Introduction: Navigating the Global Market for different types of screws and bolts

In the fast-paced world of international manufacturing, sourcing the right fasteners—specifically different types of screws and bolts—can be a daunting challenge for B2B buyers. With diverse applications ranging from construction to automotive, the selection process must consider not only the type and material of the fastener but also its intended use and regional compliance standards. This comprehensive guide serves as a vital resource for businesses across Africa, South America, the Middle East, and Europe, including markets like Vietnam and Saudi Arabia.

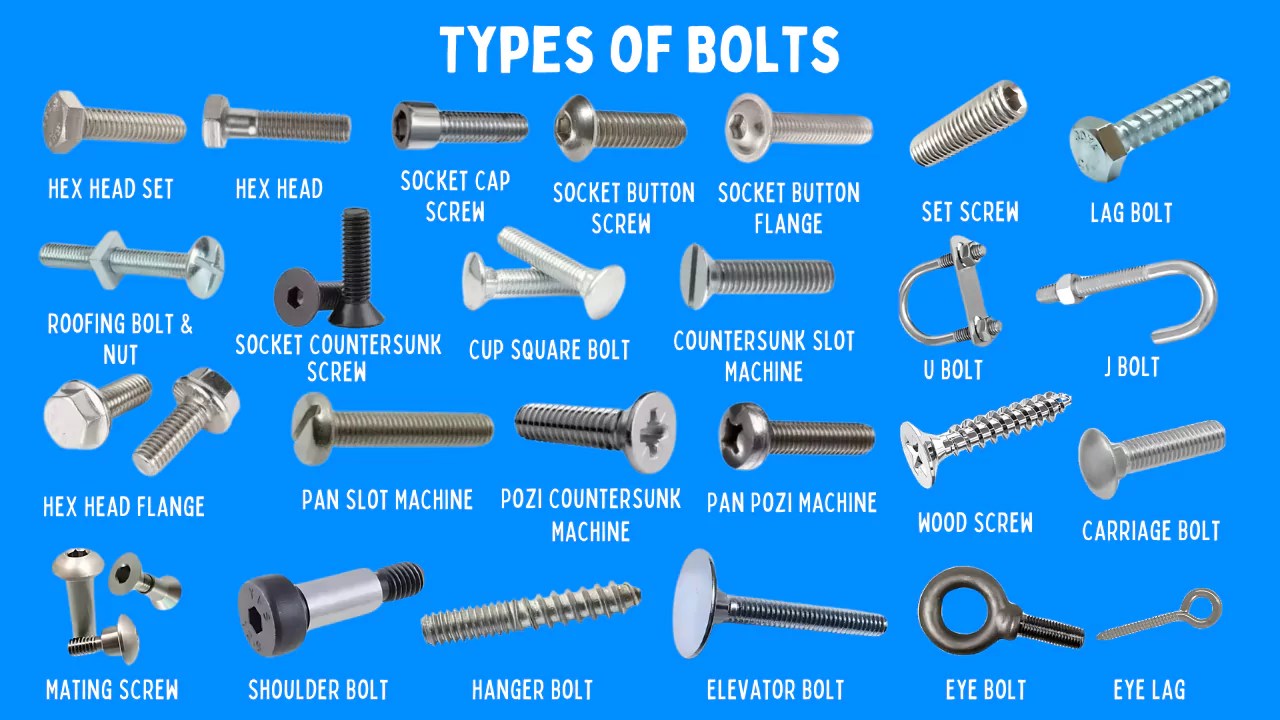

Within these pages, you will find detailed insights into various fastener types, including wood screws, machine screws, and specialized bolts such as U-bolts and lag bolts. Additionally, the guide delves into critical factors like supplier vetting, cost analysis, and material specifications, empowering you to make informed purchasing decisions. By understanding the nuances of fasteners and their applications, you can effectively navigate the complexities of the global market, ensuring that you select products that meet your operational needs while optimizing your supply chain efficiency.

Whether you are a procurement officer, a project manager, or a business owner, this guide is designed to equip you with the knowledge necessary to enhance your sourcing strategies and build lasting partnerships with suppliers around the world.

Understanding different types of screws and bolts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wood Screws | Smooth shank, tapered point, designed for wood | Furniture manufacturing, carpentry | Pros: Easy to install, good holding power. Cons: Not suitable for metal applications. |

| Hex Bolts | Hexagonal head, threaded shaft, used with nuts | Structural applications, machinery assembly | Pros: High strength, versatile. Cons: Requires tools for installation. |

| Lag Bolts | Wood thread, pointed tip, no nut required | Heavy-duty applications like decking and framing | Pros: Strong and durable, excellent for heavy loads. Cons: Limited to wood applications. |

| Eye Bolts | Circular ring at the head, used for lifting and rigging | Construction, marine, and manufacturing sectors | Pros: Ideal for tension applications. Cons: Limited load capacity compared to other bolts. |

| Socket Screws | Cylindrical head, driven with an Allen wrench | Precision machinery, automotive applications | Pros: Space-saving design, tamper-resistant. Cons: Requires specific tools for installation. |

What Are Wood Screws and Their Primary Applications?

Wood screws are specifically designed with a smooth shank and a tapered point, making them ideal for securing wood materials. Their primary applications include furniture manufacturing and carpentry, where they provide excellent holding power. When purchasing wood screws, buyers should consider the screw’s length and diameter to ensure compatibility with their specific wood types. Additionally, the material—whether stainless steel or coated options—can influence corrosion resistance and overall durability.

