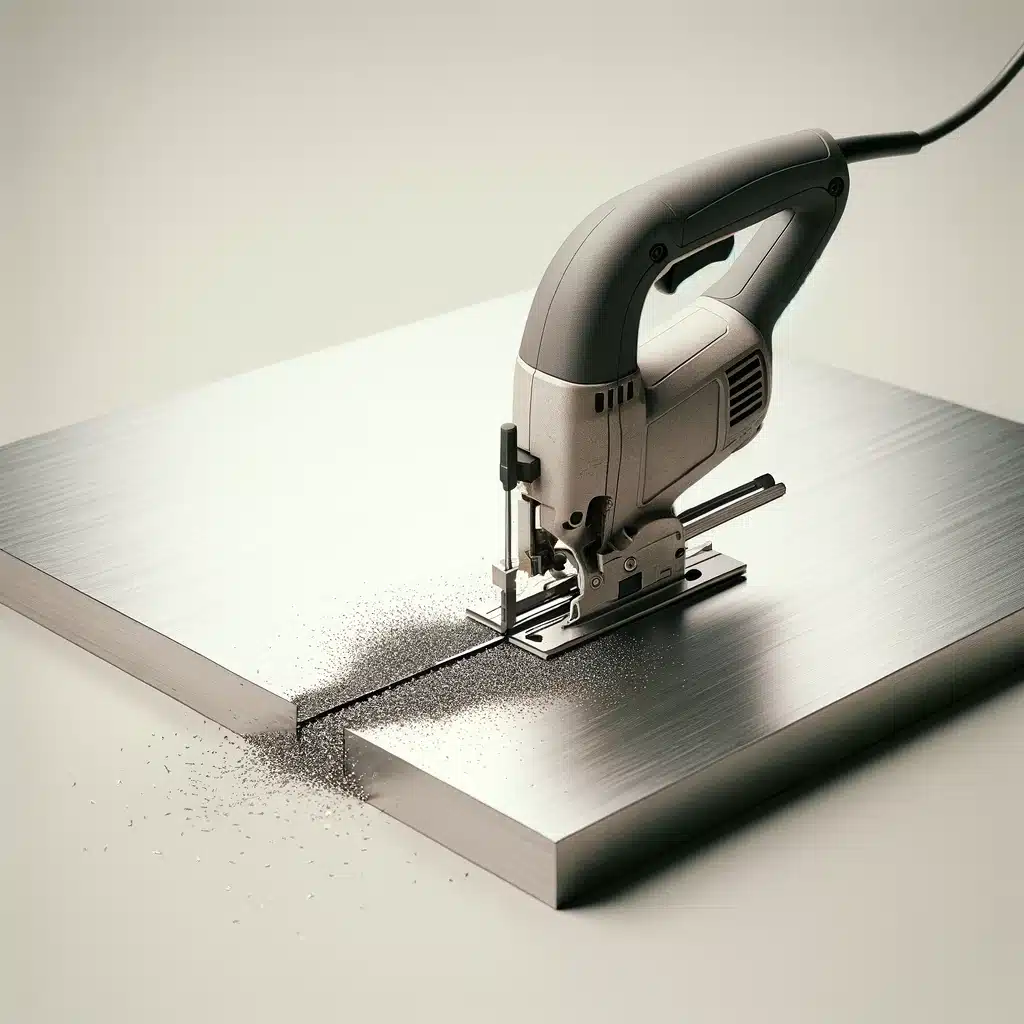

Introduction: Navigating the Global Market for cutting stainless steel with jigsaw

Navigating the complexities of cutting stainless steel with a jigsaw can be a significant hurdle for international B2B buyers. The durability and strength of stainless steel, while advantageous for various applications, often present unique challenges when sourcing the right tools and techniques. This comprehensive guide delves into the intricacies of cutting stainless steel, addressing key considerations such as blade selection, cutting methods, and optimal tools tailored for specific thicknesses and applications.

Buyers will discover insights into the types of stainless steel available, from sheets to plates, and how each type can meet diverse industry needs—from construction to food processing. Additionally, this guide emphasizes the importance of vetting suppliers, understanding cost implications, and ensuring quality standards that align with project requirements.

By empowering B2B buyers from regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Brazil, this guide serves as a valuable resource. It equips decision-makers with the knowledge necessary to make informed purchasing choices, ensuring that their projects are executed with precision and efficiency. Whether you’re a seasoned fabricator or new to metal cutting, understanding how to navigate the global market for cutting stainless steel with a jigsaw will enhance your operational success and product quality.

Understanding cutting stainless steel with jigsaw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High TPI Bi-Metal Blades | Fine tooth count (over 60 TPI) for smooth cuts; flexibility | Sheet metal fabrication, HVAC, automotive | Pros: Clean cuts, reduced burrs. Cons: Higher cost, shorter lifespan. |

| Carbide Grit Blades | Abrasive edge for cutting thicker materials | Heavy machinery, industrial applications | Pros: Effective for tough cuts. Cons: Leaves rough edges, requires finishing. |

| Variable Speed Jigsaws | Adjustable speeds to manage heat and cutting speed | Custom metalwork, prototyping | Pros: Versatile for different thicknesses. Cons: Complexity may increase maintenance. |

| Orbital Action Jigsaws | Adds a circular motion to the blade for faster cuts | High-volume manufacturing, construction | Pros: Increased speed, efficient for thicker materials. Cons: Less control for intricate cuts. |

| Straight Edge Guides | Provides support for maintaining a straight line during cuts | Precision engineering, cabinetry | Pros: Improves accuracy, reduces waste. Cons: Requires additional setup time. |

What are the Characteristics of High TPI Bi-Metal Blades?

