operations before final separation. Our structured workflow ensures precision and efficiency:

CAD File Upload and Initial Processing

Customers submit detailed CAD files (DXF, DWG, or native formats) via our secure portal. Our system performs an immediate validation check for file integrity, unit consistency, and geometric completeness. For double cut scenarios, the system specifically identifies potential nesting conflicts, shared cut lines, and required sequencing based on layer assignments or feature annotations within the CAD model. This initial scan prevents downstream errors related to part interdependence.

AI-Powered Quoting Engine

Our proprietary AI quotation system analyzes the validated CAD data, applying real-time cost algorithms for double cut operations. The engine factors in material utilization efficiency across both cut sequences, kerf compensation between nested parts, secondary operation time for intermediate handling, and potential scrap reduction from optimized nesting. The generated quote includes a visual simulation of the double cut layout, highlighting the separation between primary and secondary cut phases, along with a detailed cost breakdown showing value engineering opportunities specific to the nested configuration.

Engineering-Driven DFM Analysis

Honyo’s manufacturing engineers conduct a rigorous Design for Manufacturability review focused on double cut feasibility. This phase addresses critical interdependencies that automated systems cannot resolve, such as:

| DFM Check Category | Double Cut Specific Considerations |

|---|---|

| Geometric Integrity | Minimum bridge/tab dimensions between nested parts, kerf accumulation tolerance stack-up across both cuts |

| Process Sequencing | Optimal order of primary/secondary cuts to prevent part shift, required registration features for repositioning |

| Material Handling | Risk of part deformation during intermediate handling, support structure requirements for fragile nested arrays |

| Tolerance Stack-Up | Cumulative positional errors between cut phases, flatness control after first separation |

The DFM report provides actionable recommendations, including suggested tab placements for part retention during the first cut, adjusted kerf values for shared edges, and potential design modifications to eliminate fragile geometries prone to distortion during the dual-operation cycle. Customers receive an interactive 3D DFM markup for collaborative resolution.

Precision Production Execution

Double cut production occurs on our fiber laser systems with automated material handling. The first cut sequence processes all primary contours and internal features while retaining parts via strategically placed micro-tabs. An automated shuttle system transfers the sheet to a secondary station where tabs are severed in the second cut phase, often using a different nozzle or power setting for clean separation. Throughout both stages, our MES tracks each nested part individually using barcode-linked work orders to prevent mix-ups. Real-time monitoring ensures kerf width consistency between operations, with automatic compensation applied if material thermal conditions change.

Quality-Controlled Delivery

All double cut parts undergo nested-array dimensional verification using coordinate measuring machines (CMM) that validate positional accuracy relative to shared edges. We package nested assemblies either as pre-separated units with protective interleaving or as fully assembled arrays based on customer assembly line requirements. Final delivery includes a nest layout map correlating part IDs to their position in both cut phases, along with first-article inspection reports documenting critical inter-part dimensions affected by the dual-operation process. Typical lead time for double cut projects remains 3-5 business days from DFM sign-off, with expedited options available for qualified geometries.

Start Your Project

Double cuts in sheet metal can compromise both structural integrity and aesthetic quality, often resulting from improper tool alignment or material handling. At Honyo Prototype, our Shenzhen-based manufacturing facility employs precision-controlled fabrication processes to eliminate such defects, ensuring clean, accurate cuts that meet strict quality standards.

For engineering support or to discuss corrective actions for your sheet metal projects, contact Susan Leo at [email protected]. Our team provides end-to-end oversight from design validation to production, leveraging advanced CNC punching and laser cutting technologies to prevent defects and optimize manufacturability.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.