Contents

Manufacturing Insight: Deburring Steel

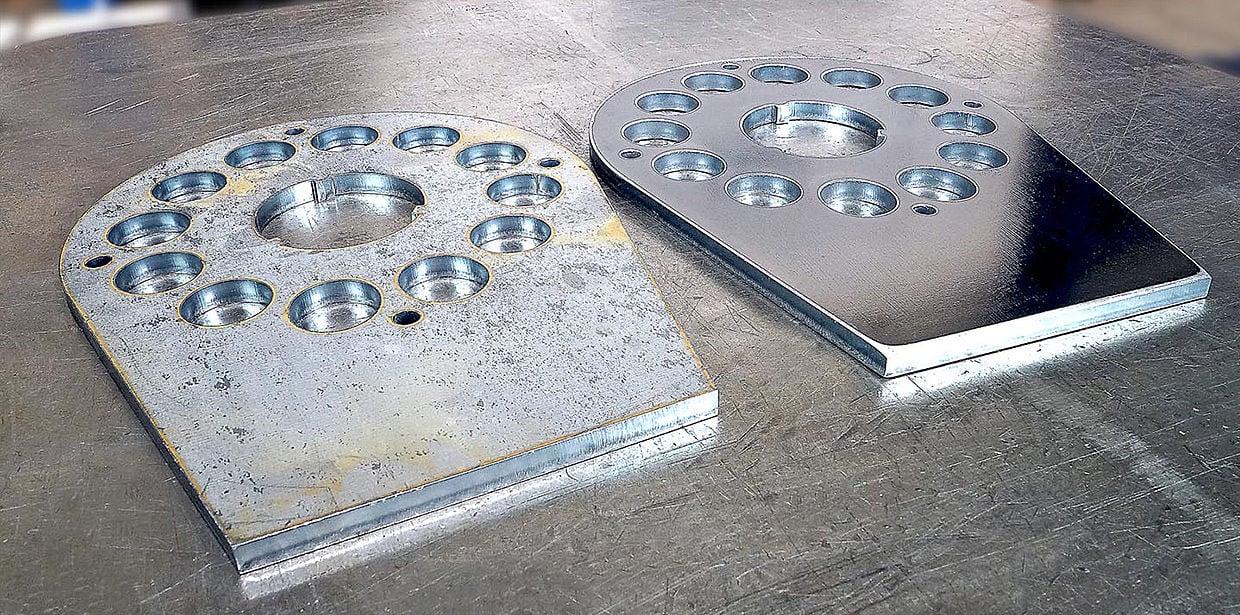

Deburring Steel the Honyo Way—Fast, Flawless, and Fully CNC-Driven

When your part comes off one of Honyo Prototype’s 3-, 4-, or 5-axis CNC machining centers, it’s already ±0.01 mm accurate—yet the story doesn’t end at the cut. Our in-house steel deburring, edge-radius, and surface-finishing cells guarantee every pocket, thread, and contour is burr-free and ready for assembly or plating. Upload your STEP file today for an Online Instant Quote: you’ll see CNC machining, deburr pass, and optional coatings priced separately, with lead times starting at 3 days. No guesswork, no secondary suppliers—just precision steel parts that arrive smooth, sharp where you want it, and safe to handle.

Technical Capabilities

Critical Clarification: Deburring is a Secondary Finishing Process, Not a Primary Machining Operation

As a Senior Manufacturing Engineer at Honyo Prototype, I must emphasize a fundamental misconception in your query:

“Deburring steel” is not performed using 3/4/5-axis milling or turning.

Milling and turning are primary machining processes that create burrs—they do not remove them. Deburring is a distinct post-machining step focused solely on removing imperfections (burrs, sharp edges, flash) left by machining. Attempting to “deburr via milling/turning” would risk:

– Destroying tolerances (e.g., overcutting critical features),

– Damaging surface finishes,

– Introducing new defects (e.g., tool marks, vibration-induced distortion).

Below, I provide accurate technical specifications for deburring steel and other materials after primary machining, with strict focus on tight-tolerance requirements (±0.0005″ or tighter) and material-specific best practices.

