Contents

Manufacturing Insight: Difference Between 316 And 304 Stainless Steel

Material Selection Matters in Precision Manufacturing

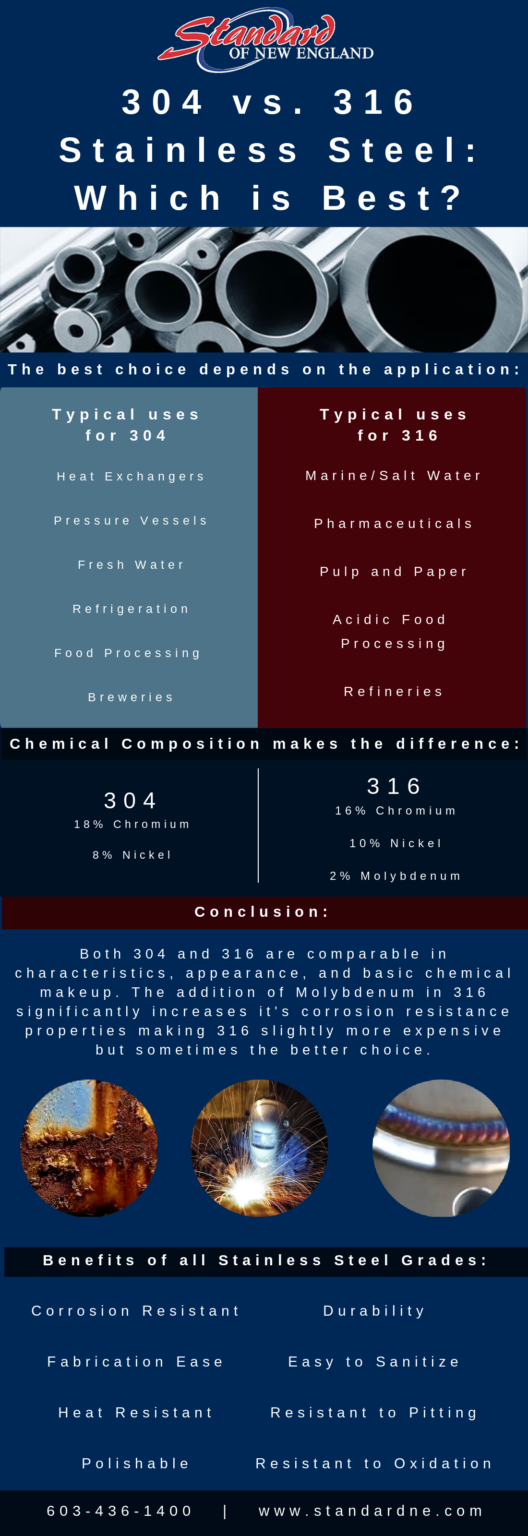

Choosing between 316 and 304 stainless steel significantly impacts part performance, longevity, and manufacturability in demanding applications. Both grades offer excellent corrosion resistance and formability, but critical compositional differences dictate their suitability for specific environments. Understanding these distinctions is essential for engineers specifying components requiring CNC machining.

