Contents

Manufacturing Insight: Definition Of Cnc Machining

Defining CNC Machining and Honyo Prototype’s Precision Manufacturing Commitment

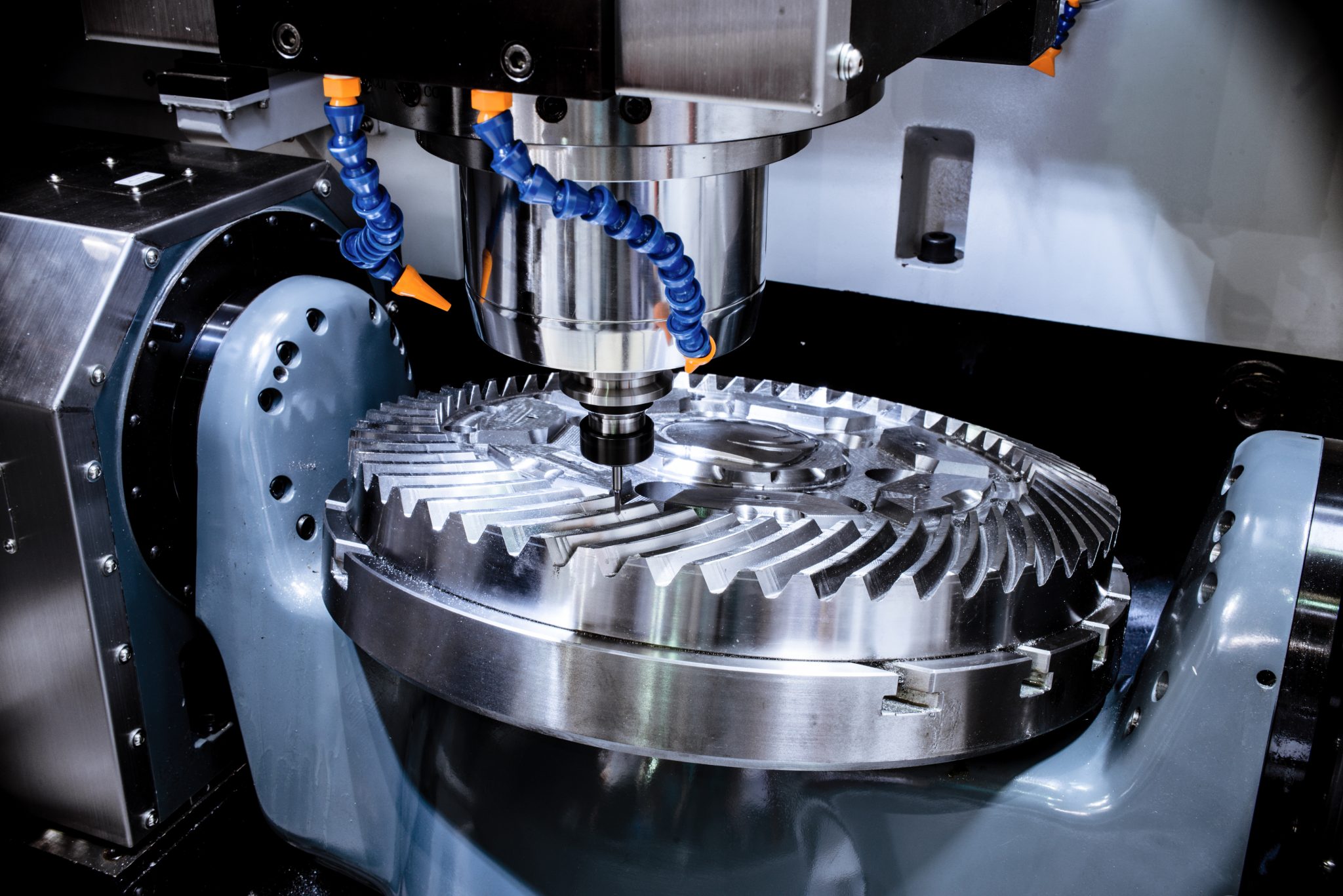

Computer Numerical Control (CNC) machining represents the cornerstone of modern precision manufacturing, utilizing pre-programmed computer software to dictate the exact movement of cutting tools and workpieces across multiple axes. This advanced subtractive process removes material from a solid block—metal, plastic, or composite—to create complex, high-tolerance components with exceptional repeatability and surface finish, far surpassing manual machining capabilities. At Honyo Prototype, we leverage this foundational technology as the backbone of our comprehensive rapid prototyping and low-volume production services, engineered specifically for demanding industrial applications.

