Introduction: Navigating the Global Market for desktop 5 axis cnc milling machine

In an increasingly competitive landscape, sourcing a desktop 5-axis CNC milling machine presents a unique set of challenges for international B2B buyers. Companies in regions such as Africa, South America, the Middle East, and Europe are seeking high-precision, versatile machinery to streamline their production processes and enhance product quality. This guide aims to illuminate the complexities of selecting the right machine, from understanding various types and applications to navigating supplier vetting and associated costs.

The comprehensive scope of this guide covers essential aspects including detailed specifications of popular models, key features that enhance usability, and insights into operational efficiencies. Additionally, it provides strategies for evaluating potential suppliers, ensuring compliance with international trade regulations, and understanding the nuances of financing options available to businesses in diverse markets. By addressing these critical areas, this guide empowers buyers to make informed purchasing decisions that align with their operational needs and strategic goals.

Equipped with actionable insights and expert recommendations, B2B buyers will be better positioned to identify the ideal desktop 5-axis CNC milling machine that not only meets their technical specifications but also contributes to long-term business growth. Whether you are a startup looking to prototype rapidly or an established manufacturer aiming to refine production capabilities, this guide serves as an indispensable resource for navigating the global market effectively.

Understanding desktop 5 axis cnc milling machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pocket NC V2-10 | Compact design, full 5-axis simultaneous motion, G-code compatible | Prototyping, education, small-scale production | Pros: Affordable, user-friendly, versatile. Cons: Limited travel space, requires CAM software. |

| Omio X8-220 | High rigidity, large working area, capable of 3+2 machining | Aerospace, automotive, custom tooling | Pros: Larger work area, robust construction. Cons: Higher initial investment, heavier weight. |

| Tormach 1100MX | Integrated tooling, high-speed spindle, user-friendly software | R&D, small batch manufacturing | Pros: Great for low-volume production, extensive support. Cons: Pricey, may need additional tooling. |

| Sienci Mill One | Open-source design, affordable entry-level option | Hobbyist projects, educational institutions | Pros: Cost-effective, easy to modify. Cons: Limited capabilities, less precision for industrial applications. |

| Bantam Tools Desktop | High precision, easy to set up, ideal for small parts | Electronics, jewelry, prototyping | Pros: High accuracy, compact footprint. Cons: Limited material compatibility, smaller build volume. |

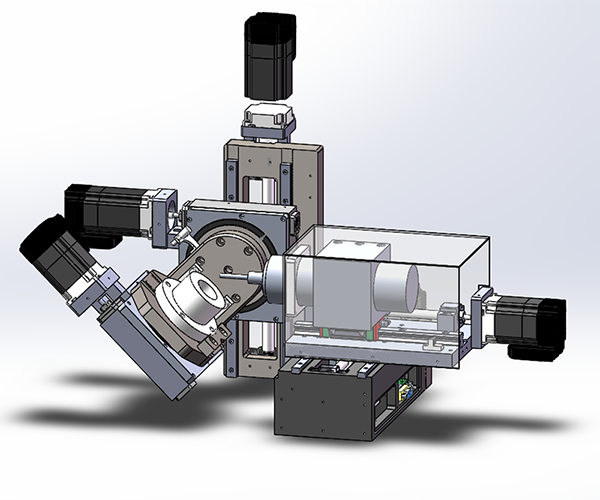

What are the key characteristics of the Pocket NC V2-10?

The Pocket NC V2-10 stands out for its compact design and full 5-axis simultaneous motion, making it ideal for prototyping and educational purposes. With the ability to handle materials up to G5 titanium hardness, it caters to a variety of applications in small-scale production. B2B buyers should consider its affordability and versatility, though its limited travel space might restrict larger projects. Additionally, it requires CAM software for operation, which can be a consideration for budget-conscious businesses.

How does the Omio X8-220 cater to larger projects?

The Omio X8-220 is characterized by its high rigidity and larger working area, making it suitable for industries like aerospace and automotive. This machine supports 3+2 machining, offering more flexibility in design. For B2B buyers, its robust construction allows for higher precision and durability in manufacturing custom tooling. However, the initial investment is higher compared to other desktop CNC mills, which may deter smaller businesses or startups.

What makes the Tormach 1100MX a popular choice for R&D?

The Tormach 1100MX features an integrated tooling system and a high-speed spindle, making it user-friendly for research and development as well as small batch manufacturing. Its extensive customer support is a significant advantage for companies new to CNC machining. While it provides excellent low-volume production capabilities, the price point may be a barrier for some businesses looking to invest in multiple machines.

Who benefits most from the Sienci Mill One?

The Sienci Mill One is an open-source design that appeals to hobbyists and educational institutions due to its affordability and ease of modification. While it offers a cost-effective solution for smaller projects, its limited capabilities and precision may not meet the demands of industrial applications. B2B buyers should assess whether the trade-offs in performance align with their project requirements.

Why is the Bantam Tools Desktop ideal for precision applications?

The Bantam Tools Desktop CNC mill is known for its high precision and ease of setup, making it ideal for small parts in electronics and jewelry. Its compact footprint allows it to fit in limited spaces, appealing to businesses with restricted work environments. However, buyers should note its limited material compatibility and smaller build volume, which might constrain more extensive manufacturing processes.

