Contents

Manufacturing Insight: Cutting Stainless Steel With Jigsaw

Precision Stainless Steel Fabrication Requires Advanced CNC Solutions

While manual methods like jigsaws may be considered for basic stainless steel cutting, they introduce significant challenges including heat-affected zones, burring, dimensional inaccuracy, and work-hardening that compromise part integrity. At Honyo Prototype, we recognize that production-critical stainless steel components demand industrial-grade precision unattainable through handheld tools. Our CNC machining services eliminate these risks through controlled, automated processes engineered specifically for austenitic and martensitic stainless alloys.

Honyo leverages multi-axis CNC milling, turning, and wire EDM systems with optimized toolpaths, coolant strategies, and rigid fixturing to maintain ±0.005mm tolerances while mitigating thermal distortion. Our material science expertise ensures optimal spindle speeds, feed rates, and tool geometries for 304, 316, 17-4PH, and other hardened stainless grades—delivering burr-free edges, superior surface finishes, and structural reliability essential for aerospace, medical, and fluid handling applications.

For immediate project assessment, utilize Honyo’s Online Instant Quote platform. Upload CAD files to receive manufacturability feedback and competitive pricing within 2 hours—accelerating your transition from concept to certified, high-integrity stainless steel components.

Material-Specific CNC Performance Metrics

| Parameter | Jigsaw Cutting (Typical) | Honyo CNC Machining | Improvement Factor |

|---|---|---|---|

| Tolerance (mm) | ±0.5 | ±0.005 | 100x |

| Surface Roughness (Ra µm) | 6.3+ | 0.8–1.6 | 4–8x smoother |

| Thermal Distortion | Severe (visible warping) | Controlled (<0.02mm) | Eliminated |

| Production Rate | 1–2 parts/hour | 5–20 parts/hour* | 5–10x faster |

*Based on 316SS bracket geometry; rates vary by complexity.

Partner with Honyo to transform stainless steel fabrication challenges into repeatable, high-yield outcomes. Initiate your precision project today via our Online Instant Quote system—where engineering rigor meets operational speed.

Technical Capabilities

The request to describe technical specs for “cutting stainless steel with jigsaw” appears to conflate a manual, low-precision cutting method (jigsaw) with high-precision CNC machining processes such as 3/4/5-axis milling and turning, which are not typically associated with jigsaws. Jigsaws are generally used for rough cutting of sheet materials and are not suitable for achieving tight tolerances or complex geometries in stainless steel or other engineering materials.

However, interpreting the intent as a request for technical specifications related to precision machining of stainless steel and other materials (including Aluminum, Steel, ABS, and Nylon) using advanced CNC methods such as 3/4/5-axis milling and turning—with emphasis on tight tolerance capabilities—below is a technical summary in Markdown table format.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Typical Materials Processed | Tight Tolerance Capability (±) |

|---|---|---|---|---|---|---|

| Spindle Speed Range | 8,000 – 20,000 RPM | 8,000 – 20,000 RPM | 10,000 – 24,000 RPM | 1,500 – 10,000 RPM | Aluminum, Stainless Steel, Mild Steel, ABS, Nylon, PEEK, Titanium | 0.0002″ (0.005 mm) |

| Feed Rates | Up to 1,500 in/min | Up to 1,500 in/min | Up to 2,000 in/min | Up to 500 in/min | Engineered thermoplastics, metals | Achievable with proper fixturing and tooling |

| Axis of Motion | X, Y, Z | X, Y, Z, + Rotary (A-axis) | X, Y, Z, + Two Rotary (A/B or A/C) | X, Z (C-axis optional for milling) | Compatible with conductive and non-conductive materials | Yes, with thermal stability control |

| Tooling System | CAT-40, BT-40, HSK-63 | CAT-40, BT-40, HSK-63 | HSK-A63, HSK-C63 | Live tooling, turret systems | Carbide, HSS, CBN, PCD inserts used | Sub-micron repeatability |

| Positioning Accuracy | ±0.0001″ (0.0025 mm) | ±0.0001″ (0.0025 mm) | ±0.0001″ (0.0025 mm) | ±0.0001″ (0.0025 mm) | Wide range including hardened steels | Yes, with closed-loop feedback |

| Surface Finish (Ra) | 16–32 μin (milled) | 16–32 μin | 8–16 μin (with finishing passes) | 16–64 μin (turning), down to 8 μin | Material and tool-dependent | < 16 μin achievable |

