Contents

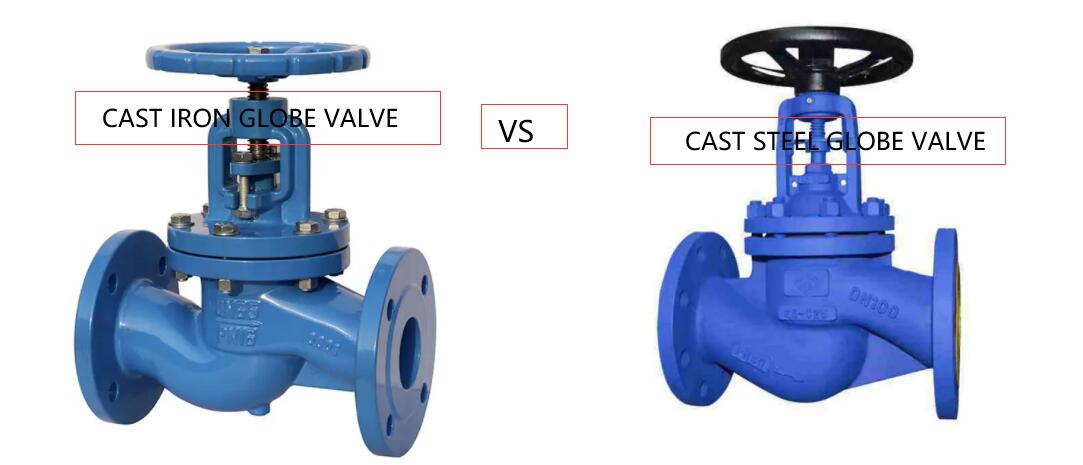

Manufacturing Insight: Difference Between Cast Iron And Carbon Steel

Material Selection Precision: Cast Iron vs. Carbon Steel for CNC Machined Components

Understanding the fundamental differences between cast iron and carbon steel is critical when specifying materials for precision CNC machined components. Both offer distinct advantages and machining characteristics that directly impact part performance, tool life, production efficiency, and final cost. Cast iron, characterized by its high carbon content (typically 2-4%) primarily in the form of graphite flakes or nodules, provides excellent vibration damping, superior wear resistance, and good compressive strength. This makes it ideal for machine tool bases, engine blocks, and brake discs. Carbon steel, with lower carbon content (usually 0.05-1.0%) and a ferritic/pearlitic microstructure, offers higher tensile strength, greater ductility, and better weldability, making it suitable for structural components, shafts, gears, and high-stress applications requiring toughness.

The machining behavior diverges significantly. Cast iron’s graphite structure acts as a built-in lubricant but is highly abrasive, demanding specialized tool geometries and coatings to combat rapid tool wear. Carbon steel tends to produce long, stringy chips and can work-harden during cutting, requiring optimized feeds, speeds, and chip control strategies. Selecting the wrong material or applying inappropriate CNC parameters for either can lead to dimensional inaccuracies, poor surface finishes, excessive scrap rates, and unplanned downtime.

Honyo Prototype leverages deep metallurgical expertise and advanced CNC machining capabilities to navigate these material complexities. Our engineering team collaborates closely with clients during the design phase to ensure optimal material selection aligned with functional requirements and manufacturability. We deploy precision 3-, 4-, and 5-axis machining centers equipped with industry-specific tooling and process parameters rigorously validated for both cast iron grades (like G20/G30) and carbon steel alloys (including 1018, 1045, and 4140). This ensures consistent part quality, tight tolerances (±0.0002″), and maximized throughput regardless of material challenges.

Key comparative properties influencing CNC machining outcomes include:

| Property | Cast Iron (Gray) | Carbon Steel (e.g., 1045) | Machining Implication |

|---|---|---|---|

| Carbon Content | 2.5-4.0% (as graphite) | 0.3-0.6% (in solution) | Graphite aids chip breaking but increases abrasion |

| Machinability | Generally good (free-machining) | Moderate (requires chip control) | Cast iron needs wear-resistant tools; steel needs sharp, positive rake tools |

| Thermal Conductivity | Low | Moderate to High | Cast iron prone to localized heating; steel dissipates heat better |

| Chip Formation | Short, brittle chips | Long, continuous chips | Cast iron less prone to chip entanglement |

| Primary Wear Mechanism | Abrasion (graphite) | Adhesion/Work Hardening | Different tool coatings required (e.g., AlTiN vs. TiN) |

Honyo’s integrated approach—from material analysis and process planning to high-precision execution—guarantees components that meet exacting performance criteria while minimizing total production costs. To accelerate your next project, utilize Honyo’s Online Instant Quote platform. Upload your CAD file, specify material requirements (including cast iron or carbon steel grades), and receive a detailed manufacturability assessment with a competitive price estimate within hours, not days. Make informed material decisions with engineering support that starts at the quote stage.