Key Industrial Applications of desktop 5 axis cnc milling machine

| Industry/Sector | Specific Application of desktop 5 axis cnc milling machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of complex components like brackets and housings | Enhanced precision leads to improved safety and performance | Compliance with stringent aerospace standards and regulations |

| Automotive | Prototyping and production of custom parts and tooling | Reduced lead times and costs for specialized components | Material compatibility and ability to handle various hardnesses |

| Medical Devices | Creating intricate implants and surgical instruments | High precision and reduced risk of failure in critical devices | Certification for biocompatibility and regulatory compliance |

| Education & Training | Hands-on training for students in machining and engineering | Equips future engineers with practical skills | Availability of training programs and support for educational institutions |

| Electronics | Fabrication of custom enclosures and circuit boards | Flexibility in design iterations and rapid prototyping | Compatibility with various electronic components and materials |

How is the Desktop 5 Axis CNC Milling Machine Used in Aerospace Applications?

In the aerospace sector, desktop 5-axis CNC milling machines are utilized to manufacture complex components, such as brackets and housings, that require high precision and intricate geometries. These machines enable manufacturers to produce parts that not only meet stringent safety standards but also improve overall aircraft performance. For international buyers, particularly in regions like Africa and South America, sourcing a machine that complies with aerospace regulations is crucial to ensure market acceptance and safety.

What Are the Benefits of Using Desktop CNC Milling Machines in Automotive Prototyping?

Automotive manufacturers leverage desktop 5-axis CNC milling machines for rapid prototyping and the production of custom parts and tooling. This capability significantly reduces lead times and costs associated with specialized components, facilitating faster time-to-market for new vehicle models. Buyers from emerging markets should consider machines that can handle various materials and hardness levels, ensuring compatibility with the diverse range of automotive applications.

How Do Medical Device Manufacturers Benefit from Desktop CNC Milling?

In the medical device industry, desktop 5-axis CNC milling machines are essential for creating intricate implants and surgical instruments. The high precision offered by these machines minimizes the risk of failure in critical medical applications, which is paramount for patient safety. Buyers in this sector must ensure that the machines meet certification for biocompatibility and adhere to regulatory compliance standards, especially when exporting to regions with strict medical device regulations.

Why Are Desktop CNC Milling Machines Important for Education and Training?

Educational institutions utilize desktop 5-axis CNC milling machines to provide hands-on training for students in machining and engineering fields. This exposure equips future engineers with practical skills that are highly valued in the job market. For international buyers, particularly in Europe and the Middle East, sourcing machines that come with comprehensive training programs and support can enhance the learning experience and ensure successful implementation in educational curricula.

What Role Do Desktop CNC Machines Play in Electronics Manufacturing?

In the electronics sector, desktop 5-axis CNC milling machines are used for fabricating custom enclosures and circuit boards. Their flexibility allows for rapid design iterations and prototyping, which is essential in a fast-paced industry. Buyers should prioritize machines that are compatible with various electronic components and materials, ensuring the ability to adapt to changing design requirements and technological advancements.

3 Common User Pain Points for ‘desktop 5 axis cnc milling machine’ & Their Solutions

Scenario 1: Navigating the Complexity of Setup and Operation

The Problem: One of the most significant challenges for B2B buyers of desktop 5-axis CNC milling machines is the complexity involved in the setup and operation of these advanced machines. New users often find the software and hardware integration intimidating, leading to frustration and potential errors in machining processes. This complexity can cause delays in production and increase the risk of costly mistakes, especially for companies aiming to streamline prototyping and manufacturing.

The Solution: To address this issue, companies should prioritize training and support during the purchasing process. When sourcing a desktop 5-axis CNC milling machine, inquire about the availability of comprehensive training programs or customer support services. Many manufacturers offer hands-on training sessions, online tutorials, and extensive documentation that can demystify the operation of these machines. Additionally, leveraging simulation software like the Pocket NC Simulator can allow users to practice and refine their skills before engaging in actual machining tasks. This proactive approach to learning not only boosts user confidence but also enhances operational efficiency, reducing the likelihood of errors in production.

Scenario 2: Material Compatibility and Machining Limitations

The Problem: B2B buyers often face challenges related to material compatibility when using desktop 5-axis CNC milling machines. While these machines are versatile, they may have limitations regarding the types of materials that can be effectively machined. This can lead to dissatisfaction if the machine cannot handle specific materials required for production, such as high-hardness metals or composite materials. Buyers may find themselves needing to invest in additional equipment to meet their diverse machining needs.

The Solution: To overcome this pain point, it is crucial for buyers to conduct thorough research on the machine’s specifications before purchasing. Understanding the material capabilities of the desktop CNC milling machine—such as the maximum hardness it can handle and the optimal materials for machining—will help buyers make informed decisions. Additionally, seeking machines that allow for customizable tooling can expand material handling capabilities. Engaging with manufacturers to discuss specific machining needs can also lead to tailored solutions, ensuring that the chosen machine aligns with the production requirements of the business.

Scenario 3: Cost Management and Return on Investment (ROI)

The Problem: Another common pain point for B2B buyers is managing the costs associated with purchasing and maintaining a desktop 5-axis CNC milling machine. The initial investment can be substantial, and companies often struggle to justify this expenditure without a clear understanding of the expected ROI. Concerns about ongoing operational costs, such as maintenance, tooling, and software updates, can further complicate the purchasing decision.

The Solution: To effectively manage costs and maximize ROI, buyers should engage in a comprehensive cost-benefit analysis before making a purchase. This analysis should include not only the upfront costs of the machine but also the potential savings from reduced production time and material waste. Buyers can also explore financing options provided by manufacturers, which can ease the burden of initial costs. Additionally, investing in machines that feature lower maintenance requirements and offer long-term warranties can further enhance the value proposition. Regular training for staff on optimal machine use and maintenance can also help minimize operational costs, ensuring the machine is running at peak efficiency and maximizing its contribution to the business’s bottom line.

