Contents

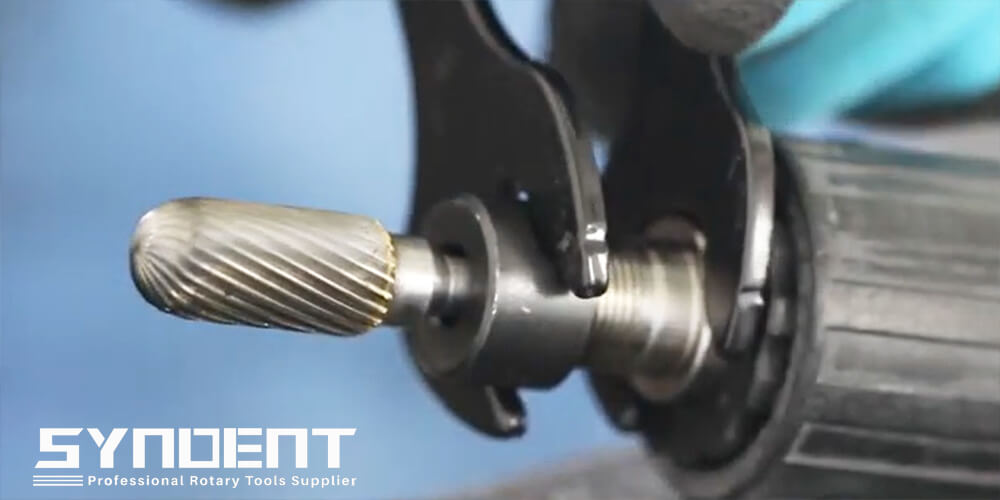

Manufacturing Insight: Die Grinder Bit For Steel

Precision Machining for Demanding Steel Applications

Honyo Prototype delivers mission-critical CNC machining expertise for high-performance tooling, including specialized die grinder bits engineered for steel. Our technical mastery in hard material machining ensures optimal edge retention, thermal stability, and geometric precision in every component. By leveraging advanced 5-axis milling centers and proprietary toolpath strategies, we achieve micron-level tolerances and superior surface finishes essential for steel fabrication, weld removal, and contouring operations where failure is not an option.

We understand that steel grinding tools demand exacting material science and process control. Honyo’s in-house capabilities span from cobalt-alloy and carbide bit fabrication to post-machining treatments like cryogenic stress relief, ensuring consistent performance under aggressive rotational loads. Our engineering team collaborates with clients to refine geometries for specific steel grades—whether mild, stainless, or hardened alloys—directly translating to extended tool life and reduced downtime in your production environment.

Accelerate your prototyping or production timeline with Honyo’s Online Instant Quote system. Upload CAD files in minutes to receive detailed manufacturability feedback and competitive pricing, eliminating traditional quoting delays. For die grinder bits or any precision steel component, we bridge design intent to flawless execution—from a single prototype to high-volume runs.

| Key Capability | Technical Advantage | Application Impact |

|---|---|---|

| 5-Axis CNC Machining | ±0.005mm tolerance on complex contours | Consistent cutting edge geometry for clean steel removal |

| Material-Specific Toolpaths | Optimized feed rates for HRC 25-60 steels | Minimized bit deflection and chatter during operation |

| In-House Metrology | Full GD&T validation with CMM reports | Guaranteed fit for collet systems and rotational balance |

Technical Capabilities

Technical specifications for a die grinder bit designed for steel must account for high precision applications in 3/4/5-axis milling and turning, particularly where tight tolerances are required. These bits are typically used for deburring, edge blending, and fine contouring after primary machining operations. While primarily optimized for steel, compatibility with aluminum, ABS, and nylon is essential for multi-material fabrication environments. Performance depends on bit geometry, coating, shank and tip configuration, and substrate material.