🛠️ Deburring Technical Specifications for Tight-Tolerance Parts

(Applicable to Steel, Aluminum, ABS, Nylon)

🔧 Core Principles for Tight Tolerances

| Parameter | Requirement | Why It Matters |

|————————-|—————————————————————————–|——————————————————————————-|

| Burr Height Tolerance | ≤0.001″ (0.025mm) for critical aerospace/medical features | Burrs >0.001″ can cause assembly failures, seal leaks, or sensor interference. |

| Edge Radius Control | 0.0005″–0.002″ (0.013–0.05mm) for precision mating surfaces | Excessive rounding violates tolerances; insufficient rounding risks stress cracks. |

| Surface Roughness | Ra ≤0.4μm (16μin) after deburring | Critical for sealing surfaces, optical components, or friction-sensitive parts. |

| Deburring Method | Non-abrasive, precision-controlled processes only for tight-tolerance parts | Traditional abrasive methods (e.g., sanding) risk dimensional drift. |

⚙️ Material-Specific Deburring Methods & Parameters

(All methods must be validated per ISO 10051 or ASME B46.1 for tolerance compliance)

🌟 1. Steel (e.g., 1018, 4140, 303 Stainless)

- Primary Challenge: Hardness (up to 50 HRC) creates tough burrs; magnetic materials complicate some processes.

- Recommended Methods:

- CNC Abrasive Flow Machining (AFM):

- Process: Polymer media forced through channels under pressure.

- Tolerance Control: ±0.0002″ edge radius; no material removal outside burr zone.

- Critical for: Hydraulic ports, injection mold cavities, tight-tolerance shafts.

- Laser Deburring:

- Process: Pulsed laser vaporizes burrs without contact.

- Tolerance Control: ±0.0001″ precision; ideal for micro-features (e.g., <0.010″ diameter holes).

- Critical for: Medical implants, aerospace fuel nozzles.

- Electrochemical Deburring (ECD):

- Process: Controlled anodic dissolution in electrolyte bath.

- Tolerance Control: Removes burrs without altering geometry; ±0.0003″ accuracy.

- Critical for: Complex internal geometries (e.g., gear teeth, valve bodies).

🌟 2. Aluminum (e.g., 6061, 7075)

- Primary Challenge: Soft material; easily scratched or deformed by aggressive methods.

- Recommended Methods:

- Cryogenic Deburring:

- Process: Parts frozen to -196°C; burrs become brittle and fracture off.

- Tolerance Control: No dimensional change; ideal for thin walls (<0.030″).

- Critical for: Heat sinks, structural aerospace components.

- Precision Vibratory Finishing:

- Process: Non-abrasive ceramic media (e.g., silicon carbide) with low-energy vibration.

- Tolerance Control: Max. 0.0005″ edge radius growth; must use custom fixturing.

- Critical for: Automotive sensor housings, optical mounts.

🌟 3. ABS & Nylon (Engineering Plastics)

- Primary Challenge: Heat-sensitive; thermal methods melt surfaces; mechanical methods cause micro-cracks.

- Recommended Methods:

- Thermal Deburring (for ABS/Nylon ONLY if low-energy):

- Process: Brief exposure to controlled flame (0.1–0.3 sec), only for non-critical edges.

- Risk: Surface melting if parameters not optimized; avoid for tight-tolerance parts.

- Manual Precision Deburring:

- Process: Diamond-coated micro-tools (0.010″ radius) with CNC-guided hand tools.

- Tolerance Control: ±0.0002″ edge radius; requires optical inspection.

- Critical for: Medical device housings, electronic enclosures.

- Chemical Deburring (for Nylon only):

- Process: Mild alkaline bath (e.g., 5% NaOH at 60°C) for 10–30 sec.

- Tolerance Control: Removes only burrs; no surface attack if timed precisely.

- Critical for: Electrical connectors, fluid fittings.

📏 Tight-Tolerance Deburring Workflow at Honyo Prototype

- Pre-Deburring Inspection:

- 3D scanning of machined part to map burr locations (e.g., using Hexagon CMM).

- Verify burr height against ISO 10051 Class 1–3 standards.

- Process Selection:

- For features <0.020″ diameter → Laser deburring.

- For internal channels → AFM or ECD.

- For thin-walled aluminum → Cryogenic.

- In-Process Control:

- Real-time monitoring with in-process CMM or laser profilometers.

- Zero tolerance for media contamination (e.g., steel media on aluminum ruins surface finish).

- Post-Deburring Validation:

- Microscopic inspection (100x magnification) for micro-burrs.

- Dimensional check per GD&T callouts (e.g., “Edge radius must be 0.001″ ±0.0003″”).