Strategic Material Selection Guide for desktop 5 axis cnc milling machine

What Are the Key Properties of Common Materials for Desktop 5 Axis CNC Milling Machines?

When selecting materials for use in desktop 5-axis CNC milling machines, it’s essential to consider their properties and how they align with the intended applications. Here are analyses of four common materials:

1. Aluminum: A Versatile Choice for Precision Machining

Key Properties: Aluminum is lightweight, with excellent machinability and corrosion resistance. It has a melting point of around 660°C and can withstand moderate temperatures without significant deformation.

Pros & Cons: The durability of aluminum makes it suitable for a wide range of applications, from prototyping to final products. It is relatively low-cost compared to other metals, which is advantageous for startups and small businesses. However, its softness can lead to wear on cutting tools, increasing manufacturing complexity over time.

Impact on Application: Aluminum is often used in aerospace, automotive, and consumer product applications. Its compatibility with various media makes it a preferred choice for parts that require both aesthetic appeal and functional integrity.

International Considerations: Buyers from regions like Africa and South America should be aware of local suppliers and standards (e.g., ASTM B221 for aluminum extrusions). Understanding local import regulations can also help mitigate delays.

2. Delrin (Acetal): Ideal for High-Precision Applications

Key Properties: Delrin is a thermoplastic with high tensile strength and rigidity, along with low friction properties. It operates effectively in a temperature range of -40°C to 80°C and exhibits excellent chemical resistance.

Pros & Cons: The key advantage of Delrin is its ability to produce high-precision parts with a smooth finish. However, it can be more expensive than aluminum and may require specialized tooling, complicating the manufacturing process.

Impact on Application: Delrin is commonly used in applications requiring low wear, such as gears, bearings, and bushings. Its compatibility with various chemicals makes it suitable for automotive and industrial applications.

International Considerations: B2B buyers should ensure that Delrin complies with international standards like ASTM D6100. Awareness of local material availability and pricing can impact sourcing decisions.

3. G5 Titanium: A Premium Material for Specialized Applications

Key Properties: G5 titanium is known for its high strength-to-weight ratio and corrosion resistance. It can withstand extreme temperatures and has a melting point of approximately 1,668°C, making it suitable for high-performance applications.

Pros & Cons: The primary advantage of G5 titanium is its durability and lightweight nature, making it ideal for aerospace and medical applications. However, its high cost and the complexity of machining it can be significant drawbacks, limiting its use to specialized projects.

Impact on Application: G5 titanium is often used in critical components where performance and reliability are paramount. Its biocompatibility makes it suitable for medical devices.

International Considerations: Buyers should be aware of compliance with ASTM F136 for titanium used in medical applications. Understanding export regulations is crucial, especially for buyers in regions with stringent import controls.

4. Mild Steel: A Cost-Effective Option for General Use

Key Properties: Mild steel is characterized by its ductility and weldability, with a melting point around 1,370°C. It has moderate corrosion resistance but can be treated for enhanced durability.

Pros & Cons: The low cost of mild steel makes it a popular choice for prototypes and less critical applications. However, its susceptibility to rust and lower strength compared to other metals can be a limitation in demanding environments.

Impact on Application: Mild steel is widely used in construction, automotive, and general manufacturing. Its versatility allows for a broad range of applications, though it may not be suitable for high-performance components.

International Considerations: B2B buyers should consider compliance with standards like ASTM A36. Understanding local market conditions and material availability is vital for effective sourcing.

Summary Table of Material Selection

| Material | Typical Use Case for desktop 5 axis cnc milling machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace, automotive, consumer products | Lightweight and corrosion-resistant | Softness can lead to tool wear | Medium |

| Delrin (Acetal) | Gears, bearings, industrial components | High precision and low friction | Higher cost and specialized tooling | High |

| G5 Titanium | Aerospace, medical devices | High strength-to-weight ratio | Expensive and complex to machine | High |

| Mild Steel | Prototypes, general manufacturing | Cost-effective and versatile | Lower strength and rust susceptibility | Low |

This strategic material selection guide provides actionable insights for international B2B buyers considering desktop 5-axis CNC milling machines. Understanding the properties, advantages, and limitations of each material can significantly enhance decision-making processes and ensure optimal application outcomes.

In-depth Look: Manufacturing Processes and Quality Assurance for desktop 5 axis cnc milling machine

What Are the Key Manufacturing Processes for Desktop 5 Axis CNC Milling Machines?

Understanding the manufacturing processes of desktop 5-axis CNC milling machines is critical for B2B buyers looking to invest in these advanced tools. The production of such machines involves several stages, each crucial for ensuring precision and quality.

How is Material Prepared for CNC Milling Machines?

The manufacturing process begins with material preparation, which involves selecting high-quality raw materials. Common materials for desktop CNC milling machines include aluminum, Delrin, and softer steels, with some models capable of handling harder materials like G5 titanium.

The raw materials are typically sourced from reputable suppliers to ensure consistency in quality. Before machining, materials undergo a rigorous quality check to confirm they meet specifications. This step may include dimensional inspections and material property assessments, ensuring that only the best materials proceed to the next phase.

What Techniques Are Used in the Forming Stage?

