Contents

Manufacturing Insight: Deburring Steel

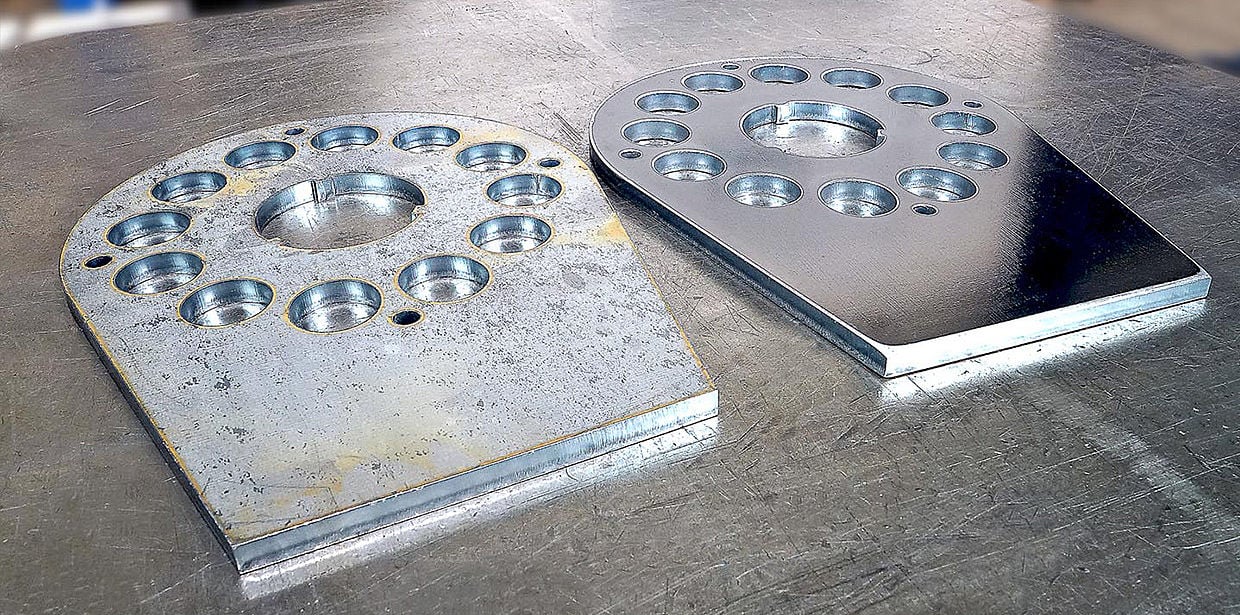

Precision Steel Deburring: Integral to Honyo Prototype’s CNC Machining Excellence

In precision metal fabrication, the presence of burrs on steel components presents significant functional, safety, and aesthetic challenges. These sharp edges or protrusions, inherent to machining processes like milling, turning, and drilling, can compromise part fitment, interfere with assembly, create failure points under stress, and pose handling hazards. Effective deburring is not merely a finishing step; it is a critical quality control requirement for high-performance steel parts used in demanding industries such as aerospace, medical devices, and industrial automation.

At Honyo Prototype, we recognize that true manufacturing precision extends beyond the initial cut. Our advanced CNC machining services are engineered with deburring seamlessly integrated into the production workflow. Utilizing state-of-the-art 3-, 4-, and 5-axis CNC milling and turning centers, we employ optimized toolpaths, specialized cutters, and controlled machining parameters designed to minimize burr formation at the source. For applications requiring absolute edge perfection, our in-house capabilities include precision vibratory finishing, thermal energy deburring, and selective robotic deburring – all performed under stringent quality protocols to meet exacting dimensional tolerances and surface finish specifications. This integrated approach eliminates costly secondary operations, reduces lead times, and ensures every steel component shipped from Honyo meets the highest standards of functionality and reliability.

Engineers and procurement professionals seeking rapid validation of manufacturability and cost for their steel prototypes or production runs can leverage Honyo Prototype’s Online Instant Quote platform. Simply upload your CAD file to receive a detailed, transparent quote for precision CNC machining – including optimized deburring strategies – within hours, accelerating your path from design to flawless physical part.

Technical Capabilities

Technical Specifications for Deburring in Precision Machining – Focus on 3/4/5-Axis Milling and Turning with Tight Tolerances

Deburring is a critical post-machining process that ensures component functionality, surface finish, and interchangeability—especially in high-precision environments involving 3/4/5-axis milling and turning operations. When working with tight tolerances (typically ±0.0005″ to ±0.005″), the removal of burrs without affecting dimensional accuracy or edge geometry is essential. Below is a breakdown of deburring specifications across common engineering materials.