How Do Hex Bolts Stand Out in Industrial Applications?

Hex bolts are characterized by their hexagonal heads and threaded shafts, which allow them to be used effectively with nuts. These fasteners are widely used in structural applications and machinery assembly due to their high strength and versatility. B2B buyers should assess the material grade of hex bolts, as this impacts load-bearing capacity and corrosion resistance. Proper installation tools are necessary, which may involve additional costs for buyers.

Why Choose Lag Bolts for Heavy-Duty Applications?

Lag bolts, also known as lag screws, feature wood threads and pointed tips, making them suitable for heavy-duty applications without the need for nuts. Commonly used in decking and framing, they offer exceptional strength and durability. Buyers should evaluate the length and gauge of lag bolts to ensure they meet load requirements. While they are limited to wood applications, their ability to bear heavy loads makes them a preferred choice in construction.

What Are the Benefits of Using Eye Bolts in Rigging?

Eye bolts feature a circular ring at the head, making them ideal for lifting, rigging, and anchoring applications. Commonly used in construction and marine industries, they are designed to handle tension effectively. Buyers should consider the load capacity and material of eye bolts to ensure they meet safety standards. While they excel in tension applications, their load capacity may be lower than that of other bolt types, which is a crucial consideration for heavy-duty needs.

How Do Socket Screws Enhance Precision in Machinery?

Socket screws, with their cylindrical heads, are driven using an Allen wrench, making them a popular choice in precision machinery and automotive applications. Their space-saving design allows for efficient use in tight spaces, while their tamper-resistant feature enhances security. Buyers should focus on the screw’s material and finish to ensure it meets specific environmental conditions. The requirement for specialized tools can be a drawback, but the benefits often outweigh this limitation in high-precision applications.

Key Industrial Applications of different types of screws and bolts

| Industry/Sector | Specific Application of different types of screws and bolts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Use of lag bolts for securing structural components in buildings | Provides reliable support for heavy loads, ensuring safety and stability | Material strength, corrosion resistance, and compliance with local building codes |

| Automotive | Application of hex bolts in vehicle assembly and repair | Ensures durability and safety in automotive components, minimizing failure risks | Compatibility with vehicle specifications and standards, availability of sizes |

| Manufacturing | Use of socket screws in machinery assembly and maintenance | Facilitates efficient assembly and disassembly, reducing downtime | Precision engineering requirements and availability of custom sizes |

| Oil & Gas | Use of flange bolts in pipeline installations | Ensures leak-proof connections and structural integrity in harsh environments | Material specifications for corrosion resistance and pressure ratings |

| Marine | Application of eye bolts for rigging and securing equipment | Enhances safety in marine operations by providing reliable anchoring solutions | Compliance with maritime standards and resistance to saltwater corrosion |

How are Different Types of Screws and Bolts Used in the Construction Industry?

In the construction sector, lag bolts are commonly employed to secure structural components such as beams and joists. Their robust design allows them to bear heavy loads, making them ideal for high-stress applications. International buyers should consider sourcing lag bolts that meet local building codes and standards to ensure safety and compliance. Additionally, selecting materials with high corrosion resistance is crucial, especially in regions with adverse weather conditions.

What Role Do Hex Bolts Play in the Automotive Industry?

Hex bolts are integral to vehicle assembly and repair processes, providing strong and durable connections in various automotive components, from engines to chassis. These fasteners must meet stringent automotive standards to ensure safety and reliability. For international buyers, it’s essential to source hex bolts that align with specific vehicle models and specifications. Availability of diverse sizes and grades is also a critical factor in maintaining efficient inventory management.

How Are Socket Screws Utilized in Manufacturing?

Socket screws are widely used in machinery assembly and maintenance within manufacturing environments. Their design allows for easy access in tight spaces, facilitating efficient assembly and disassembly. For B2B buyers, precision engineering is paramount, as socket screws need to fit specific applications accurately. Sourcing considerations should include the availability of custom sizes and materials that can withstand the operational demands of machinery.

Why Are Flange Bolts Important in the Oil & Gas Sector?

Flange bolts are crucial for creating leak-proof connections in pipeline installations within the oil and gas industry. They are designed to distribute loads evenly, ensuring structural integrity under high pressure. International buyers must focus on sourcing flange bolts made from materials that offer excellent corrosion resistance, particularly in harsh environments. Additionally, compliance with industry-specific pressure ratings is essential to ensure operational safety and reliability.

How Do Eye Bolts Enhance Safety in Marine Operations?

Eye bolts are vital for rigging and securing equipment in marine applications, providing reliable anchoring solutions that enhance safety during operations. Their design allows for easy attachment of ropes and chains, making them indispensable in various marine tasks. B2B buyers in this sector should prioritize sourcing eye bolts that comply with maritime standards and are resistant to saltwater corrosion to ensure longevity and reliability in challenging environments.

3 Common User Pain Points for ‘different types of screws and bolts’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Fastener for Specific Applications

The Problem: B2B buyers often face the challenge of selecting the appropriate type of screw or bolt for their specific applications, especially when dealing with a diverse range of materials and structural requirements. For instance, a construction company in Saudi Arabia may need to choose between lag bolts and carriage bolts for securing timber beams to metal frameworks. The wrong choice can lead to structural integrity issues, increased costs, and project delays, all of which are critical in a competitive market.