High TPI (Teeth Per Inch) bi-metal blades are designed for clean cuts in stainless steel and other metals. Their fine tooth count, typically over 60 TPI, allows for precise cutting with minimal burr formation, making them ideal for applications in sheet metal fabrication, HVAC, and automotive sectors. When purchasing, consider the balance between cost and longevity, as these blades tend to be pricier but offer superior performance.

How Do Carbide Grit Blades Differ in Application?

Carbide grit blades utilize an abrasive edge that excels at cutting through thicker stainless steel materials. They are commonly used in heavy machinery and industrial applications where durability is paramount. While these blades can handle tough cuts, they often leave rough edges that necessitate additional finishing work. Buyers should weigh the need for efficiency against the potential for increased labor costs due to post-cut finishing.

Why Choose Variable Speed Jigsaws for Metal Cutting?

Variable speed jigsaws provide flexibility in cutting speeds, enabling operators to manage heat generation effectively while working with different thicknesses of stainless steel. This adaptability makes them suitable for custom metalwork and prototyping. However, the complexity of these tools may lead to increased maintenance requirements, which is a vital consideration for B2B buyers focused on long-term operational costs.

What Advantages Do Orbital Action Jigsaws Offer?

Orbital action jigsaws introduce a circular motion to the cutting process, allowing for quicker cuts in thicker materials. This feature is particularly beneficial in high-volume manufacturing and construction settings where time efficiency is crucial. However, the trade-off is that they may provide less control for intricate cuts, which could impact precision work. Companies must assess their specific cutting needs when considering this tool type.

How Can Straight Edge Guides Enhance Cutting Accuracy?

Using straight edge guides with jigsaws significantly improves cutting accuracy by providing support to maintain a straight line during cuts. This is especially important in precision engineering and cabinetry, where the quality of the cut directly affects the final product. While they require additional setup time, the benefits of reduced waste and enhanced precision often justify the effort for B2B buyers focused on quality outcomes.

Key Industrial Applications of cutting stainless steel with jigsaw

| Industry/Sector | Specific Application of cutting stainless steel with jigsaw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Cutting stainless steel sheets for custom equipment design | Ensures hygienic and durable equipment tailored to specific needs | Quality of stainless steel, compliance with food safety standards |

| Construction | Fabricating stainless steel frames and supports | Provides strong, corrosion-resistant structures for long-lasting projects | Thickness and type of stainless steel, local sourcing options |

| Automotive Manufacturing | Custom brackets and components for vehicles | Enhances performance and durability of automotive parts | Precision of cuts, availability of specialized jigsaw blades |

| HVAC Systems | Creating ductwork and fittings from stainless steel sheets | Improves efficiency and longevity of HVAC installations | Resistance to corrosion, thickness of materials, sourcing speed |

| Marine Industry | Fabricating components for ships and marine equipment | Increases lifespan and reduces maintenance costs in harsh environments | Marine-grade stainless steel, compliance with industry regulations |

How is Cutting Stainless Steel with a Jigsaw Utilized in Food Processing?

In the food processing industry, cutting stainless steel with a jigsaw is crucial for creating custom equipment such as food preparation tables, shelving, and storage units. The ability to make precise cuts allows manufacturers to tailor equipment to specific operational needs, ensuring efficiency and hygiene. Buyers in this sector must prioritize sourcing high-quality stainless steel that meets food safety standards, as well as blades designed for clean cuts to maintain sanitary surfaces.

What Role Does Jigsaw Cutting Play in Construction Projects?

Within construction, jigsaws are employed to cut stainless steel for frames, supports, and decorative elements. The strength and corrosion resistance of stainless steel make it an ideal choice for structures exposed to harsh weather conditions. Businesses must consider the thickness of the steel and the type of jigsaw blades that can handle these materials effectively. Local sourcing options can also impact project timelines and costs, making it essential for buyers to evaluate suppliers carefully.

Why is Jigsaw Cutting Important in Automotive Manufacturing?

In automotive manufacturing, jigsaws facilitate the creation of custom brackets and components that are integral to vehicle assembly. The precision cutting capability of a jigsaw allows manufacturers to produce parts that fit perfectly, enhancing the overall performance and durability of vehicles. Buyers need to ensure they have access to high-quality blades that can withstand the rigors of cutting stainless steel, as well as a reliable supply chain to avoid production delays.

How Does Jigsaw Cutting Benefit HVAC Systems?

Cutting stainless steel with a jigsaw is vital in the HVAC industry for fabricating ductwork and fittings. This method allows for the creation of components that are not only efficient but also resistant to corrosion, which is essential in maintaining system integrity over time. Businesses should focus on sourcing materials that meet specific thickness requirements and ensure that they have the right blades for clean, accurate cuts to optimize installation processes.

In What Ways Does the Marine Industry Utilize Jigsaw Cutting?

The marine industry relies on jigsaw cutting to fabricate components for ships and marine equipment, where durability and resistance to harsh environments are paramount. Stainless steel’s properties make it an ideal choice for marine applications, reducing maintenance costs and increasing lifespan. Buyers must consider sourcing marine-grade stainless steel and ensure compliance with industry regulations to guarantee the quality and longevity of their products.

3 Common User Pain Points for ‘cutting stainless steel with jigsaw’ & Their Solutions

Scenario 1: Difficulty Achieving Clean Cuts in Stainless Steel

The Problem: Many B2B buyers in the metalworking industry face the challenge of achieving clean, precise cuts when using jigsaws on stainless steel. Stainless steel’s inherent hardness and work-hardening properties can lead to rough, jagged edges. This issue is particularly frustrating for fabricators who require high-quality finishes for their products, as the need for extensive post-cutting cleanup can increase labor costs and extend project timelines.