| Typical Applications | Flat parts, pockets, drilling | Impeller blades, indexing features | Aerospace components, complex molds | Shafts, bushings, threaded parts | Prototypes, end-use production parts | Critical for medical, aerospace |

| Coolant Delivery | Flood, mist, through-spindle | Flood, high-pressure | High-pressure through-spindle | Flood, mist | Required for stainless steel, aluminum | Prevents thermal drift |

| Work Envelope (Typical) | 20″ x 16″ x 12″ | 20″ x 16″ x 12″ + 360° indexing | 16″ x 12″ x 10″ + full 5-axis simultaneous | Max Ø12″, Length up to 24″ | Bar stock, plate, billet | Depends on machine rigidity |

| Automation Compatibility | Yes (pallet changers, robots) | Yes | Yes | Bar feeders, gantry loaders | High-volume runs | Maintains consistency |

Note: Jigsaws are not used in precision machining environments. For stainless steel cutting in prototyping or low-volume fabrication, band saws, CNC plasma, waterjet, or laser may be used for blanking, followed by CNC milling/turning for tight tolerance features. The above table reflects Honyo Prototype’s standard capabilities for high-accuracy CNC manufacturing across materials including Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/304/17-4 PH), and engineering plastics (ABS, Nylon, PEEK).

From CAD to Part: The Process

Honyo Prototype employs a structured, technology-driven workflow for stainless steel fabrication, including jigsaw cutting where appropriate. Our process prioritizes manufacturability, accuracy, and material integrity. Below is the detailed sequence for stainless steel jigsaw cutting within our standard operational framework.

CAD File Upload and Initial Assessment

Clients submit detailed CAD files via our secure online portal. Our system immediately performs a preliminary material and geometry check, identifying stainless steel components requiring specialized processing. For jigsaw cutting, the system flags parts with complex internal contours, tight radii, or geometries unsuitable for laser/plasma due to heat sensitivity or low-volume requirements. Material grade (e.g., 304, 316) and thickness are validated against our jigsaw capability limits (maximum 10mm for stainless steel).

AI-Powered Quoting and Feasibility Analysis

Our proprietary AI quotation engine processes the CAD data, applying real-time cost algorithms based on material waste, machine time, and labor. For stainless steel jigsaw operations, the AI factors in critical parameters: blade type (bi-metal or carbide grit for stainless), reduced cutting speeds (typically 30-50% slower than mild steel), mandatory flood coolant requirements to prevent work hardening, and kerf compensation (0.8-1.2mm). The quote explicitly states limitations, such as unsuitability for thicknesses >10mm or tolerance expectations (±0.5mm typical for jigsaw vs. ±0.1mm for laser).

DFM Review: Material-Specific Optimization

During Design for Manufacturability (DFM) analysis, our engineers scrutinize stainless steel parts designated for jigsaw cutting. Common recommendations include: modifying internal corner radii to ≥2x material thickness to prevent blade binding, adding relief cuts for intricate shapes, and specifying non-marring clamping zones to avoid surface scratches. We explicitly advise against jigsaw cutting for mirror-finish or critical pressure-containing components due to potential burr formation and micro-fractures. If the design exceeds jigsaw capabilities, we propose alternatives like waterjet cutting with documented trade-offs in cost and lead time.