The Solution: To effectively address this issue, buyers should invest time in understanding the specific requirements of their projects, including load-bearing capacities, environmental conditions, and material compatibility. Utilizing comprehensive fastener catalogs and datasheets will enable buyers to compare the specifications of different screws and bolts. Furthermore, collaborating with suppliers who provide technical support can enhance decision-making. For example, leveraging the expertise of a supplier to evaluate the tensile strength and corrosion resistance of bolts can ensure that the selected fasteners meet safety and longevity standards.

Scenario 2: Managing Inventory and Supply Chain Challenges

The Problem: Many B2B buyers, particularly in regions like Africa and South America, encounter significant challenges in managing inventory and ensuring a steady supply of screws and bolts. Fluctuations in demand, coupled with supply chain disruptions, can lead to stockouts or overstock situations, affecting project timelines and increasing costs. For example, a manufacturer might experience delays in production due to the unavailability of specific screw types that are critical for assembly.

The Solution: To mitigate inventory challenges, buyers should adopt a proactive inventory management strategy that includes forecasting demand based on historical usage patterns and upcoming projects. Implementing an automated inventory system can streamline this process, allowing for real-time tracking of stock levels. Additionally, establishing relationships with multiple suppliers can provide backup options in case of shortages. Buyers should also consider bulk purchasing for frequently used fasteners to reduce costs and ensure availability, thus maintaining production schedules and avoiding costly delays.

Scenario 3: Ensuring Compliance with International Standards

The Problem: B2B buyers operating in international markets face the complexity of ensuring that their fasteners comply with various regional and international standards. For instance, a construction firm in Europe may struggle to ascertain whether the screws and bolts sourced from different suppliers meet the necessary European Union standards for construction materials. Non-compliance can result in legal liabilities, project rework, and damage to reputation.

The Solution: To navigate compliance effectively, buyers should familiarize themselves with the relevant standards, such as ISO, ASTM, and specific regional regulations. Partnering with suppliers who are certified and knowledgeable about these standards can help ensure that all sourced fasteners meet compliance requirements. Additionally, requesting certifications and test reports from suppliers can provide assurance of quality and compliance. Maintaining a checklist of necessary documentation and standards for each project can also streamline the procurement process and minimize the risk of non-compliance, ultimately safeguarding the buyer’s interests and reputation in the marketplace.

Strategic Material Selection Guide for different types of screws and bolts

What Are the Key Properties of Common Materials Used for Screws and Bolts?

When selecting the appropriate materials for screws and bolts, understanding the key properties of each material is vital to ensure optimal performance in specific applications. Here, we analyze four common materials: stainless steel, carbon steel, titanium, and nylon, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Stainless Steel Perform in Fastener Applications?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it ideal for applications exposed to harsh environments. It can withstand high temperatures and pressures, which is particularly beneficial in industries such as automotive and aerospace. The austenitic grades, like 304 and 316, are commonly used for screws and bolts due to their excellent mechanical properties.

Pros: Stainless steel offers high strength and resistance to rust and corrosion, which extends the lifespan of fasteners. It is also aesthetically pleasing, making it suitable for visible applications.

Cons: The main drawback is its higher cost compared to carbon steel. Additionally, it can be more challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel fasteners are compatible with various media, including water, chemicals, and high-temperature environments. However, they may not be suitable for applications involving chlorides, which can lead to stress corrosion cracking.

Considerations for International Buyers: Compliance with standards like ASTM A193 or DIN 931 is crucial. Buyers from regions like the Middle East and Europe often prefer stainless steel for its reliability in corrosive environments.

What Are the Advantages of Carbon Steel in Fastener Manufacturing?

Carbon steel is a widely used material for screws and bolts due to its strength and affordability. It is available in various grades, such as low, medium, and high carbon steel, allowing for flexibility in applications.

Pros: Carbon steel is cost-effective and has good tensile strength, making it suitable for a range of applications, including construction and automotive.

Cons: The primary limitation is its susceptibility to corrosion, which can be mitigated through coatings or galvanization. However, these treatments may add to the overall cost.

Impact on Application: Carbon steel fasteners are best suited for dry, indoor environments. In humid or corrosive conditions, they may fail prematurely without protective coatings.

Considerations for International Buyers: Buyers should ensure that carbon steel fasteners meet relevant standards like ASTM A325 or DIN 933. In regions like Africa and South America, where cost sensitivity is high, carbon steel remains a popular choice.

Why Is Titanium Considered a Premium Material for Fasteners?

Titanium is a premium material known for its high strength-to-weight ratio and excellent corrosion resistance. It is particularly advantageous in aerospace and medical applications where weight and biocompatibility are critical.

Pros: Titanium fasteners are lightweight yet incredibly strong, making them ideal for applications where reducing weight is essential. They also resist corrosion in aggressive environments.

Cons: The high cost of titanium can be a significant barrier for many applications. Additionally, titanium is more challenging to machine, which can increase production costs.

Impact on Application: Titanium screws and bolts are suitable for high-stress applications and environments with exposure to seawater or chemicals.

Considerations for International Buyers: Compliance with standards like ASTM F136 is essential, especially in the aerospace sector. Buyers in Europe and the Middle East may prioritize titanium for its performance in demanding applications.

What Role Does Nylon Play in Fastener Applications?