The Solution: To overcome this challenge, it is crucial to select the right jigsaw blade designed specifically for cutting stainless steel. Opt for blades with a high tooth count (60 TPI or higher) and a bi-metal construction that enhances durability and cutting efficiency. Additionally, employing a slower cutting speed can help prevent work hardening, allowing the blade to maintain its sharpness longer. For optimal results, secure the stainless steel sheet using clamps to minimize vibration during cutting, which can cause the blade to wander and result in uneven cuts. Incorporating a straightedge guide will also aid in maintaining a straight line, significantly reducing the need for post-cutting adjustments.

Scenario 2: Excessive Blade Wear and Breakage

The Problem: A common frustration among B2B buyers is the rapid wear and breakage of jigsaw blades when cutting stainless steel. This not only leads to increased costs due to frequent blade replacements but also disrupts workflow and productivity. Buyers often find themselves questioning the quality of the blades or their cutting techniques, which can further complicate the issue.

The Solution: To mitigate blade wear, it’s essential to choose high-quality jigsaw blades that are specifically rated for stainless steel. Look for blades made from high-speed steel (HSS) or bi-metal materials, which offer better resistance to heat and wear. Additionally, ensure that the cutting process is continuous without lingering in one spot, as this can lead to overheating and premature blade failure. Implementing proper cutting techniques, such as maintaining three teeth in contact with the material at all times, can also enhance performance. Regularly inspecting and replacing blades before they become excessively worn can help maintain cutting efficiency and reduce downtime.

Scenario 3: Inconsistent Cutting Angles and Shapes

The Problem: B2B buyers frequently encounter challenges in achieving consistent cutting angles and intricate shapes when working with jigsaws on stainless steel. This is especially true for those in industries where precise specifications are critical, such as automotive or aerospace manufacturing. The inability to maintain accuracy can lead to waste, rework, and unsatisfied clients.

The Solution: To enhance precision in cutting angles and shapes, buyers should consider investing in a jigsaw with variable speed control and a laser guide system. These features allow for better visibility and more controlled cutting speeds, which are essential for intricate work. Additionally, using a template or jig can help maintain consistent angles and patterns, minimizing the risk of error. It is also advisable to practice on scrap pieces of stainless steel to refine techniques before working on final projects. Ensuring that the blade is appropriate for the thickness and type of stainless steel being cut will further improve accuracy and reduce the likelihood of mistakes. Regular maintenance of the jigsaw and the use of high-quality blades will also contribute to overall cutting performance.

Strategic Material Selection Guide for cutting stainless steel with jigsaw

When cutting stainless steel with a jigsaw, selecting the right materials for blades and accessories is crucial for achieving optimal results. Below, we analyze four common materials used in this context, focusing on their properties, advantages and disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Bi-Metal Jigsaw Blades for Cutting Stainless Steel?

Bi-metal jigsaw blades are a popular choice for cutting stainless steel due to their unique construction, which combines high-speed steel (HSS) teeth with a flexible backing made from carbon steel. This design allows the blades to withstand the heat generated during cutting while maintaining flexibility to prevent breakage.

Pros & Cons: Bi-metal blades offer superior durability and longevity compared to standard steel blades, making them suitable for repetitive tasks. However, they tend to be more expensive than single-material options, which could impact budget-sensitive projects.

Impact on Application: These blades are effective for cutting various thicknesses of stainless steel, making them versatile for different applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, especially when sourcing from regions like Europe or South America, where quality control is critical.

How Do Carbide-Tipped Blades Enhance Cutting Performance on Stainless Steel?

Carbide-tipped blades are engineered for heavy-duty applications and are particularly effective for cutting harder materials, including thicker stainless steel sheets. The carbide tips provide exceptional wear resistance and cutting efficiency.

Pros & Cons: The main advantage of carbide-tipped blades is their ability to maintain sharpness over extended use, resulting in cleaner cuts. However, they are generally more expensive and may require specialized handling due to their brittleness.

Impact on Application: These blades are ideal for industrial applications where precision and durability are paramount, such as in construction and manufacturing.

Considerations for International Buyers: Buyers should be aware of local market preferences and standards, as some regions may favor specific blade types based on availability and cost.

Why Are High-Speed Steel (HSS) Blades Considered a Cost-Effective Option?

High-speed steel (HSS) blades are a cost-effective option for cutting stainless steel, particularly for lighter gauge materials. They are known for their ability to withstand high temperatures without losing hardness.

Pros & Cons: HSS blades are relatively inexpensive and widely available, making them a popular choice for budget-conscious projects. However, they may not last as long as bi-metal or carbide-tipped blades, especially when cutting thicker materials.

Impact on Application: These blades are suitable for less demanding applications where precision is less critical, such as DIY projects or light fabrication work.

Considerations for International Buyers: Given their affordability, HSS blades may be appealing to buyers in developing markets. However, it’s essential to ensure they meet local safety and quality standards.

How Do Specialty Blades Designed for Stainless Steel Affect Cutting Efficiency?

Specialty blades designed specifically for stainless steel often feature a unique tooth design and coating to reduce friction and heat buildup, enhancing cutting efficiency.

Pros & Cons: These blades provide cleaner cuts and reduced burr formation, which is beneficial for applications requiring a high-quality finish. However, they can be more expensive and may not be readily available in all markets.

Impact on Application: Specialty blades are ideal for precision work in industries such as automotive and aerospace, where the quality of the cut is critical.

Considerations for International Buyers: Buyers should research local suppliers to ensure availability and may need to consider import regulations when sourcing specialty blades.

Summary Table of Material Selection for Cutting Stainless Steel with Jigsaw

| Material | Typical Use Case for cutting stainless steel with jigsaw | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Bi-Metal Blades | General fabrication and construction | Superior durability and longevity | Higher cost than standard blades | Medium |

| Carbide-Tipped Blades | Heavy-duty industrial applications | Exceptional wear resistance | More expensive and brittle | High |

| High-Speed Steel Blades | DIY projects and light fabrication | Cost-effective and widely available | Shorter lifespan than premium blades | Low |

| Specialty Blades | Precision cutting in automotive and aerospace industries | Cleaner cuts with reduced burr formation | Higher cost and limited availability | High |

This analysis provides a comprehensive overview of the materials available for cutting stainless steel with a jigsaw, highlighting their properties, advantages, and considerations for international B2B buyers. Understanding these factors can aid in making informed purchasing decisions that align with specific project requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cutting stainless steel with jigsaw

What Are the Key Manufacturing Processes for Cutting Stainless Steel with a Jigsaw?

