Contents

Manufacturing Insight: Die Casting Machines

Precision Integration for Die Cast Components Through Advanced CNC Machining

Die casting delivers high-volume metal parts with excellent dimensional stability, yet complex geometries and stringent tolerance requirements often necessitate precision secondary operations. At Honyo Prototype, we specialize in bridging this gap with dedicated CNC machining services engineered specifically for post-cast refinement. Our 5-axis milling and turning capabilities ensure critical features—such as sealing surfaces, threaded inserts, and undercuts—achieve micron-level accuracy while maintaining material integrity. This integration eliminates assembly errors and accelerates time-to-market for automotive, aerospace, and consumer electronics applications where cast-to-specification alignment is non-negotiable.

Our technical team collaborates directly with die casters to optimize part designs for manufacturability, addressing challenges like porosity compensation and thermal distortion during machining. By leveraging ISO 9001-certified processes and calibrated CMM validation, we consistently hold tolerances to ±0.005 mm on aluminum, zinc, and magnesium alloys. This precision transforms near-net-shape castings into fully functional components ready for validation testing or low-volume production, reducing scrap rates and eliminating costly rework cycles.

Accelerate your prototyping workflow with Honyo’s Online Instant Quote system. Upload CAD files in STEP, IGES, or native formats to receive detailed manufacturability feedback and competitive pricing within hours—not days. This digital gateway streamlines collaboration from initial concept to first-article submission, ensuring your die cast assemblies meet exacting performance criteria without project timeline disruptions. Partner with us to convert casting potential into engineered reality.

Technical Capabilities

Die casting machines are primarily used for high-pressure injection of molten metal into precision molds, typically for non-ferrous metals like aluminum and zinc. However, the post-processing of die-cast components often requires advanced CNC machining capabilities such as 3-axis, 4-axis, and 5-axis milling and turning to achieve tight tolerances and complex geometries. The following technical specifications outline key performance parameters relevant to CNC machining systems commonly integrated into die casting production lines for finishing operations.

| Parameter | Description |

|---|---|

| Machining Axes | 3-axis: Standard X, Y, Z linear motion for basic milling. 4-axis: Adds rotational A-axis (X-axis rotation), enabling machining of multiple sides. 5-axis: Full simultaneous motion with two rotational axes (e.g., A and B), allowing complex contours and undercuts without re-fixturing. |

| Spindle Speed | Up to 24,000 RPM for high-precision aluminum and plastic machining; up to 15,000 RPM for hardened steel. High-frequency spindles ensure surface finish quality and tool life. |

| Positioning Accuracy | ±0.002 mm (±0.00008 in) for high-end 5-axis systems. Critical for tight-tolerance die-cast components in automotive and aerospace. |

| Repeatability | ±0.001 mm (±0.00004 in), ensuring consistent part quality across production runs. |

| Tool Changer Capacity | 24–60 tools in automatic tool changer (ATC), supporting mixed milling and turning operations. |

| Work Envelope (Typical) | 800 mm × 600 mm × 500 mm (X×Y×Z), scalable for large die-cast housings. |

| Control System | Fanuc, Siemens, or Heidenhain CNC controls with 5-axis interpolation and thermal compensation. |

| Materials Processed | Aluminum (e.g., A380, ADC12): Most common die-cast material; easily machined with high-speed CNC. Steel (e.g., tool steel, mild steel): For molds, inserts, or structural components; requires robust tooling. ABS & Nylon: Used for prototyping or hybrid assemblies; low cutting forces, high feed rates. |

| Tolerance Capability | ±0.01 mm to ±0.025 mm (±0.0004–0.001 in) typical; down to ±0.005 mm with precision grinding or diamond tooling. Geometric tolerances (GD&T) compliant to ISO 2768 or customer-specific standards. |

| Surface Finish | Ra < 0.8 µm (32 µin) achievable with fine milling; polishing or grinding for mirror finishes on visible surfaces. |

| Coolant & Lubrication | High-pressure through-spindle coolant for aluminum; minimum quantity lubrication (MQL) for plastics to prevent deformation. |