Technical Capabilities

Technical Comparison: Cast Iron vs Carbon Steel in Precision Machining Applications

When evaluating cast iron and carbon steel for high-precision 3-axis, 4-axis, and 5-axis milling and turning operations—particularly under tight tolerance requirements (±0.0005″ or better)—several material properties significantly influence machinability, tool life, dimensional stability, and surface finish. Below is a comparative analysis focused on performance in CNC machining environments, including considerations for common companion materials such as aluminum, steel (general), ABS, and nylon.

| Parameter | Cast Iron (Gray Iron, Class 30/40) | Carbon Steel (e.g., 1018, 1045) | Notes for Aluminum, Steel, ABS, Nylon |

|---|---|---|---|

| Composition | Iron with 2.5–4.0% carbon, 1–3% silicon; graphite flakes in microstructure | Iron with 0.1–1.0% carbon; no free graphite; ferrite/pearlite matrix | Aluminum: low density, high thermal conductivity. Steel: broad category; includes alloy and tool steels. ABS: amorphous thermoplastic. Nylon: semi-crystalline engineering thermoplastic. |

| Machinability | Excellent due to graphite acting as a built-in lubricant; produces short, brittle chips | Moderate to good; generates continuous chips; higher tool wear than cast iron | Aluminum: very high machinability; requires sharp tools and high speeds. ABS/Nylon: easy to machine but prone to melting or burring if not controlled. |

| Tool Wear | Low to moderate; abrasive graphite phase can wear carbide tools over time | Higher than cast iron; adhesive wear and built-up edge common | Aluminum: low tool wear with proper coatings. ABS/Nylon: minimal tool wear but require sharp cutting edges. |

| Thermal Stability | High thermal conductivity and damping capacity; excellent for vibration absorption | Lower damping capacity; more prone to thermal expansion during prolonged cuts | Critical in tight tolerance work; cast iron base structures preferred for machine tool beds. |

| Dimensional Stability | High; minimal residual stress in cast forms; excellent for precision fixtures | Moderate; may require stress-relieving heat treatment to maintain tolerances | For tight tolerance parts, both materials require stable stock and proper fixturing. |

| Surface Finish | Good; graphite inclusions can leave micro-pitting but allow fine finishes with proper toolpath | Very good; capable of smooth finishes with appropriate feeds/speeds | Aluminum: excellent surface finish achievable. ABS/Nylon: good finish but may require post-processing. |

| Use in Fixturing & Workholding | Preferred for precision machine bases, tables, and fixtures due to damping | Used in structural components but less ideal for high-precision fixturing | Aluminum fixtures common for light-duty or rapid prototyping. ABS/Nylon used for soft jaws or protective tooling. |

| Typical Applications in 3/4/5-Axis Machining | Machine tool structures, precision plates, inspection tables | Shafts, gears, structural components requiring strength and weldability | Aluminum: aerospace, enclosures. ABS: prototypes. Nylon: wear components. |

| Coolant Requirements | Often machined dry due to self-lubricating graphite | Typically requires coolant to manage heat and prevent work hardening | Aluminum: requires coolant to prevent galling. Thermoplastics: often machined dry. |

| Tight Tolerance Suitability | Excellent for stable, long-term dimensional accuracy | Good, but more sensitive to thermal and residual stress effects | All materials benefit from environmental control in sub-micron tolerance applications. |

Summary for Honyo Prototype Applications

For 3/4/5-axis milling and turning operations involving tight tolerances, cast iron offers superior damping and thermal stability, making it ideal for precision tooling, fixtures, and machine components. Carbon steel provides higher tensile strength and weldability but requires more careful thermal and stress management. When machining aluminum, ABS, or nylon on these platforms, the base material’s stability—often cast iron—ensures consistent part accuracy. Carbon steel remains a strong choice for functional end-use parts but demands more rigorous process control in high-precision workflows.