Nylon is a polymer material that offers unique properties, including lightweight, flexibility, and resistance to chemicals. It is often used for non-structural applications or as a locking mechanism in combination with metal fasteners.

Pros: Nylon is resistant to a wide range of chemicals and provides good insulation properties. It is also lightweight and can be produced at a lower cost than metals.

Cons: The main limitation is its lower strength compared to metals, making it unsuitable for high-load applications. Additionally, nylon can degrade under UV exposure.

Impact on Application: Nylon fasteners are ideal for applications requiring electrical insulation or chemical resistance, such as in electronics and automotive components.

Considerations for International Buyers: Buyers should ensure that nylon fasteners meet relevant standards such as ASTM D4066. In regions with high humidity, like parts of South America, the choice of nylon may be influenced by environmental factors.

Summary Table of Material Selection for Screws and Bolts

| Material | Typical Use Case for different types of screws and bolts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine applications, automotive, and construction | High corrosion resistance and durability | Higher cost and machining complexity | High |

| Carbon Steel | Construction, automotive, and general-purpose fasteners | Cost-effective with good tensile strength | Susceptible to corrosion without coatings | Low |

| Titanium | Aerospace, medical, and high-performance applications | Lightweight and excellent corrosion resistance | High cost and challenging to machine | High |

| Nylon | Electrical insulation, automotive, and non-structural | Lightweight and chemical resistance | Lower strength and UV degradation | Med |

This strategic material selection guide provides insights for international B2B buyers, enabling informed decisions based on performance, cost, and environmental factors.

In-depth Look: Manufacturing Processes and Quality Assurance for different types of screws and bolts

What Are the Main Stages of Manufacturing Different Types of Screws and Bolts?

The manufacturing of screws and bolts involves several key stages that ensure the production of high-quality fasteners. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The process begins with the selection of appropriate raw materials, which can range from carbon steel to stainless steel and even polymers. Material preparation involves cutting the raw material into specific lengths and shapes. Techniques such as annealing may be employed to improve ductility and reduce hardness, making the material easier to work with during subsequent forming processes.

Forming: What Techniques Are Used to Shape Screws and Bolts?

The forming stage is critical, as it determines the final shape and dimensions of the fasteners. Common techniques include:

- Cold Heading: This process involves deforming the material at room temperature to create the head of the screw or bolt without losing any material. This method is energy-efficient and preserves the material’s integrity.

- Thread Rolling: After forming the head, threads are rolled onto the shank of the screw or bolt. This technique enhances the strength of the threads compared to cutting, which can weaken the material.

- Machining: For more complex fasteners like socket screws or eye bolts, machining may be necessary to achieve precise dimensions and tolerances.

How Is Assembly Managed in the Production of Screws and Bolts?

In many cases, screws and bolts are not standalone products; they may require additional components such as nuts and washers. During the assembly stage, these components are often combined to ensure that they meet specific design requirements. Automated systems may be used to streamline this process, improving efficiency and reducing the likelihood of human error.

What Finishing Techniques Are Employed for Quality Enhancement?

The finishing stage involves several processes that improve the appearance and performance of screws and bolts. Common techniques include:

- Plating: This method involves applying a layer of metal (such as zinc or nickel) to enhance corrosion resistance.

- Heat Treatment: Processes like quenching and tempering can increase the strength and hardness of fasteners, making them suitable for heavy-duty applications.

- Coating: Non-metallic coatings, such as polymer-based finishes, may also be applied to improve chemical resistance and reduce friction.

How Is Quality Assurance Implemented During the Manufacturing Process?

Quality assurance is vital in ensuring that screws and bolts meet international standards and customer expectations. Various checkpoints and testing methods are employed throughout the manufacturing process.

What International Standards Govern the Quality of Screws and Bolts?

Many manufacturers adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Additionally, industry-specific standards may apply, such as the CE marking for products sold within the European Economic Area or API specifications for oil and gas applications. These standards help ensure that fasteners are manufactured to a consistent quality level.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Regular inspections are conducted during production to monitor adherence to quality standards and identify any deviations early.

- Final Quality Control (FQC): Completed products undergo a thorough inspection and testing to ensure they meet all specifications before shipment.

What Common Testing Methods Are Used to Ensure Quality?

Common testing methods employed in the quality assurance process include:

- Mechanical Testing: Tensile, hardness, and impact tests assess the mechanical properties of the fasteners.

- Visual Inspection: This non-destructive method checks for surface defects, dimensional accuracy, and overall appearance.

- Functional Testing: Fasteners may be subjected to functional tests to ensure they perform effectively in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of their suppliers:

-

Supplier Audits: Conducting regular audits can help assess a supplier’s manufacturing processes and quality assurance measures. This can include reviewing documentation and observing practices on-site.

-

Requesting Quality Reports: Buyers should request quality assurance documentation, including certificates of compliance and test reports. This documentation provides insight into the supplier’s adherence to industry standards.

-

Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of a supplier’s quality control processes. This is particularly valuable for international buyers who may not have the resources to conduct in-person audits.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Different regions may have varying standards and regulations governing manufacturing processes. Buyers should be aware of local compliance requirements and ensure that their suppliers can meet both international and regional standards.

Additionally, cultural differences in business practices may affect communication regarding quality expectations. Establishing clear channels of communication and expectations can help mitigate misunderstandings and ensure that quality standards are consistently met.

Conclusion: Why Is Understanding Manufacturing Processes and Quality Assurance Crucial for B2B Buyers?

