Introduction: Navigating the Global Market for dice creator

In an increasingly competitive landscape, sourcing custom dice that align with unique branding and gaming needs presents a significant challenge for B2B buyers. Whether you are a game developer, a corporate gift provider, or an educational institution, the ability to create bespoke dice can enhance your product offerings and marketing strategies. This guide delves into the multifaceted world of dice creation, covering various types—from traditional six-sided dice to elaborate polyhedral options—and exploring their diverse applications in gaming, education, and promotional events.

International buyers, particularly from Africa, South America, the Middle East, and Europe, will find this resource invaluable for navigating the complexities of supplier selection, understanding pricing structures, and ensuring quality standards. By providing insights into the latest trends and technologies in dice manufacturing, this guide empowers businesses to make informed purchasing decisions. Whether you seek to establish partnerships with reliable suppliers or explore innovative design options that cater to your specific market, our comprehensive approach equips you with the knowledge needed to stand out in a global market.

Unlock the potential of custom dice to elevate your business offerings and captivate your audience, ensuring that every roll not only adds fun but also reinforces your brand identity.

Understanding dice creator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Printed Dice | Full-color artwork, logos, or text; various shapes (D6, D20) | Board game manufacturing, promotional items | Pros: High customization, enhances branding; Cons: May require design expertise. |

| Engraved Dice | Laser-engraved designs, durable finish | Corporate gifts, awards | Pros: Elegant appearance, long-lasting; Cons: Limited color options. |

| Digital Dice | Customizable online tool, multiple sides, interactive use | Educational tools, game development | Pros: Versatile applications, easy to use; Cons: Lacks physical presence. |

| Polyhedral Dice | Variety of shapes beyond standard D6, customizable colors | Tabletop gaming, collectible items | Pros: Unique designs, appeals to niche markets; Cons: Higher production costs. |

| Printable Dice | Create your own designs with text or images, easily accessible | Educational resources, DIY projects | Pros: Cost-effective, user-friendly; Cons: Limited durability compared to manufactured dice. |

What Are the Characteristics of Custom Printed Dice?

Custom printed dice are designed to incorporate unique artwork, logos, or text, making them ideal for branding and marketing purposes. They typically come in various shapes, including standard D6 and polyhedral options. B2B buyers, especially in the board game manufacturing sector, find these dice valuable for creating a distinctive product that stands out in the market. While they offer high customization potential, businesses may need design expertise to maximize their visual impact.

How Do Engraved Dice Differ from Other Types?

Engraved dice feature laser-engraved designs, providing a sophisticated look that appeals to businesses seeking elegant corporate gifts or awards. These dice are durable and can withstand regular use, making them a great investment for promotional events. However, the limited color options may not suit all branding needs, and businesses should consider their target audience’s preferences when selecting this type.

What Are the Benefits of Using Digital Dice?

Digital dice are an innovative solution for educational and game development applications, allowing users to create customizable dice online. They can feature various sides and interactive elements, making them suitable for classroom engagement or game design prototyping. While their versatility and ease of use are significant advantages, the lack of a physical product may deter businesses that prioritize tangible marketing tools.

Why Choose Polyhedral Dice for Tabletop Gaming?

Polyhedral dice offer a range of shapes beyond the standard D6, appealing to tabletop gaming enthusiasts and collectors. Their customizable colors and designs can enhance the gaming experience and attract niche markets. However, the production costs for these unique designs may be higher, and businesses should evaluate their budget against the potential return on investment when considering this option.

What Makes Printable Dice a Cost-Effective Solution?

Printable dice allow users to create custom designs with text or images easily, making them an excellent choice for educational resources and DIY projects. Their accessibility and low cost make them appealing for businesses operating on tight budgets. However, buyers should be aware of the limited durability compared to manufactured dice, which may impact their long-term usability in commercial settings.

Key Industrial Applications of dice creator

| Industry/Sector | Specific Application of dice creator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Custom educational dice for interactive learning | Enhances student engagement and learning outcomes | Quality of materials, customization options, and pricing |

| Gaming & Entertainment | Unique dice for tabletop games and role-playing games | Differentiates products in a competitive market | Design flexibility, production capabilities, and lead times |

| Marketing & Promotions | Branded promotional dice for corporate events | Increases brand visibility and creates memorable marketing tools | Minimum order requirements, printing quality, and logistics |

| Event Planning | Custom dice for themed events and weddings | Provides a unique, personalized experience for attendees | Design options, production speed, and cost-effectiveness |

| Collectibles & Hobby Shops | Custom collectible dice for enthusiasts | Appeals to niche markets and enhances customer loyalty | Material variety, limited edition options, and sourcing reliability |

How Can Custom Dice Enhance Educational Experiences?

In the education sector, custom dice can be tailored for specific learning objectives, such as vocabulary building, math practice, or language skills. For instance, teachers can create dice featuring letters, numbers, or images relevant to their curriculum. This interactive tool not only promotes engagement but also addresses diverse learning styles. International buyers from regions like Africa and South America may seek affordable options that can be easily shipped and produced in small batches, ensuring accessibility for various educational settings.