Once materials are prepared, the forming stage begins. This process primarily involves precision machining, where CNC machines cut and shape the material to the desired specifications.

Key techniques during this phase include:

- CNC Milling: Using rotary cutters to remove material, CNC milling allows for complex geometries to be achieved.

- 5-Axis Machining: This advanced technique enables simultaneous movement along multiple axes, offering unparalleled precision and flexibility in design.

- Tool Path Optimization: Advanced software is utilized to create efficient tool paths that minimize machining time while maximizing accuracy.

Each technique is implemented with strict adherence to engineering drawings and specifications, ensuring that the final product meets quality expectations.

What Does the Assembly Process Involve?

The assembly of desktop CNC milling machines is a meticulous process that combines various components into a cohesive unit. This stage typically involves the integration of:

- Mechanical Components: These include the frame, linear guides, motors, and spindles, which must be assembled with high precision to ensure proper alignment and functionality.

- Electrical Systems: Wiring, control systems, and software interfaces are installed to provide the necessary functionality for the machine.

- Calibration: After assembly, machines undergo calibration to ensure that all movements are accurate and within specified tolerances. This step is critical for maintaining performance and reliability.

A dedicated team of engineers and technicians typically oversees the assembly process to ensure every machine is built to the highest standards.

How is Finishing Achieved in Desktop CNC Milling Machines?

Finishing is the final stage in the manufacturing process, focusing on enhancing the aesthetic and functional aspects of the machine. This may include surface treatments such as anodizing, powder coating, or polishing to improve durability and appearance.

Additionally, during this phase, final inspections are conducted to ensure that all components are functioning correctly and that the machine meets all operational standards before shipping.

What Quality Assurance Measures Are Implemented?

Quality assurance is vital in the manufacturing of desktop 5-axis CNC milling machines, ensuring that the final products meet both international and industry-specific standards.

Which International Standards Are Relevant for Quality Assurance?

B2B buyers should be aware of various international standards, such as:

- ISO 9001: This standard focuses on quality management systems and is crucial for companies aiming to ensure consistent quality in their products and services.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For machines that might be used in the oil and gas sector, API standards ensure that equipment meets specific performance and safety criteria.

These certifications not only enhance product credibility but also assure buyers of the quality and reliability of their investments.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria before being used in production.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the machining process, ensuring that each stage adheres to quality standards.

- Final Quality Control (FQC): Once assembly and finishing are complete, the entire machine undergoes a thorough inspection to verify that it meets all specifications and performance standards.

What Testing Methods Are Commonly Used?

Several testing methods are utilized to confirm the quality and functionality of desktop 5-axis CNC milling machines:

- Dimensional Inspection: Utilizing precision measuring tools to ensure that the machine components meet specified dimensions.

- Functional Testing: Operating the machine to verify that all features, including motion and control systems, perform as expected.

- Material Testing: Assessing the physical properties of materials used in the machine to confirm they meet required standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to ensure that their suppliers adhere to stringent quality control measures. Here are some strategies:

- Conducting Supplier Audits: Regular audits of suppliers can provide insight into their manufacturing processes, quality control measures, and adherence to industry standards.

- Requesting Quality Reports: Suppliers should be able to provide documentation of their quality assurance practices, including inspection reports and certifications.

- Utilizing Third-Party Inspection Services: Engaging independent inspectors can provide an unbiased evaluation of the supplier’s quality assurance processes and the final product.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

- Regulatory Compliance: Buyers should familiarize themselves with local regulations and standards that may differ from international norms. This knowledge can help in negotiating terms and ensuring compliance upon importation.

- Cultural Differences in Quality Expectations: Different regions may have varying expectations regarding quality and performance. Understanding these differences can aid in selecting the right supplier.

- Logistical Considerations: International shipping and customs can introduce additional complexities. Ensuring that suppliers maintain quality standards throughout the supply chain is vital to prevent issues upon delivery.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for desktop 5-axis CNC milling machines is crucial for B2B buyers. By focusing on these elements, businesses can make informed decisions that will contribute to their operational success and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘desktop 5 axis cnc milling machine’

When sourcing a desktop 5-axis CNC milling machine, a systematic approach is essential to ensure that you select a machine that meets your operational needs and business goals. This guide provides a step-by-step checklist to help B2B buyers navigate the complexities of procurement, ensuring a successful purchase.

Step 1: Define Your Technical Specifications

Understanding your specific machining requirements is the first step in the sourcing process. This includes determining the types of materials you will be working with, such as aluminum or softer steels, and the desired precision and speed of machining.

– Considerations:

– Maximum material hardness (e.g., G5 titanium vs. softer materials).

– Travel dimensions for the X, Y, and Z axes to accommodate your projects.

Step 2: Research Potential Suppliers

Investigating various suppliers is crucial for making an informed decision. Start by compiling a list of manufacturers that specialize in desktop 5-axis CNC machines.

– What to look for:

– Reputation in the industry and customer reviews.

– Experience with international shipping, especially to your region (e.g., Africa, South America, Middle East, Europe).

Step 3: Evaluate Supplier Certifications

Ensure that your potential suppliers possess the necessary certifications and compliance with international standards. This is particularly important for machinery that may be subject to export regulations.

– Key certifications to verify:

– ISO certifications demonstrating quality management.

– Compliance with local and international safety standards.

Step 4: Request Detailed Product Information

Before making a commitment, request comprehensive product specifications and user manuals. This will provide insight into the machine’s capabilities and operational requirements.

