Contents

Manufacturing Insight: Dmg Cnc

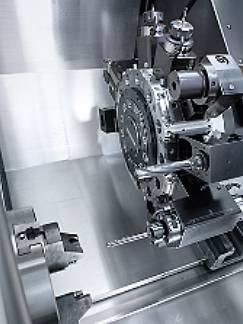

Precision CNC Machining Powered by DMG MORI Technology at Honyo Prototype

Honyo Prototype delivers industry-leading CNC machining services engineered for demanding industrial applications, leveraging a strategic fleet of advanced DMG MORI multi-axis machining centers. Our partnership with DMG MORI ensures access to cutting-edge milling and turning platforms renowned for exceptional rigidity, thermal stability, and micron-level precision. This foundation enables us to consistently produce complex, high-integrity components across aerospace, medical, energy, and automation sectors where tolerances and material integrity are non-negotiable.

Our comprehensive CNC capabilities span 3-axis, 4-axis, and 5-axis milling, precision turning, and mill-turn operations, supporting a wide range of engineering alloys, composites, and plastics. Every process is executed under stringent ISO 9001:2015 certified quality management systems, with integrated in-process inspection and final CMM verification to guarantee conformance to the most exacting specifications. We prioritize rapid iteration and on-time delivery without compromising quality, making us a trusted partner for prototyping through low-volume production.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload your CAD file directly to our platform for a detailed, transparent cost estimate within hours—no manual submission delays. This seamless digital workflow provides immediate pricing clarity for CNC-milled and turned parts, empowering faster decision-making and project kickoff. Experience the convergence of DMG MORI precision engineering and responsive manufacturing execution by requesting your quote today.

Technical Capabilities

Honyo Prototype – DMG MORI CNC Capabilities Overview

DMG MORI CNC machines utilized at Honyo Prototype deliver high-precision machining across 3, 4, and 5-axis milling platforms as well as multi-axis turning centers. These systems are engineered for tight tolerance production, repeatability, and superior surface finishes, meeting stringent requirements in aerospace, medical, and industrial manufacturing sectors.

The following table outlines the key technical specifications and capabilities relevant to 3/4/5-axis milling and turning operations, including performance with common engineering materials such as Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification / Capability |

|---|---|

| Axes Configuration | 3-axis, 4-axis (indexed or continuous), 5-axis simultaneous (full 5-axis contouring) |

| Positioning Accuracy | ±0.002 mm (X, Y, Z axes) |

| Repeatability | ±0.001 mm |

| Spindle Speed (Milling) | Up to 24,000 rpm (standard), optional high-speed spindles up to 42,000 rpm |

| Spindle Power (Milling) | 30–80 kW depending on model |

| Turning Center Spindles | Dual-spindle, Y-axis, and B-axis capability; live tooling for mill-turn operations |

| Tolerance Range | ±0.005 mm typical; down to ±0.002 mm achievable under tight control |

| Surface Finish (Ra) | As low as 0.4 μm (machined), 0.8 μm typical for critical surfaces |

| Work Envelope (Milling) | Up to 1,300 x 1,000 x 800 mm (X, Y, Z); varies by model (e.g., DMU 85 monoBLOCK, DMU 125) |

| Tool Capacity | 30–120 tools (automatic tool changer), with RFID tool monitoring |

| Control System | Siemens SINUMERIK 840D sl, Heidenhain TNC, or DMG MORI CELOS (integrated process management) |

| Coolant Systems | High-pressure through-spindle coolant (up to 70 bar); optional minimum quantity lubrication (MQL) |

| Materials Supported | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 303/316), ABS, Nylon (6/66), PEEK, Delrin |

| Aluminum Machining | High-speed capability with optimized tool paths; excellent chip evacuation |

| Steel Machining | High-torque spindles for hardened steels up to 62 HRC |

| Plastic Machining (ABS, Nylon) | Low-vibration setup; sharp tooling and optimized feeds to prevent melting or burring |

| In-Process Metrology | On-machine probing (touch-trigger and scanning) for setup verification and part alignment |