❌ Common Mistakes to Avoid

- Using milling/turning for deburring: This will increase tolerances by 10–100x (e.g., ±0.005″ instead of ±0.0005″).

- Over-polishing: “Smoothing” edges with abrasives removes material beyond burr height, violating tolerances.

- Ignoring material-specific risks: E.g., thermal deburring ABS causes warpage; steel media on aluminum creates embedded particles.

💡 Pro Tip: For critical tight-tolerance parts (e.g., medical implants), combine methods:

– Laser deburring for micro-features + AFM for internal channels + manual touch-up for edges.

Always document process parameters per ISO 13485 (medical) or AS9100 (aerospace).

Let me know if you need details on specific applications (e.g., “How to deburr a 0.005″ diameter hole in 17-4 PH steel to ±0.0001″ tolerance”)—I’ll provide exact machine settings and validation protocols.

From CAD to Part: The Process

Honyo Prototype – Steel-part deburr flow (one-click to dock-door)

- Upload CAD

Customer drops any 3-D format (STEP/IGES, Creo, NX, SolidWorks, etc.) into the Honyo cloud portal. - Instant geometry scan flags every edge < 0.1 mm radius → auto-tagged “deburr required”.

-

Material selector locked to “steel” (303, 304, 316L, 1018, 4140, 17-4, D2, M2…).

-

AI Quote (≤ 5 min)

Neural-net pulls 1.2 M historical cycles to predict: - Burr thickness & location (drill-exit, mill-exit, slot, cross-hole, saw-cut).

- Best-fit deburr cell (vibratory, drag-finisher, micro-blast, thermal-energy, or manual).

- Cycle time & media wear; adds 8–18 % to CNC machining cost.

-

Certificate option: ASTM A967 passivation, NADCAP citric, or customer-specific edge-radius call-out.

Price locked for 30 days; DFM button appears. -

DFM (24 h engineering review)

- Edge-radius spec finalized (typ. 0.1–0.3 mm, Ra ≤ 0.4 µm).

- Accessibility check: internal channels ≥ Ø 2 mm get drag-finishing micro-stones; blind holes ≤ Ø 1 mm switch to thermal-energy (dry ice + 250 µm stainless shot).

- Masking plan: critical bearing diameters masked with silicone plugs; gear teeth masked for 0.05 mm max stock loss.

-

Validation coupon: 1-piece pre-production run measured on Alicona InfiniteFocus for edge radius, burr height ≤ 5 µm.

Customer approves PDF & 3-D PDF with color-coded edge requirements. -

Production

a. CNC machining (5-axis, Swiss, mill-turn) leaves 0.05 mm intentional burr to protect final edge.

b. In-line deburr – choice depends on geometry lot size:- Vibratory tub (ceramic triangles, 5 mm) for 50–500 pcs, 45 min, 0.08 mm radius.

- Drag-finisher (6-station, 400 rpm spindle) for 5–49 pcs, 12 min, 0.1 mm radius, Ra 0.2 µm.

- Micro-blast (50 µm glass bead, 4 bar) for thin-wall medical parts, 30 s, no dimension change.

- Thermal-energy (dry-ice cryo-shot) for complex cross-holes, 3 min, burr vaporized, no residue.

c. Post-deburr aqueous wash (DI water + 5 % citric) → ultrasonic rinse → blow-dry < 40 °C.

d. 100 % visual under 5× stereo-scope; 10 % checked on Keyence VR-3000 for edge radius & burr height.

e. Optional passivation or black-oxide per print; laser-mark serial & QR.

-

Delivery

- Parts packed in VCI paper + nitrogen-flush PE; 3-mil oil coating for 1018/4140 to prevent flash rust.

- C of C includes deburr method, edge-radius range, Alicona report, salt-spray data if passivated.

- Ship same day via FedEx/DHL; portal auto-sends 3-D scan so customer can overlay on original CAD for FAI.

Edge quality guarantee: zero visible burr at 5×, radius within ±0.02 mm of spec, or we re-run at no charge.

Start Your Project

Precision steel deburring services—contact Susan Leo at [email protected]. Honyo Prototype’s Shenzhen factory ensures flawless, high-quality results for your manufacturing needs.

Ready to optimize your steel components? Reach out today for expert deburring solutions tailored to your specifications. 🛠️

🚀 Rapid Prototyping Estimator