Guide Contents

Project Insight: Delrin Plastic Sheets

Manufacturing Insight: Delrin Plastic Sheets – Precision Engineered for Speed

Why Speed & Precision Matter in Product Development

Performance Demands: Delrin’s exceptional mechanical properties (low friction, high stiffness, dimensional stability) require precise manufacturing to maintain integrity—especially for critical applications in automotive, medical, or consumer electronics.

Time-to-Market Pressure: Startups face relentless deadlines; delays in tooling or production can derail launches, investor milestones, and competitive advantage.

Quality Consistency: Even minor deviations in mold design or material handling can compromise part functionality. Precision ensures every component meets functional and aesthetic specs.

Honyo Prototype: Accelerating Delrin Production with Digital Manufacturing

Online Instant Quote: Submit your design in seconds and receive real-time pricing for Delrin injection molding projects—no manual quotes, no delays. Our AI-driven platform instantly analyzes geometry, material requirements, and production complexity.

AI-Powered Design Validation: Our proprietary system flags Delrin-specific challenges (shrinkage rates, gate placement, warpage risks) during mold flow analysis—reducing prototyping iterations by up to 40% and accelerating time-to-validation.

Rapid Bridge Tooling: Steel or aluminum molds built in 5–10 days for low-volume runs (100–10,000+ parts). Perfect for pre-production validation, small-batch orders, or bridging gaps before full-scale production.

End-to-End Digital Workflow: Track every step of your project—from tooling to delivery—via a single dashboard. Automated updates, transparent communication, and on-time delivery guarantees let you focus on innovation, not logistics.

“At Honyo, we don’t just manufacture parts—we engineer speed into your product journey. With Delrin’s performance meets our digital agility, your vision becomes reality faster than ever.”