For B2B buyers sourcing screws and bolts, a thorough understanding of manufacturing processes and quality assurance is essential. It enables them to make informed decisions when selecting suppliers, ensuring that the fasteners they procure meet their specific requirements and industry standards. By prioritizing quality, buyers can enhance their own product reliability and ultimately drive customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different types of screws and bolts’

Introduction

This sourcing guide provides a practical checklist for B2B buyers looking to procure various types of screws and bolts. Understanding the nuances of fasteners is essential for ensuring that your projects are not only successful but also cost-effective. This guide will help you navigate the complexities of sourcing by outlining key steps that will streamline your procurement process.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the screws and bolts you need. Consider factors such as material type, size, thread count, and any specific standards (e.g., ISO, ASTM) that your project requires. This clarity will prevent costly errors during the procurement process.

- Material Selection: Choose between stainless steel, carbon steel, or polymers based on environmental conditions and load requirements.

- Size and Threading: Ensure you have the correct dimensions and thread types to fit your existing components.

Step 2: Identify Your Application Needs

Different applications require specific types of fasteners. Evaluate the environment where the screws and bolts will be used, such as exposure to moisture, chemicals, or heavy loads. This assessment will guide you in selecting the right type of fastener.

- Load-Bearing Capacity: Determine if you need lag bolts for heavy-duty applications or machine screws for lighter tasks.

- Environmental Resistance: Choose corrosion-resistant materials for outdoor or humid applications.

Step 3: Research Potential Suppliers

Before making any commitments, conduct thorough research on potential suppliers. Investigate their reputation, product offerings, and experience in your specific industry. Look for suppliers who specialize in the types of screws and bolts you require.

- Supplier Reviews: Check online platforms for reviews and testimonials from previous clients.

- Industry Experience: A supplier with experience in your sector will understand your unique needs and challenges.

Step 4: Request Samples and Specifications

Once you have a shortlist of suppliers, request samples of the screws and bolts you plan to purchase. This will allow you to assess the quality and ensure they meet your specifications before placing a bulk order.

- Quality Assurance: Examine the samples for any defects or inconsistencies.

- Compliance Documentation: Ensure that the samples come with relevant certifications or compliance documents.

Step 5: Verify Supplier Certifications

Confirm that your chosen suppliers hold the necessary certifications and adhere to international quality standards. This step is vital for ensuring that the fasteners will perform as expected in your applications.

- ISO Certification: Look for suppliers with ISO 9001 or similar certifications.

- Material Certifications: Ensure the materials used comply with relevant industry standards to guarantee performance and safety.

Step 6: Negotiate Terms and Conditions

Before finalizing your order, negotiate terms and conditions with your supplier. Discuss pricing, lead times, minimum order quantities, and return policies to establish a mutually beneficial agreement.

- Pricing Flexibility: Inquire about bulk discounts or long-term partnership pricing.

- Delivery Terms: Clarify shipping options and expected delivery times to avoid project delays.

Step 7: Plan for After-Sales Support

Lastly, consider the after-sales support provided by your supplier. A reliable supplier will offer assistance with installation, troubleshooting, and replacement parts if needed.

- Technical Support: Verify if they offer technical assistance for installation and maintenance.

- Warranty Information: Understand the warranty terms and what they cover to protect your investment.

By following these steps, you can ensure a streamlined and effective sourcing process for screws and bolts, leading to successful project outcomes and long-term partnerships with suppliers.

Comprehensive Cost and Pricing Analysis for different types of screws and bolts Sourcing

What Are the Key Cost Components in Sourcing Screws and Bolts?

When sourcing screws and bolts, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

Materials account for a significant portion of the total cost. Common materials like stainless steel, alloy steel, and polymers each have varying price points influenced by market demand and availability. Labor costs will vary based on the manufacturing location, with regions like Southeast Asia often offering lower labor costs compared to Europe or North America.

Manufacturing overhead encompasses utilities, facility costs, and indirect labor, which can fluctuate based on local economic conditions. Tooling costs are particularly pertinent for custom screws and bolts, as specialized molds or dies can lead to higher upfront investments.

Quality Control is an essential component, particularly for industries that require compliance with strict standards. Investing in robust QC processes can add to the cost but is vital for ensuring product reliability. Finally, logistics costs, including transportation and warehousing, can significantly impact overall pricing, especially for international shipments.

How Do Price Influencers Affect the Cost of Screws and Bolts?

Several factors influence pricing, including volume or minimum order quantities (MOQ), specifications and customization, material choices, quality certifications, supplier factors, and Incoterms.

High-volume orders generally lead to lower per-unit costs due to economies of scale, making it advantageous for buyers to consolidate their purchases. Specifications and customization also play a critical role; unique designs or specific materials will often incur additional costs.

The quality of materials and the presence of certifications (like ISO or ASTM) can elevate prices but may be necessary for certain applications. Supplier factors—such as reputation, reliability, and geographic location—also influence pricing. Suppliers in regions with higher labor costs may charge more, but they might also offer superior quality or service.

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms can help buyers manage costs related to duties, insurance, and shipping logistics effectively.

What Negotiation Strategies Can Help B2B Buyers Achieve Cost Efficiency?

For B2B buyers, effective negotiation strategies are crucial for achieving cost efficiency. Start by gathering market intelligence to understand prevailing prices and identify potential suppliers. Leverage volume purchases to negotiate better rates or additional services, such as expedited shipping or extended payment terms.