Cutting stainless steel with a jigsaw involves several critical manufacturing processes that ensure the final product meets industry standards and customer requirements. The main stages of production include material preparation, forming, assembly, and finishing. Each stage requires specific techniques and tools tailored to the unique properties of stainless steel.

How Is Material Prepared for Cutting Stainless Steel?

Material preparation is the first step in the manufacturing process. This involves selecting the appropriate grade of stainless steel, typically 304 or 316, based on the application requirements. The material is then cut into manageable sizes, often in sheets or plates, to facilitate easier handling and cutting.

Before cutting, the stainless steel surface must be cleaned to remove any contaminants that could affect the quality of the cut. This may involve degreasing or using specific cleaning agents to ensure that the metal is free from oils, dust, and other debris. Proper material handling techniques are essential to prevent any damage during this stage, as stainless steel is susceptible to scratches and dents.

What Techniques Are Used During the Forming Stage?

The forming stage is where the actual cutting takes place. For stainless steel, using a jigsaw requires specific techniques to ensure precision and quality. The choice of blade is paramount; a fine-tooth blade with a high tooth-per-inch (TPI) count is recommended to minimize rough edges and prevent the material from work-hardening.

When cutting, it is crucial to maintain a steady hand and employ a guide for straight cuts. The jigsaw’s variable speed settings can also be adjusted based on the thickness of the material being cut, with slower speeds often yielding better results for thicker gauges. Additionally, securing the stainless steel sheet with clamps or vises is essential to prevent vibrations that could lead to inaccuracies.

How Is Assembly Done After Cutting?

In many cases, assembly may not be a separate stage but rather an extension of the cutting process. If the stainless steel is part of a larger component or structure, it may need to be joined with other pieces. This could involve welding, bolting, or other joining techniques that are compatible with stainless steel.

Quality control during this stage is vital to ensure that the assembled components fit together correctly and meet the specified tolerances. If the cutting was done inaccurately, it could lead to misalignment and additional costs in rework or material waste.

What Finishing Techniques Are Applied to the Cut Stainless Steel?

Finishing techniques are employed to enhance the appearance and performance of the cut stainless steel. Common methods include deburring, which removes sharp edges created during the cutting process, and polishing, which improves the aesthetic appeal of the metal.

Surface treatments, such as passivation, can also be applied to enhance corrosion resistance, especially in environments where the stainless steel will be exposed to moisture or chemicals. The choice of finishing technique will depend on the intended application and customer requirements.

What Quality Assurance Measures Are Essential in the Cutting Process?

Quality assurance (QA) is a critical aspect of the manufacturing process for cutting stainless steel. International standards such as ISO 9001 provide a framework for ensuring consistent quality across production lines. For industry-specific applications, certifications like CE and API may also be necessary, depending on the market and end-use of the product.

How Are QC Checkpoints Implemented?

Quality control checkpoints are established throughout the manufacturing process to monitor and verify product quality. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): During the cutting and assembly processes, periodic inspections are conducted to ensure that dimensions, tolerances, and surface finishes are within acceptable limits.

-

Final Quality Control (FQC): Once the cutting and finishing processes are complete, a final inspection is performed to verify the overall quality of the finished product.

What Common Testing Methods Are Used to Ensure Quality?

Several testing methods are employed to ensure the quality of cut stainless steel. These include:

-

Visual Inspection: A basic method to check for surface defects, rough edges, and overall appearance.

-

Dimensional Inspection: Utilizing calipers and gauges to ensure that the cut dimensions meet specifications.

-

Mechanical Testing: This may involve tensile strength tests to verify the material’s integrity after cutting, especially for thicker sections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, it is essential to verify the quality control processes of potential suppliers. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards and industry-specific requirements.

-

Requesting Quality Reports: Suppliers should be able to provide documentation detailing their quality control procedures, including inspection reports and certifications. This information can help buyers gauge the supplier’s commitment to quality.

-

Engaging Third-Party Inspectors: For additional assurance, buyers may consider hiring third-party inspection services to conduct independent assessments of the supplier’s products and processes. These services can provide unbiased evaluations and help identify any potential quality issues.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating quality control and certification can be complex for international B2B buyers. Different regions may have varying standards and regulations, which can affect the procurement process. For instance, compliance with European Union standards (CE marking) is essential for products sold in Europe, while API certifications may be necessary for oil and gas applications.

Buyers should be aware of these nuances and ensure that their suppliers are compliant with the relevant standards for their specific market. This not only helps in maintaining quality but also facilitates smoother logistics and regulatory approvals.

In summary, understanding the manufacturing processes and quality assurance measures involved in cutting stainless steel with a jigsaw is essential for B2B buyers. By focusing on material preparation, cutting techniques, assembly, and finishing, as well as robust quality control protocols, buyers can make informed decisions that align with their business needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cutting stainless steel with jigsaw’

To ensure successful and efficient cutting of stainless steel with a jigsaw, it’s essential for B2B buyers to follow a structured approach when sourcing materials and equipment. This guide outlines a practical checklist to streamline the procurement process, allowing you to make informed decisions that enhance your cutting operations.

Step 1: Identify Your Project Requirements

Understanding the specific requirements of your project is crucial. Determine the thickness and type of stainless steel you will be cutting, as well as the dimensions of the pieces needed. This information will help in selecting the appropriate jigsaw blades and tools, ensuring they are suited to the material’s properties.