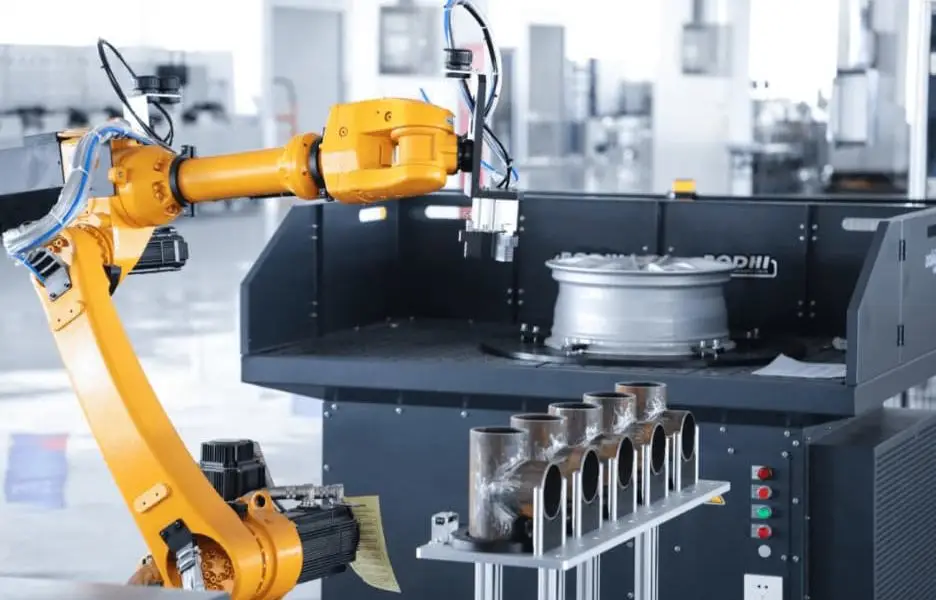

| Integration with Die Casting | Automated part transfer from casting cell to CNC station via robotics; in-process probing for closed-loop quality control. |

These machining systems are essential for achieving the dimensional accuracy, surface integrity, and functional performance required in high-integrity die-cast components, especially when used in powertrain, electronic enclosures, or medical devices.

From CAD to Part: The Process

Honyo Prototype Die Casting Process Flow

Client-submitted CAD files initiate our streamlined die casting workflow. We accept native formats including STEP AP203/214, Parasolid, and IGES, with strict validation for geometric integrity and unit consistency. Files undergo automated topology checks to flag non-manufacturable features like undercuts below 1° draft or wall thickness deviations before entering the quoting phase.

AI-Powered Quoting System

Our proprietary AI engine analyzes validated CAD geometry against live material costs, machine availability, and historical defect databases. The system generates a statistically validated quote within 2 business hours, including precise cycle time projections based on part volume, gating complexity, and thermal simulation data. Critical parameters such as projected fill time, required clamp force, and recommended ejection temperature are embedded in the quotation PDF for engineering review.

Engineering-Driven DFM Analysis

All quotes trigger mandatory Design for Manufacturability review by senior process engineers. This phase identifies high-risk features using Moldflow simulation for porosity prediction and thermal stress mapping. We provide actionable revision recommendations with annotated CAD markups – for instance, suggesting minimum 1.5mm uniform wall thickness for A380 aluminum to prevent cold shuts, or optimizing rib-to-wall ratios to avoid sink marks. Clients receive a formal DFM report with risk severity ratings (Critical/Major/Minor) and cost-impact analysis for each suggested change.

Precision Production Execution

Approved designs move to production on our climate-controlled die casting floor housing 80-1250 ton Cold Chamber machines. We implement real-time process monitoring with sensors tracking 12 critical parameters per cycle: molten metal temperature (±5°C tolerance), injection velocity profile, intensification pressure ramp rate, and die temperature gradients. Each lot undergoes first-article inspection per AS9102 standards, with CMM reports for critical dimensions and X-ray porosity verification for aerospace/medical components. Secondary operations including CNC machining, heat treatment, and surface finishing occur in-house under unified quality control.

Quality-Controlled Delivery

Final shipments include comprehensive documentation: dimensional inspection reports with GD&T callouts, material test certificates (per ASTM B85/B179), and process capability data (Cp/Cpk ≥1.33 for critical features). Logistics utilize serialized, humidity-controlled containers with IoT temperature tracking for sensitive alloys. Standard lead time is 15-20 days from DFM approval, with expedited options for qualified emergency orders. All deliveries meet PPAP Level 3 requirements unless otherwise specified in the purchase agreement.

Start Your Project

Explore high-performance die casting machines engineered for precision and durability. Built and quality-controlled at our Shenzhen manufacturing facility, our machines deliver consistent results for demanding production environments.

For technical specifications, pricing, or custom configuration support, contact Susan Leo at [email protected]. Let’s discuss how we can support your manufacturing goals with reliable, in-house built solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.