Introduction: Navigating the Global Market for decorative acrylic sheets

In the competitive landscape of global commerce, sourcing decorative acrylic sheets presents a unique challenge for international B2B buyers. With a diverse array of products available, from textured finishes to vibrant colors, understanding the nuances of these materials is crucial for making informed purchasing decisions. This guide aims to demystify the complexities surrounding decorative acrylic sheets, offering insights into various types, their applications across industries, and essential considerations for supplier vetting.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Vietnam, will find actionable strategies to navigate pricing structures and shipping logistics, ensuring they maximize value while minimizing risk. By delving into factors such as durability, aesthetic appeal, and functionality, this comprehensive resource equips buyers with the knowledge necessary to select the right acrylic solutions that align with their business needs.

Whether you are looking to enhance retail displays, design innovative interior spaces, or create protective barriers, understanding the intricate details of decorative acrylic sheets will empower you to make strategic decisions that drive success. This guide is your essential tool for exploring the global market effectively and efficiently.

Understanding decorative acrylic sheets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Frosted Acrylic | Translucent surface that diffuses light | Office partitions, decorative panels | Pros: Privacy, aesthetic appeal. Cons: May scratch easily. |

| Glitter Acrylic | Vibrant colors with glitter effects | Retail displays, signage, event decor | Pros: Eye-catching, versatile. Cons: Glitter may wear off. |

| Matte Acrylic | Non-reflective finish, available in various colors | Furniture, wall art, and custom displays | Pros: Reduces glare, stylish. Cons: Limited light transmission. |

| Textured Acrylic | Various surface patterns for unique aesthetics | Architectural applications, lighting fixtures | Pros: Unique design, hides fingerprints. Cons: More expensive. |

| Transparent Acrylic | High clarity and transparency, customizable | Protective barriers, display cases | Pros: Lightweight, shatter-resistant. Cons: Can scratch easily. |

What are the Characteristics of Frosted Acrylic Sheets?

Frosted acrylic sheets are known for their translucent quality, allowing light to diffuse while providing privacy. This makes them ideal for applications such as office partitions and decorative panels, where both light and seclusion are essential. B2B buyers should consider the thickness and UV resistance of these sheets, as some projects may require enhanced durability against sunlight exposure. While they offer aesthetic appeal, buyers should be aware that the surface can be prone to scratching, which may impact long-term performance.

How Do Glitter Acrylic Sheets Enhance Retail Displays?

Glitter acrylic sheets are characterized by their vibrant colors and embedded glitter, making them particularly effective for retail displays and signage. The eye-catching nature of these sheets can attract consumer attention, enhancing the overall shopping experience. When purchasing, businesses should evaluate the quality of the glitter application, as lower-quality products may see the glitter wear off over time. While they provide a unique decorative element, the sparkle may not be suitable for all brands, so alignment with brand identity is crucial.

Why Choose Matte Acrylic for Custom Displays?

Matte acrylic sheets feature a non-reflective finish that is available in a wide range of colors, making them a popular choice for furniture, wall art, and custom displays. Their ability to reduce glare makes them suitable for environments where lighting is critical, such as galleries or showrooms. Buyers should consider the intended application and whether the matte finish will complement their design goals. While matte acrylics enhance visual appeal, they may limit light transmission and are more susceptible to showing fingerprints.