- Consider thickness: For instance, cutting 18-gauge stainless steel requires a different blade than thicker materials.

- Define the cut quality: Decide if a smooth finish is necessary or if minor post-processing will suffice.

Step 2: Select the Right Jigsaw Blade

Choosing the correct blade is vital for achieving clean cuts and maximizing efficiency. Look for blades specifically designed for cutting stainless steel, with fine teeth per inch (TPI) to prevent the material from work hardening.

- TPI recommendation: Aim for blades with at least 60 TPI for thin gauges to ensure three teeth are engaged at all times.

- Material considerations: Carbide or bi-metal blades are ideal for durability and longevity.

Step 3: Evaluate Potential Suppliers

Before making any purchases, thoroughly vet potential suppliers. This step ensures you are working with reputable vendors who provide high-quality products.

- Request documentation: Ask for certifications, product specifications, and case studies relevant to your industry.

- Seek feedback: Connect with other businesses or industry peers to gather insights on their experiences with the suppliers.

Step 4: Assess Tool Compatibility

Ensure that the jigsaw and the selected blades are compatible. This assessment is critical to avoid operational inefficiencies and potential safety hazards during cutting.

- Check specifications: Verify the jigsaw model and its ability to handle the chosen blade size and type.

- Consider additional features: Look for jigsaws with variable speed settings for better control over the cutting process.

Step 5: Establish a Safe Cutting Environment

Setting up a safe and efficient workspace is essential for successful cutting operations. A well-organized environment minimizes the risk of accidents and enhances productivity.

- Use proper safety gear: Equip workers with gloves, goggles, and ear protection to ensure safety during the cutting process.

- Prepare the workspace: Ensure adequate ventilation and a sturdy workbench to secure the stainless steel while cutting.

Step 6: Plan for Waste Management

Effective waste management strategies can help reduce costs and improve efficiency. Establishing a plan for scrap material can lead to additional savings.

- Recycle scrap: Identify local recycling facilities that accept stainless steel.

- Optimize cuts: Strategically plan your cuts to minimize waste and maximize usable material.

Step 7: Monitor and Evaluate Performance

Once you begin cutting, continuously monitor the performance of the jigsaw and blades. Regular evaluations will help identify areas for improvement and ensure consistent quality.

- Inspect cut quality: Regularly assess the edges of the cuts for smoothness and precision.

- Adjust techniques as needed: Be prepared to modify your approach based on observed outcomes, such as blade wear or cutting speed.

By following this checklist, B2B buyers can effectively navigate the complexities of cutting stainless steel with a jigsaw, ensuring a smooth procurement process and successful project outcomes.

Comprehensive Cost and Pricing Analysis for cutting stainless steel with jigsaw Sourcing

When considering the costs associated with cutting stainless steel using a jigsaw, it’s essential to break down the various components that contribute to the overall expenditure. Understanding these elements can help B2B buyers make informed decisions and optimize their sourcing strategy.

What Are the Key Cost Components in Cutting Stainless Steel with a Jigsaw?

-

Materials: The primary cost is the stainless steel itself, which can vary significantly based on the grade (e.g., 304, 316) and thickness (gauge) required for the project. Prices fluctuate due to market demand, alloy composition, and regional availability. For instance, stainless steel is generally more expensive than carbon steel, which affects the overall project budget.

-

Labor: Labor costs encompass the wages paid to skilled workers who operate the jigsaw and manage the cutting process. This includes the time spent setting up, executing cuts, and performing any necessary finishing work. Skilled labor can command higher rates, particularly in regions with a shortage of qualified technicians.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, equipment maintenance, and facility expenses. Overhead can vary depending on the location and scale of the operation, influencing overall pricing.

-

Tooling: The choice of jigsaw blades significantly impacts costs. High-quality, fine-toothed blades suitable for stainless steel cutting may have higher upfront costs but provide better durability and cutting performance. Frequent blade replacements can increase costs, especially when working with thicker materials or intricate designs.

-

Quality Control (QC): Implementing stringent quality control measures ensures that the cuts meet specified tolerances. This may involve additional labor and inspection processes, contributing to overall costs. Certifications and compliance with international standards can also elevate prices but are essential for certain industries.

-

Logistics: Transporting stainless steel sheets and the finished components can incur significant costs, particularly for international shipments. Factors such as distance, shipping method, and associated duties or tariffs must be considered in the total pricing structure.

-

Margin: Suppliers typically add a markup to cover risks, profits, and market fluctuations. Understanding the margin expectations of your suppliers can help in negotiating better deals.

How Do Price Influencers Affect Costs for B2B Buyers?

Several factors can influence the pricing structure when sourcing stainless steel cutting services:

-

Volume/MOQ: Higher order quantities often lead to reduced per-unit costs due to economies of scale. Buyers should consider consolidating orders to achieve better pricing.

-

Specifications and Customization: Custom dimensions or specific grades of stainless steel may incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected charges.

-

Materials: The type and quality of stainless steel selected can significantly affect pricing. Buyers should assess their material needs against available options to balance cost and quality.

-

Quality and Certifications: Industries such as aerospace and food processing require specific certifications, which can increase costs. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can also impact pricing. Established suppliers may offer premium services but at higher prices. Evaluating multiple suppliers can yield competitive quotes.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is critical for calculating total landed costs. Buyers must consider who bears the cost and risk at various stages of transport.

What Are Some Negotiation and Cost-Efficiency Tips for International Buyers?

-

Leverage Volume Discounts: Engage suppliers in discussions about volume discounts. Placing bulk orders or establishing long-term contracts can lead to significant savings.

-

Evaluate Total Cost of Ownership: Beyond initial purchase prices, consider the total cost of ownership, including maintenance, operational efficiency, and potential downtime.

-

Explore Local Suppliers: Sourcing from local suppliers in regions like Africa or South America can reduce logistics costs and lead times. It can also simplify negotiations due to fewer regulatory hurdles.

