Contents

Manufacturing Insight: Denver Sheet Metal Fabrication

Precision Sheet Metal Fabrication Solutions for Denver’s Advanced Manufacturing Sector

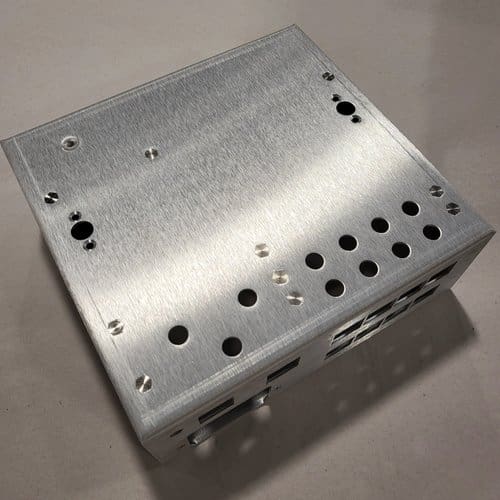

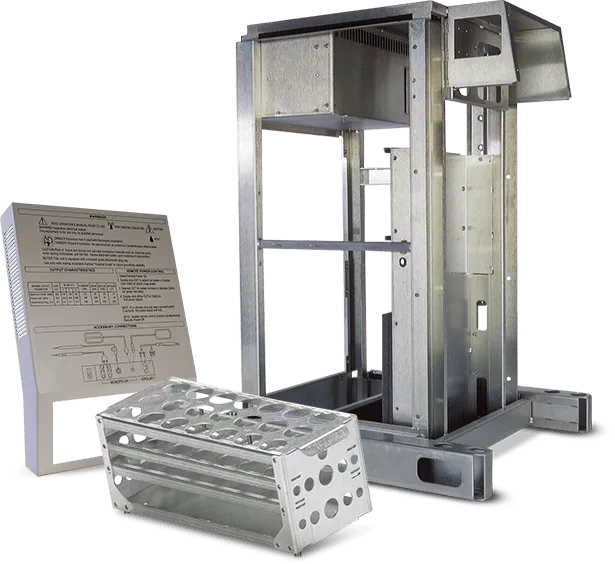

Honyo Prototype delivers comprehensive sheet metal fabrication services engineered to meet the demanding requirements of Denver’s aerospace, medical device, industrial equipment, and technology sectors. Our Colorado-based facility combines advanced CNC punching, laser cutting, precision forming, and robotic welding capabilities with rigorous quality control processes to produce complex components from materials including stainless steel, aluminum, copper, and specialty alloys. We consistently achieve tight tolerances down to ±0.005 inches and support high-mix, low-to-medium volume production runs essential for prototyping and bridge manufacturing.

A critical differentiator for engineering teams and procurement professionals is our industry-leading Online Instant Quote system. This proprietary platform provides real-time, accurate pricing and lead time estimates within seconds of uploading your CAD file, eliminating the traditional multi-day quoting delays that stall project timelines. The system automatically analyzes geometric complexity, material requirements, and finishing specifications to generate a transparent cost breakdown.

Supported CAD File Formats for Instant Quoting

| Format Type | Compatible Extensions |

|————-|———————|

| Native CAD | .SLDPRT, .SLDASM, .PRT, .ASM, .IPT, .IAM, .PRT |

| Neutral Formats | .STEP, .IGES, .DXF, .DWG, .STL |

This integration of technical capability with digital efficiency ensures Denver manufacturers accelerate product development cycles while maintaining the highest standards of dimensional accuracy and material integrity. Partner with Honyo Prototype for sheet metal solutions where engineering expertise meets operational speed.

Technical Capabilities

Denver Sheet Metal Fabrication – Technical Specifications

The following table outlines the technical capabilities for sheet metal fabrication services in Denver, focusing on laser cutting, bending, and welding processes. These specifications reflect standard industry practices and equipment commonly used in precision fabrication environments.

| Process | Capability | Tolerances | Materials Supported | Notes |

|---|---|---|---|---|

| Laser Cutting | CO2 or Fiber Laser; Max Power: 4 kW | ±0.005 in (0.13 mm) | Aluminum (up to 0.5 in / 12.7 mm) Steel (up to 0.75 in / 19.05 mm) ABS (up to 0.25 in / 6.35 mm) Nylon (up to 0.25 in / 6.35 mm) |

ABS and nylon are non-metallic substrates; typically cut with CO2 laser only. Not suitable for high-volume production due to melting risk. |

| Bending | CNC Press Brake; Max Bend Length: 10 ft (3.05 m); Max Tonnage: 300 tons | ±0.5° angular tolerance ±0.005 in linear |

Aluminum (up to 0.375 in / 9.5 mm) Steel (up to 0.375 in / 9.5 mm) |

ABS and nylon generally not bent via press brake; thermoforming preferred for plastics. Tooling optimized for V-die bending with standard K-factors applied. |

| Welding | MIG, TIG, and Spot Welding; Pulsed Arc and Robotic Options Available | ±0.010 in (0.25 mm) fit-up | Aluminum (all series commonly used: 5052, 6061) Steel (Carbon, Mild, and Stainless: 304, 316) |

ABS and nylon are not weldable via arc methods; joining done via adhesives or mechanical fasteners. TIG preferred for aluminum; MIG for high-speed steel fabrication. |

Additional Notes:

Material thickness ranges are based on standard machine capacity and part geometry.

Surface finishes available: deburred, grinded, powder coated, or anodized (for aluminum).

First-article inspection and FAI reports available upon request.

Design for Manufacturability (DFM) support provided prior to production.