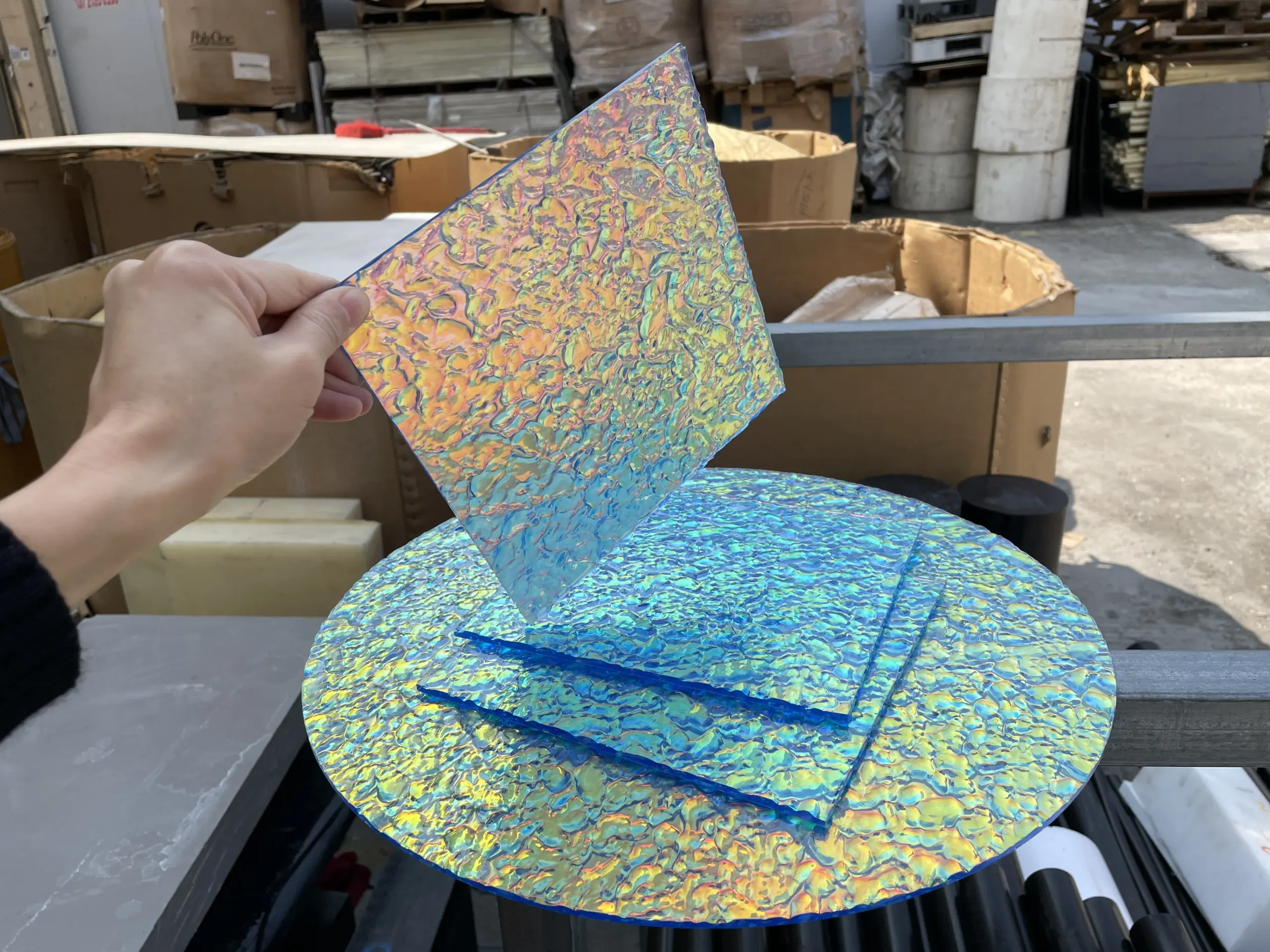

What are the Benefits of Textured Acrylic Sheets?

Textured acrylic sheets come with various surface patterns, providing unique aesthetics that can be leveraged in architectural applications and lighting fixtures. These sheets not only enhance design but also help to hide fingerprints and smudges, maintaining a cleaner appearance over time. When considering these sheets, B2B buyers should assess the specific texture and its compatibility with their intended use. Although they can be more expensive than standard sheets, the unique design elements often justify the investment.

How Do Transparent Acrylic Sheets Offer Versatility?

Transparent acrylic sheets are prized for their high clarity and customizable options, making them suitable for a wide range of applications including protective barriers and display cases. Their lightweight and shatter-resistant properties provide significant advantages over traditional glass, especially in environments where safety is a concern. Buyers should evaluate the thickness and potential for scratching when selecting transparent acrylic, as these factors can influence durability and long-term usability. While they offer excellent visibility, care must be taken to maintain their surface quality.

Key Industrial Applications of decorative acrylic sheets

| Industry/Sector | Specific Application of Decorative Acrylic Sheets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail Displays | Use in point-of-purchase displays and signage | Enhances visibility and attracts customers with vibrant designs | Durability, optical clarity, and customization options |

| Interior Design | Wall partitions and decorative panels | Adds aesthetic value while providing functional space separation | Material thickness, finish options, and ease of installation |

| Lighting Solutions | Light diffusers and decorative lighting fixtures | Improves light distribution and creates unique lighting effects | UV resistance, color options, and compatibility with existing fixtures |

| Hospitality Industry | Decorative elements in hotels, restaurants, and cafes | Elevates ambiance and customer experience through visual appeal | Customization for branding, durability, and maintenance ease |

| Architecture & Construction | Facades and decorative elements in buildings | Combines design with structural integrity, offering weather resistance | Sourcing for bulk orders, weight specifications, and installation guidelines |

How Are Decorative Acrylic Sheets Used in Retail Displays?

In the retail sector, decorative acrylic sheets are commonly utilized for point-of-purchase displays and signage. These sheets enhance visibility, drawing customers’ attention with vibrant colors and unique patterns. The lightweight yet durable nature of acrylic allows for intricate designs that can withstand the rigors of a retail environment. Buyers should consider sourcing options that provide high optical clarity and customization capabilities to align with their brand aesthetics.

What Role Do Decorative Acrylic Sheets Play in Interior Design?

In interior design, decorative acrylic sheets serve as wall partitions and decorative panels, adding both functionality and aesthetic appeal. They can create visually striking separations within spaces, effectively managing light while maintaining openness. International buyers should focus on the material thickness and finish options to meet their design needs while ensuring ease of installation for efficient project execution.

How Are Decorative Acrylic Sheets Beneficial in Lighting Solutions?

Decorative acrylic sheets are essential in the lighting industry, particularly as light diffusers and decorative lighting fixtures. They improve light distribution, creating unique effects that enhance the ambiance of a space. Buyers must prioritize UV resistance and a variety of color options to ensure compatibility with existing fixtures and to meet specific project requirements.

What Are the Applications of Decorative Acrylic Sheets in the Hospitality Industry?

In the hospitality sector, decorative acrylic sheets are used to create eye-catching elements in hotels, restaurants, and cafes. These sheets elevate the overall ambiance, contributing to a memorable customer experience. When sourcing for these applications, businesses should consider customization options for branding, along with durability and maintenance ease, to ensure long-lasting visual appeal.

How Are Decorative Acrylic Sheets Used in Architecture and Construction?

In architecture and construction, decorative acrylic sheets are employed for facades and various decorative elements in buildings. They offer a combination of design flexibility and structural integrity, capable of withstanding weather conditions while providing aesthetic value. Buyers in this sector should focus on sourcing for bulk orders, understanding weight specifications, and ensuring compliance with installation guidelines to streamline project execution.

3 Common User Pain Points for ‘decorative acrylic sheets’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Decorative Acrylic Sheets

The Problem: B2B buyers often struggle with sourcing decorative acrylic sheets that meet their specific quality standards. Many suppliers offer products that do not conform to the desired durability, optical clarity, or aesthetic appeal. This challenge is particularly pronounced in regions where local suppliers may lack the technical capacity to provide premium materials, leading to a reliance on international shipments that can be unpredictable in quality and delivery times. The lack of reliable suppliers can result in project delays, increased costs, and compromised end products that do not meet client expectations.