Honyo Prototype delivers end-to-end CNC solutions, encompassing 3-axis, 4-axis, and 5-axis milling alongside precision CNC turning. Our capabilities extend from intricate aerospace brackets and medical device housings to robust industrial tooling and automotive subsystems, all executed within an ISO 9001-certified environment. We prioritize material efficiency, stringent GD&T adherence, and rapid iteration cycles, ensuring your designs transition seamlessly from CAD model to functional, production-intent hardware. Crucially, our process integrates seamless engineering support to optimize manufacturability without compromising design intent.

Accelerating your path from concept to physical validation, Honyo Prototype features an industry-leading Online Instant Quote system. This proprietary platform provides detailed, transparent pricing and lead time estimates for CNC milling and turning projects within 30 seconds—no manual submission or login required. Simply upload your STEP or IGES file, specify material and quantity requirements, and receive actionable manufacturing feedback immediately, significantly reducing procurement friction for engineering teams. This commitment to speed and clarity underscores our dedication to becoming your strategic partner in precision component realization. Initiate your project with confidence by leveraging Honyo Prototype’s technical expertise and streamlined quoting process.

Technical Capabilities

CNC machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a workpiece to produce precision components. The process is widely used for creating high-accuracy parts across industries such as aerospace, medical, automotive, and industrial equipment. Key configurations include 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, each offering different degrees of rotational and linear movement for enhanced geometric capability.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Motion Axes | X, Y, Z linear axes | X, Y, Z + A (rotation around X) | X, Y, Z + A and B (or C) rotary axes | X (radial), Z (axial), with spindle rotation | N/A |

| Typical Use Case | Flat or planar geometry, simple features | Indexing around one rotary axis (e.g. drilling holes on sides) | Complex contours, organic shapes, deep cavities | Cylindrical parts (shafts, bushings, fittings) | Critical dimensions requiring ±0.001″ (±0.025 mm) or tighter |

| Max Work Envelope (Typical) | 20″ x 40″ x 20″ | 20″ x 40″ x 20″ + rotary indexing | 16″ x 30″ x 20″ with full continuous 5-axis | Diameter up to 16″, length up to 48″ | Depends on machine and setup, typically up to 24″ in any axis |

| Surface Finish (Typical) | 32–125 μin Ra | 32–125 μin Ra | 16–63 μin Ra (complex surfaces) | 16–63 μin Ra (machined cylindrical) | As low as 8–16 μin Ra with fine finishing passes |

| Materials Compatible | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon | Same as 3-axis, with improved access for complex setups | Same, optimized for hard-to-reach features | Same, especially suited for bar stock forms | All materials, with enhanced stability for Aluminum and Steel |

| Aluminum Machinability | Excellent; high MRR, low tool wear | Good; indexing improves access | Excellent; reduced tool interference | Excellent; smooth finishes at high RPM | Achieves ±0.0005″ with proper fixturing and thermal control |

| Steel Machinability | Good; requires rigid setup and carbide tools | Moderate; longer cycle times | Moderate to good; benefits from tool tilt | Good; especially for case-hardened steels | ±0.001″ typical, ±0.0002″ achievable with precision turning |

| ABS Machinability | Good; low melting point requires sharp tools and low heat | Good; vacuum fixturing recommended | Moderate; risk of chatter; shallow depths | Limited; rarely turned, more milled | ±0.002″ typical due to thermal expansion |

| Nylon Machinability | Moderate; prone to deflection, requires sharp cutting | Moderate; clamping must avoid deformation | Moderate; best with cryogenic cooling | Good; for bushings, rollers, insulators | ±0.0015″ achievable with stable setup and dry environment |

Note: Tight tolerance performance is highly dependent on machine calibration, tooling quality, fixturing rigidity, environmental control (temperature, vibration), and operator expertise. 5-axis milling allows for single-setup machining of complex geometries, reducing cumulative tolerance stack-up. CNC turning is ideal for high-precision rotational parts, especially when combined with live tooling (mill-turn centers) for secondary milling operations.