-

Request Detailed Quotes: Ensure quotes include all cost components, allowing for better comparisons and negotiations. Transparency in pricing helps identify areas for potential savings.

-

Stay Informed on Market Trends: Regularly monitor the stainless steel market for price fluctuations and shifts in demand. Being informed can provide leverage during negotiations.

By understanding these cost components, price influencers, and negotiation strategies, B2B buyers can optimize their sourcing of stainless steel cutting services, ensuring both quality and cost-effectiveness in their projects.

Alternatives Analysis: Comparing cutting stainless steel with jigsaw With Other Solutions

Understanding Alternatives for Cutting Stainless Steel

When it comes to cutting stainless steel, selecting the right method can significantly impact the efficiency and quality of the work. While using a jigsaw is a popular option due to its accessibility and versatility, other cutting methods offer distinct advantages and disadvantages that may better suit specific applications. This section compares cutting stainless steel with a jigsaw against other viable alternatives to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Cutting Stainless Steel With Jigsaw | Plasma Cutting | Band Saw |

|---|---|---|---|

| Performance | Moderate; may require multiple passes and blade changes | High; clean cuts with minimal burrs | High; efficient for straight cuts |

| Cost | Low to moderate (tool and blade costs) | Moderate to high (equipment cost) | Moderate (machine and blade costs) |

| Ease of Implementation | Simple setup; requires skill for accuracy | Requires training and safety measures | Requires setup but straightforward operation |

| Maintenance | Frequent blade replacements needed | Minimal maintenance; ensure air supply | Regular blade checks and replacements |

| Best Use Case | Small projects, intricate shapes, DIY | Heavy-duty applications, thick materials | Straight cuts in thicker materials |

Detailed Breakdown of Alternatives

1. Plasma Cutting

Plasma cutting is an advanced method that utilizes a high-velocity jet of ionized gas to cut through stainless steel. This technique excels in delivering clean and precise cuts, especially for thicker materials. The main advantage of plasma cutting is its speed and the minimal amount of post-cutting work required, as it typically produces fewer burrs. However, the initial investment in plasma cutting equipment can be significant, and operators need specialized training to handle the machines safely and effectively. This method is best suited for industrial applications where high-volume cutting is necessary.

2. Band Saw

The band saw is a popular choice for cutting stainless steel, particularly when straight cuts are required. This method uses a continuous loop of serrated metal to slice through material, providing efficiency and versatility. Band saws can handle various thicknesses and are known for producing smooth cuts with minimal waste. While the setup may require more space and initial investment, once operational, they require less frequent maintenance compared to jigsaws. Band saws are ideal for fabricators and manufacturers dealing with bulk materials that need consistent and accurate cuts.

Conclusion: How to Choose the Right Cutting Solution for Your Needs

Selecting the appropriate cutting method for stainless steel depends on several factors, including the nature of the project, budget constraints, and desired precision. For smaller, intricate tasks, a jigsaw may provide sufficient performance at a lower cost. In contrast, for larger-scale operations or thicker materials, investing in plasma cutting or a band saw may offer greater efficiency and quality. B2B buyers should carefully assess their specific requirements, including volume, material thickness, and available resources, to determine the best cutting solution that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for cutting stainless steel with jigsaw

What Are the Key Technical Properties for Cutting Stainless Steel with a Jigsaw?

When cutting stainless steel with a jigsaw, understanding the material’s technical properties is critical for ensuring precision and efficiency. Here are some essential specifications:

-

Material Grade

Stainless steel comes in various grades, with 304 and 316 being the most common in industrial applications. The grade affects corrosion resistance, strength, and machinability. For instance, 304 is suitable for food processing, while 316 offers superior resistance to saltwater, making it ideal for marine applications. B2B buyers must select the appropriate grade based on the end-use to avoid costly mistakes. -

Thickness Tolerance

The thickness of the stainless steel sheet or plate affects the cutting process. Common thicknesses range from 16 gauge (1.5 mm) to 1/4 inch (6.35 mm). Tolerances can vary, so it’s essential to specify the acceptable range (e.g., ±0.02 inches) in the purchase order. Accurate thickness ensures that the jigsaw blade can perform effectively, leading to cleaner cuts and reduced wear on blades. -

Tensile Strength

Stainless steel generally exhibits high tensile strength, ranging from 505 MPa to 860 MPa. This property determines how well the material can withstand pulling forces without breaking. For jigsaw cutting, a material with lower tensile strength may be easier to cut, making it crucial for buyers to understand the tensile characteristics of the steel they are working with. -

Surface Finish

The surface finish of stainless steel can significantly impact the cutting process and the final aesthetic of the product. Common finishes include mill finish, brushed, and polished. Buyers should be aware that different finishes may require specific jigsaw blades and cutting techniques to achieve the desired results. -

Work Hardening Rate

Stainless steel work hardens quickly, which means that as the material is cut, it can become harder and more difficult to work with. Understanding this property is vital for selecting the right speed and technique when using a jigsaw. If not managed properly, work hardening can lead to blade breakage and increased costs.

What Are the Common Trade Terms Used in Stainless Steel Cutting?

Familiarity with industry terminology can streamline communication and negotiations. Here are some essential terms relevant to cutting stainless steel:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of stainless steel cutting, buyers may need to source jigsaw blades or machines from OEMs that specialize in high-quality metalworking tools. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it can impact inventory costs and lead times. Buyers should negotiate MOQs based on their project requirements to optimize supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should provide detailed specifications when issuing RFQs for stainless steel cutting tools to receive accurate pricing and avoid misunderstandings. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Knowing the applicable Incoterms (e.g., FOB, CIF) is essential for B2B transactions involving stainless steel, as they clarify cost allocation and risk management. -

TPI (Teeth Per Inch)

TPI refers to the number of teeth on a saw blade per inch. For cutting stainless steel, a higher TPI (such as 18-32) is typically recommended to achieve smoother cuts. Understanding TPI helps buyers select the right jigsaw blades for their specific cutting needs.