What Role Do Custom Dice Play in the Gaming and Entertainment Industry?

The gaming and entertainment industry thrives on unique and personalized experiences. Custom dice can enhance tabletop games and role-playing games by providing players with unique designs that reflect their themes or characters. This customization allows game creators to stand out in a saturated market, increasing the perceived value of their products. B2B buyers in Europe and the Middle East may prioritize suppliers with quick turnaround times and robust design capabilities to meet the demands of game launches and expansions.

How Can Businesses Leverage Custom Dice for Marketing and Promotions?

In marketing, custom dice serve as innovative promotional items that can capture attention at trade shows or corporate events. By incorporating company logos or marketing messages, businesses can create memorable giveaways that resonate with their target audience. For international B2B buyers, considerations such as the ability to produce small quantities, high-quality printing, and efficient shipping options are crucial for ensuring successful promotional campaigns.

Why Are Custom Dice Valuable for Event Planning?

Event planners can utilize custom dice to create themed experiences for weddings, parties, or corporate events. Personalized dice can serve as unique table decorations or interactive games that entertain guests, enhancing the overall experience. Buyers in regions like Saudi Arabia and Vietnam may look for suppliers who offer diverse design options and can accommodate various cultural themes, ensuring that the custom dice align with their event’s aesthetic and purpose.

How Do Custom Dice Cater to Collectors and Hobby Shops?

Custom collectible dice appeal to hobbyists and collectors who seek unique items to enhance their gaming experience. By offering limited editions or artist-designed pieces, businesses can tap into niche markets and foster customer loyalty. For B2B buyers in South America and Europe, sourcing quality materials and ensuring reliability in production are key factors that can influence purchasing decisions, as these buyers often seek to build a diverse inventory that caters to passionate collectors.

3 Common User Pain Points for ‘dice creator’ & Their Solutions

Scenario 1: Navigating Customization Complexity in Dice Design

The Problem: Many B2B buyers, particularly those in the tabletop gaming industry, face the challenge of navigating the intricate process of customizing dice. Buyers may struggle with understanding the available options—such as material types, printing techniques, and design specifications. This complexity can lead to confusion, miscommunication with suppliers, and ultimately, subpar products that do not meet the envisioned requirements. For instance, a game developer might desire unique polyhedral dice with specific colors and designs but find it difficult to articulate these requirements clearly, risking delays and additional costs.

The Solution: To streamline the customization process, buyers should engage with manufacturers that offer user-friendly design interfaces or dedicated customer support. Investing time in using an online dice creator tool can help visualize the final product, allowing for real-time adjustments to colors, shapes, and designs. Additionally, establishing clear communication channels with the supplier is crucial. Buyers should prepare a detailed design brief that includes examples of desired aesthetics, materials, and functional requirements. By doing so, they can facilitate a smoother design process and ensure that the final product aligns with their vision.

Scenario 2: Overcoming Production Limitations and Minimum Order Quantities

The Problem: A frequent pain point for B2B buyers is the imposition of minimum order quantities (MOQs) by manufacturers. Many companies are hesitant to commit to large orders, especially when testing new product concepts or entering niche markets. This restriction can hinder creativity and innovation, particularly for smaller game publishers or educational institutions looking to integrate custom dice into their curriculum. The fear of overstocking unsold products can stifle the willingness to experiment with unique designs.

The Solution: Buyers should seek out dice manufacturers that offer flexible production options, including low or no minimum order quantities. This approach allows businesses to experiment with custom dice designs without the pressure of large financial commitments. Additionally, buyers can explore manufacturers that provide prototyping services, enabling them to create a small batch of dice for testing before scaling up production. Leveraging these options allows companies to gather valuable feedback, assess market demand, and make informed decisions on future orders.

Scenario 3: Ensuring Quality and Durability in Custom Dice

The Problem: Quality assurance is a significant concern for B2B buyers when sourcing custom dice. Many buyers report instances where the final products did not meet their quality expectations, leading to dissatisfaction from end-users. Issues such as fading prints, chipped edges, or substandard materials can tarnish a brand’s reputation and affect customer loyalty. This is particularly critical for businesses that depend on the perceived quality of their products to attract and retain customers.

The Solution: To mitigate quality concerns, buyers should prioritize sourcing from reputable manufacturers with a proven track record in the industry. Requesting samples before placing bulk orders can help assess the quality of materials and printing techniques firsthand. Furthermore, buyers should inquire about the manufacturer’s quality control processes, including any certifications or guarantees that ensure durability. Engaging in thorough due diligence—such as reading reviews, asking for references, and reviewing case studies—can significantly enhance the buyer’s confidence in their choice of supplier. This proactive approach not only ensures the delivery of high-quality products but also fosters long-term partnerships with trusted manufacturers.