| Parameter | Aluminum | Steel | ABS | Nylon |

|---|---|---|---|---|

| Typical Burr Formation | Low to moderate; soft, stringy burrs | Moderate to high; hard, sharp burrs | Low; fragile, flash-like burrs | Moderate; flexible, fibrous burrs |

| Common Machining Process | 3/4/5-axis milling, CNC turning | 5-axis milling, CNC turning | 3/4-axis milling | 3/4-axis milling, turning |

| Tolerance Range | ±0.0005″ – ±0.005″ | ±0.001″ – ±0.005″ | ±0.005″ – ±0.010″ | ±0.005″ – ±0.010″ |

| Deburring Methods | Brush deburring, CNC stone tools, thermal, manual with non-metallic tools | CNC deburring, abrasive flow, vibratory finishing, manual with carbide tools | Hand filing, air-file tools, abrasive pads | Hand deburring, rotary files, sandpaper |

| Tooling Recommendations | Diamond-coated brushes, PCD tools, soft abrasive stones | CBN or carbide deburring tools, ceramic media | Soft nylon brushes, non-woven abrasive wheels | Flexible shaft tools, fine-grit abrasives |

| Surface Finish Concerns | High; risk of smearing or oxidation | Critical for fatigue resistance and coating | Cosmetic finish important | Wear resistance and flexibility retention |

| Automation Compatibility | High – suitable for robotic and CNC deburring | High – integrates well with automated systems | Moderate – requires care to avoid deformation | Moderate – flexible material complicates automation |

| Special Considerations | Non-ferrous, high thermal conductivity; avoid built-up edge | High hardness; may require multi-stage deburring | Low melting point; avoid heat generation | Hygroscopic; sensitive to moisture and heat |

Notes on Tight Tolerance Applications

In aerospace, medical, and precision industrial components, deburring must not alter the engineered edge breaks or chamfers specified in GD&T. For aluminum and steel, in-process deburring using the primary CNC machine (via toolpath-controlled edge rolling or micro-milling) is increasingly adopted to maintain tolerances. For plastics like ABS and nylon, mechanical methods must be carefully controlled to prevent deformation or dimensional shift due to low stiffness and thermal sensitivity.

Deburring strategies should be validated through edge inspection (e.g., optical comparators, tactile probes) and functional testing, particularly in assemblies requiring press fits, sealing surfaces, or dynamic loading.

From CAD to Part: The Process

Honyo Prototype integrates deburring steel components as a critical, non-negotiable phase within our end-to-end manufacturing workflow. This process is systematically embedded from initial design evaluation through final inspection to ensure burr-free, functionally reliable parts that meet stringent industry standards for steel fabrication. Below is the precise sequence and technical execution:

Upload CAD

Customers submit native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system immediately performs geometric validation, flagging features prone to burr generation in steel—such as sharp internal corners, thin walls, or intersecting milled surfaces—based on material-specific heuristics. Steel’s work-hardening tendency necessitates early identification of high-risk zones to prevent micro-burrs that compromise fatigue resistance or assembly.

AI Quote

Our proprietary AI engine analyzes the CAD geometry alongside steel grade specifications (e.g., 304 stainless, 1018 carbon steel) to auto-generate a quote inclusive of deburring methodology and cost. The algorithm factors in burr formation probability using historical data from 50,000+ steel parts, estimating time/cost for mechanical, thermal, or chemical deburring based on part complexity, tolerance class (per ISO 2768), and edge requirements. Customers receive transparent line-item costing for deburring before order confirmation.

DFM (Design for Manufacturability)

During engineering review, our team collaborates with the client to optimize steel part designs for burr minimization. We recommend critical adjustments such as adding intentional edge breaks (0.1–0.3 mm chamfers), adjusting toolpath strategies to avoid climb milling on hardened steel, or modifying hole tolerances to accommodate robotic deburring tool access. For welded steel assemblies, we specify post-weld grinding parameters to eliminate slag and heat-affected zone (HAZ) irregularities. All suggestions are justified with metallurgical rationale and cost-benefit analysis.

Production

Deburring is executed via methodical, steel-specific protocols:

Mechanical Deburring: For medium-complexity steel parts, we deploy automated vibratory finishing with ceramic media (size-graded to part geometry) or CNC robotic deburring arms with carbide-tipped tools. Parameters like amplitude (1.5–3.0 mm) and duration (10–45 mins) are calibrated to steel hardness (e.g., 200–300 HB) to prevent surface smearing.

Thermal Energy Method (TEM): High-volume small steel components undergo controlled combustion (2,000–3,000°C) in a pressurized chamber, vaporizing burrs without dimensional change—ideal for intricate internal features.

Electrochemical Deburring: For critical aerospace/medical steel components, we use pulsed DC electrolysis to remove burrs from precision holes (±0.025 mm tolerance) without altering base material properties.

All processes adhere to ASTM F963-17 for edge smoothness, with real-time in-process validation via optical comparators.

Delivery

Pre-shipment, every steel component undergoes multi-stage deburring verification:

1. Tactile inspection with 400-grit abrasive paper to detect micro-burrs

2. Magnified (10x) edge examination per MIL-STD-1312

3. Functional gauge testing for assembly-critical interfaces

Documentation includes a Deburring Certificate specifying method, process parameters, and post-deburring surface roughness (Ra) measurements. Parts are packaged in anti-corrosion VCI paper to prevent flash rust during transit, with full traceability via serialized work orders.

This integrated approach ensures steel components arrive burr-free, dimensionally stable, and ready for mission-critical applications—eliminating downstream rework costs for our clients. Honyo’s steel deburring process is certified to ISO 9001:2015 and AS9100D for aerospace compliance.

Start Your Project

Looking for precision deburring services for steel components? Honyo Prototype offers high-quality, efficient deburring solutions tailored to your manufacturing needs. With our advanced equipment and skilled technicians in our Shenzhen factory, we ensure burr-free, smooth finishes that meet strict industry standards.

For quotes or technical inquiries, contact Susan Leo at [email protected]. Let us support your production with reliable, scalable deburring services from China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.