The Solution: To overcome sourcing challenges, buyers should establish relationships with reputable suppliers known for their quality assurance processes. It’s essential to request samples before committing to larger orders, allowing for a thorough evaluation of the material’s properties. Additionally, buyers should consider suppliers who provide detailed product specifications, including UV resistance, thickness, and impact ratings. Engaging with manufacturers that offer certifications can also ensure that the acrylic sheets meet international standards. Utilizing platforms that facilitate direct communication with suppliers can help streamline the procurement process, ensuring that all specifications are clearly communicated and understood.

Scenario 2: Navigating the Complexities of Customization

The Problem: Many businesses require customized decorative acrylic sheets tailored to specific dimensions, colors, or textures to fit unique design requirements. However, the customization process can be cumbersome and fraught with miscommunication, leading to incorrect orders and wasted materials. This is especially challenging for businesses in industries such as interior design or architecture, where precise specifications are critical to project success. Missteps in customization can result in costly delays and dissatisfaction among clients.

The Solution: To effectively manage the customization process, buyers should clearly define their requirements before initiating contact with suppliers. Creating detailed design briefs that include dimensions, color samples, and texture preferences can minimize misunderstandings. It’s beneficial to work with suppliers that offer design consultation services, as they can provide insights into material capabilities and limitations. Furthermore, utilizing 3D modeling software to visualize the final product before production can help ensure that expectations align with the actual outcome. Establishing a feedback loop with suppliers during the production phase can also facilitate adjustments and reduce the likelihood of errors.

Scenario 3: Managing Cost Efficiency While Maintaining Quality

The Problem: B2B buyers often face the challenge of balancing cost efficiency with the need for high-quality decorative acrylic sheets. In competitive markets, there is pressure to minimize expenses without compromising on quality, which can be particularly daunting for businesses operating on tight margins. This tension can lead to purchasing decisions that favor lower-cost materials, ultimately impacting the durability and aesthetic appeal of the final product.

The Solution: To effectively manage costs while ensuring quality, buyers should adopt a strategic sourcing approach. This includes conducting a thorough market analysis to identify suppliers that offer competitive pricing without sacrificing quality. Buyers can also negotiate bulk purchasing agreements that can lead to cost savings over time. Additionally, considering the total cost of ownership (TCO) rather than just the upfront price can provide a clearer picture of long-term value. Investing in high-quality decorative acrylic sheets may result in lower maintenance costs and longer product lifespans, ultimately saving money in the long run. Engaging with suppliers who offer warranties or guarantees can provide an added layer of financial protection, allowing businesses to confidently invest in quality materials.

Strategic Material Selection Guide for decorative acrylic sheets

What Are the Key Properties of Common Decorative Acrylic Sheet Materials?

When selecting decorative acrylic sheets, international B2B buyers must consider various materials, each with unique properties that affect performance, durability, and suitability for specific applications. Here, we analyze four common materials used in decorative acrylic sheets: standard acrylic, frosted acrylic, glitter acrylic, and textured acrylic.

What Are the Key Properties of Standard Acrylic Sheets?

Standard acrylic sheets, also known as polymethyl methacrylate (PMMA), are widely used due to their excellent optical clarity and shatter resistance. They typically have a temperature tolerance of up to 80°C and are resistant to many chemicals, making them suitable for various environments.

Pros: The lightweight nature of standard acrylic makes it easy to handle and install. Its high transparency allows for vibrant color reproduction and light transmission, which is essential for applications like signage and display cases.

Cons: While durable, standard acrylic can scratch easily and may become brittle over time when exposed to UV light unless treated. The cost is moderate, but additional protective coatings can increase the overall expense.

Impact on Application: Standard acrylic is compatible with a wide range of media, including paints and adhesives, making it versatile for decorative applications.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial, especially in regions like Europe and the Middle East. Buyers should also consider the local climate, as UV stability may be a concern in sunny regions.

How Do Frosted Acrylic Sheets Differ in Performance?

Frosted acrylic sheets are treated to create a translucent effect, diffusing light while maintaining privacy. They can withstand temperatures similar to standard acrylic but offer enhanced scratch resistance due to their matte surface.

Pros: Frosted acrylic is ideal for applications requiring light diffusion, such as office partitions and decorative lighting. Its aesthetic appeal and privacy features make it a popular choice in interior design.

Cons: While they are more resistant to scratches, frosted sheets can be more challenging to clean without leaving streaks. They tend to be slightly more expensive than standard acrylic due to the additional processing involved.

Impact on Application: Frosted acrylic is often used in environments where glare reduction is necessary, making it suitable for lighting fixtures and decorative screens.

Considerations for International Buyers: Buyers should verify that frosted acrylic complies with local building codes, especially in commercial applications. Additionally, understanding the local market’s aesthetic preferences can guide material selection.

What Are the Unique Features of Glitter Acrylic Sheets?

Glitter acrylic sheets incorporate glitter particles within the acrylic matrix, offering a unique decorative effect. They are typically available in various colors and finishes, with temperature resistance similar to standard acrylic.

Pros: The eye-catching appearance of glitter acrylic makes it perfect for creative applications, such as signage, art projects, and event displays. They are lightweight and easy to fabricate.

Cons: Glitter acrylic can be more expensive than standard options, and the glitter may not be suitable for all applications due to potential shedding. Additionally, they may not be as suitable for high-traffic areas due to their potential for scratching.

Impact on Application: These sheets are often used in artistic and promotional contexts, where visual impact is paramount.

Considerations for International Buyers: Buyers should consider the cultural significance of colors and designs in their target markets, especially in regions like Africa and South America where vibrant aesthetics are favored.