Strategic Material Selection Guide for dice creator

What Are the Key Materials for Dice Creation in B2B Markets?

When selecting materials for dice creation, B2B buyers must consider several factors, including product performance, cost, and suitability for specific applications. Below is a detailed analysis of four common materials used in dice manufacturing, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Do Different Plastic Materials Perform in Dice Manufacturing?

Acrylic is a popular choice for custom dice due to its clarity and aesthetic appeal. It offers good impact resistance and can be easily colored or printed with custom designs. Acrylic dice are lightweight and can withstand moderate pressure, making them suitable for various gaming environments. However, they can be prone to scratching and may not perform as well under extreme temperatures.

Pros: Lightweight, customizable, good clarity.

Cons: Susceptible to scratches, limited temperature resistance.

Impact on Application: Ideal for tabletop games that require visually appealing components.

Considerations for International Buyers: Ensure compliance with local regulations regarding plastic materials, especially in markets with strict environmental standards.

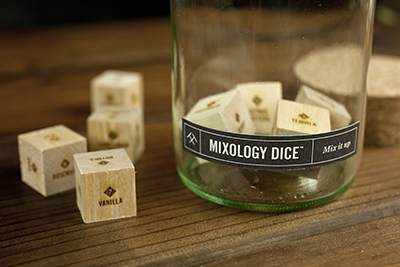

What Are the Advantages of Using Wood for Dice?

Wood offers a unique aesthetic and tactile experience that many gamers appreciate. It is durable and can be sourced sustainably, aligning with eco-friendly practices. However, wood can be more expensive than synthetic alternatives and may require additional processing to achieve a smooth finish. Temperature fluctuations can also affect wood’s integrity, leading to warping or cracking.

Pros: Eco-friendly, durable, unique appearance.

Cons: Higher cost, potential for warping, requires more manufacturing steps.

Impact on Application: Suitable for premium or collectible dice aimed at niche markets.

Considerations for International Buyers: Be aware of sourcing regulations and certifications for wood products, especially in regions prioritizing sustainable forestry.

How Do Metal Dice Compare in Terms of Performance?

Metal dice, often made from zinc alloy or aluminum, provide exceptional durability and a premium feel. They are resistant to wear and can withstand high pressure and temperature variations, making them suitable for intense gaming sessions. However, metal dice can be heavier and more expensive than their plastic or wooden counterparts.

Pros: Highly durable, premium feel, resistant to wear.

Cons: Heavier, higher cost, potential for corrosion if not properly treated.

Impact on Application: Ideal for high-end gaming products and collectors.

Considerations for International Buyers: Ensure compliance with metal content regulations and standards, particularly in regions with strict import controls.

What Role Do Resin Materials Play in Custom Dice Production?

Resin is increasingly popular for custom dice due to its versatility and ability to encapsulate various materials, such as glitter or gemstones. It allows for intricate designs and can be molded into various shapes. However, the curing process can be time-consuming, and resin can be sensitive to UV light, which may affect its longevity.

Pros: Highly customizable, allows for unique designs, good durability.

Cons: Longer production time, UV sensitivity.

Impact on Application: Excellent for bespoke or artistic dice aimed at collectors.

Considerations for International Buyers: Check local regulations regarding resin materials, especially in regions with strict chemical guidelines.

Summary Table of Material Selection for Dice Creation

| Material | Typical Use Case for dice creator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Custom gaming dice | Lightweight and customizable | Susceptible to scratches | Medium |

| Wood | Premium collectible dice | Eco-friendly and durable | Higher cost and potential warping | High |

| Metal | High-end gaming products | Highly durable and premium feel | Heavier and more expensive | High |

| Resin | Artistic and bespoke dice | Highly customizable | Longer production time | Medium |

In summary, selecting the right material for dice creation involves balancing aesthetic appeal, durability, cost, and compliance with local regulations. International B2B buyers should carefully evaluate these factors to ensure they meet market demands while adhering to industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dice creator

What Are the Main Stages of Manufacturing Custom Dice?

The manufacturing process for custom dice involves several critical stages that ensure high-quality products that meet client specifications. Understanding these stages is essential for B2B buyers looking to source custom dice effectively.

Material Preparation

The first step in the manufacturing process is material preparation. Depending on the desired type of dice, materials can include plastics (such as acrylic or resin), wood, or even metal. For instance, polyhedral dice often use high-quality acrylic for durability and aesthetic appeal. Suppliers typically source these materials from certified vendors to ensure compliance with international quality standards.

Material preparation also includes color selection and mixing. In the case of custom dice with unique designs, the colors must be accurately matched to the specifications provided by the client. This stage often involves the use of color matching technology to ensure consistency across all production runs.

Forming: How Are Custom Dice Shaped?

Once the materials are prepared, the next stage is forming. This involves shaping the raw materials into the desired dice forms. Techniques may vary based on the type of dice being produced:

-

Injection Molding: Commonly used for standard 6-sided dice and polyhedral dice, this technique involves injecting molten plastic into a mold. This method allows for high precision and the ability to produce large quantities efficiently.

