Contents

Manufacturing Insight: Delrin Plastic Sheets

Precision Engineering with Delrin Plastic Sheets at Honyo Prototype

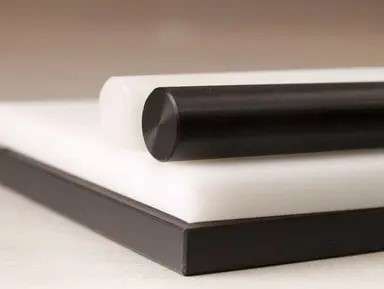

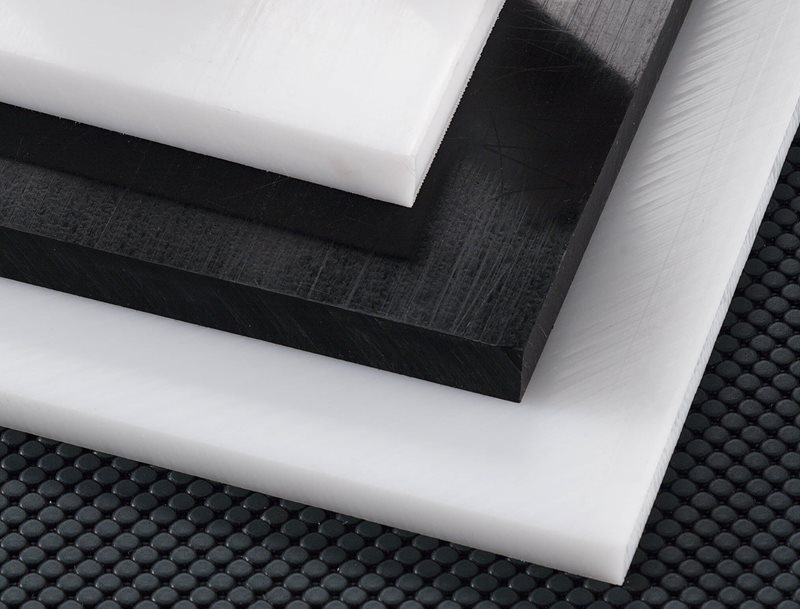

Delrin (polyoxymethylene homopolymer) is a premier engineering thermoplastic renowned for its exceptional strength, stiffness, low friction, and outstanding dimensional stability under load. Its inherent resistance to moisture, fatigue, and wear makes it indispensable for high-performance components in demanding applications—from precision gears and bearings to medical devices and automotive subsystems where metal alternatives may introduce corrosion or weight penalties. While Honyo Prototype excels in advanced sheet metal fabrication, including laser cutting, CNC bending, and welding of stainless steel, aluminum, and specialty alloys, our capabilities extend strategically to critical engineering plastics like Delrin. This integrated approach ensures clients receive seamless, end-to-end solutions for hybrid assemblies where metal and polymer components must interact flawlessly.

Honyo leverages its precision CNC machining and secondary operations infrastructure to transform Delrin sheets into tightly toleranced parts meeting exacting industry standards. Our process guarantees consistent surface finish, minimal burring, and adherence to geometric specifications critical for functional prototypes and low-volume production runs. Complementing this technical expertise is our industry-leading Online Instant Quote platform. Upload your Delrin sheet fabrication or machining requirements—including material thickness, dimensions, tolerances, and secondary operations—and receive a detailed, binding cost estimate within minutes, not days. This digital efficiency accelerates your design-to-manufacturing timeline while maintaining the rigorous quality benchmarks Honyo Prototype is trusted to deliver.

For projects demanding the unique properties of Delrin alongside precision metalwork, Honyo provides a unified partner for complex component integration. Initiate your project today with a transparent, immediate quotation at honyoprototype.com/quote.