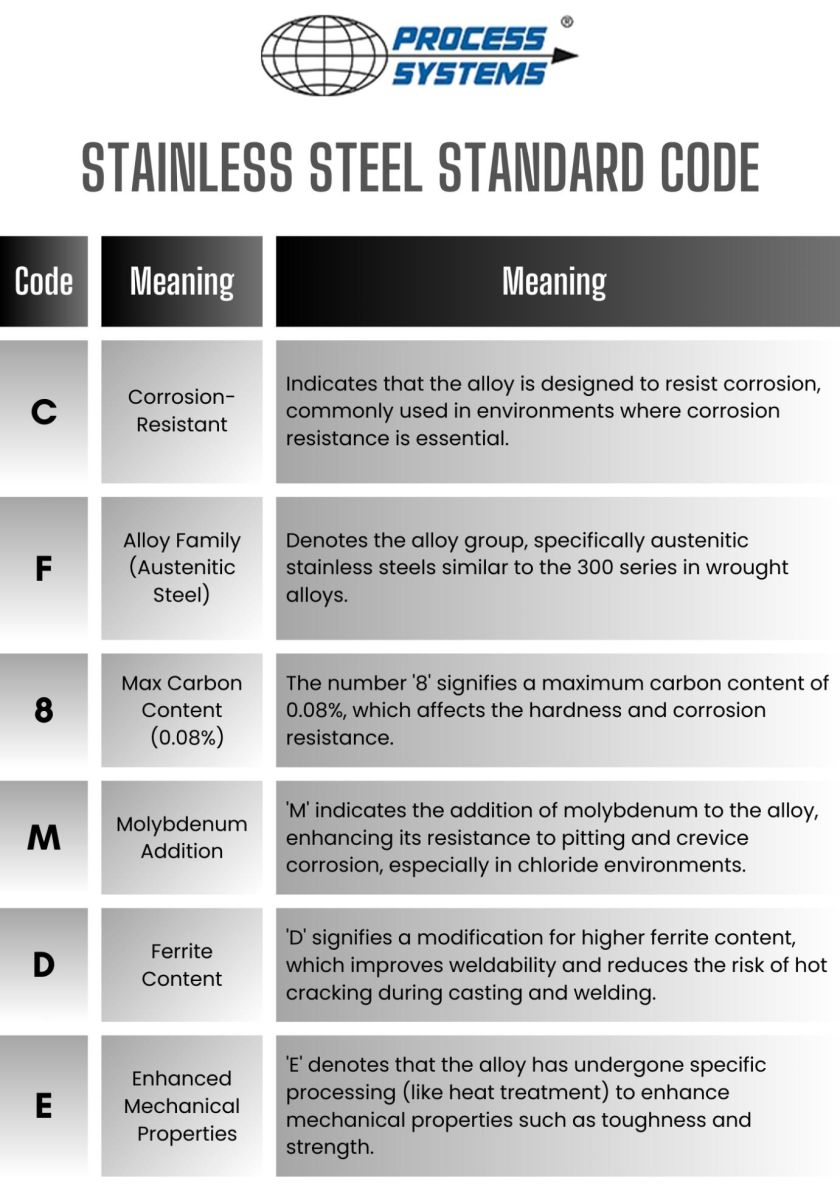

The primary differentiator lies in molybdenum content. 304 stainless steel (18% Cr, 8% Ni) provides robust general-purpose corrosion resistance. 316 stainless steel (16% Cr, 10% Ni, 2% Mo) incorporates molybdenum, dramatically enhancing resistance to pitting and crevice corrosion, particularly in chloride-rich or acidic conditions like marine, chemical processing, or medical sterilization environments. This makes 316 indispensable for critical applications where failure is not an option, though it typically commands a higher material cost and presents slightly greater machining challenges.

Honyo Prototype leverages deep metallurgical expertise to optimize CNC machining for both 304 and 316 stainless steel. Our advanced 3-5 axis milling and turning centers, combined with proprietary toolpath strategies and coolant management protocols, ensure exceptional dimensional accuracy, superior surface finishes, and minimized tool wear specific to each alloy’s work-hardening characteristics. We routinely machine complex geometries in these materials for aerospace, medical device, and semiconductor clients where material integrity and precision are non-negotiable.

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Key Alloying | 18% Cr, 8% Ni | 16% Cr, 10% Ni, 2% Mo |

| Corrosion Resistance | Good (general) | Excellent (chlorides/acids) |

| Typical Applications | Food processing, architecture | Marine hardware, chemical tanks, surgical implants |

| Machinability | Slightly better | Slightly more challenging |

Partner with Honyo to transform your stainless steel component designs into high-integrity production parts. Utilize our Online Instant Quote platform for rapid, transparent pricing on CNC-machined 304 or 316 stainless steel prototypes and low-volume production runs, backed by full material certification and rigorous quality control. Start your project today with engineering-grade accuracy.