-

Casting: For more intricate designs, such as those requiring custom engravings or swirls, casting techniques are often employed. This involves pouring a liquid resin into a mold where it hardens into the desired shape.

-

3D Printing: Increasingly popular for prototyping and small runs, 3D printing enables the creation of complex designs that traditional methods may struggle to replicate. This method is particularly useful for custom one-off designs or unique color patterns.

Assembly and Finishing: What Techniques Enhance Quality?

After forming, the next steps are assembly and finishing. This stage may include:

-

Polishing and Surface Treatment: To enhance the visual appeal and tactile quality of the dice, a polishing process is often employed. This may involve tumbling with abrasive materials or applying coatings to achieve a glossy finish.

-

Printing and Engraving: Custom designs, logos, or numbers are applied using high-quality printing techniques such as UV printing or pad printing. Engraving can also be used for more permanent designs, particularly with wooden or metal dice.

-

Quality Checks: Before moving on to packaging, dice undergo initial quality checks to ensure they meet the required specifications. This step is crucial for identifying defects early in the process.

What Quality Assurance Standards Should B2B Buyers Consider?

For international B2B buyers, understanding quality assurance standards is vital to ensure that the products meet both regulatory requirements and customer expectations.

Relevant International Standards

-

ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization looking to enhance customer satisfaction through consistent quality. Suppliers that hold ISO 9001 certification demonstrate a commitment to quality processes.

-

CE Marking: For dice marketed within the European Union, CE marking indicates compliance with health, safety, and environmental protection standards. This is crucial for buyers in Europe who want assurance that products meet European regulations.

-

API Standards: For specialized applications, such as dice used in educational settings or professional gaming, adherence to specific industry standards (like those set by the American Petroleum Institute for safety and quality) can be beneficial.

What Are the Key Quality Control Checkpoints in Dice Manufacturing?

Quality control (QC) is a multi-faceted approach that involves various checkpoints throughout the manufacturing process.

Incoming Quality Control (IQC)

This initial stage involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Common practices include:

- Material Certification: Ensuring materials come with the appropriate certification, confirming their quality and safety.

- Visual Inspection: Conducting visual checks for any obvious defects or inconsistencies.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC measures are in place to monitor production quality. This includes:

- Random Sampling: Regular sampling of products during production to identify defects.

- Process Monitoring: Using statistical process control (SPC) techniques to monitor key parameters during manufacturing, ensuring they remain within specified limits.

Final Quality Control (FQC)

Before packaging, a final quality check is conducted. This includes:

- Comprehensive Testing: Each batch of dice may undergo functional testing, such as rolling tests, to ensure they perform as expected.

- Dimensional Checks: Verifying that the size and shape of the dice conform to specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For buyers, verifying a supplier’s quality control processes is essential in ensuring product reliability. Here are actionable steps:

Conducting Audits

Regular audits can provide insights into a supplier’s manufacturing processes and quality control measures. Buyers should look for:

- Documentation: Suppliers should provide detailed documentation of their QC processes, including inspection reports and compliance certifications.

- Factory Visits: If possible, visiting the manufacturing facility can help buyers understand the production environment and quality control measures in place.

Requesting Quality Reports

Buyers can request periodic quality reports that detail the results of IQC, IPQC, and FQC checks. These reports should include:

- Defect Rates: Information on the percentage of products that pass or fail quality checks.

- Corrective Actions: Documentation of any corrective actions taken in response to quality issues.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. This can be particularly useful for buyers from regions like Africa and South America, where local supplier capabilities may vary widely.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of international manufacturing and quality control requires awareness of regional standards and practices. Buyers should consider:

- Cultural Differences: Be aware of how cultural differences may impact communication and expectations regarding quality.

- Regulatory Variations: Understand that regulations governing product safety and quality can vary significantly from one region to another, necessitating careful consideration of local laws.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing custom dice, ensuring they receive products that not only meet their specifications but also adhere to international quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dice creator’

Introduction

Sourcing custom dice for your business can be a complex process, especially when considering the variety of designs, materials, and functionalities available. This guide aims to streamline your procurement efforts by providing a clear, actionable checklist. By following these steps, you can ensure that you select a supplier that meets your needs while also delivering high-quality products.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly define the technical specifications for your custom dice. Consider factors such as the type of dice (e.g., D6, polyhedral), materials (plastic, wood, etc.), and any custom designs or engravings you want. A well-defined specification will help suppliers provide accurate quotes and timelines.

Step 2: Research Potential Suppliers

Take the time to research various suppliers in the market. Look for companies that specialize in custom dice production and have positive reviews. Pay attention to their experience level, product range, and any certifications that may indicate quality standards.

