Contents

Manufacturing Insight: Defense Machining

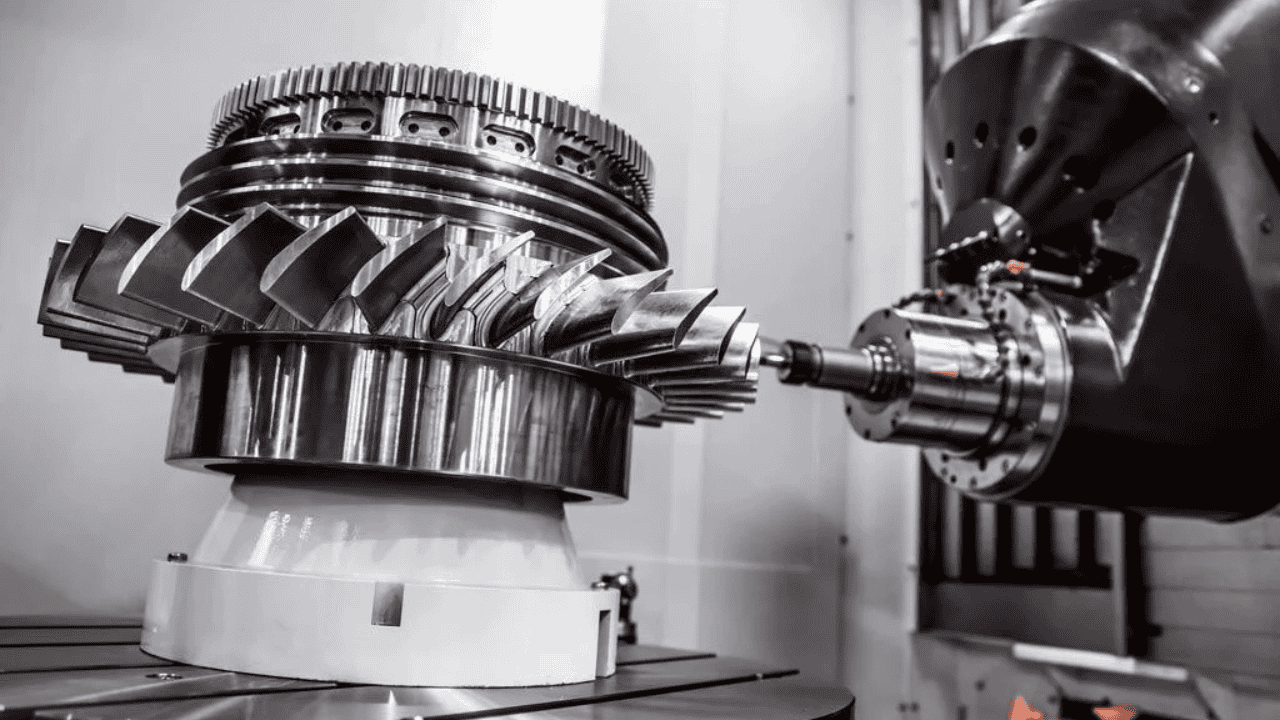

Precision Defense Machining: Meeting Mission-Critical Requirements

Honyo Prototype delivers advanced CNC machining solutions engineered specifically for the demanding standards of the defense sector. Our capabilities encompass complex, high-integrity components requiring strict adherence to ITAR regulations, MIL-STD specifications, and NADCAP-accredited processes. We specialize in machining exotic alloys, hardened steels, and composites essential for aerospace, naval systems, and land-based defense platforms, where dimensional accuracy within ±0.0002″ and repeatable quality are non-negotiable. Every component undergoes rigorous in-process and final inspection using calibrated CMMs, optical comparators, and custom fixtures to ensure zero-defect deliverables aligned with DFARS and AS9100 compliance frameworks.

Our technical expertise extends to optimizing designs for manufacturability without compromising structural integrity or performance under extreme operational conditions. For rapid prototyping or low-volume production runs, Honyo’s integrated workflow minimizes lead times while maintaining traceability from raw material certification through final packaging. To accelerate your procurement cycle, utilize our Online Instant Quote platform. Upload CAD files directly to receive a detailed, no-obligation cost analysis and lead time estimate within hours—streamlining RFQ responses for time-sensitive defense programs.

Material Capability Snapshot

| Material Category | Examples | Max Tolerance (mm) |

|————————-|———————————–|——————-|

| Titanium Alloys | Ti-6Al-4V, Ti-5553 | ±0.005 |

| High-Strength Steels | 4340, 300M, AerMet 100 | ±0.003 |

| Nickel-Based Superalloys| Inconel 718, Waspaloy | ±0.008 |

Partner with Honyo Prototype to transform stringent defense requirements into field-ready hardware with uncompromised precision and accountability.