— Susan Leo, Founder of Honyo Prototype

Honyo Capabilities & Technology

Precision Delrin® Manufacturing for Low-Volume Production

Material-Specific Expertise for Delrin® Applications

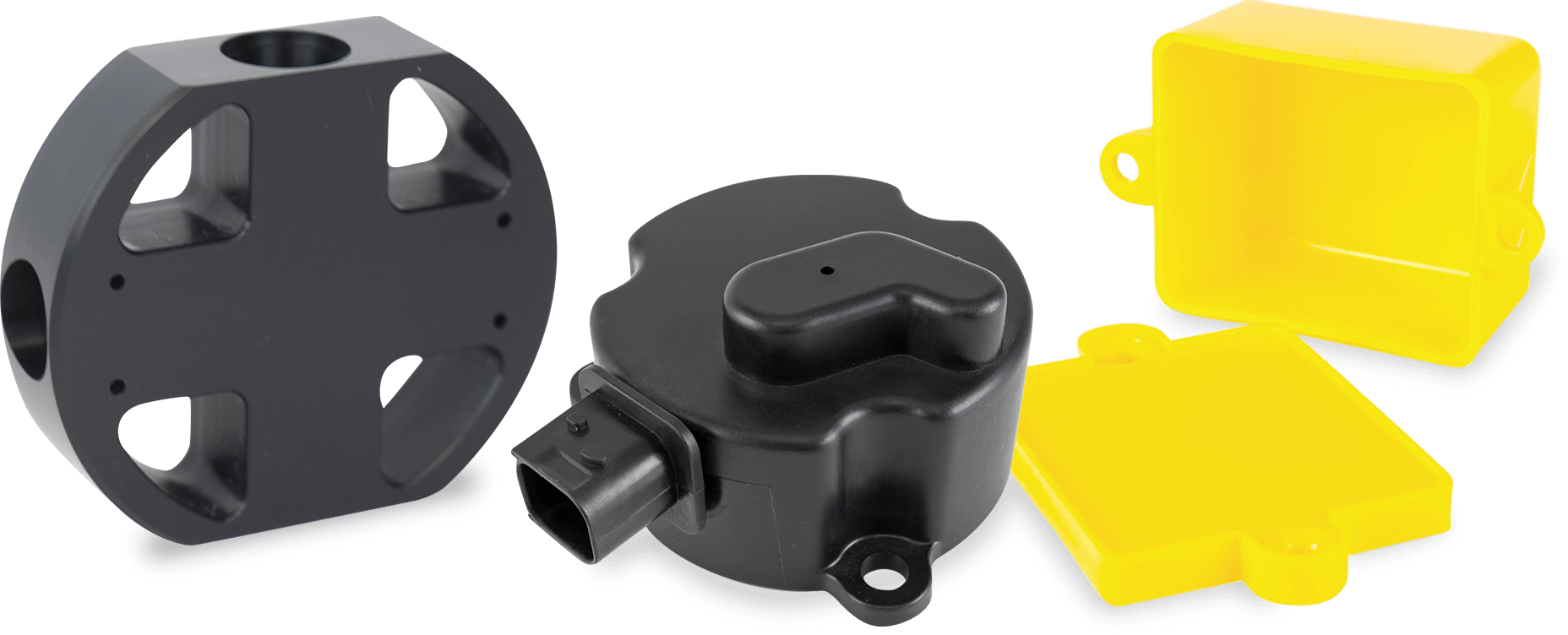

Optimized for Delrin®’s Unique Properties: Leverage its high strength, dimensional stability, low friction, and abrasion resistance with steel/aluminum molds engineered for precise thermal control and surface finish.

Advanced Multi-Material Capabilities: Seamlessly integrate overmolding and insert molding for complex assemblies—no secondary operations required.

Customizable Sheet Dimensions: From standard cut-to-size sheets to bespoke geometries, we handle black, white, and natural Delrin® homopolymer with micron-level accuracy.

Agile Bridge Tooling for Scalable Production

Rapid Tooling for 100–10,000+ Parts: Bridge the gap between prototyping and full-scale production with tooling that slashes lead times by up to 50% vs. traditional methods.

AI-Powered Instant Quote Platform: Get real-time pricing, material costs, and delivery estimates in seconds—no manual quotes or delays.

Fast Turnaround Guarantee: Prototype to delivery in 7–10 days for urgent hardware startup needs, with expedited options for critical projects.

Uncompromising Quality Assurance

ISO 9001-Certified Processes: Rigorous in-process inspections and final QA checks ensure every part meets aerospace-grade tolerances (±0.001″).

Material Traceability: Full certification for Delrin® homopolymer batches, with chemical and mechanical testing at every stage.

Dedicated Engineering Support: Our team collaborates with you to optimize designs for manufacturability—reducing costs and eliminating production bottlenecks.

“At Honyo Prototype, we don’t just manufacture parts—we solve engineering challenges. With Delrin®’s performance and our agile tooling, you’ll hit market deadlines without sacrificing quality.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes

At Honyo Prototype, we empower hardware startups and product engineers with precision-engineered thermoplastics and tailored surface finishes. Leverage our AI-powered instant quote platform to optimize material selection and accelerate production — all with lead times as fast as 3 days.

Thermoplastic Material Portfolio

Delrin® (POM Homopolymer): High strength, low friction, exceptional dimensional stability. Ideal for gears, bearings, automotive components, and precision mechanical parts. Available in black, white, and natural colors.

ABS: Impact-resistant, easy to machine, and cost-effective. Perfect for consumer electronics housings, automotive interiors, and prototyping.

Polycarbonate (PC): High heat resistance (up to 135°C) and optical clarity. Best for transparent enclosures, safety shields, and optical applications.

Polypropylene (PP): Chemical resistance, flexibility, and fatigue durability. Used in medical devices, living hinges, and chemical-resistant components.

TPE/TPU: Elasticity, soft-touch feel, and abrasion resistance. Ideal for grips, seals, wearables, and flexible parts.

Surface Finishes for Plastic Components

Precision Polishing: Achieve optical clarity or smooth tactile finishes for aesthetic or functional surfaces (e.g., optical lenses, medical devices).

Paint & Powder Coating: Custom color matching with UV-resistant finishes (requires surface preparation for adhesion).