Step 3: Evaluate Supplier Capabilities

It’s essential to assess whether a supplier can meet your specific needs. Inquire about their production capabilities, including minimum order quantities, turnaround times, and customization options. A supplier with flexible production processes will be better equipped to handle both small and large orders.

- Customization options: Can they accommodate unique designs or logos?

- Production technology: Do they use modern techniques for quality assurance?

Step 4: Request Samples

Before making a bulk order, request samples of the dice you are interested in. This step is crucial for evaluating the quality of the product, including material durability and print fidelity. Ensure that the samples reflect the specifications you provided, as this will give you a clear picture of the final product.

Step 5: Verify Supplier Certifications

Check for relevant certifications that indicate compliance with industry standards. Certifications may include ISO quality management, safety standards, and environmental compliance. This verification not only helps ensure product quality but also reduces risks associated with sourcing.

Step 6: Understand Pricing Structures

Request detailed pricing information, including costs for different quantities and customization options. Be aware of any hidden fees such as setup costs or shipping charges. Understanding the full pricing structure will aid in budgeting and help you negotiate better terms with suppliers.

Step 7: Establish Clear Communication Channels

Once you have selected a supplier, establish clear communication channels for ongoing dialogue. This includes discussing timelines, updates on production, and any potential issues that may arise. Effective communication fosters a strong relationship, ensuring a smoother procurement process.

By following these steps, you can navigate the complexities of sourcing custom dice more efficiently, ensuring that you partner with a supplier that aligns with your business needs and expectations.

Comprehensive Cost and Pricing Analysis for dice creator Sourcing

What Are the Key Cost Components in Sourcing Custom Dice?

When sourcing custom dice, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. Common options include plastic, resin, wood, and specialty materials for premium products. High-quality materials tend to elevate the price but can enhance the perceived value of the dice.

-

Labor: Labor costs are influenced by the complexity of the design and the level of customization required. Skilled artisans may be necessary for intricate designs, which can raise labor costs.

-

Manufacturing Overhead: This includes the costs of running the production facility, such as utilities and equipment maintenance. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Tooling costs are incurred when creating molds for custom dice. These costs can vary based on the complexity and number of different designs required.

-

Quality Control (QC): Ensuring that the dice meet specified quality standards is vital. Investing in thorough QC processes may raise initial costs but can reduce returns and dissatisfaction in the long run.

-

Logistics: Shipping costs can fluctuate based on the distance, weight, and volume of the order. International buyers should factor in customs duties and taxes, which can further affect the total cost.

-

Margin: The supplier’s desired profit margin will also play a role in the final price. Understanding the market rates and competitive pricing can help in negotiations.

How Do Price Influencers Affect the Cost of Custom Dice?

Several factors can influence pricing when sourcing custom dice. Understanding these can empower buyers to make informed decisions.

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. It’s essential to assess your demand carefully to leverage pricing advantages.

-

Specs/Customization: The complexity of the design and the extent of customization directly affect pricing. Simple designs with standard features are generally more cost-effective than intricate, fully customized options.

-

Materials and Quality/Certifications: Higher-quality materials and certifications (such as safety standards) can increase costs. However, they also enhance the product’s appeal, especially in markets where quality is paramount.

-

Supplier Factors: The location and reputation of the supplier can impact costs. Suppliers in regions with lower labor costs may offer more competitive pricing, but buyers must also consider reliability and quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the cost and risk at different stages of the shipping process. This knowledge can lead to more favorable negotiations and a clearer understanding of total expenses.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

B2B buyers can optimize their sourcing process for custom dice by employing strategic approaches:

-

Negotiation: Establishing clear communication with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate on volume discounts or payment terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, handling, and potential returns. A lower initial price may lead to higher TCO if quality issues arise.

-

Pricing Nuances for International Buyers: For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding currency fluctuations and international shipping nuances is vital. Ensuring clarity on delivery times and responsibilities can prevent unexpected costs.

-

Disclaimer for Indicative Prices: Always remember that prices can vary significantly based on the aforementioned factors. Requesting quotes based on specific requirements will yield more accurate cost estimates.

By focusing on these components and influences, B2B buyers can navigate the sourcing landscape for custom dice more effectively, ensuring they make informed decisions that align with their business goals.

Alternatives Analysis: Comparing dice creator With Other Solutions

Introduction

In the realm of custom dice production, the ability to create unique and personalized dice can significantly enhance game experiences and marketing strategies. However, buyers must consider various alternatives when evaluating a dice creator. This analysis compares ‘dice creator’ with notable alternatives, including custom dice manufacturers and digital dice solutions, to help B2B buyers make informed decisions.