Technical Capabilities

Technical Comparison: 304 vs 316 Stainless Steel in Precision Machining (3/4/5-Axis Milling & Turning) with Relevance to Other Common Materials

When selecting between 304 and 316 stainless steel for tight-tolerance components in multi-axis milling and precision turning operations, key differences in chemical composition, machinability, corrosion resistance, and thermal properties must be considered. Additionally, comparing these to other frequently machined materials such as Aluminum, Steel (general carbon steel), ABS, and Nylon helps contextualize performance, tooling requirements, and process parameters.

| Property / Material | 304 Stainless Steel | 316 Stainless Steel | Aluminum (6061-T6) | Carbon Steel (1018/1045) | ABS | Nylon (PA6/PA66) |

|---|---|---|---|---|---|---|

| Chemical Composition | 18% Cr, 8% Ni, no Mo | 16–18% Cr, 10–14% Ni, 2–3% Mo | 97.9% Al, 1% Mg, 0.6% Si | ~0.18–0.45% C, Fe balance | C₃H₃N (acrylonitrile butadiene styrene) | Polyamide with amide linkages |

| Corrosion Resistance | Good in mild environments | Excellent, especially against chlorides and acids due to molybdenum | Good (forms oxide layer) | Poor (requires coating) | Moderate, degrades under UV/solvents | Good against chemicals, absorbs moisture |

| Machinability (Relative Rating) | 45–50% of free-machining steel | 40–45% of free-machining steel | 90–100% (excellent) | 50–70% (good) | Excellent (low cutting forces) | Good (soft, but can gum up) |

| Tool Wear (in Milling/Turning) | Moderate to high – work hardening, galling | Higher than 304 – Mo increases abrasiveness | Low – minimal tool wear | Moderate – higher than aluminum | Very low – sharp tools preferred | Low – but built-up edge possible |

| Recommended Tooling | Carbide with TiAlN coating, high positive rake | Carbide with AlTiN coating, high-pressure coolant | Carbide or HSS, polished flutes | Carbide, HSS acceptable | Carbide, sharp geometry | Carbide, sharp cutting edges |

| Typical Feed/Speed (Milling, Approx.) | 80–120 SFM, 0.002–0.005 IPT | 60–100 SFM, 0.0015–0.004 IPT | 500–800 SFM, 0.005–0.010 IPT | 200–350 SFM, 0.004–0.008 IPT | 500–1000 SFM, 0.005–0.012 IPT | 300–600 SFM, 0.004–0.008 IPT |

| Tight Tolerance Capability (±) | ±0.0002″ to ±0.0005″ achievable with thermal control | ±0.0002″ to ±0.0005″ – requires stable setup and coolant | ±0.0001″ to ±0.0003″ – low thermal expansion helps | ±0.0002″ to ±0.0005″ – good stability | ±0.001″ to ±0.005″ – prone to creep | ±0.001″ to ±0.003″ – hygroscopic effects limit precision |

| Thermal Expansion (µin/in-°F) | 9.6 | 9.6 | 13.1 | 6.5 | ~25–30 | ~50–70 |

| Thermal Conductivity (BTU/hr-ft-°F) | 9.4 | 8.5 | 134 | 26 | ~1.2 | ~0.25 |

| Common Applications in Precision Machining | Food processing, general hardware | Marine, chemical, medical, harsh environments | Aerospace, electronics, prototypes | Industrial machinery, shafts | Enclosures, jigs, prototypes | Gears, bushings, wear parts |

Notes on High-Axis Machining (3/4/5-Axis):

304 Stainless Steel: Suitable for complex geometries but requires rigid setups due to work hardening. Peck drilling and climb milling reduce heat buildup. Ideal for components needing moderate corrosion resistance.

316 Stainless Steel: Preferred in corrosive environments. The addition of molybdenum increases strength and abrasiveness, demanding slower speeds, high-pressure coolant, and robust tooling. More challenging in deep cavity milling due to chip evacuation issues.

Aluminum: Highly favorable in 5-axis due to high material removal rates and low cutting forces. Excellent for rapid prototyping and lightweight precision parts.

Carbon Steel: Predictable machining behavior; good for high-strength structural components but requires post-process coating for corrosion resistance.

ABS & Nylon: Used for non-metallic prototypes or functional parts. Require sharp tools and optimized feeds to avoid melting or deformation. Not suitable for high-temperature environments.

Conclusion: For tight-tolerance, multi-axis machining, 316 stainless steel offers superior corrosion resistance over 304 but demands more aggressive tooling strategies and process control. When comparing across materials, aluminum leads in machinability and precision, while engineering plastics like ABS and Nylon provide cost-effective prototyping solutions with dimensional trade-offs.