| Parameter | Specification Description |

|---|---|

| Intended Material | Steel (mild, stainless, tool steel); secondary use on aluminum, ABS, nylon |

| Cutting Material | Solid carbide or high-speed steel (HSS) with TiN, TiCN, or AlTiN coating for wear resistance and heat dissipation |

| Shank Diameter | 6 mm or 1/4 inch (6.35 mm), precision ground for runout < 0.01 mm |

| Tip Geometry | Ball nose, cylinder, or tapered form; multi-flute (2–4 flutes) for smooth finish and chip evacuation |

| Coating | AlTiN preferred for steel (up to 800°C oxidation resistance); TiN acceptable for lighter use |

| Tolerance | ±0.005 mm on diameter; concentricity maintained within 0.01 mm over active cutting length |

| Cutting Diameter | 3 mm to 10 mm (common range), with custom options for micro-finishing |

| Overall Length | 50 mm to 100 mm, optimized for tool clearance in 5-axis operations |

| Application | Deburring internal corners, blending weld seams, precision edge finishing in tight spaces |

| Compatibility | Fits standard die grinders, micro motors, and CNC spindle holders (ER collet or shrink fit) |

| Speed Range | 15,000–30,000 RPM (adjustable based on material: lower for steel, higher for aluminum/ABS/nylon) |

| Surface Finish | Capable of achieving Ra ≤ 0.8 µm when used in finishing passes |

| Use with Coolant | Recommended for steel; optional for aluminum, ABS, and nylon due to lower heat buildup |

Note: When operating in 3/4/5-axis CNC environments, tool path optimization and spindle stability are critical to maintain tight tolerances. Carbide bits with rigid shanks minimize vibration, ensuring accuracy across all listed materials. For non-metallic materials like ABS and nylon, reduced feed rates and sharp cutting edges prevent melting or burring.

From CAD to Part: The Process

CAD Upload and Validation

Clients submit 3D CAD models of die grinder bits designed for steel applications, typically in STEP or IGES format. Honyo’s system immediately validates geometric integrity, confirming critical features such as flute geometry, shank tolerances, and cutting-edge profiles meet minimum manufacturability thresholds for hardened steel substrates. The platform checks for common errors like non-manifold edges or undersized radii that could compromise tool strength during high-RPM steel grinding operations.

AI-Powered Quoting Engine

Our proprietary AI engine analyzes the validated CAD file against real-time material costs, machine availability, and steel-specific processing parameters. For steel die grinder bits, the system factors in variables such as alloy type (e.g., 4140, A2, or M2 tool steel), required hardness (typically 58-65 HRC), and secondary operations like cryogenic treatment. The quote includes granular cost breakdowns for material waste, machine time for precision grinding, and surface finishing, delivered within 90 minutes with 95% accuracy based on historical production data.

Engineering DFM Analysis

Honyo’s manufacturing engineers conduct a rigorous Design for Manufacturability review focused on steel tooling constraints. This phase identifies risks such as: excessive flute depth causing chatter during grinding, inadequate core thickness risking breakage, or non-optimal helix angles reducing chip evacuation in steel. Recommendations may include adjusting relief angles for improved edge retention or modifying the gullet geometry to handle ferrous swarf. Clients receive a formal DFM report with actionable revisions before proceeding.

Precision Production Sequence

Production begins with CNC milling of the blank from certified steel stock, followed by heat treatment to achieve target hardness. The critical grinding phase uses 5-axis CNC tool grinders with diamond-coated wheels operating at 25,000 RPM to form cutting edges with ±0.005mm tolerance. Each bit undergoes:

Flute grinding with controlled helix geometry

Precision edge honing to 25-50 micron land width

Optional TiAlN coating for extended steel-cutting life

100% runout verification at 30,000 RPM

Quality-Controlled Delivery

Final inspection includes optical comparator checks of critical dimensions, Rockwell hardness validation, and functional testing on steel workpieces. Every shipment includes a traceability certificate documenting material lot numbers, heat treatment curves, and inspection data per ISO 9001 standards. Die grinder bits are packaged in anti-corrosion foam inserts within rigid containers, with standard delivery in 7-10 business days for quantities under 100 units. Expedited 72-hour options are available for urgent steel fabrication projects.

Start Your Project

Looking for high-performance die grinder bits designed specifically for steel applications? Our precision-engineered bits are manufactured in our Shenzhen facility to ensure durability, accuracy, and extended tool life under demanding conditions. Trusted by professionals across industries, Honyo Prototype delivers consistent quality backed by advanced production standards.

For product inquiries or custom solutions, contact Susan Leo at [email protected]. We offer fast response times and reliable support for all your industrial tooling needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.