| Comparison Aspect | ‘Dice Creator’ | Custom Dice Manufacturer (e.g., BoardGamesMaker) | Digital Dice Tool (e.g., Gynzy) |

|---|---|---|---|

| Performance | High-quality physical dice | High-quality physical dice, customizable designs | Virtual simulation with various options |

| Cost | Varies by design complexity | Competitive pricing, no minimum order | Generally free or low-cost subscriptions |

| Ease of Implementation | User-friendly design interface | Easy online design tool, professional assistance available | Simple to integrate into lessons or games |

| Maintenance | Physical storage and care | Minimal maintenance required for durable products | No maintenance, cloud-based access |

| Best Use Case | Personalized gaming experiences | Unique marketing tools, gifts, and tabletop games | Educational tools, classroom engagement |

Detailed Breakdown of Alternatives

Custom Dice Manufacturer (e.g., BoardGamesMaker)

Custom dice manufacturers like BoardGamesMaker offer a robust solution for businesses looking to create high-quality, personalized dice. They provide a wide variety of options, including standard and polyhedral dice, with the ability to add custom designs or engravings. The primary advantage of this approach is the tangible product that enhances gaming experiences and can serve as promotional items. However, the cost can vary based on design complexity, and buyers must account for physical storage and care of the products.

Digital Dice Tool (e.g., Gynzy)

Digital dice tools like Gynzy present an innovative approach to dice usage, particularly in educational settings. These tools allow users to create customizable virtual dice that can be integrated into lessons or games. The main benefits include cost-effectiveness and ease of use, as they typically require no physical space and can be accessed from any device with internet connectivity. However, the lack of a physical product may not satisfy those looking for a tangible gaming experience, limiting their application primarily to educational contexts.

Conclusion

When choosing between ‘dice creator’ and its alternatives, B2B buyers should consider their specific needs and use cases. For businesses focused on creating physical, branded products, custom dice manufacturers provide a compelling solution. Conversely, for educational institutions or organizations seeking cost-effective, interactive tools, digital dice solutions may be more appropriate. Ultimately, the decision should align with the goals of the buyer, balancing factors such as performance, cost, and intended application.

Essential Technical Properties and Trade Terminology for dice creator

What Are the Key Technical Properties of Custom Dice in B2B Manufacturing?

When engaging with a dice creator or manufacturer, understanding the essential technical properties of custom dice is vital for making informed decisions. Here are some critical specifications:

-

Material Grade

The choice of material significantly influences the durability, aesthetics, and performance of dice. Common materials include plastic, resin, wood, and metal. Each material has its unique properties; for instance, resin offers vibrant colors and detailed designs, while wood provides a classic and premium feel. Selecting the right material grade ensures that the dice meet specific usage requirements and customer expectations. -

Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the dice. High tolerance levels are crucial for ensuring uniformity in shape and size, which directly affects gameplay and user experience. In a B2B context, specifying tolerance levels can help manufacturers deliver products that conform to industry standards, thereby reducing defects and enhancing customer satisfaction. -

Printing Method

The printing method used to apply designs on the dice can vary, including methods such as UV printing, pad printing, and laser engraving. Each method has different implications for durability, detail, and cost. Understanding the available printing techniques allows businesses to choose options that align with their branding strategies and target market preferences. -

Finish

The finish of the dice, whether matte, glossy, or textured, impacts both appearance and functionality. A glossy finish may enhance visual appeal but can affect grip, while a matte finish might be more suitable for certain gaming environments. B2B buyers should consider how the finish aligns with their branding and user experience goals. -

Imprint Area

The imprint area is the space available for custom designs, logos, or text on the dice. A larger imprint area allows for more elaborate designs, which can enhance marketing efforts. Understanding the imprint area helps businesses plan their branding and promotional strategies effectively.

What Are the Common Trade Terms Used in the Dice Manufacturing Industry?

Familiarity with industry jargon is essential for effective communication with manufacturers and suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom dice, an OEM may create dice that are then branded and sold by a game company. Understanding OEM relationships can help businesses navigate supply chain dynamics and ensure quality control. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers as it affects inventory management and cost considerations. Knowing the MOQ helps businesses plan their production runs and budget accordingly. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. In the dice manufacturing sector, submitting an RFQ allows businesses to compare pricing, terms, and conditions from different manufacturers, ensuring they make cost-effective decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping and freight transactions. Understanding these terms is essential for B2B buyers to clarify logistics, insurance, and risk management during the transportation of custom dice. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. In the context of custom dice, understanding lead times helps businesses plan their inventory and launch schedules effectively, ensuring they meet market demands without delays.

By grasping these technical properties and industry terminologies, B2B buyers can navigate the custom dice manufacturing landscape more effectively, leading to better purchasing decisions and successful partnerships.

Navigating Market Dynamics and Sourcing Trends in the dice creator Sector

What are the Current Market Dynamics and Key Trends in the Dice Creator Sector?

The global dice creator market is experiencing significant growth, driven by the increasing popularity of tabletop games and educational tools that utilize dice. This surge in demand is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where both traditional and digital gaming markets are expanding. Customization is a key trend, with businesses offering bespoke designs that cater to unique consumer preferences. Advances in technology, such as online design tools and 3D printing, are facilitating this trend, allowing buyers to create personalized products with minimal lead time.