Consider engaging in long-term contracts or partnerships with suppliers, which can lead to more favorable pricing structures and reliability in supply. Be open to discussing alternative materials or specifications that may lower costs without compromising quality.

Understanding the Total Cost of Ownership (TCO) is essential. This encompasses not just the purchase price, but also costs related to installation, maintenance, and disposal. A lower initial price may not always equate to the best value if the product requires frequent replacement or additional maintenance.

What Pricing Nuances Should International B2B Buyers Be Aware Of?

International buyers from regions like Africa, South America, the Middle East, and Europe need to consider several pricing nuances. Currency fluctuations can impact costs, so locking in prices early or using hedging strategies may be beneficial. Additionally, tariffs and trade regulations can significantly affect the final price, necessitating a thorough understanding of local regulations.

Freight costs can vary widely depending on the shipping method and distance, so it’s advisable to compare quotes from multiple logistics providers. Lastly, cultural differences in negotiation styles and business practices can influence discussions, making it essential to approach negotiations with cultural sensitivity and adaptability.

Disclaimer

Prices mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. Always request quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing different types of screws and bolts With Other Solutions

Exploring Alternatives to Different Types of Screws and Bolts

In various industries, the choice of fasteners is crucial for ensuring the integrity and functionality of assemblies. While screws and bolts are the go-to solutions for many applications, there are alternative fastening technologies that can achieve similar results. This section evaluates different types of screws and bolts against two viable alternatives: adhesive bonding and rivets. Understanding these options can help B2B buyers make informed decisions based on their specific requirements.

| Comparison Aspect | Different Types of Screws and Bolts | Adhesive Bonding | Rivets |

|---|---|---|---|

| Performance | High tensile strength; versatile | Good for uniform load distribution; limited by surface preparation | Excellent shear strength; permanent |

| Cost | Moderate; varies by material | Generally lower for large areas; can increase with surface prep | Moderate; labor-intensive installation |

| Ease of Implementation | Relatively straightforward; requires tools | Requires careful application; curing time needed | Requires specific tools; once installed, cannot be removed easily |

| Maintenance | Low; can be removed and replaced | High; can degrade over time with environmental exposure | Low; stable once installed, but difficult to replace |

| Best Use Case | General assembly, machinery, furniture | Lightweight materials, non-structural applications | Aircraft, automotive, and heavy structural applications |

What Are the Pros and Cons of Adhesive Bonding?

Adhesive bonding is a method that uses various types of adhesives to join materials together. One of its primary advantages is the ability to create a seamless bond across large surface areas, distributing stress evenly. This is particularly beneficial in applications involving thin or delicate materials. Additionally, adhesives can be less expensive for large projects, as they eliminate the need for numerous fasteners. However, adhesive bonding requires meticulous surface preparation and curing time, which can delay production. Furthermore, environmental factors such as temperature and humidity can affect the adhesive’s performance over time, necessitating careful consideration of the operational environment.

How Do Rivets Compare to Screws and Bolts?

Rivets provide a strong, permanent fastening solution that is widely used in industries such as aerospace and automotive. Their primary advantage lies in their high shear strength, making them ideal for applications that require resistance to heavy loads. Rivets can also be installed quickly and do not require threads, making them useful in situations where traditional fasteners may be impractical. However, rivets are permanent, meaning that if maintenance or replacement is needed, the rivet must be drilled out, which can be labor-intensive and costly. Additionally, the installation requires specialized tools, which may not be available in all settings.

How Can B2B Buyers Choose the Right Fastening Solution?

When selecting the appropriate fastening solution, B2B buyers should carefully assess their specific project requirements, including load conditions, material compatibility, and environmental factors. For applications where removable and adjustable connections are necessary, different types of screws and bolts may be the best option. Conversely, if the assembly is meant to be permanent and subjected to high shear forces, rivets could be more suitable. Adhesive bonding might be the preferred choice for applications involving lightweight materials or where aesthetics are a priority. By considering these factors, buyers can choose the most effective and efficient fastening solution for their needs.

Essential Technical Properties and Trade Terminology for different types of screws and bolts

What Are the Key Technical Properties of Screws and Bolts in B2B Transactions?

When sourcing screws and bolts for industrial applications, understanding their technical properties is essential for ensuring product compatibility and reliability. Here are several critical specifications to consider:

-

Material Grade

The material grade indicates the strength and durability of screws and bolts. Common materials include stainless steel, carbon steel, and titanium. Each material has specific properties that affect corrosion resistance, tensile strength, and overall longevity. For B2B buyers, selecting the appropriate material is crucial to meet project requirements and environmental conditions, especially in demanding applications such as construction and manufacturing. -

Thread Pitch

Thread pitch refers to the distance between threads on a screw or bolt. It affects how tightly the fastener can be secured and influences load distribution. Different applications may require fine or coarse threads, and understanding these distinctions helps buyers select the right fasteners for specific uses. A mismatch in thread pitch can lead to installation difficulties and compromised structural integrity. -

Tolerance Levels

Tolerance levels specify the acceptable limits of variation in dimensions, which are critical for ensuring that screws and bolts fit properly with other components. Tight tolerances are often necessary in precision engineering applications where alignment and fit are paramount. Buyers must consider tolerance specifications to avoid issues during assembly that could lead to performance failures. -

Finish and Coating

The finish or coating of screws and bolts affects their appearance, corrosion resistance, and wear characteristics. Common finishes include zinc plating, black oxide, and anodizing. B2B buyers should assess the environmental conditions where the fasteners will be used to choose the appropriate finish that enhances durability and prevents corrosion, especially in humid or corrosive environments. -

Load Rating

Load rating indicates the maximum load a fastener can safely bear. This specification is critical when determining which screws or bolts to use for specific applications, especially in structural and heavy-load scenarios. Understanding load ratings helps prevent premature failure, ensuring safety and reliability in B2B projects.