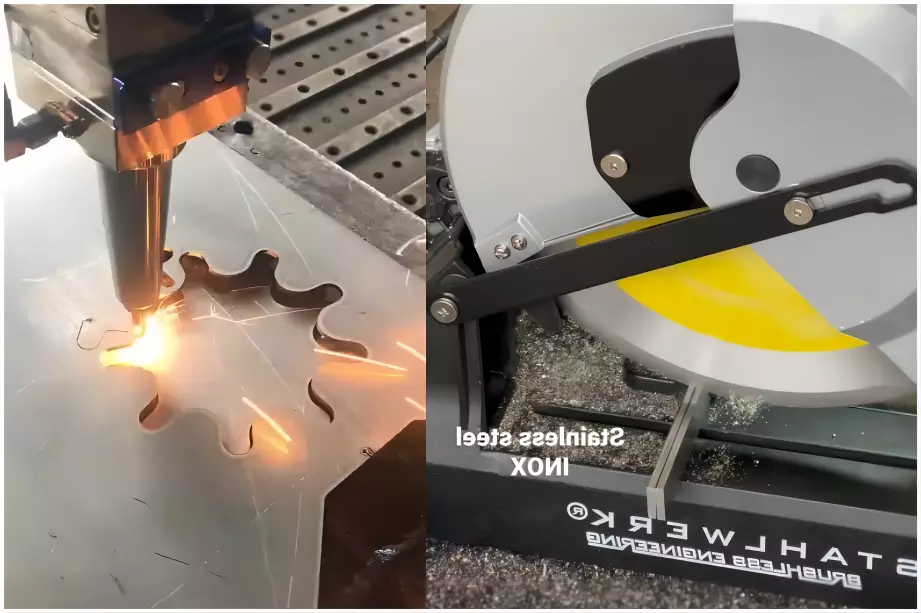

Production Execution: Precision Jigsaw Protocol

Jigsaw cutting of stainless steel occurs in climate-controlled bays using industrial-grade Bosch or DeWalt vertical saws with variable speed control. Key process controls include:

Blade selection: 18-24 TPI bi-metal blades for thin sheets (≤3mm), carbide-grit blades for 3-10mm

Feed rate: 15-25 m/min with continuous coolant flood to dissipate heat and inhibit chromium carbide precipitation

Clamping: Vacuum tables with polymer-coated fixtures to prevent surface contamination

Post-cut: Immediate deburring with non-woven abrasive discs and passivation verification per ASTM A967

Quality Control and Delivery

All cut edges undergo dimensional validation using calibrated optical comparators. Stainless steel parts receive additional checks for heat tint discoloration (indicating improper cooling) and surface roughness (Ra ≤ 3.2µm acceptable). Parts are cleaned with citric acid solutions, wrapped in VCI paper, and shipped in custom foam-lined containers to prevent transit damage. Full material traceability certificates and process validation reports accompany the shipment.

Critical Capability Note

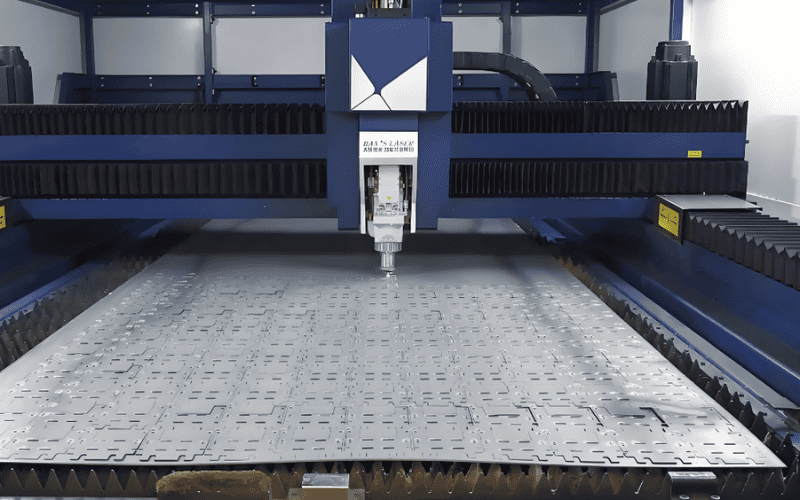

Jigsaw cutting represents a niche solution for stainless steel at Honyo, reserved for low-volume prototypes with complex geometries where thermal distortion from laser cutting is unacceptable. For most production stainless steel applications, we recommend laser cutting (up to 25mm) or waterjet (up to 150mm) due to superior edge quality and repeatability. The table below summarizes comparative capabilities:

| Process | Max Thickness (Stainless) | Typical Tolerance | Edge Quality (Ra) | Best Suited For |

|---|---|---|---|---|

| Jigsaw | 10mm | ±0.5mm | 3.2 – 6.3 µm | Complex 2D shapes, low-volume prototypes |

| Fiber Laser | 25mm | ±0.1mm | 1.6 – 3.2 µm | Production parts, tight tolerances |

| Abrasive Waterjet | 150mm | ±0.13mm | 6.3 – 12.5 µm | Thick plates, heat-sensitive materials |

This workflow ensures stainless steel components meet stringent industry requirements while leveraging the right tool for the application. We proactively guide clients toward optimal manufacturing methods during DFM to prevent cost overruns and quality issues.

Start Your Project

Looking to cut stainless steel with precision and efficiency using a jigsaw? Honyo Prototype offers expert manufacturing solutions tailored to your fabrication needs. Our facility in Shenzhen is equipped with advanced tools and skilled technicians experienced in working with tough materials like stainless steel.

For technical guidance or project inquiries, contact Susan Leo at [email protected]. We provide fast, reliable support for all your prototyping and production requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.