Additionally, the rise of e-commerce platforms has transformed how international buyers source dice products. Suppliers now offer low minimum order quantities, making it easier for businesses to test markets without significant upfront investment. The integration of digital solutions in the educational sector, where customizable digital dice are used for teaching various subjects, is also gaining traction. This trend reflects a broader shift towards interactive and engaging learning experiences, driving demand for innovative dice solutions.

Moreover, as sustainability becomes a priority for many businesses, the dice creator sector is seeing an increase in eco-friendly materials and practices. Suppliers are adopting sustainable sourcing methods and promoting products made from recycled or biodegradable materials. This trend resonates well with environmentally conscious buyers, influencing purchasing decisions.

How is Sustainability and Ethical Sourcing Impacting the Dice Creator Sector?

Sustainability and ethical sourcing are becoming increasingly important in the dice creator sector. As global awareness of environmental issues rises, businesses are seeking suppliers that prioritize eco-friendly practices. This shift is particularly relevant for international buyers who aim to align their purchasing decisions with corporate social responsibility goals.

The environmental impact of traditional manufacturing processes can be significant, prompting companies to adopt greener alternatives. Suppliers are now focusing on using sustainable materials, such as recycled plastics and organic dyes, to create dice products. Additionally, many manufacturers are obtaining green certifications that validate their commitment to environmentally friendly practices, making it easier for B2B buyers to identify suitable partners.

Ethical sourcing also encompasses fair labor practices and transparency in supply chains. Buyers are increasingly seeking manufacturers that adhere to ethical labor standards, ensuring that their products are not only environmentally sustainable but also socially responsible. This focus on ethical sourcing can enhance brand reputation and foster customer loyalty, particularly among consumers who value corporate responsibility.

What is the Brief Evolution of the Dice Creator Sector Relevant to B2B Buyers?

The dice creator sector has evolved significantly over the past few decades, adapting to changes in consumer preferences and technological advancements. Initially dominated by traditional manufacturing methods, the industry has embraced digital transformation, allowing for the customization of dice through online platforms. This evolution has enabled businesses to cater to niche markets, such as educational tools and personalized gaming experiences.

The introduction of 3D printing technology has further revolutionized the sector, allowing for rapid prototyping and the production of complex designs without the constraints of conventional manufacturing. As a result, B2B buyers can now source unique and innovative dice products that align with their specific needs, enhancing their competitive advantage in the market.

Moreover, the growing interest in board games and tabletop gaming has fueled demand for custom dice, prompting suppliers to expand their offerings. This evolution has made the dice creator sector more dynamic and responsive to market trends, providing international buyers with diverse sourcing opportunities that meet their unique requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of dice creator

-

How do I ensure the quality of custom dice from a supplier?

To ensure the quality of custom dice, request samples before placing a bulk order. Evaluate the materials used, the clarity of the print, and the craftsmanship of the dice. Additionally, verify the supplier’s production processes, certifications, and previous client reviews. Establishing a clear communication channel can also help address any concerns early in the process. Finally, consider including quality assurance checks within your contract, specifying the standards your products must meet upon delivery. -

What is the best customization option for my dice?

The best customization option depends on your target audience and purpose. For marketing, consider dice featuring your logo or brand colors, which enhance brand visibility. If creating gaming products, think about unique designs or functional aspects, like engraved numbers or symbols for better usability. Collaborate with your supplier to understand the full range of options available, including color swirls, materials, and shapes, to create dice that resonate with your customers. -

What are the typical minimum order quantities (MOQs) for custom dice?

MOQs for custom dice can vary significantly based on the supplier and the complexity of your design. Some suppliers offer no minimum order, while others may require a minimum of 50 or 100 units. It’s important to discuss your specific needs with potential suppliers to find one that aligns with your production goals. Smaller orders may come at a higher unit cost, so weigh your budget against your needs for flexibility and inventory management. -

How do I vet a supplier for international dice production?

Vetting a supplier involves several steps. Start by checking their business credentials, including years in operation, industry certifications, and client testimonials. Request case studies or examples of previous work to assess quality. Additionally, consider visiting the facility if possible or conducting virtual tours. Finally, verify their shipping capabilities and understand their terms of service, including return policies and warranties, to ensure they can meet your international trade requirements. -

What payment terms should I expect when ordering custom dice?

Payment terms can vary by supplier but typically include options like upfront payment, a deposit with the balance due upon delivery, or net payment terms (e.g., net 30 or net 60 days). Be sure to clarify these terms before finalizing your order. Additionally, inquire about payment methods accepted, such as wire transfers, credit cards, or letters of credit, especially for international transactions, to ensure secure and efficient processing. -

How can I manage logistics for international shipments of custom dice?