What Are Common Trade Terms Used in the Screws and Bolts Industry?

Navigating the fastener industry requires familiarity with specific jargon and terms that are commonly used. Here are some essential trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of screws and bolts, OEM suppliers provide fasteners that meet the specifications required for the final product. Understanding OEM relationships is vital for buyers seeking custom fasteners tailored to their specific applications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it impacts inventory management and cost-effectiveness. Knowing the MOQ helps in planning procurement strategies, especially for bulk purchases. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. B2B buyers use RFQs to compare costs and capabilities from different suppliers, enabling informed decision-making. Crafting a clear RFQ can lead to better pricing and service agreements. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers involved in cross-border procurement, as they clarify aspects such as shipping, risk, and cost responsibilities. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. This term is critical for project planning and supply chain management. B2B buyers must consider lead times to align with project schedules and avoid delays in production. -

Certification Standards

Certification standards (such as ISO or ASTM) ensure that screws and bolts meet specific quality and safety requirements. Familiarity with these standards helps buyers select compliant products, ensuring reliability and safety in their applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that contribute to the success of their projects and the overall efficiency of their operations.

Navigating Market Dynamics and Sourcing Trends in the different types of screws and bolts Sector

What Are the Key Drivers Shaping the Market for Screws and Bolts?

The global screws and bolts market is influenced by several key drivers, including industrial growth, technological advancements, and evolving consumer preferences. Regions such as Africa, South America, the Middle East, and Europe are witnessing significant construction and manufacturing booms, leading to increased demand for fasteners. Emerging economies are investing in infrastructure projects, which directly boosts the requirement for various types of screws and bolts.

Moreover, technology plays a crucial role in transforming sourcing trends. The rise of e-commerce platforms facilitates easier access to suppliers, enabling international B2B buyers to compare products, prices, and specifications in real time. Additionally, advancements in manufacturing processes, such as automation and precision engineering, are enhancing the quality and diversity of fastener products available in the market.

Another notable trend is the increasing customization of screws and bolts to meet specific application needs. Buyers are seeking suppliers who can provide tailored solutions, including unique sizes, materials, and finishes. This trend is particularly relevant for sectors like automotive and construction, where precision and reliability are paramount.

How Important is Sustainability and Ethical Sourcing in the Screws and Bolts Industry?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the screws and bolts sector. The environmental impact of fastener production, including carbon emissions and waste generation, has prompted a shift towards more sustainable practices. Buyers are increasingly favoring suppliers who implement eco-friendly manufacturing processes and use recyclable materials.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for demonstrating a commitment to sustainability. Additionally, using ‘green’ materials, such as recycled metals and biodegradable polymers, is gaining traction. These practices not only help mitigate environmental impacts but also enhance brand reputation and appeal to eco-conscious consumers.

Moreover, transparency in supply chains is critical. Buyers are demanding more information about the sourcing of materials and the labor practices of their suppliers. Establishing ethical supply chains not only ensures compliance with international standards but also fosters trust and long-term partnerships between buyers and suppliers.

How Has the Screws and Bolts Market Evolved Over Time?

The evolution of the screws and bolts market is marked by significant technological advancements and changing consumer needs. Initially, fasteners were crafted manually, limiting their availability and consistency. The Industrial Revolution brought mechanization, leading to mass production and standardization of screws and bolts.

In the late 20th century, the introduction of new materials, such as polymers and advanced alloys, expanded the functionality of fasteners, allowing for applications in diverse industries, including automotive, aerospace, and construction. The rise of digital technology in the 21st century further transformed the market, enabling efficient inventory management, online sourcing, and enhanced customer engagement.

Today, the focus on sustainability and ethical sourcing is reshaping how screws and bolts are produced and distributed, positioning the industry for continued growth and adaptation in response to global challenges. As the market evolves, international B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their operational goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of different types of screws and bolts

-

How do I choose the right type of screw or bolt for my project?

Choosing the right screw or bolt depends on the materials you are fastening, the load requirements, and environmental factors. For wood applications, wood screws with a tapered point are ideal. For metal, machine screws or hex bolts provide better strength. Consider the size, length, and thread type, as well as the finish to prevent corrosion. Always consult with your supplier for specific recommendations based on your project’s unique requirements. -

What is the best material for screws and bolts in humid environments?

In humid or corrosive environments, stainless steel is the best choice due to its resistance to rust and corrosion. For extreme conditions, consider using coated or galvanized fasteners, which offer additional protection. If weight is a concern, titanium bolts may be suitable, though they are more expensive. It’s essential to evaluate the specific environmental conditions and choose materials that will maintain integrity over time. -

What are the minimum order quantities (MOQs) for screws and bolts?