– Specific details to ask for:

– Technical specifications including spindle speed, tool holder types, and software compatibility.

– Warranty information and after-sales support options.

Step 5: Assess Shipping and Lead Times

Understanding the logistics involved in the procurement process is critical. Verify the lead times for manufacturing and shipping, as these can significantly impact your project timeline.

– Important factors:

– Timeframes for standard orders versus custom configurations.

– Potential delays due to export licenses or regional regulations.

Step 6: Inquire About After-Sales Support and Training

Post-purchase support is vital for the successful operation of your CNC milling machine. Ensure that the supplier offers adequate training and ongoing technical support.

– Support services to consider:

– Access to remote service subscriptions and maintenance contracts.

– Availability of training sessions for your team to maximize the machine’s capabilities.

Step 7: Evaluate Payment Terms and Financing Options

Finally, consider the financial aspects of your purchase. Different suppliers may offer various payment terms and financing options, which can influence your cash flow and budgeting.

– Key considerations:

– Availability of financing for business customers, particularly for startups.

– Payment methods accepted, including credit terms or installment plans.

By following this structured checklist, B2B buyers can make a well-informed decision when procuring a desktop 5-axis CNC milling machine, ensuring that it aligns with their operational needs and strategic objectives.

Comprehensive Cost and Pricing Analysis for desktop 5 axis cnc milling machine Sourcing

What Are the Key Cost Components in Sourcing Desktop 5-Axis CNC Milling Machines?

When sourcing desktop 5-axis CNC milling machines, understanding the cost structure is crucial for B2B buyers, particularly in international markets. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. High-quality metals such as aluminum, delrin, and titanium (up to G5 hardness) may result in higher upfront costs. Suppliers often source these materials from specific regions, which can influence prices based on local market conditions.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality. It’s essential to assess the skill level and experience of the workforce involved in production.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Manufacturers in developed regions may have higher overhead costs, which could reflect in their pricing.

-

Tooling: The initial investment in tooling can be substantial. Custom tooling for specific projects will increase costs, while standardized tooling may help to keep expenses down. Buyers should consider whether the tooling will be reusable for future projects.

-

Quality Control (QC): Implementing rigorous quality control measures can add to costs but is essential for ensuring product reliability. Buyers should inquire about the QC processes employed by suppliers to guarantee the quality of the machines.

-

Logistics: Shipping costs are a significant factor, particularly for international buyers. The cost of freight can vary based on the shipping method, distance, and any tariffs or duties imposed on imports.

-

Margin: Suppliers typically apply a margin to cover their costs and ensure profitability. This margin can fluctuate based on market competition and demand.

How Do Pricing Influencers Affect the Cost of Desktop 5-Axis CNC Milling Machines?

Several factors can influence the pricing of desktop 5-axis CNC milling machines:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Buyers should negotiate minimum order quantities (MOQs) that align with their operational needs.

-

Specifications and Customization: Customized machines tailored to specific applications will generally command higher prices. Buyers need to balance their requirements with budget constraints.

-

Materials and Quality Certifications: Machines made from high-grade materials and those that meet international quality standards (e.g., ISO certifications) will typically have a higher price point. Buyers should verify certifications to ensure compliance with their local regulations.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a proven track record may charge more due to their perceived quality and service.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly influence the total landed cost.

What Are the Best Tips for Negotiating Prices on Desktop 5-Axis CNC Milling Machines?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can benefit from the following negotiation tips:

-

Leverage Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including maintenance, operational expenses, and potential downtime. Presenting a TCO analysis can strengthen your negotiation position.

-

Be Prepared to Walk Away: Establish a clear budget and be willing to explore other suppliers if your terms are not met. This approach can often lead to better offers from reluctant sellers.

-

Build Relationships with Suppliers: Developing long-term relationships can lead to better pricing and terms. Frequent communication and trust can yield discounts or more favorable payment terms.

-

Research Market Prices: Understanding the market rates for desktop 5-axis CNC milling machines helps in negotiating effectively. Use industry reports or competitor pricing as benchmarks.

-

Consider Local Support and Service: Suppliers offering local support may charge a premium, but the value added through service and maintenance can justify the cost.

Disclaimer on Indicative Prices

Prices for desktop 5-axis CNC milling machines can vary significantly based on the aforementioned factors. Buyers are encouraged to obtain multiple quotes and conduct thorough due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing desktop 5 axis cnc milling machine With Other Solutions

Understanding Alternatives to Desktop 5 Axis CNC Milling Machines

In the realm of precision machining, desktop 5 axis CNC milling machines offer unique capabilities, particularly for small-scale operations and prototyping. However, several alternative solutions exist that can serve similar purposes, each with distinct advantages and disadvantages. This analysis provides an overview of the key alternatives to desktop 5 axis CNC milling machines, enabling B2B buyers to make informed decisions based on their specific requirements.

| Comparison Aspect | Desktop 5 Axis CNC Milling Machine | Alternative 1 Name: 3D Printer | Alternative 2 Name: Conventional CNC Milling Machine |

|---|---|---|---|

| Performance | High precision for complex geometries | Good for prototyping and simple parts | Excellent for large-scale production and heavy materials |

| Cost | Moderate ($6,900) | Low to moderate ($200 – $5,000) | High ($20,000+) |

| Ease of Implementation | Requires some setup and training | User-friendly, minimal setup | Complex, often requires skilled operators |

| Maintenance | Moderate, regular calibration needed | Low, minimal maintenance required | High, regular upkeep and skilled maintenance needed |

| Best Use Case | Prototyping, educational purposes | Rapid prototyping, low-volume production | Mass production, heavy-duty machining |

Analyzing Alternatives: Pros and Cons

3D Printer

3D printing technology has gained popularity for its ability to produce prototypes quickly and cost-effectively. It excels in creating complex shapes and geometries that would be challenging to achieve with traditional machining. However, 3D printers typically have limitations regarding material strength and surface finish, making them less suitable for functional parts that need to endure high stress or wear. The initial investment can be relatively low, but ongoing costs for filament and maintenance should be considered.