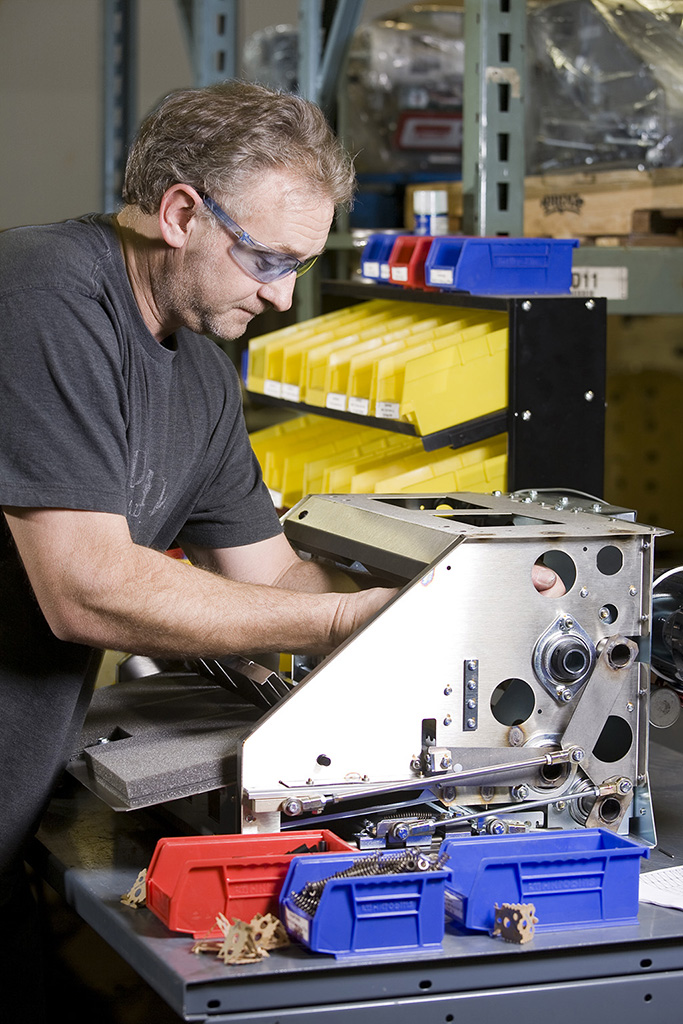

From CAD to Part: The Process

Honyo Prototype executes sheet metal fabrication through a rigorously defined technical workflow designed for speed, precision, and manufacturability. The process begins when a client uploads their CAD file (STEP, IGES, DWG, or native formats) to our secure portal. Our system immediately initiates geometry validation to ensure file integrity and compatibility with our production machinery. Any critical errors, such as missing features or unsupported file types, trigger an automated notification to the client for correction before proceeding.

The validated CAD data then feeds directly into our proprietary AI-driven quoting engine. This system analyzes over 200 geometric and material parameters—including bend counts, hole density, material grade/thickness, surface finish requirements, and feature tolerances—to generate a comprehensive cost estimate within minutes. Unlike manual quoting, our AI cross-references real-time data on material costs, machine utilization rates, and labor variables, providing a transparent breakdown of material, fabrication, finishing, and assembly costs. Historical production data from 15,000+ prior jobs ensures accuracy within a 3% margin for standard geometries.

Following client acceptance of the quote, the design enters our mandatory Design for Manufacturability (DFM) review phase. Our engineering team conducts a dual-path analysis: automated simulation checks for minimum bend radii, hole-to-edge distances, and feature spacing against ISO 2768 tolerances, while a senior manufacturing engineer performs a contextual review for assembly implications, tooling constraints, and secondary process integration. Critical DFM focus areas include:

| DFM Parameter | Standard Requirement | Honyo Enhancement |

|---|---|---|

| Bend Relief | Minimum 0.5t width | AI-suggested optimal relief geometry |

| Hole-to-Bend Distance | ≥ 2.5x material thickness | Dynamic calculation based on bend angle |

| Feature Density | ISO 2768-MK | Heat distortion simulation for clustered features |

| Tolerance Stackup | Client-specified | Statistical analysis with SPC capability |

Clients receive a detailed DFM report with actionable revision suggestions, not just pass/fail notifications. Typical resolution time for DFM feedback is under 4 business hours. Upon client approval of the DFM report, the job moves to production scheduling. Our MES system assigns the optimal machine cell (e.g., Trumpf laser cutters, Amada press brakes with 0.02mm repeatability) based on material type, volume, and geometric complexity. All critical operations undergo in-process CMM verification at defined hold points, with full traceability via serialized barcodes synced to our cloud quality database.

Final inspection follows AS9102 First Article Inspection standards for aerospace clients or ISO 128-24 for general industrial work, with full GD&T validation where specified. Components ship via tracked logistics with real-time GPS monitoring, and all quality documentation—including material certs, CMM reports, and process parameter logs—is accessible through the client portal. This integrated workflow reduces time-to-prototype by 65% versus industry averages while maintaining a <0.5% first-pass yield defect rate across our Denver facility’s 25,000 sq ft production floor. The system’s closed-loop feedback continuously refines our AI models using actual production outcomes, ensuring quoting accuracy and manufacturability guidance improve with every job.

Start Your Project

For precision sheet metal fabrication services tailored to your Denver-based operations, contact Susan Leo at [email protected]. Honyo Prototype offers end-to-end manufacturing solutions with rapid prototyping, CNC machining, and high-quality sheet metal fabrication. Our ISO-certified factory in Shenzhen ensures strict quality control, on-time delivery, and seamless scalability for both low and high-volume production runs. Partner with a trusted global manufacturer backed by decades of engineering expertise. Reach out today to request a quote or discuss your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.