What Advantages Do Textured Acrylic Sheets Offer?

Textured acrylic sheets feature various surface patterns that enhance light diffusion and aesthetics. They generally have similar temperature and chemical resistance properties to standard acrylic.

Pros: The textures can add depth and interest to designs, making them suitable for applications like wall panels and decorative elements. They also help hide fingerprints and scratches.

Cons: The manufacturing process for textured sheets can be complex, potentially leading to higher costs. Additionally, the specific textures may limit their compatibility with certain adhesives and paints.

Impact on Application: Textured acrylic is ideal for architectural applications where both aesthetics and functionality are required.

Considerations for International Buyers: Understanding local design trends and preferences can significantly influence the selection of textured acrylic sheets, particularly in regions with a rich design heritage.

Summary Table of Material Selection

| Material | Typical Use Case for decorative acrylic sheets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Acrylic | Signage, display cases | Excellent optical clarity | Scratches easily | Medium |

| Frosted Acrylic | Office partitions, decorative lighting | Light diffusion and privacy | Challenging to clean | Medium |

| Glitter Acrylic | Art projects, event displays | Eye-catching aesthetic | Potential for glitter shedding | High |

| Textured Acrylic | Wall panels, decorative elements | Adds depth and interest | Higher manufacturing complexity | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and considerations of various decorative acrylic sheets, enabling informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for decorative acrylic sheets

What Are the Key Stages in the Manufacturing Process of Decorative Acrylic Sheets?

The manufacturing of decorative acrylic sheets is a multi-step process that ensures high-quality products suitable for various applications. This process typically includes material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

The primary raw material for acrylic sheets is poly(methyl methacrylate) (PMMA), known for its clarity, durability, and versatility. During the material preparation stage, PMMA resin is meticulously chosen based on the desired characteristics of the final product. Additives such as colorants and UV stabilizers may be incorporated to enhance aesthetics and performance.

The resin is usually in pellet form, which is pre-dried to remove any moisture that may affect the quality of the finished sheet. This is crucial, as moisture can lead to defects during the molding process.

How Are Decorative Acrylic Sheets Formed?

The forming stage often employs techniques like extrusion and casting.

-

Extrusion involves forcing melted acrylic resin through a die to create sheets of specified thickness. This method is commonly used for large production volumes and offers excellent consistency in sheet dimensions. The extruded sheets can then be cut into desired sizes for various applications.

-

Casting, on the other hand, is a slower process that involves pouring liquid acrylic into molds. This technique allows for the creation of thicker sheets and offers more intricate designs, such as patterns and textures. Cast sheets are typically known for their superior optical clarity and finish.

Both methods require precise temperature control and careful monitoring to ensure the final product meets the required specifications.

What Finishing Techniques Are Commonly Used?

Finishing is the final stage in the manufacturing process and involves several techniques to enhance the visual appeal and functionality of the acrylic sheets. Common finishing techniques include:

-

Polishing: This is done to achieve a high-gloss surface and improve clarity. Mechanical polishing or chemical polishing may be employed based on the desired finish.

-

Texturing: Various textures can be applied to the surface of the sheets to diffuse light or provide a decorative element. This is particularly important for applications in the lighting and interior design industries.

-

Coating: Protective coatings may be applied to enhance UV resistance or scratch resistance, thus extending the lifespan of the sheets in various environments.

How Is Quality Assurance Implemented in the Production of Acrylic Sheets?

Quality assurance is paramount in the production of decorative acrylic sheets. It ensures that the products meet international standards and customer expectations.

What International Standards Are Relevant for Quality Assurance?

International standards such as ISO 9001 play a critical role in guiding the quality management processes within manufacturing facilities. ISO 9001 emphasizes a systematic approach to managing an organization’s processes to enhance customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE marking and API standards may also apply, particularly for products intended for construction or safety applications. CE marking indicates compliance with European health, safety, and environmental requirements.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is implemented at various stages of production through several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process. This includes checking temperature, pressure, and material consistency to prevent defects.

-

Final Quality Control (FQC): After production, finished sheets undergo rigorous testing for clarity, thickness, and surface quality. This ensures that the products meet both internal and external standards.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to verify the quality of decorative acrylic sheets:

-

Visual Inspection: This is a fundamental step where sheets are checked for surface imperfections, clarity, and color consistency.

-

Mechanical Testing: Tests such as impact resistance and tensile strength are conducted to ensure that the sheets can withstand operational demands.

-

Optical Testing: Measurements of light transmission and clarity are essential for applications in signage and display cases.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

What Are Effective Methods for Supplier Verification?

-

Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control practices, and overall compliance with international standards.

-

Quality Reports: Requesting comprehensive quality reports can provide insights into the QC processes employed by the supplier, including details on testing results and compliance with relevant standards.

-

Third-party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control measures, helping buyers make informed decisions.

What Nuances Should International Buyers Be Aware Of?

International buyers must be aware of regional regulations and standards that may affect quality assurance. For instance, the requirements for acrylic sheets used in construction can differ significantly between countries. Buyers should ensure that their suppliers are compliant with both local and international standards to avoid potential legal and operational issues.

Understanding these aspects of manufacturing processes and quality assurance will empower B2B buyers to make informed decisions when sourcing decorative acrylic sheets, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘decorative acrylic sheets’

In the competitive market for decorative acrylic sheets, making informed sourcing decisions is crucial for B2B buyers. This checklist is designed to guide you through the procurement process, ensuring that you select the best materials for your projects while minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the decorative acrylic sheets you need. Consider factors such as thickness, size, color, finish, and any specific patterns or textures. Defining these specifications upfront helps you communicate effectively with suppliers and ensures you receive products that meet your project needs.