Conventional CNC Milling Machine

Conventional CNC milling machines are well-established in the manufacturing industry for their ability to handle large volumes and tough materials. They offer superior performance for mass production and can machine a wide range of materials with high precision. However, the cost of these machines is significantly higher than desktop models, and they often require skilled operators for setup and maintenance. They are best suited for companies with high production demands and the capability to manage complex machining processes.

Making the Right Choice for Your Business

When selecting the appropriate machining solution, B2B buyers should consider several factors, including production volume, material types, and the complexity of the parts being manufactured. For startups or educational institutions focused on prototyping, a desktop 5 axis CNC milling machine may provide the ideal balance of cost and capability. Conversely, businesses aiming for high-volume production with diverse material requirements might find conventional CNC milling machines to be a more suitable investment. Meanwhile, for rapid prototyping needs with less stringent material requirements, a 3D printer could serve as an effective and budget-friendly alternative. Understanding these alternatives and their respective strengths can empower buyers to choose the best solution tailored to their operational needs.

Essential Technical Properties and Trade Terminology for desktop 5 axis cnc milling machine

When considering the purchase of a desktop 5-axis CNC milling machine, understanding its technical properties and trade terminology is crucial for making informed decisions. This section outlines key specifications and industry terms that are vital for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Technical Properties of a Desktop 5-Axis CNC Milling Machine?

-

Material Compatibility

The ability of a CNC milling machine to work with various materials is fundamental. For instance, machines like the Pocket NC V2-10 can cut materials with hardnesses up to G5 Titanium, but they are optimized for softer materials like Delrin and aluminum. Understanding material compatibility is essential for buyers to ensure the machine meets their production requirements and can handle the specific materials they intend to use. -

Travel Range

The travel range refers to the maximum movement of the machine’s cutting tool across the X, Y, and Z axes. For example, the Pocket NC V2-10 has a travel range of 5.0 inches (Y), 4.55 inches (X), and 3.55 inches (Z). A larger travel range can increase the versatility of the machine, allowing for the machining of larger or more complex components, which is particularly beneficial for companies looking to scale their operations. -

Precision and Tolerance

Precision is the degree to which a machine can reproduce a specific measurement. Tolerance refers to the allowable variation in that measurement. High precision and tight tolerances are critical in industries such as aerospace and medical device manufacturing, where even minor deviations can lead to significant issues. Buyers must assess the machine’s specifications to ensure it meets their quality standards. -

Control Software

The software used to operate the CNC machine, such as Kinetic Control, significantly impacts usability and efficiency. Advanced software can support features like tool point control center (TCPC), enhancing programming intuitiveness and precision. Understanding the software capabilities is vital for buyers, as it influences the learning curve, operational efficiency, and overall productivity of the machine. -

Export Compliance

Export compliance is essential for international buyers, especially when purchasing from manufacturers in countries like the USA. Machines such as the Pocket NC are subject to regulations that restrict sales to authorized end-users and countries. Buyers should familiarize themselves with these regulations to avoid legal issues and ensure smooth transactions.

What Are Common Trade Terms Related to Desktop CNC Milling Machines?

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source machines or components, as it influences product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for businesses that may not require large volumes but still need to meet supplier conditions. Knowing the MOQ can help businesses manage their inventory and budget effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price bids for specific products or services. For buyers, issuing an RFQ is a strategic way to ensure competitive pricing and gather information on various suppliers’ offerings, which can aid in decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping logistics, costs, and liability, which are crucial for international trade. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. For businesses, understanding lead times is vital for planning production schedules and inventory management. Buyers should inquire about lead times to ensure they align with their operational timelines.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when considering desktop 5-axis CNC milling machines, facilitating smoother procurement processes and enhancing operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the desktop 5 axis cnc milling machine Sector

What Are the Current Market Dynamics and Key Trends in the Desktop 5 Axis CNC Milling Machine Sector?

The desktop 5-axis CNC milling machine market is witnessing a transformative phase, driven by several global factors. The increasing demand for precision engineering in industries such as aerospace, automotive, and healthcare is propelling the adoption of advanced machining technologies. Furthermore, the trend towards miniaturization of components is enhancing the relevance of compact and efficient machines, like the Pocket NC V2-10, which can operate effectively in limited spaces typical of small workshops and educational environments.

Emerging technologies, including automation and artificial intelligence, are reshaping how businesses approach CNC machining. Automation facilitates faster production times and consistency, while AI-driven software enhances machine learning capabilities for improved operational efficiency. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, this means sourcing machines that not only meet their immediate needs but also offer scalability for future technological advancements.

Additionally, the growing focus on rapid prototyping and on-demand manufacturing is influencing sourcing strategies. B2B buyers are increasingly looking for machines that can reduce lead times and allow for quick iterations in design. The ability to work with a variety of materials, including softer metals and polymers, broadens the applicability of desktop CNC machines across different sectors, making them a versatile investment for manufacturers and educational institutions alike.