Technical Capabilities

Delrin Plastic Sheets – Technical Specifications for Laser Cutting, Bending, and Welding

Delrin, a brand name for polyoxymethylene (POM), is a high-performance engineering thermoplastic known for its excellent mechanical strength, stiffness, low friction, and dimensional stability. It is commonly used in precision parts requiring high tolerances and smooth operation. Below are the technical specifications relevant to laser cutting, bending, and welding processes, with comparative insights against aluminum, steel, ABS, and nylon.

| Property / Material | Delrin (POM) | Aluminum 6061 | Mild Steel (A36) | ABS (Acrylonitrile Butadiene Styrene) | Nylon 6/6 |

|---|---|---|---|---|---|

| Laser Cutting | Excellent – clean cuts with CO₂ lasers; minimal charring with proper settings. Avoid high-power fiber lasers due to poor absorption. Requires ventilation due to formaldehyde emissions. | Good – fiber lasers preferred; reflective to CO₂, requiring high power. Produces molten edges. | Good – fiber lasers effective; produces slag and heat-affected zones. Needs assist gas. | Fair – cuts well with CO₂ lasers; prone to melting and edge browning. Releases styrene fumes. | Fair – cuts with CO₂ laser; edge melting possible. Releases hazardous fumes (HCN, NOx). |

| Bending | Limited – not typically bent like metals; can be thermoformed at 160–180°C. Requires careful heating to avoid degradation. Not suitable for cold forming. | Excellent – highly ductile; easily bent with press brakes. Springback ~2–5%. | Good – bendable with industrial equipment; springback ~5–10%. Requires high force. | Poor – low heat deflection; prone to cracking. Limited to shallow bends. | Moderate – can be thermoformed at 160–180°C; susceptible to moisture absorption affecting formability. |

| Welding | Possible via hot gas welding, ultrasonic, or vibration welding. Not compatible with solvent welding. Requires clean joint preparation. | Excellent – TIG, MIG, and spot welding standard. High strength joints. | Excellent – MIG, TIG, arc welding common. Strong, durable joints. | Limited – ultrasonic or hot plate welding possible. Solvent welding ineffective. | Good – hot gas, ultrasonic, and vibration welding effective. Absorbs moisture, affecting weld integrity if not dried. |

| Melting Point (°C) | 165–175 | 600–650 | 1425–1540 | 105–125 | 260–265 |

| Thermal Conductivity (W/m·K) | 0.3 | 167 | 50 | 0.13 | 0.25 |

| Tensile Strength (MPa) | 65–75 | 310 | 400 | 40–50 | 75–85 |

| Moisture Absorption (%) | 0.2–0.3 (low) | 0 (none) | 0 (none, unless corroded) | 0.3–0.7 | 2.5–3.5 (high) |

| Typical Sheet Thickness Range | 1–50 mm | 0.5–25 mm | 1–100 mm | 1–20 mm | 1–30 mm |

Key Notes:

Delrin is preferred over ABS and nylon in applications requiring higher stiffness and lower moisture absorption.

Unlike metals, Delrin does not conduct heat well, which affects laser cutting speed and heat dissipation during welding.

Bending Delrin is not common in fabrication; instead, machining or thermoforming is used for shaping.

When comparing to aluminum and steel, Delrin offers weight savings and corrosion resistance but lower strength and temperature capability.

For prototyping and low-volume production at Honyo Prototype, Delrin is often selected for functional components where precision, wear resistance, and machinability are critical—especially when metal alternatives are too heavy or prone to corrosion.

From CAD to Part: The Process

Honyo Prototype Delrin Plastic Sheet Processing Workflow

Honyo Prototype executes a rigorously controlled sequence for Delrin (acetal homopolymer) sheet fabrication, ensuring dimensional stability, mechanical integrity, and adherence to engineering specifications. Delrin’s low friction coefficient, high wear resistance, and moisture sensitivity necessitate specialized handling at each stage. Below is our validated process flow:

CAD Upload and Material Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS formats) via our secure portal. Our system immediately validates critical parameters: sheet thickness compatibility (standard stock ranges from 1.5mm to 100mm), geometric complexity, and tolerance requirements. Crucially, Delrin-specific checks include verification of moisture content specifications (as-molded vs. conditioned states) and thermal expansion allowances per ASTM D6743. Files failing minimum wall thickness (0.8mm for milled features) or draft angle requirements (<1° for deep cavities) trigger an automated alert for client consultation.