From CAD to Part: The Process

Honyo Prototype implements a rigorously defined CNC machining workflow designed for precision, efficiency, and client transparency. This integrated process ensures manufacturability while minimizing time-to-part and reducing non-conformance risks. Below is the technical breakdown of each phase.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and geometric completeness. This step eliminates common upstream errors such as missing datums or inconsistent units before engineering review begins. All uploaded data is encrypted and stored in our ISO 27001-certified environment, ensuring IP protection throughout the project lifecycle.

AI-Powered Quoting Engine

Validated CAD models enter our proprietary AI quoting system, which analyzes geometric complexity, feature tolerances, material requirements, and surface finish specifications. The engine cross-references real-time data from our machine shop floor, including current capacity on HAAS and DMG MORI equipment, material pricing feeds from certified suppliers, and historical production metrics. Within 2 hours, clients receive a detailed quote specifying exact lead times, cost breakdowns by operation, and preliminary material recommendations. Crucially, the AI flags potential manufacturability concerns at this stage—such as thin walls below 0.5mm or deep cavities exceeding 10:1 aspect ratios—enabling early risk mitigation.

Engineering-Led DFM Analysis

All quotes undergo mandatory review by our in-house manufacturing engineering team. This phase extends beyond automated analysis to human expertise in geometric dimensioning and tolerancing (GD&T) optimization. Engineers perform:

Tolerance stack-up analysis against ISO 2768 medium accuracy standards

Toolpath simulation for hard-to-reach features

Material utilization optimization to reduce waste

Fixture strategy validation for 5-axis accessibility

Clients receive a formal DFM report with actionable recommendations, such as suggesting alternative radii for end mills or consolidating setups. Only after client approval of the DFM report does the project advance, ensuring alignment on technical feasibility.

Precision Production Execution

Approved jobs move to production with full traceability:

Material certification (e.g., EN AW-2024 T351 for aluminum) is verified upon receipt

First-article inspection (FAI) per AS9102 standards for critical features

In-process checks at predefined stages using calibrated CMMs and optical comparators

Real-time machine monitoring via MTConnect for spindle load, vibration, and thermal compensation

Our facility maintains ISO 9001:2015 and IATF 16949 certifications, with environmental controls holding temperatures at 20±1°C to minimize thermal drift during micron-level machining.

Quality-Controlled Delivery

Final inspection includes comprehensive dimensional validation against the original CAD model using Zeiss CONTURA CMMs, with full inspection reports available via client portal. Parts undergo visual inspection per ASTM E3022 for surface defects and are packaged with anti-corrosion VCI paper for shipment. Standard lead times by complexity are:

| Complexity Tier | Features Included | Typical Lead Time |

|---|---|---|

| Standard | Tolerances ±0.1mm, basic geometries | 5-7 business days |

| Medium | Tight tolerances (±0.025mm), multiple setups | 8-12 business days |

| High | Micro-machining (<±0.01mm), complex 5-axis contours | 13-20 business days |

All deliveries include digital dossiers with inspection data, material certs, and process documentation. This closed-loop system ensures 99.2% on-time delivery performance while providing clients with auditable manufacturing evidence for regulated industries.

Start Your Project

Learn more about the definition of CNC machining and how precision manufacturing can elevate your prototyping and production needs. Contact Susan Leo at [email protected] for expert guidance and engineering support. Honyo Prototype operates a state-of-the-art factory in Shenzhen, delivering high-accuracy CNC-machined parts for industries worldwide. Let our team help you bring your designs to life with speed, precision, and reliability.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.