- Thickness and Size: Determine the dimensions required for your application, keeping in mind that standard sizes may vary by supplier.

- Finish and Texture: Specify if you need a glossy, matte, or textured finish, as these can significantly affect the aesthetic and functional properties of the sheets.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers that specialize in decorative acrylic sheets. Look for companies with a solid reputation in the industry, preferably those with experience in your specific market region, such as Africa, South America, the Middle East, or Europe.

- Online Reviews and Testimonials: Check customer feedback to gauge supplier reliability and product quality.

- Industry Reputation: Look for suppliers that are recognized within industry associations or have certifications relevant to your market.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps you assess their capability to meet your needs and ensures they have a track record of reliability.

- Request Samples: Ask for product samples to evaluate quality firsthand before placing a bulk order.

- Assess Production Capacity: Ensure the supplier can handle your order volume and timelines without compromising quality.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers adhere to relevant industry standards and certifications. This verification is critical for maintaining product quality and compliance with local regulations, especially if you are importing materials.

- Quality Standards: Look for ISO certifications or compliance with regional safety standards relevant to decorative acrylic sheets.

- Sustainability Practices: Consider suppliers who follow environmentally friendly practices, which can enhance your brand’s reputation.

Step 5: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, initiate negotiations on pricing, payment terms, and delivery schedules. Ensure that you understand all costs involved, including shipping and potential tariffs, which can affect your overall budget.

- Bulk Discounts: Inquire about discounts for larger orders or long-term partnerships.

- Payment Terms: Clarify payment methods and timelines to avoid any financial misunderstandings.

Step 6: Establish a Clear Communication Channel

Effective communication with your chosen supplier is essential for a successful partnership. Establish a point of contact and agree on communication methods and frequency to ensure that any issues can be addressed promptly.

- Regular Updates: Set expectations for regular updates on order status and delivery timelines.

- Feedback Mechanism: Create a process for providing feedback on product quality and service, fostering continuous improvement.

Step 7: Plan for Quality Assurance and Testing

After receiving your decorative acrylic sheets, implement a quality assurance process to inspect the materials against your original specifications. This step is vital to ensure that the products meet your expectations and are ready for use in your applications.

- Inspection Protocols: Develop a checklist for inspecting the sheets upon arrival, focusing on dimensions, finish, and any defects.

- Testing Procedures: If applicable, perform any necessary tests to ensure the sheets meet functional requirements, particularly if they will be used in demanding applications.

By following this checklist, you can streamline your sourcing process and secure high-quality decorative acrylic sheets that align with your business goals.

Comprehensive Cost and Pricing Analysis for decorative acrylic sheets Sourcing

What Are the Key Cost Components in Sourcing Decorative Acrylic Sheets?

When sourcing decorative acrylic sheets, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of acrylic used significantly influences cost. For instance, standard clear acrylic may be less expensive than specialized options like UV-filtering or textured sheets. Prices can range from $1.49 to $19.95 per sheet depending on the specifications and finishes.

-

Labor: Labor costs encompass not only the production workforce but also skilled labor for customization and finishing processes. Countries with lower labor costs can provide a competitive advantage in pricing, but this must be balanced against quality.

-

Manufacturing Overhead: This includes expenses such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these costs, ultimately benefiting the buyer.

-

Tooling: Custom tooling for specific designs or patterns can add to the initial investment but may lead to lower costs per unit over time, especially for larger orders.

-

Quality Control (QC): Ensuring high standards through rigorous QC processes can increase costs but is essential for maintaining product quality, particularly for international buyers who may face stringent regulations.

-

Logistics: Shipping costs can vary significantly based on the mode of transport, distance, and Incoterms. International shipping often incurs additional fees, including customs duties and taxes, which must be factored into the total cost.

-

Margin: Suppliers typically mark up their costs to achieve a profit margin. Understanding the supplier’s pricing strategy can provide insight into potential negotiation points.

How Do Price Influencers Affect the Cost of Decorative Acrylic Sheets?

Several factors influence pricing in the decorative acrylic sheets market, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect unit pricing. Bulk orders often qualify for discounts, making it crucial for buyers to assess their needs carefully.

-

Specifications and Customization: Custom designs, colors, and finishes can significantly impact pricing. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Materials Quality and Certifications: Higher quality materials and industry certifications often lead to increased costs. Buyers in regions with strict compliance standards should prioritize suppliers who can provide relevant certifications.

-

Supplier Factors: The supplier’s location, reputation, and operational efficiencies can all affect pricing. Established suppliers may charge more but offer reliability and superior customer service.

-

Incoterms: Understanding Incoterms is critical for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect total costs.

What Buyer Tips Can Help Optimize Cost-Efficiency?

To maximize cost-efficiency when sourcing decorative acrylic sheets, consider the following strategies:

-

Negotiation: Approach suppliers with a clear understanding of your requirements and leverage volume for better pricing. Building long-term relationships can also yield favorable terms.

-

Total Cost of Ownership (TCO): Evaluate the full lifecycle cost of the sheets, including installation, maintenance, and potential replacement costs. This holistic view can guide more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of potential currency fluctuations, tariffs, and local taxes that may affect pricing when importing decorative acrylic sheets. Researching the market and understanding local regulations can help mitigate unforeseen expenses.

Disclaimer

The prices and insights provided in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult multiple suppliers and conduct thorough due diligence to ensure the best sourcing decisions.