How Does Sustainability and Ethical Sourcing Impact the Desktop 5 Axis CNC Milling Machine Sector?

Sustainability has become a critical consideration for B2B buyers in the desktop CNC milling machine sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting companies to seek machines that are designed with sustainability in mind. Buyers are increasingly interested in manufacturers that utilize eco-friendly materials and practices, as well as those that offer energy-efficient machines that reduce carbon footprints.

The importance of ethical supply chains cannot be overstated. B2B buyers are now more vigilant about the sources of the materials used in manufacturing CNC machines. They are inclined towards suppliers who can provide transparency regarding their sourcing processes, ensuring that components are acquired from responsible and sustainable sources. Certifications such as ISO 14001 (Environmental Management) and compliance with green standards are becoming essential criteria in the decision-making process.

Moreover, as the demand for sustainable practices grows, manufacturers are innovating by incorporating recycled materials and environmentally friendly designs into their machines. This not only meets buyer expectations but also positions companies favorably in a competitive market increasingly focused on corporate social responsibility.

How Has the Desktop 5 Axis CNC Milling Machine Evolved Over Time?

The evolution of desktop 5-axis CNC milling machines can be traced back to the need for precision and versatility in machining. Initially, CNC technology was predominantly reserved for large industrial machines, which were expensive and often impractical for smaller operations. However, advancements in technology and a surge in demand for compact solutions have led to the development of smaller, more affordable machines.

The introduction of models like the Pocket NC marked a significant milestone, making 5-axis machining accessible to startups, educational institutions, and hobbyists. These machines are designed to fit on desktops while offering robust capabilities, including the ability to handle complex geometries and diverse materials.

As the industry continues to innovate, the emphasis is now on integrating smart technologies that enhance user experience and operational efficiency. The incorporation of user-friendly software interfaces and automation features is driving further adoption among a wider range of users, ultimately transforming how precision parts are manufactured across various sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of desktop 5 axis cnc milling machine

-

1. How do I choose the right desktop 5-axis CNC milling machine for my business?

When selecting a desktop 5-axis CNC milling machine, consider your specific machining needs, including the types of materials you’ll work with, such as aluminum or titanium. Evaluate the machine’s capabilities, such as its travel dimensions and simultaneous motion features. Also, assess the software compatibility, as standard G-code support is essential for ease of use. Lastly, consider the manufacturer’s support and warranty options, especially if you’re new to CNC machining, as comprehensive training and customer service can greatly enhance your experience. -

2. What are the import regulations for purchasing CNC machines from the U.S.?

Import regulations vary by country and may include tariffs, import duties, and compliance with local standards. For buyers in Africa, South America, the Middle East, and Europe, it’s essential to check the U.S. Export Administration Regulations (EAR) regarding the export of CNC machines. Ensure you have the necessary documentation, such as an import license if required. Consulting with a local customs broker can provide clarity on these requirements and help streamline the import process to avoid delays. -

3. What is the minimum order quantity (MOQ) for desktop 5-axis CNC milling machines?

The minimum order quantity (MOQ) for desktop 5-axis CNC milling machines can vary by manufacturer. Many suppliers may allow the purchase of a single unit, especially for smaller machines designed for startups and educational purposes. However, for bulk orders, particularly for larger businesses, negotiating favorable terms may be possible. Always clarify the MOQ with the supplier before proceeding, as this can impact your budget and lead time. -

4. What payment terms should I expect when purchasing a CNC machine internationally?

Payment terms for international purchases of CNC machines typically include options like upfront payment, bank transfers, and letters of credit. Some suppliers may offer financing options for established businesses with a good credit history. It’s crucial to review the supplier’s payment policies to understand any potential upfront costs, deposit requirements, or payment schedules. Additionally, consider currency exchange rates and transaction fees, which can affect the total cost. -

5. How can I ensure the quality of the desktop 5-axis CNC milling machine I am purchasing?

To ensure quality, request detailed specifications and certifications from the manufacturer. Look for machines that have undergone rigorous testing and come with warranties. Engaging in direct communication with the supplier can also provide insights into their quality control processes. Additionally, consider seeking reviews or testimonials from other businesses that have purchased the same machine, as firsthand experiences can inform your decision. -

6. What customization options are available for desktop CNC milling machines?

Many manufacturers offer customization options for desktop CNC milling machines to meet specific operational needs. Common customizations may include specialized tooling, software adaptations, or additional features like enhanced cooling systems. When discussing your requirements with the supplier, be clear about your intended applications and any specific modifications you desire. This dialogue can lead to a tailored solution that maximizes the machine’s utility for your business. -

7. What logistics considerations should I keep in mind when importing CNC machines?

When importing CNC machines, logistics considerations include shipping methods, lead times, and handling of customs clearance. Choose a reliable shipping partner experienced in transporting heavy machinery to ensure safe delivery. Understand the expected lead times for both production and shipping, as these can vary significantly based on the supplier’s location and your destination. Additionally, verify that the supplier can assist with customs documentation to facilitate a smooth import process. -

8. How can I get support and training for using my new CNC machine?

Support and training options vary by manufacturer. Look for suppliers that offer comprehensive training programs, either online or onsite, to help your team effectively operate the CNC machine. Many manufacturers provide resources such as video tutorials, manuals, and customer service hotlines for ongoing assistance. Additionally, consider joining user forums or communities where you can share experiences and gain insights from other CNC users, enhancing your operational knowledge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Desktop 5 Axis Cnc Milling Machine Manufacturers & Suppliers List