By grasping these essential properties and terms, B2B buyers can make informed decisions when procuring stainless steel and related cutting tools, ultimately leading to better project outcomes.

Navigating Market Dynamics and Sourcing Trends in the cutting stainless steel with jigsaw Sector

What Are the Key Market Trends Influencing the Cutting Stainless Steel with Jigsaw Sector?

The market for cutting stainless steel with jigsaws is witnessing significant shifts driven by global demand for precision and efficiency in metal fabrication. Factors such as industrial growth in Africa, South America, the Middle East, and Europe are propelling advancements in cutting technology. The need for high-quality stainless steel cuts, especially in sectors like construction and manufacturing, has led to innovations in jigsaw blades designed specifically for metal cutting. Emerging trends indicate a shift towards automated and digitally controlled cutting processes that enhance accuracy and reduce waste, appealing to B2B buyers looking for cost-effective solutions.

Moreover, there is a growing emphasis on customization and versatility in tool design. International buyers are increasingly seeking blades that can handle a range of stainless steel thicknesses, particularly in regions like Brazil and Saudi Arabia, where diverse industrial needs prevail. Additionally, the rise of e-commerce platforms has facilitated easier access to specialized cutting tools, enabling B2B buyers to source high-quality products from global suppliers without geographical constraints.

How Is Sustainability and Ethical Sourcing Shaping the Cutting Stainless Steel with Jigsaw Market?

Sustainability has become a critical consideration in the sourcing of materials and tools for cutting stainless steel. The environmental impact of metalworking processes, including emissions and waste generation, is prompting buyers to prioritize suppliers that adopt eco-friendly practices. Ethical sourcing, encompassing the responsible procurement of materials and adherence to fair labor practices, is now a key criterion for B2B buyers, particularly in Europe and North America.

Buyers are increasingly interested in ‘green’ certifications and materials that signify a commitment to sustainability. Tools and blades made from recyclable materials or those that reduce energy consumption during the cutting process are gaining traction. This shift not only aligns with global sustainability goals but also enhances brand reputation and consumer trust. As a result, B2B buyers are encouraged to engage with manufacturers who transparently communicate their sustainability practices and offer products that contribute to a lower environmental footprint.

How Has the Cutting Stainless Steel with Jigsaw Sector Evolved Over Time?

The evolution of the cutting stainless steel sector, particularly with jigsaws, reflects broader technological advancements and changing industry demands. Initially, the cutting of stainless steel was largely manual, relying on traditional saws and blades that struggled to deliver precision on tougher materials. However, as industries grew and the demand for high-quality finishes increased, manufacturers began developing specialized jigsaw blades optimized for stainless steel.

Today, innovations such as variable-speed motors and advanced blade materials have significantly improved cutting efficiency and accuracy. The introduction of high-tooth-per-inch (TPI) blades allows for cleaner cuts, reducing the need for post-processing. Moreover, the integration of digital technologies in cutting tools has enabled automated solutions that cater to complex cutting requirements, marking a pivotal shift in the sector. This historical context underscores the importance of staying abreast of technological advancements to meet the evolving needs of B2B buyers in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of cutting stainless steel with jigsaw

-

How do I solve issues with cutting stainless steel using a jigsaw?

To address challenges when cutting stainless steel with a jigsaw, ensure you are using the correct blade type—preferably a fine-toothed blade designed for metal cutting. Maintain a steady cutting speed to prevent work hardening, which can dull the blade. It’s essential to secure the material properly to minimize vibration and movement during cutting. If you encounter rough edges, consider using a file or sandpaper for finishing. Additionally, ensure your workspace is well-ventilated and safe to handle the sparks generated during the process. -

What is the best jigsaw blade for cutting stainless steel?

For cutting stainless steel, a jigsaw blade with a high tooth count (60 TPI or more) is recommended to achieve a clean and precise cut. Bi-metal blades or carbide-tipped blades are ideal for their durability and ability to handle the toughness of stainless steel. When working with thinner gauges, a fine-toothed blade will help reduce the risk of chipping. Always verify the blade’s compatibility with your jigsaw model and consider using variable speed settings to optimize the cutting process. -

What are the key considerations when sourcing jigsaw blades for stainless steel?

When sourcing jigsaw blades for stainless steel, evaluate the blade’s material, tooth count, and compatibility with your jigsaw. Look for suppliers that provide detailed specifications and performance ratings. It’s advisable to request samples to assess quality before committing to larger orders. Additionally, consider the supplier’s ability to meet your specific needs regarding customization, such as blade lengths or tooth configurations, to ensure optimal performance for your cutting applications. -

How can I ensure the quality of stainless steel when sourcing for cutting?

To ensure the quality of stainless steel, verify that suppliers adhere to industry standards such as ASTM or ISO certifications. Request material test reports to confirm the composition and properties of the stainless steel. It’s also beneficial to inquire about the supplier’s quality assurance processes, including inspection methods and defect rates. Establishing long-term relationships with reputable suppliers can enhance trust in the quality of the materials provided. -

What are the minimum order quantities (MOQ) for stainless steel and jigsaw blades?

Minimum order quantities (MOQ) for stainless steel sheets and jigsaw blades can vary widely by supplier. Typically, MOQs may range from a few sheets to several tons, depending on the material type and supplier’s production capabilities. For jigsaw blades, MOQs might be lower, often starting at a few dozen units. It’s advisable to discuss your specific needs with potential suppliers to explore options for smaller orders or custom arrangements that can accommodate your business requirements. -

What payment terms are common in international trade for cutting tools?