From CAD to Part: The Process

Honyo Prototype’s Integrated Material Differentiation Process for 304 vs. 316 Stainless Steel

At Honyo Prototype, technical accuracy in material selection is embedded throughout our workflow. When a client uploads a CAD file specifying stainless steel, our system proactively identifies whether 304 or 316 is appropriate based on geometric and environmental requirements. This begins during the CAD Upload phase, where our AI engine cross-references part geometry, tolerances, and declared application conditions (e.g., marine exposure, chemical contact) against material property databases. If the CAD lacks explicit material designation, the system flags it for immediate clarification to prevent downstream errors.

The AI Quote stage dynamically calculates cost and lead time differentials between 304 and 316. Our algorithms factor in real-time scrap rates, machining complexity (316’s higher work-hardening rate increases tool wear by ~15%), and raw material premiums (316 typically carries a 20-30% cost uplift over 304). Crucially, the quote includes a technical justification summary: if the part operates in chloride-rich environments (>200 ppm), 316 is mandated due to its molybdenum content; otherwise, 304 is recommended for cost efficiency. Clients receive this rationale alongside pricing, enabling informed decisions before commitment.

During DFM (Design for Manufacturability) analysis, our engineers conduct a granular assessment of material suitability. Key differentiators evaluated include:

| Property | 304 Stainless Steel | 316 Stainless Steel | Critical Impact on DFM |

|---|---|---|---|

| Molybdenum Content | 0% | 2-3% | Determines chloride corrosion resistance; 316 required for saltwater exposure |

| Pitting Resistance (PREN) | 18-20 | 24-26 | 316 withstands 5x longer in ASTM B117 salt spray tests |

| Machinability (Relative) | 70% | 45% | 316 demands slower feeds/speeds, increasing cycle time |

| Weldability | Excellent | Good (risk of hot cracking) | 316 requires stricter interpass temp control |

If the design specifies 304 for a marine application, DFM triggers an automated alert with corrosion risk data, proposing 316 as a corrective action. This prevents non-conformance before production begins.

In Production, material verification is non-negotiable. Upon raw material receipt, we validate 316 vs. 304 via:

Mill test reports (MTRs) confirming ASTM A240/A480 compliance

Handheld XRF spectroscopy for on-spot elemental verification (Mo detection critical for 316)

Batch traceability logs tied to the work order. Machining parameters are auto-adjusted: 316 uses 25% lower cutting speeds and specialized tool coatings to mitigate galling.

Finally, Delivery includes comprehensive documentation:

Material certification with actual chemical composition (C, Cr, Ni, Mo percentages)

DFM report detailing why 304/316 was selected or modified

In-process inspection records validating material integrity. For medical or aerospace parts, we provide full EN 10204 3.1 certificates.

This end-to-end integration ensures clients never receive a “generic” stainless steel part. Material differentiation is a continuous technical checkpoint—not a one-time footnote—driving reliability in high-stakes applications.

Start Your Project

Understanding the Difference Between 316 and 304 Stainless Steel

304 and 316 stainless steels are both austenitic alloys known for their corrosion resistance and durability, but they differ significantly in composition and performance. 304 stainless steel contains 18% chromium and 8% nickel, making it ideal for general-purpose applications such as kitchen equipment, fasteners, and architectural components. It offers excellent resistance to a wide range of atmospheric environments and many chemicals.

316 stainless steel, on the other hand, includes an additional 2–3% molybdenum, which enhances its resistance to chlorides and acidic environments. This makes 316 the preferred choice for marine applications, chemical processing, and medical devices where exposure to saltwater or corrosive substances is a concern.

While 304 is more cost-effective and widely used, 316 provides superior performance in harsher conditions, justifying its higher price in demanding environments.

For technical consultation or material selection support, contact Susan Leo at [email protected]. Honyo Prototype operates a precision manufacturing facility in Shenzhen, offering prototyping and low-volume production with certified material traceability and strict quality control.

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Chromium | 18% | 18% |

| Nickel | 8% | 10% |

| Molybdenum | 0% | 2–3% |

| Corrosion Resistance | Good | Excellent (especially to chlorides) |

| Typical Applications | Food processing, appliances | Marine, chemical, medical |

| Cost | Lower | Higher |

Reach out to Susan Leo today for material recommendations tailored to your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.