Textured Surfaces: Molded-in textures for grip enhancement or visual appeal (e.g., matte, leather-grain, or custom patterns).

Laser Engraving: Permanent markings without material distortion (ideal for serial numbers, logos, or functional indicators).

💡 Note: Anodizing applies only to metals. For plastics, we recommend chemical treatments or specialized coatings for enhanced durability.

Choosing the Right Material for Your Application

Optimize performance and cost with data-driven insights:

Mechanical Load: Delrin® excels in high-stress applications requiring stiffness and wear resistance (e.g., automotive connectors).

Chemical Exposure: PP outperforms in corrosive environments; Delrin® handles moderate chemicals (avoid strong acids/bases).

Temperature Range: PC handles >100°C; Delrin® maintains performance up to 100°C (ideal for moderate heat applications).

Cost Efficiency: ABS offers the best value for general-purpose parts; Delrin® delivers premium performance at a moderate premium.

✨ Pro Tip: Use our AI-driven Material Selector Tool to input your application requirements (load, environment, budget) and get instant recommendations. For low-volume production (100–10,000+ parts), Delrin®’s machinability and bridge tooling compatibility make it a top choice for precision components — no minimum order, fast turnaround, and seamless integration with our rapid tooling process.

Ready to optimize your design?

→ Get an instant quote in under 60 seconds — our platform analyzes your specs and recommends the ideal material/finish for maximum performance and cost-efficiency.

→ Ship in 3–5 days with Honyo Prototype’s agile manufacturing ecosystem.

Engineered for innovation. Delivered at speed. 🚀

From Quote to Part: Our Process

How It Works: From CAD to Part

Engineered for speed, precision, and transparency—your Delrin® injection-molded parts, accelerated.

1. Upload Your CAD File

Submit designs in any standard format (STEP, STL, IGES, etc.) via our secure cloud platform

Instant validation checks for compatibility and integrity—no file size limits or delays

Zero manual intervention: Your geometry is ready for analysis the moment you hit “Upload”

2. Get Instant AI-Powered Quote

Proprietary AI engine analyzes geometry, material (Delrin® homopolymer), and volume in seconds

Real-time pricing with full transparency: Tooling costs, per-part pricing, shipping, and lead time breakdown

No hidden fees, no waiting—quotes delivered in <60 seconds, 24/7

3. Expert DFM Analysis & Optimization

Our manufacturing engineers provide actionable feedback to eliminate production risks (e.g., wall thickness, draft angles, gate placement)

Collaborative platform for quick revisions—no back-and-forth emails or delays

Optimize for cost, strength, and cycle time before tooling begins

4. Rapid Production & Delivery

Bridge tooling for low-volume runs (100–10,000+ parts)—molds built in 5–10 days

Precision injection molding with Delrin® homopolymer for exceptional wear resistance, low friction, and dimensional stability

Real-time production tracking + guaranteed on-time delivery—directly to your door, anywhere in the world

Why it matters:

For hardware startups and engineers, this isn’t just a process—it’s a competitive advantage. Cut weeks off your timeline, avoid costly tooling mistakes, and get to market faster with Honyo’s AI-driven workflow. Innovation isn’t optional—it’s built in.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Delrin Solutions, Engineered for Speed

Instant AI-Powered Quoting: Upload your design or specs and receive an accurate cost breakdown in seconds—no back-and-forth, just clear pricing.

Rapid Bridge Tooling for Low-Volume Production: From 100 to 10,000+ parts, our steel/aluminum molds deliver consistent quality without the high costs of full-scale tooling.

Fast Turnaround Guarantee: Prototype to production in days, not weeks. Our Shenzhen/Dongguan facilities are optimized for speed without compromising precision.

Ready to Move Forward?

Founder Susan Leo and our engineering team are ready to bring your vision to life.

📧 Email: [email protected]

📞 Call: +86 139 2843 8620

📍 Visit: Our Shenzhen/Dongguan facilities—where innovation meets manufacturing excellence.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.