1. Pentamachine – Pocket NC V2-10

Domain: pentamachine.com

Registered: 2020 (5 years)

Introduction: {“name”: “Pocket NC V2-10”, “price”: “$6,900.00”, “type”: “5-axis tabletop CNC mill”, “capabilities”: {“max_material_hardness”: “G5 Titanium”, “optimal_materials”: [“delrin”, “aluminum”, “softer steels”], “motion”: “full 5-axis simultaneous motion”, “machining_types”: [“3+2”, “full simultaneous 5 axis”]}, “travel_dimensions”: {“Y”: “5.0 inches / 128.3 mm”, “X”: “4.55 inches / 115.5 mm”, “Z”: “3.55…

2. PocketNC – 5-Axis Machining Solution for Hobbyists

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: PocketNC: https://www.pentamachine.com/all-products/p/pocket-nc-v2-50chb-or-chk; DesktopNC: https://desktopequip.com/desktopnc-turbo/; Intended for hobbyist use, suitable for soft metals and wood; Requires software for full 5-axis machining, such as Fusion 360 which costs $1,600 a year; 3+1 machining possible without full software.

3. 5AXISMAKER – Desktop CNC Machines

Domain: 5axismaker.co.uk

Registered: 2022 (3 years)

Introduction: 5AXISMAKER offers desktop CNC machines that provide both 5-axis milling and 3D printing capabilities. These machines are designed for various applications including dental aligners, product design, architecture, aerospace, automotive, sculpture, and props. The machines are noted for their affordability and compact size, allowing for complex designs to be rendered perfectly in one run. They utilize…

4. MDAPrecision – TN5-V6-TC8 High Precision CNC Mill

Domain: mdaprecision.com

Registered: 2003 (22 years)

Introduction: This company, MDAPrecision – TN5-V6-TC8 High Precision CNC Mill, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Xinshan Tech – Benchtop 5-Axis Mill

Domain: build-its-inprogress.blogspot.com

Introduction: Benchtop 5-Axis Mill; Manufacturer: Xinshan Tech; Weight: ~70 kg; Spindle: 800W ER-11 water cooled; Drive: Brushless servos with integrated controllers; Linear axes: Hiwin ballscrews; Rotary axes: Harmonic drive reductions with crossed roller bearings; Control software: Basic functionality with some mis-translations; First part produced: Front side of a motor housing; Tool used: Datron 3mm single-…

6. Carbide 3D – 5 Axis Desktop Mill

Domain: community.carbide3d.com

Registered: 2013 (12 years)

Introduction: 5 Axis Desktop Mill; designed for machining parts with a 4-sided rotation; capable of cutting materials like plastic and foam; not suitable for metals like steel or aluminum; features a design for a 4-sided jig; uses 2″ x 2″ x 5″ aluminum tube with 3/16th walls; includes M6 set screws (10mm-16mm); smallest stepover of 0.036mm; accuracy of 35µm on X/Y and 10µm on Z; potential applications in lost f…

7. Desktop NC Mate – Miniature Five-Axis CNC Machine

Domain: desktopequip.com

Registered: 2023 (2 years)

Introduction: This company, Desktop NC Mate – Miniature Five-Axis CNC Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Haas – Super Mini Mill 2

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: 1. **Machine Types Considered:** 5-axis mills, specifically looking at Super Mini Mill 2, VF1 with TR160 trunnion, Robodrill, Brother with trunnion, Doosan, Haas UMC500, UMC750, Kitamura MedCenter5AX, Doosan DNM 200/5AX.

2. **Part Size:** Typically small, with a large part being 10in x 10in.

3. **Materials:** Mostly aluminum, some stainless steel, rarely tool steels.

4. **Taper Preference:**…

9. Instructables – DIY Desktop 5-Axis CNC Mill

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: DIY Desktop 5-axis CNC Mill

Key Components:

– CNC Router: CNC 2417 Mini

– MACH3 USB CNC Interface Board: BL-UsbMach-v2.1

– Stepper Motor Driver Controller Boards: 5 x TB6600

– Stepper Motors: 2 x NEMA 17

– Relay Module

– Power Supply: ATX PC Power Supply

– Timing Belts: 2 GT2 Timing Belts (2mm Pitch 6mm Width)

– Bearings: 4 x 608RS 8 x 22 x 7 mm Deep Groove Ball Bearings

– Additional Supplies: Sc…

Strategic Sourcing Conclusion and Outlook for desktop 5 axis cnc milling machine

In the rapidly evolving landscape of manufacturing, the strategic sourcing of desktop 5-axis CNC milling machines presents a significant opportunity for international B2B buyers. These machines, such as the Pocket NC V2-10, offer unparalleled versatility and precision, making them ideal for diverse industries, from education to advanced prototyping. Their ability to handle various materials, including softer steels and aluminum, enhances their appeal for businesses looking to streamline operations and reduce lead times.

Investing in these advanced machines not only facilitates rapid design iterations but also empowers businesses in emerging markets across Africa, South America, the Middle East, and Europe. With the growing demand for customized solutions, sourcing high-quality CNC milling technology becomes crucial for maintaining competitiveness.

As you consider your sourcing strategy, prioritize suppliers that offer robust support and user-friendly interfaces, ensuring a smooth integration into your operations. The future of manufacturing is here, and by embracing these innovative technologies, you position your business for success. Take the next step in your manufacturing journey today—explore options and connect with trusted suppliers to elevate your production capabilities.