Managing logistics involves coordinating with your supplier and freight forwarder to ensure timely delivery. Discuss shipping options early in the process, including express vs. standard shipping, and understand customs regulations in your country. Maintain clear communication with your supplier about timelines and any potential delays. Additionally, consider using a logistics partner who specializes in international trade to streamline the process and mitigate risks related to customs clearance. -

What are the common uses for custom dice in B2B settings?

Custom dice are versatile and can be used for various purposes in B2B settings. They are popular in promotional campaigns, serving as unique giveaways that enhance brand recognition. Additionally, custom dice are essential in the gaming industry for board games and tabletop games, providing a fun and engaging element. Businesses also use them in educational tools or as part of interactive training materials, making them a valuable asset across different sectors. -

How do I handle disputes or issues with my custom dice order?

To handle disputes effectively, maintain open communication with your supplier throughout the production process. If issues arise, document all correspondence and gather evidence of the problem, such as photos of defective products. Refer to your contract for resolution procedures, including warranty claims or return policies. If necessary, escalate the issue to a higher management level within the supplier’s organization. For international orders, consider involving a third-party mediator if disputes cannot be resolved amicably.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Dice Creator Manufacturers & Suppliers List

1. Board Games Maker – Custom Dice

Domain: boardgamesmaker.com

Registered: 2013 (12 years)

Introduction: Custom Dice with your own design available in various types including D6, Polyhedral (D4, D8, D10, D12, D20), and Engraved Dice. Full color printing and laser engraving options are offered with no minimum order requirement. Standard dice available in multiple colors and materials such as wood and plastic. Custom dice can be designed for board games, personal gifts, weddings, and marketing events. …

2. Gynzy – Digital Dice Tool

Domain: gynzy.com

Registered: 2007 (18 years)

Introduction: Digital Dice is a customizable dice tool with unlimited applications, allowing users to choose between standard 6-sided dice, dice with numbers, and dice with up to 20 sides. It can display colors and can be customized by adding individual letters, words, or nonsense words with CVC patterns. Users can facilitate games, practice addition by rolling multiple dice and checking answers with a calculat…

3. Tools for Educators – Custom Dice Maker

Domain: toolsforeducators.com

Registered: 2008 (17 years)

Introduction: Printable dice maker from Tools for Educators allows users to create custom dice with pictures, text, or both. Users can make dice with just text or select an image category. Suggested uses include communication exercises, vocabulary practice, sentence construction, phonics activities, math practice, and conversation starters. The resource is free for end users, but redistribution, modification, o…

4. Inner Drive Studios – Dice (Creator) Pack

Domain: assetstore.unity.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Dice (Creator) Pack”, “category”: “3D Props”, “publisher”: “Inner Drive Studios”, “price”: “$5”, “file_size”: “217.3 MB”, “latest_version”: “1.2”, “latest_release_date”: “Jan 24, 2019”, “original_unity_version”: “5.6.6”, “license_type”: “Single Entity”, “refund_policy”: “Covered by the Unity Refund Policy”, “customer_rating”: “Rated by 85,000+ customers”, “community_support”: “Su…

5. DND DICE – Customizable Dice Sets

Domain: dnddice.com

Registered: 2009 (16 years)

Introduction: This company, DND DICE – Customizable Dice Sets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Kraken Dice – Resin & Specialty Dice Sets

Domain: krakendice.com

Registered: 2017 (8 years)

Introduction: New Kraken Dice, Resin Dice, 14pc Dice Sets, Kraken Sharp Edge Dice, Color Changing Glitter Dice, Glow In The Dark Dice, Inclusion Dice Sets, Limited Edition Collector Sets, Matte Finish Dice Sets, Spindown D20’s, Acrylic Dice, Kraken Signature’s Dice Sets, 10mm Mini Dice Sets, Gummi Candies, Liquid Core, PRAWject Dice Sets, Primeval by Alchemy Dice Co, Raw Sets, Oversized D20’s (30mm, 34mm, 40mm,…

Strategic Sourcing Conclusion and Outlook for dice creator

What Are the Key Insights for B2B Buyers in the Dice Creation Market?

In conclusion, strategic sourcing in the dice creation market presents significant opportunities for international B2B buyers. Custom dice not only enhance the gaming experience but also serve as unique marketing tools, allowing businesses to differentiate their offerings. The ability to order in small quantities with no minimums encourages innovation and flexibility, making it easier for companies to test new designs and concepts without substantial financial risk.

As the demand for personalized gaming experiences grows, suppliers who leverage advanced manufacturing technologies and customizable options will be at the forefront of this evolving market. Buyers from regions such as Africa, South America, the Middle East, and Europe should consider establishing partnerships with manufacturers that prioritize quality and offer comprehensive design support.

How Can You Prepare for the Future of Custom Dice?

Looking ahead, B2B buyers are encouraged to explore collaborations with manufacturers that demonstrate a commitment to sustainability and ethical sourcing. By doing so, you will not only enhance your product offerings but also align with the growing consumer demand for responsible business practices. Engage with suppliers today to unlock the potential of custom dice and position your business for success in this vibrant marketplace.