Minimum order quantities vary significantly among suppliers. Typically, MOQs can range from a few hundred to several thousand pieces, depending on the fastener type and the supplier’s production capabilities. When sourcing internationally, it’s crucial to discuss MOQs upfront to avoid unexpected costs. Suppliers may offer flexibility for long-term contracts or bulk orders, so negotiating based on your needs can be beneficial. -

What payment terms should I expect when sourcing screws and bolts internationally?

Payment terms can differ widely depending on the supplier’s policies and your relationship with them. Common terms include 30% upfront payment with the balance due upon shipment, or net 30/60 days after delivery. Ensure you clarify terms before finalizing orders to avoid cash flow issues. Using secure payment methods, such as letters of credit or escrow services, can further protect your investment in international transactions. -

How can I ensure the quality of screws and bolts from my supplier?

To ensure quality, request certifications such as ISO 9001 or industry-specific standards that verify the supplier’s manufacturing processes. Conduct factory audits if possible, and ask for samples to test before placing large orders. Establishing a solid quality assurance process that includes inspections during production and upon arrival will help mitigate risks. Building a long-term relationship with reliable suppliers can also enhance trust in product quality. -

What logistics considerations should I keep in mind when importing fasteners?

Logistics is crucial when importing screws and bolts. Consider shipping methods, transit times, and customs regulations in your country. It’s important to work with a logistics partner familiar with international shipping to navigate tariffs and documentation. Ensure that the supplier provides accurate shipping information to avoid delays. Establishing clear communication about delivery schedules will help manage expectations and reduce disruptions. -

How do I vet suppliers for screws and bolts in international markets?

When vetting suppliers, start by checking their reputation through online reviews and industry references. Look for suppliers with a proven track record in your specific fastener type. Request detailed information about their manufacturing processes, certifications, and quality control measures. Engaging in direct communication can also provide insight into their responsiveness and reliability. Additionally, consider visiting the supplier’s facility if feasible. -

Can I customize screws and bolts for my specific applications?

Yes, many suppliers offer customization options for screws and bolts, including specific lengths, diameters, materials, and finishes. Discuss your requirements with potential suppliers to see if they can accommodate your needs. Customizing fasteners can enhance performance and compatibility with your projects. Be aware that custom orders may come with higher MOQs and longer lead times, so planning ahead is essential.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Different Types Of Screws And Bolts Manufacturers & Suppliers List

1. Bolt Depot – Fasteners and Screws

Domain: boltdepot.com

Registered: 1999 (26 years)

Introduction: Fastener Categories: Wood Screws (WS), Machine Screws (MS), Thread Cutting Machine Screws, Sheet Metal Screws (SMS), Self Drilling Screws, Hex Bolts (HHMB or HXBT), Carriage Bolts, Lag Bolts, Flange Bolts, Socket Screws, Eye Bolts, Eye Lags, U-Bolts, J-Bolts, Shoulder Bolts, Elevator Bolts, Sex Bolts, Mating Screws, Hanger Bolts, Set Screws. Head Styles: Flat (FH), Oval (OH or OV), Pan (PN), Truss…

2. Digi-Key – Threaded Fasteners

Domain: forum.digikey.com

Registered: 1995 (30 years)

Introduction: Types of threaded fasteners include: 1. Bolts: External threads, fasten with a nut, common head type is Hex, thread types are coarse (UNC) or fine (UNF). 2. Cap Screws: Similar to bolts but with tighter tolerances, also have external threads. 3. Machine Screws: Used for precision applications, uniform diameter threads, can be used with a nut or threaded holes, various head types (Phillips, flat, h…

3. Kellogg Supply Co – Screws

Domain: kelloggsupplyco.com

Registered: 1997 (28 years)

Introduction: Screws are fasteners used to adhere materials together, designed specifically for various functions. Key types include: 1. Wood Screws: Coarse threads, smooth shank, tapered head; used for wood construction; may require pilot holes. 2. Deck Screws: Similar to wood screws; self-tapping; corrosion-resistant; designed for decking applications. 3. Drywall Screws: Self-tapping head; countersinks withou…

4. Pinterest – 26 Types of Screws Explained

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: 26 types of screws and their uses, explained with pictures.

5. Helix Steel – Bolts, Nuts & Washers

Domain: helixsteel.ph

Introduction: 40+ Different Types of Bolts and Nuts and Washers, including: 1. Carriage Bolts – smooth, large diameter head, square neck for easy installation in various materials. 2. Flange Bolts – round flange under head for load distribution, ideal for metal fastening. 3. Plow Bolts – square neck and flat head, used in farm and heavy machinery. 4. Hex Head Bolts – hexagonal heads, machine threads, used with …

Strategic Sourcing Conclusion and Outlook for different types of screws and bolts

In the dynamic landscape of fasteners, understanding the diverse types of screws and bolts is essential for international B2B buyers. Key takeaways include recognizing the specific applications and benefits of each fastener type, from wood screws to hex bolts, and the importance of selecting the right materials, such as stainless steel or polymers, to ensure durability and performance. Strategic sourcing not only enhances supply chain efficiency but also fosters partnerships that can lead to cost savings and innovation.

As global markets continue to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, there is a significant opportunity for businesses to leverage their sourcing strategies to gain a competitive edge. By staying informed about trends in fastener technology and material science, buyers can make informed decisions that align with their operational needs.

Looking ahead, we encourage international B2B buyers to actively engage with suppliers, explore new product offerings, and consider the long-term implications of their sourcing choices. This proactive approach will empower organizations to not only meet current demands but also anticipate future challenges in the fastener industry.