Alternatives Analysis: Comparing decorative acrylic sheets With Other Solutions

Exploring Alternatives to Decorative Acrylic Sheets: A Comparative Analysis

In the realm of decorative materials, decorative acrylic sheets stand out for their versatility and aesthetic appeal. However, various alternatives exist that may also fulfill specific project requirements. This analysis compares decorative acrylic sheets with two viable alternatives: polycarbonate sheets and glass panels. Understanding the strengths and weaknesses of each option will enable B2B buyers to make informed decisions based on their unique needs.

| Comparison Aspect | Decorative Acrylic Sheets | Polycarbonate Sheets | Glass Panels |

|---|---|---|---|

| Performance | High impact resistance; lightweight and shatterproof. | Excellent impact resistance; less optical clarity than acrylic. | Superior optical clarity; heavy and fragile. |

| Cost | Generally affordable; prices vary with customization. | Typically lower cost than glass; moderate pricing. | Higher upfront costs; installation can be expensive. |

| Ease of Implementation | Easy to cut and shape; requires basic tools. | Similar ease of use; can be cut and shaped on-site. | More complex; requires professional installation. |

| Maintenance | Low maintenance; easy to clean with mild detergents. | Low maintenance; resistant to yellowing over time. | Requires careful handling; prone to scratches and breakage. |

| Best Use Case | Ideal for decorative applications, signage, and displays. | Suitable for safety applications, greenhouses, and outdoor settings. | Best for high-end aesthetics in residential or commercial spaces. |

What Are the Advantages and Disadvantages of Polycarbonate Sheets?

Polycarbonate sheets are a strong alternative to decorative acrylic sheets. They possess excellent impact resistance and are nearly unbreakable, making them suitable for applications where safety is a priority, such as in schools or public spaces. The cost is generally lower than glass, and they are relatively lightweight, which aids in installation. However, polycarbonate may not offer the same level of optical clarity as acrylic, potentially affecting visual aesthetics. Additionally, while they are resistant to yellowing, they may still scratch more easily than acrylic.

How Do Glass Panels Compare to Decorative Acrylic Sheets?

Glass panels are often regarded for their superior optical clarity and high-end finish, making them a preferred choice for luxury applications. They are particularly effective in settings where aesthetics are paramount, such as in upscale retail environments or residential spaces. However, glass is heavier and more fragile than both acrylic and polycarbonate, leading to higher shipping and installation costs. Maintenance can also be more demanding, as glass requires careful handling to avoid scratches and breakage.

How Can B2B Buyers Choose the Right Decorative Solution?

Selecting the right decorative solution involves evaluating specific project requirements, including budget constraints, desired aesthetic qualities, and the intended application environment. Decorative acrylic sheets are ideal for applications needing lightweight, shatter-resistant materials with customizable designs. Polycarbonate sheets serve well in safety-focused scenarios, while glass panels are best suited for high-end projects where clarity and elegance are crucial. By understanding the distinct advantages and limitations of each alternative, B2B buyers can make informed choices that align with their operational needs and aesthetic goals.

Essential Technical Properties and Trade Terminology for decorative acrylic sheets

What Are the Key Technical Properties of Decorative Acrylic Sheets?

When sourcing decorative acrylic sheets for various applications, understanding the technical properties is crucial for making informed purchasing decisions. Here are several essential specifications to consider:

1. Material Grade

Material grade refers to the quality and type of acrylic used, typically categorized as extruded or cast acrylic. Cast acrylic sheets generally offer superior optical clarity and are more resistant to UV light, making them ideal for high-end applications. This distinction is vital as it affects durability, clarity, and overall performance.

2. Thickness and Tolerance

The thickness of acrylic sheets is usually measured in millimeters or inches, with common sizes ranging from 1/16” to 1”. Tolerance indicates the allowable variation from the specified thickness. Precise thickness and tolerance are crucial for applications requiring specific fitting or structural integrity, as deviations can compromise the design and functionality.

3. Impact Resistance

Acrylic sheets are known for their excellent impact resistance, often rated as being ten times stronger than glass. This property is particularly important for applications in environments prone to breakage or where safety is a concern. Understanding the impact resistance helps buyers ensure that the sheets meet safety standards for their intended use.

4. UV Resistance

Many decorative acrylic sheets come with UV-resistant properties, preventing color fading and degradation over time when exposed to sunlight. This characteristic is essential for outdoor applications or areas with high light exposure, ensuring long-lasting aesthetic appeal and functionality.

5. Surface Finish

Acrylic sheets can have various surface finishes, including glossy, matte, or textured. The choice of finish affects both the appearance and functionality of the sheets, such as glare reduction or light diffusion. Buyers should consider the desired aesthetic and practical needs when selecting the surface finish.

What Are Common Trade Terms Related to Decorative Acrylic Sheets?

Familiarity with industry jargon can streamline communication and negotiations in the B2B environment. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end product. Understanding the OEM relationship is vital for buyers who may need to source decorative acrylic sheets as part of larger assemblies or finished goods.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it can affect inventory costs and the overall budget. Knowing the MOQ helps buyers plan their purchasing strategy effectively.

3. RFQ (Request for Quotation)

An RFQ is a standard business process wherein a buyer requests a quote from suppliers for specific products or services. This term is important for initiating the procurement process and ensuring that all potential suppliers provide comparable pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, costs, and risks associated with transporting decorative acrylic sheets across borders.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This term is crucial for project planning and inventory management, especially for businesses that rely on timely delivery for production schedules.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the procurement of decorative acrylic sheets with confidence, ensuring they select the right materials and terms for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the decorative acrylic sheets Sector

What Are the Key Trends and Market Dynamics Influencing Decorative Acrylic Sheets?

The decorative acrylic sheets market is experiencing significant growth, driven by a surge in demand across various sectors, including construction, automotive, and signage. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek innovative materials, decorative acrylic sheets are increasingly recognized for their versatility, aesthetic appeal, and durability. Key trends include the rise of customization, where manufacturers offer tailored solutions to meet specific design requirements. This trend is fueled by advancements in digital printing technologies, enabling intricate designs and patterns that cater to diverse market preferences.