From CAD to Part: The Process

Honyo Prototype integrates material science expertise throughout our prototyping workflow to ensure optimal material selection and manufacturability. When clients submit designs involving cast iron or carbon steel components, our process systematically addresses material differentiation and application suitability as follows:

Upload CAD

Upon CAD model submission, our system validates material specifications against geometric complexity and tolerance requirements. Engineers immediately flag ambiguous material calls like “cast iron” or “carbon steel” requiring clarification. For instance, generic terms trigger alerts to distinguish between gray iron ASTM A48 Class 30 (for vibration-damping bases) versus ductile iron ASTM A536 (for impact-resistant housings), or between low-carbon 1018 steel (for weldable fixtures) versus high-carbon 1095 steel (for spring applications). This prevents downstream errors in production planning.

AI Quote Generation

Our AI engine cross-references material properties with real-time supply chain data during quoting. Key differentiators automatically assessed include:

| Property | Cast Iron (Typical Gray Iron) | Carbon Steel (Typical 1045) |

|---|---|---|

| Carbon Content | 2.5–4.0% | 0.3–0.6% |

| Machinability | Excellent (graphite acts as chip breaker) | Moderate (requires controlled feeds/speeds) |

| Weldability | Poor (requires preheat/post-weld heat treatment) | Good (with proper procedures) |

| Casting Suitability | High (low melting point, fluidity) | Low (prone to shrinkage/cracks) |

| Primary Use Case | Static structures, machine bases | Shafts, gears, structural components |

The quote explicitly states implications: e.g., “Gray iron recommended for this bracket geometry due to superior damping; carbon steel would require costly post-casting machining.”

DFM Analysis

Our manufacturing engineers conduct rigorous Design for Manufacturability reviews focusing on material-specific constraints:

Cast iron components undergo gating system validation to prevent shrinkage cavities, while carbon steel parts are checked for weld joint accessibility and heat treatment distortion risks. We advise clients when material substitutions could reduce costs—such as recommending ASTM A126 Class B cast iron instead of machined carbon steel for pump housings, saving 30–40% in production costs while meeting pressure requirements. Thermal expansion coefficients are verified against assembly tolerances, particularly critical in mixed-material assemblies.

Production Execution

Material-specific protocols activate during manufacturing: Cast iron parts enter our foundry-controlled process with strict cooling rate management to ensure graphite flake structure, while carbon steel components undergo pre-weld cleaning and controlled interpass temperatures. In-process inspections include spark testing for material verification and hardness spot-checks per ASTM E10/E18. Any deviation from specified material properties triggers immediate containment per our AS9100-compliant procedures.

Delivery and Documentation

Final shipments include full material traceability: Mill test reports for carbon steel (showing actual carbon content within ASTM A29 limits) or foundry analysis certificates for cast iron (confirming silicon/graphite structure). We provide application-specific guidance—e.g., noting that the delivered gray iron bracket requires stress-relief annealing before precision machining, while the carbon steel shaft must undergo quenching per ASTM A38. This ensures clients understand post-delivery handling requirements tied to material characteristics.

Throughout this workflow, Honyo’s technical team proactively educates clients on material trade-offs, transforming theoretical differences into actionable manufacturing decisions that reduce time-to-prototype and prevent field failures.

Start Your Project

Understanding the difference between cast iron and carbon steel is critical when selecting materials for your manufacturing projects. Cast iron offers excellent wear resistance and damping capacity, making it ideal for applications requiring stability and vibration absorption. On the other hand, carbon steel provides superior tensile strength and ductility, allowing for greater formability and structural performance under stress.

Each material has distinct composition, mechanical properties, and manufacturing considerations that influence cost, machinability, and end-use performance. Choosing the right one impacts product durability, production efficiency, and overall project success.

For expert guidance tailored to your specific application, contact Susan Leo at [email protected]. With our precision manufacturing facility located in Shenzhen, Honyo Prototype delivers high-quality material solutions with fast turnaround and strict quality control. Let us help you make the right material choice from the start.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.