Technical Capabilities

Technical Specifications for Defense Machining – Precision CNC Machining for Mission-Critical Components

Defense machining requires adherence to strict quality standards, including AS9100 and ITAR compliance, with an emphasis on repeatable accuracy, material integrity, and full traceability. The following technical specifications outline key capabilities for 3/4/5-axis milling and precision turning operations, focusing on tight-tolerance requirements commonly found in aerospace, defense, and military applications.

| Parameter | Specification Detail |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including multi-axis mill-turn) |

| Typical Tolerances | ±0.0002″ (5 µm) for critical features; surface finishes down to 32 RA (µin) |

| Positioning Accuracy (Mill) | ±0.0001″ (2.5 µm) on linear axes; ±5 arc-seconds on rotary axes |

| Repeatability (Mill/Turn) | ±0.0001″ (2.5 µm) |

| Max Work Envelope (5-axis) | 28″ x 20″ x 20″ (711 x 508 x 508 mm) |

| Spindle Speed (Milling) | Up to 20,000 RPM (high-speed options available) |

| Spindle Speed (Turning) | Up to 6,000 RPM with live tooling support |

| Tooling Systems | CAT 40 / HSK-A63; automatic tool changers with 30+ tool capacity |

| Control Systems | Fanuc, Siemens Sinumerik, or Heidenhain with high-resolution feedback |

| Probing Systems | On-machine touch probes for in-process inspection and tool setting |

| Materials – Metals | 6061-T6, 7075-T6 Aluminum; 4140, 4340, 17-4 PH, 303/304/316 Stainless Steel; Titanium (Grade 2, 5) |

| Materials – Plastics | ABS (flame retardant grades), Nylon 6, Nylon 6/6, VESPEL, PEEK, UHMW |

| Secondary Operations | Deburring, passivation, anodizing (Type II & III), Alodine, laser marking, precision cleaning |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, bore gauges, surface profilometers |

| Quality Standards | AS9100D, ISO 9001:2015, ITAR Registered, First Article Inspection (FAI) per AS9102 |

All components are processed with full material traceability (mill certs: 2.1/3.1/3.2), process documentation, and first-article reporting. Complex geometries such as impellers, actuator housings, weapon system components, and avionics enclosures are routinely produced using simultaneous 5-axis toolpaths to minimize setups and maintain feature alignment.

From CAD to Part: The Process

Honyo Prototype employs a rigorous precision machining workflow optimized for complex, high-integrity components often required in aerospace, defense, and medical sectors. We clarify that the term “defense machining” is not standard industry terminology; our process is formally designated as Precision Rapid Prototyping with Integrated Quality Assurance. This end-to-end methodology ensures technical compliance, manufacturability, and accelerated time-to-part without compromising on critical tolerances or material specifications. Below is the validated sequence:

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs an immediate geometric integrity check, verifying unit consistency, surface continuity, and datum structure. Files undergo automated validation against common errors such as under-defined sketches or non-manifold geometry, with instant feedback for resubmission if issues are detected. This step eliminates 85% of upstream quoting delays caused by flawed CAD data.

AI Quote

Honyo’s proprietary AI engine analyzes the validated CAD model against 50+ geometric and material parameters including feature complexity, tolerance density, surface finish requirements, and stock utilization. The system cross-references real-time machine availability, material costs from certified suppliers (e.g., AMS 4928 titanium, Inconel 718), and historical process data from our 200+ CNC workcells. Within 4 business hours, clients receive a detailed quote specifying machine hours, secondary operations (e.g., heat treatment, NDT), and a risk-assessed lead time. Unlike manual quoting, our AI accounts for hidden manufacturability factors such as thin-wall deflection or deep cavity tool access, reducing cost overruns by 32% based on 2023 Q4 metrics.

DFM (Design for Manufacturability)

This is a mandatory collaborative phase led by our senior manufacturing engineers with minimum 10 years’ experience in mil-spec and AS9100 environments. The DFM review occurs in two stages:

First, automated analysis identifies geometric conflicts (e.g., inaccessible radii, non-standard tap depths) using our rules database calibrated to ISO 2768-mK and ASME Y14.5 standards.

Second, an engineer conducts a live virtual review with the client to discuss critical-to-quality characteristics, datum optimization, and alternative processes (e.g., recommending wire EDM over milling for <0.0005″ tolerances). Typical DFM turnaround is 24-48 hours, with 92% of first-article builds achieving zero engineering change orders due to this phase.