Another notable trend is the growing preference for lightweight materials. Compared to traditional glass, decorative acrylic sheets are not only shatter-resistant but also easier to handle and install, significantly reducing labor costs. Additionally, the market is witnessing an upsurge in the incorporation of smart technologies, such as light-diffusing and UV-filtering capabilities, enhancing the functional value of acrylic sheets in architectural and interior design applications.

Emerging markets, particularly in Africa and South America, are recognizing the potential of decorative acrylic sheets for sustainable architecture and interior design. Buyers are increasingly aware of the need to source materials that align with global sustainability goals while enhancing their projects’ aesthetic appeal.

How Is Sustainability and Ethical Sourcing Impacting the Decorative Acrylic Sheets Market?

Sustainability is becoming a pivotal concern for B2B buyers in the decorative acrylic sheets sector. The environmental impact of production processes, including energy consumption and waste generation, is under scrutiny. As a result, many manufacturers are adopting greener practices, such as utilizing recycled materials and reducing the carbon footprint of their operations.

Ethical sourcing has gained importance, as buyers prioritize suppliers who demonstrate a commitment to responsible supply chain practices. This includes ensuring fair labor conditions and sourcing raw materials from environmentally sustainable sources. Certifications such as ISO 14001 (Environmental Management) and the use of recycled acrylic materials can enhance a supplier’s credibility and appeal to environmentally conscious buyers.

B2B buyers should consider suppliers who offer products certified for their environmental performance. Green certifications not only signify a commitment to sustainability but can also influence purchasing decisions, particularly in regions where eco-friendly practices are mandated by regulations or increasingly demanded by consumers.

What Is the Brief History of Decorative Acrylic Sheets in the B2B Context?

The evolution of decorative acrylic sheets can be traced back to the mid-20th century when acrylic, a lightweight and shatter-resistant alternative to glass, was first commercialized. Initially used primarily in the automotive and aviation industries, its applications expanded into architecture and interior design as designers began to appreciate its aesthetic qualities.

Over the decades, advancements in manufacturing techniques have led to the development of various finishes and patterns, enhancing its decorative appeal. The introduction of digital printing technologies in the 21st century revolutionized the industry, enabling customized designs that cater to the specific needs of B2B buyers. Today, decorative acrylic sheets are an integral part of modern design, offering limitless possibilities for creativity while meeting the demands of functionality and sustainability.

In conclusion, the decorative acrylic sheets sector is positioned for continued growth, driven by market dynamics that favor innovation, sustainability, and customization. B2B buyers must navigate these trends to make informed sourcing decisions that align with their business goals and the evolving market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of decorative acrylic sheets

-

1. How do I choose the right decorative acrylic sheets for my project?

Choosing the right decorative acrylic sheets involves assessing your specific needs, including aesthetics, durability, and functionality. Consider factors such as the intended application—whether for signage, furniture, or architectural features. Evaluate the various finishes and textures available, such as matte, gloss, or patterned options, to find one that aligns with your design vision. Additionally, ensure the acrylic sheet meets necessary safety and regulatory standards in your region. -

2. What are the advantages of using acrylic sheets over glass for decorative applications?

Acrylic sheets offer several advantages over glass, including being lighter, shatter-resistant, and easier to fabricate. They provide superior optical clarity and can be produced in various colors and finishes, enhancing design flexibility. Acrylic is also less prone to breakage, reducing safety concerns, particularly in high-traffic areas. These qualities make acrylic an ideal choice for decorative applications in both commercial and residential settings. -

3. What customization options are available for decorative acrylic sheets?

Customization options for decorative acrylic sheets include various colors, thicknesses, finishes (such as matte or gloss), and patterns. Manufacturers often offer CNC routing, edge finishing, and fabrication services to tailor sheets to your project’s specifications. It’s advisable to discuss your requirements with potential suppliers to ensure they can accommodate your customization needs, including any unique designs or dimensions. -

4. What are the typical minimum order quantities (MOQs) for decorative acrylic sheets?

Minimum order quantities for decorative acrylic sheets can vary significantly depending on the supplier and the type of sheet. Generally, MOQs may range from as low as 5 sheets to over 100 sheets for bulk orders. It’s essential to inquire about MOQs when requesting quotes to understand the scale of your order and whether it aligns with your project budget. -

5. How can I ensure quality assurance when sourcing decorative acrylic sheets?

To ensure quality assurance, work with reputable suppliers who provide detailed product specifications and certifications. Request samples to evaluate the material’s quality, clarity, and finish before placing larger orders. Additionally, inquire about the supplier’s quality control processes, including testing for impact resistance, UV stability, and dimensional accuracy, to confirm that the sheets meet your standards. -

6. What payment terms should I expect when purchasing decorative acrylic sheets internationally?

Payment terms for international purchases of decorative acrylic sheets typically include options such as advance payment, letters of credit, or payment upon delivery. It’s crucial to clarify these terms upfront with your supplier to avoid misunderstandings. Additionally, consider discussing payment methods that offer protection, such as escrow services, especially for larger transactions or first-time orders. -

7. What logistics considerations should I keep in mind when importing decorative acrylic sheets?

When importing decorative acrylic sheets, consider factors such as shipping methods, lead times, and customs regulations in your country. Work with suppliers experienced in international shipping to ensure compliance with import/export laws. Additionally, factor in shipping costs, potential tariffs, and insurance to protect your investment during transit. Clear communication with your logistics provider will help streamline the delivery process. -

8. How do I vet potential suppliers for decorative acrylic sheets?

To vet potential suppliers, conduct thorough research, including checking customer reviews, testimonials, and industry certifications. Request references and inquire about their experience in supplying acrylic sheets to businesses in your region. Visiting the supplier’s facility, if feasible, can also provide insights into their production capabilities and quality control processes. Establishing a strong line of communication will help you assess their reliability and responsiveness to your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Decorative Acrylic Sheets Manufacturers & Suppliers List