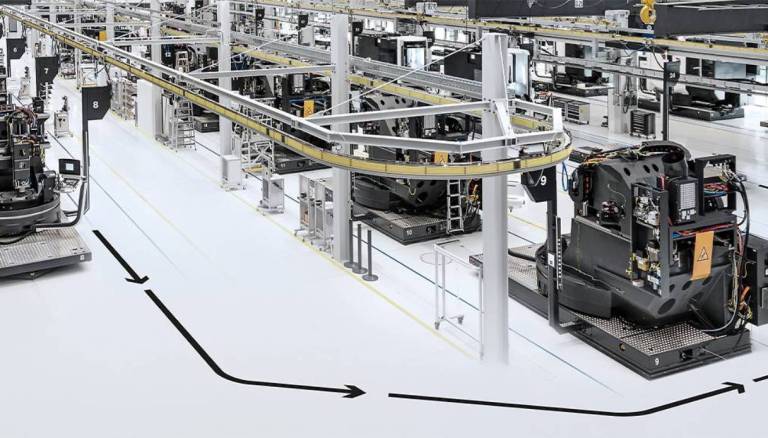

| Automation Ready | Compatible with pallet systems, robotic loaders, and FMS integration |

These specifications reflect the capabilities enabled by DMG MORI’s advanced kinematics, thermal stability design, and precision linear guideways. At Honyo Prototype, these systems are operated under strict environmental and process controls to maintain micron-level tolerances across all qualified materials.

From CAD to Part: The Process

Honyo Prototype executes precision CNC machining through a rigorously defined workflow optimized for speed, accuracy, and manufacturability. The process for handling CNC projects—commonly referenced internally as DMG CNC work (denoting high-precision machining on DMG MORI equipment)—follows five sequential phases with integrated quality gates. Below is the technical workflow:

CAD File Upload and Initial Processing

Customers initiate the process via our secure client portal, uploading native CAD formats (STEP, IGES, Parasolid) or industry-standard 2D/3D drawings. The system performs automated validation for file integrity, unit consistency, and geometric completeness. Invalid submissions trigger immediate client notification with specific error diagnostics. Validated files enter the quoting pipeline within 15 minutes of upload.

AI-Powered Quoting Engine

Our proprietary AI quotation system analyzes the CAD geometry, material specifications, tolerances, and surface finish requirements. Machine learning algorithms cross-reference historical production data, real-time machine availability, and material costs to generate a technically viable quote within two hours. The output includes cost breakdowns by machining operation, estimated cycle time, and critical process limitations. Clients receive a secure link to review, adjust priorities (e.g., cost vs. lead time), and formally approve.

Engineering-Driven DFM Analysis

Upon quote acceptance, Honyo’s manufacturing engineers conduct a formal Design for Manufacturability review. This phase identifies geometric features that increase cost or risk—such as thin walls, deep cavities, or non-standard tolerances—and proposes actionable optimizations. Key DFM parameters evaluated include:

| Parameter Category | Critical Checks | Honyo Standard Threshold |

|---|---|---|

| Geometric Complexity | Undercuts, internal radii, aspect ratios | Minimum radius = 0.5x feature depth |

| Tolerance Stack-Up | Interdependent GD&T callouts | ±0.025mm typical; tighter requires secondary operations |

| Material Utilization | Stock size vs. part volume | >35% material savings triggers redesign suggestion |

| Fixturing Feasibility | Datum accessibility, clamping surfaces | 3+ unobstructed fixture points required |

Engineers collaborate with clients via digital markup tools to resolve conflicts before programming begins. Unresolved issues escalate to senior engineering within 4 business hours.

CNC Production Execution

Approved designs move to production on DMG MORI 5-axis milling centers or precision lathes with integrated probing. Each job follows:

CAM programming using hyperMILL with collision avoidance simulation

First-article inspection via CMM against original CAD (AS9102 format)

In-process checks at critical operation intervals

Real-time machine data logging (spindle load, vibration, thermal drift)

All parts receive unique serialized barcoding for full traceability from raw material to shipment. High-mix/low-volume batches leverage our flexible manufacturing cells with <30-minute changeover times.

Quality-Controlled Delivery

Final inspection verifies dimensional compliance, surface roughness (Ra values), and material certifications per ASME Y14.5. Shipping documentation includes:

FAI report with deviation analysis

Material test certificates (MTRs)

Process capability data (Cp/Cpk where applicable)

Parts are packaged in anti-static, humidity-controlled containers with shock indicators. Standard lead time is 5–7 business days post-DFM approval; expedited options (72-hour) available for qualified geometries. Global delivery uses tracked logistics with real-time shipment visibility via client portal.

Start Your Project

For more information on DMG CNC capabilities and services, contact Susan Leo at [email protected]. Our advanced manufacturing facility is located in Shenzhen, China, ensuring precision engineering and fast turnaround for your prototyping and production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.