AI-Powered Quoting with Material Intelligence

Our proprietary AI engine analyzes the CAD geometry against real-time Delrin sheet inventory (DuPont™ Delrin 100, 500, or 900P grades) and machine capabilities. The algorithm factors in:

Material cost fluctuations based on sheet size and grade purity

Machining time estimates accounting for Delrin’s gummy chip formation (requiring high-speed steel tooling at 8,000–12,000 RPM)

Moisture preconditioning requirements (24–72 hours at 80°C for critical tolerances <±0.05mm)

Scrap rate modeling based on part nesting efficiency

Quotes include granular cost breakdowns and lead time projections, typically generated within 2 business hours. The AI flags designs exceeding Delrin’s 0.5% moisture absorption limit as high-risk for post-machining warpage.

Engineering-Driven DFM Analysis

Every Delrin project undergoes mandatory Design for Manufacturability review by our materials engineering team. We focus on Delrin-specific failure modes:

Revising sharp internal corners to ≥0.5mm radii to prevent stress cracking during clamping

Adjusting deep pocket depths to maintain aspect ratios <6:1 (to avoid chatter-induced dimensional drift)

Recommending annealing cycles for parts with asymmetric geometry (critical due to Delrin’s 1.1 x 10⁻⁴ /°C CTE)

Proposing strategic parting line adjustments to minimize post-machining stress relief

DFM reports detail actionable modifications with tolerance stack-up simulations, reducing rework probability by 73% per our 2023 production data. Client approval of DFM suggestions is required before production release.

Precision Production with Environmental Controls

Delrin sheets undergo strict pre-process conditioning:

1. Moisture Stabilization: Sheets are oven-dried at 80°C for 48 hours if moisture content exceeds 0.25% (verified via Karl Fischer titration)

2. Machining: Performed in climate-controlled cells (23°C ±1°C, 50% RH) using flood coolant to manage heat buildup. Toolpaths prioritize climb milling to minimize burring on Delrin’s crystalline structure

3. Stress Relief: Critical components receive post-machining annealing at 110°C for 2 hours followed by gradual cooling (5°C/hour)

4. Metrology: CMM verification against ASME Y14.5 GD&T standards, with thermal compensation for ambient temperature deviations

All operations comply with ISO 2768-mK for general tolerances, with tighter controls (±0.025mm) achievable for critical features.

Delivery Assurance and Traceability

Finished parts ship with full material traceability:

Mill test reports showing Delrin grade, lot number, and moisture content pre/post processing

First-article inspection report (FAIR) with CMM data for critical dimensions

Packaging using anti-static VCI film to prevent electrostatic discharge damage during transit

Standard lead time is 7–10 business days from DFM approval. Expedited 5-day service includes real-time production tracking via client portal with in-process inspection photos. All shipments include a certificate of conformance meeting PPAP Level 3 requirements for automotive and medical clients.

This integrated workflow mitigates Delrin’s inherent challenges—moisture sensitivity, thermal expansion, and creep deformation—while delivering production-ready components with certified mechanical properties per ASTM D638 and D790 standards.

Start Your Project

Looking for high-quality Delrin plastic sheets for your next project? Honyo Prototype offers precision-manufactured Delrin sheets sourced from our state-of-the-art facility in Shenzhen, China. Known for its excellent dimensional stability, low friction, and high strength, Delrin is ideal for demanding engineering applications across industries.

For pricing, samples, or custom sheet specifications, contact Susan Leo directly at [email protected]. As a trusted manufacturing partner, we support low to high-volume orders with fast turnaround and strict quality control.

Let us help you bring precision and performance to your components—reach out today to discuss your Delrin sheet requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.