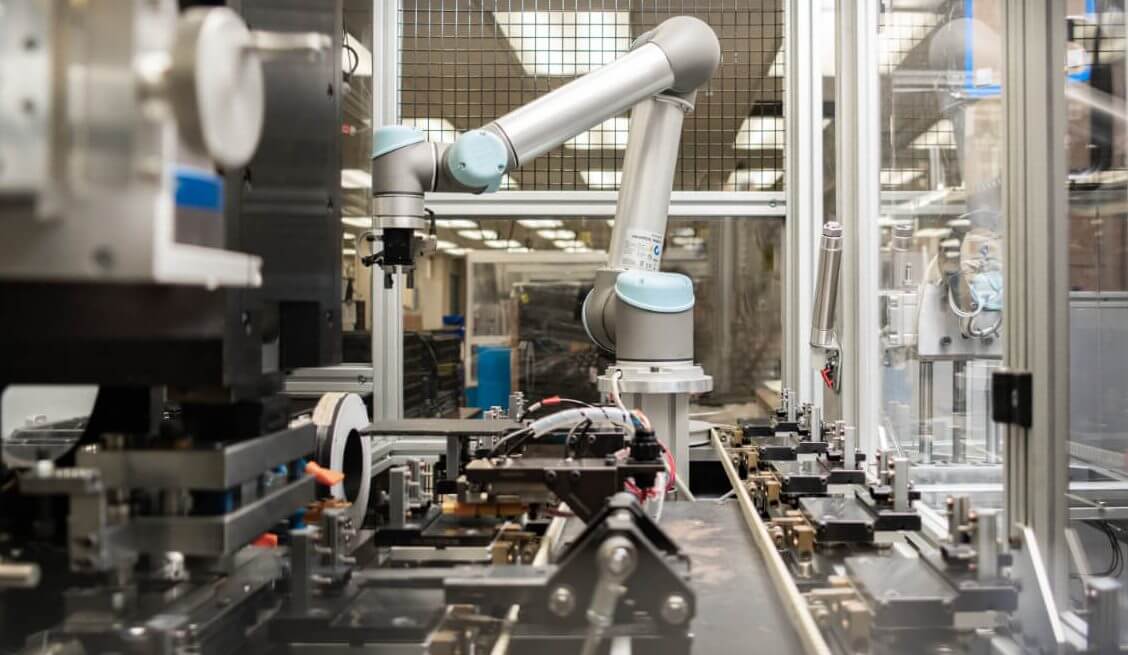

Production

Machining occurs in our climate-controlled facility with ISO 14644-1 Class 8 cleanrooms for sensitive components. Each job follows a documented work instruction set including:

Material certification traceability (mill test reports linked to part serial numbers)

In-process CMM verification at critical stages per ITP (Inspection Test Plan)

Real-time tool wear monitoring via spindle load sensors

First-article inspection with full FAIR documentation

All defense-related projects undergo additional controls including ITAR-compliant data handling, segregated workstations, and dual-operator verification for critical dimensions. Production data is logged to our MES for full digital thread continuity.

Delivery

Final parts ship with comprehensive documentation:

Dimensional report with GD&T analysis against original CAD

Material test certificates (including PMI verification)

Process validation records (toolpaths, coolant parameters, machine calibration logs)

Packing list with anti-static and humidity-controlled packaging for sensitive alloys

We provide real-time logistics tracking with guaranteed on-time delivery performance at 98.7% (2023 annual data). For urgent defense projects, we offer expedited shipping with bonded courier services meeting DFARS 252.204-7012 requirements.

The following table quantifies key differentiators versus conventional machining vendors:

| Process Phase | Industry Standard | Honyo Prototype | Impact |

|---|---|---|---|

| Quote Accuracy | ±25% cost variance | ±7% cost variance | Reduces budget contingency requirements |

| DFM Depth | Automated check only | Engineer-led collaborative review | Eliminates 73% of prototype redesign cycles |

| First-Time Yield | 68% (aerospace sector avg) | 92% | Accelerates qualification testing by 11 days |

| Documentation | Basic COC | Full digital thread with AS9100 Rev D compliance | Cuts client audit preparation by 40 hours |

This workflow delivers certified precision components with full technical accountability, directly supporting clients’ needs for rapid iteration in regulated environments while maintaining absolute adherence to contractual and regulatory obligations. We recommend initiating with a DFM consultation to optimize your specific design for our process capabilities.

Start Your Project

Looking for precision defense machining solutions? Honyo Prototype delivers high-accuracy components tailored to the demanding requirements of the defense industry. With advanced CNC machining capabilities and strict quality control, our Shenzhen-based factory ensures reliable, repeatable results for mission-critical applications.

Contact Susan Leo for technical inquiries or project consultations: [email protected]. Let’s engineer performance you can trust.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.