1. A&C Plastics – Patterned Plexiglass Sheets

Domain: acplasticsinc.com

Registered: 1997 (28 years)

Introduction: Patterned Plexiglass Sheets are decorative and functional plastic sheets made from acrylic, also known as Poly(methyl methacrylate). They are durable, transparent, shatter-resistant, and offer optical clarity, making them ideal for protective barriers, display cases, and signage. A&C Plastics offers a variety of patterned plastic sheets that provide aesthetic appeal while being ten times stronger …

2. Lumicor – Quick Ship Resin Panels

Domain: lumicor.com

Registered: 2000 (25 years)

Introduction: Lumicor offers a Quick Ship program featuring a selection of materials that are available for fast delivery. The program includes a variety of designs and finishes, allowing for quick turnaround times on projects. Key products include Lumicor’s signature resin panels, which are customizable and suitable for various applications such as architectural, interior design, and furniture. The Quick Ship …

3. Custom Made Better – Acrylic Sheets Collection

Domain: custommadebetter.com

Registered: 2020 (5 years)

Introduction: Acrylic Sheets Collection includes various thicknesses (1/8″, 1/16″, 1/4″, 1/32″) and colors (Clear, Reds, Oranges, Yellows, Greens, Blues, Purples, Pinks, Beige & Browns, Gray, Silver, Gold). Available finishes include Gloss/Gross, Matte/Gross, Transparent, Frosted, Mirror, Metallic, Iridescent, Color Changing, and Specialty. There are also options for custom printing and acrylic blanks. Featured…

4. Outwater – Decorative Acrylic Panels

Domain: outwater.com

Registered: 1995 (30 years)

Introduction: This company, Outwater – Decorative Acrylic Panels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Tap Plastics – Acrylic Sheets

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: Acrylic Sheets, Cast Clear, Cut to Size, available in various thicknesses and sizes. Ideal for a range of applications including displays, signage, and protective barriers. Offers excellent clarity, UV resistance, and impact strength.

6. Galaxy Plastic – Decorative Acrylic Sheets

Domain: galaxyplastic.com

Registered: 2006 (19 years)

Introduction: Decorative Acrylic Sheets available in sizes: 1/8″, 3/16″, 1/4″. Product types include Pearls, Glitters, Marbles, Rain, Stipples, Granites, Stained Glass, Flourescents, and Novelties. Custom jobs and specials/closeouts are also offered. Samples can be requested.

7. AcrylicMe – Premium Acrylic Sheets for Laser Cutting

Domain: acrylicmethat.com

Registered: 2020 (5 years)

Introduction: Best Acrylic Sheets and Plexiglass for Laser Cutting, including various types such as Glitter Cast Acrylic Sheets, Light Diffusing Acrylic Sheets, Patterned Acrylic Sheets, Transparent Acrylic Sheets, Translucent Acrylic Sheets, Gloss Acrylic Sheets, Holographic Acrylic Sheets, Iridescent Acrylic Sheets, Shimmering Acrylic Sheets, Decorative Acrylic Sheets, Opaque Acrylic Sheets, Pearlescent Acryl…

8. Rothko & Frost – Cast Acrylic Sheets

Domain: rothkoandfrost.com

Registered: 2010 (15 years)

Introduction: Cast Acrylic Sheets available in the UK. Options include clear and colored sheets, suitable for laser cutting. Free UK shipping on orders over £30.

9. Professional Plastics – Acrylic Sheet – Rain Pattern

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: Acrylic Sheet – Rain Pattern, available in various sizes, thicknesses, and colors. It offers excellent clarity, durability, and weather resistance. Ideal for applications requiring light diffusion and aesthetic appeal. Commonly used in signage, displays, and decorative projects.

10. Canal Plastic – Opaque Colored Acrylic Plexiglass Sheets

Domain: canalplastic.com

Registered: 2004 (21 years)

Introduction: Opaque Colored Acrylic Plexiglass Sheets available in various colors including White, Black, Red, Turquoise, Pink, Dark Blue, Yellow, Orange, Baby Blue, and Teal. Regular price starting at $3.68. Dimensions offered: 6″ x 12″, 12″ x 12″, 12″ x 18″, 12″ x 24″, 18″ x 24″, 18″ x 32″, 24″ x 24″, 24″ x 36″, 24″ x 48″, 2″ x 2″, Sample 48″ x 72″, Sample 48″ x 96″, and Custom Size. Thickness options: 1/16″…

Strategic Sourcing Conclusion and Outlook for decorative acrylic sheets

The dynamic market for decorative acrylic sheets presents a multitude of opportunities for international B2B buyers. As businesses increasingly seek materials that blend aesthetic appeal with functional durability, acrylic sheets stand out due to their versatility, safety features, and diverse design options. Strategic sourcing is essential for navigating this competitive landscape, enabling buyers to identify reliable suppliers who offer high-quality products tailored to specific needs.

Key takeaways include the importance of evaluating suppliers based on their product range, customization capabilities, and delivery times. For buyers in Africa, South America, the Middle East, and Europe, forming partnerships with suppliers that understand local market trends can enhance product offerings and improve customer satisfaction.

Looking ahead, the demand for decorative acrylic sheets is expected to grow, driven by innovations in design and manufacturing. Now is the time for B2B buyers to engage with suppliers, leverage their expertise, and explore new applications for acrylic in various industries. By prioritizing strategic sourcing, businesses can not only secure quality materials but also position themselves as leaders in their respective markets. Embrace this opportunity to elevate your product offerings and drive growth in your business.