Common payment terms in international trade for cutting tools, including jigsaw blades and stainless steel, often include options such as letter of credit, advance payment, or open account terms. It’s crucial to negotiate payment terms that balance risk and cash flow management. Many suppliers may require a deposit upfront, especially for custom orders. Always ensure that payment terms are documented clearly in the sales contract to avoid misunderstandings. -

How can I evaluate and vet suppliers for cutting stainless steel?

To evaluate and vet suppliers for cutting stainless steel, start by reviewing their industry reputation through customer reviews and testimonials. Request references from past clients to gauge their reliability and service quality. Inspect the supplier’s production facilities, if possible, to assess their capabilities and quality control processes. Additionally, ensure that the supplier complies with relevant certifications and standards specific to your industry to confirm their credibility. -

What logistics considerations should I keep in mind when importing stainless steel?

When importing stainless steel, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Collaborate with a freight forwarder experienced in handling metal products to navigate the complexities of international shipping. Ensure that the supplier provides the necessary documentation, including certificates of origin and customs declarations. Additionally, plan for potential delays in transit and customs clearance to avoid disruptions in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Cutting Stainless Steel With Jigsaw Manufacturers & Suppliers List

1. Bosch – T118EFS & T118AHM

2. Hobby Machinist – Jigsaw Blade for Stainless Sheet

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: Jigsaw Blade for cutting 18-gauge (0.050″) stainless sheet. Recommended for clean cuts, but may require filing down edges. Suggested tooth count: over 60 TPI for effective cutting. Alternative options discussed include using an abrasive cutoff disk in an angle grinder or a circular saw with a fine tooth negative rake carbide blade. Users noted the importance of keeping the blade cutting to avoid w…

3. Festool – Trion PS 300 Jigsaw

Domain: festoolownersgroup.com

Registered: 2007 (18 years)

Introduction: Trion PS 300 jigsaw; capable of cutting steel up to 4 mm thick; recommended to use cutting oil for blade cooling; blades may wear out quickly when cutting hardened steel or cast iron; aluminum oxide grit blades recommended for steel; caution advised due to sparks and hot metal bits.

4. Stainless Steel Cutting Jig Saw Blades ‘T’ Shank – 18 TPI

Domain: bandsawoutlet.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Stainless Steel Cutting Jig Saw Blades ‘T’ Shank”, “MSRP”: “”, “current_price”: “$12.57”, “TPI”: “18”, “dimensions”: “3-1/4 x 3/8 x .039”, “pack_sizes”: [“1”, “3”, “5”], “product_number”: “T CS318T”, “application”: “5/64″ – 3/16″ / 2.0mm – 4.8mm Stainless, 5/64″ – 7/32″ / 2.0mm – 5.6mm Metal”, “features”: [“Long Life in Hard-to-Cut Metals”, “High performance carbide welded to cut…

5. Bosch – T118A & T118EFS Jigsaw Blades

Domain: diynot.com

Registered: 2000 (25 years)

Introduction: Bosch T118A Sheet Steel Jigsaw Blades 92mm 5 Pack – Suitable for cutting non-perforated metal sheets, fully hardened high grade HSS blade material, milled wavy-set teeth. Bosch T118EFS Sheet Stainless Steel Jigsaw Blade 83mm 5 Pack – Bi-metal, fully hardened HSS tooth strip, highly elastic carbon steel body for cutting stainless steel sheets, milled wavy-set teeth. Erbauer Stainless Steel Cutting …

6. Bosch – Jigsaw Blades for Stainless Steel

Domain: weldingweb.com

Registered: 2003 (22 years)

Introduction: 1. Jigsaw Blades for Cutting Stainless Steel: Users recommend using high-quality blades for cutting stainless steel, such as those with a high tooth count (50 TPI recommended for 16 gauge stainless). 2. Brands Mentioned: Bosch and Lenox are highlighted as reliable brands for jigsaw blades. Specific models include Bosch T118G (36-tooth) and Bosch T118GFS (special for stainless steel). 3. Blade Type…

7. Diablo – Jigsaw Blade Ultimate Stainless Steel

Domain: diablotools.com.au

Introduction: {‘item_number’: ‘2608667375’, ‘product_name’: ‘Diablo Jigsaw Blade Ultimate Stainless Steel ≤3mm’, ‘application’: ‘Straight and Clean Cut ≤3mm, Stainless Steel’, ‘length’: ’82 mm’, ‘pack_quantity’: ‘1’, ‘tooth_design’: ‘Tungsten Carbide Tipped’, ‘bar_tpi’: ‘1.1 mm’, ‘working_length’: ’59 mm’, ‘ideal_for’: ‘Stainless Steel Sheet’, ‘suggested_projects’: ‘Ideal for stainless steel sheet metal 1.5 – 3…

8. YBW – 316 Stainless Steel Cutting Tools

Domain: forums.ybw.com

Registered: 1997 (28 years)

Introduction: 1.5mm thick 316 stainless steel sheet; Cutting tools mentioned: Hacksaw, Junior hacksaw, Dremel with normal (reddish and slate grey) cutting disks, Dremel fibre reinforced cutting disk, angle grinder with thin steel cutting disc, variable speed jigsaw with Bosch T118GFS Stainless Steel Cutting Jigsaw Blade; Recommended cutting discs: 1mm thick discs specifically made for cutting stainless steel, a…

Strategic Sourcing Conclusion and Outlook for cutting stainless steel with jigsaw

In the competitive landscape of metalworking, mastering the art of cutting stainless steel with a jigsaw is essential for achieving precision and efficiency. Key takeaways emphasize the importance of selecting the right tools and techniques tailored to the unique properties of stainless steel. For international B2B buyers, understanding the nuances of material selection, blade types, and cutting speeds can significantly impact the quality of the final product.

Strategic sourcing plays a pivotal role in ensuring access to high-quality materials and tools, ultimately leading to improved operational efficiency and reduced costs. As industries in Africa, South America, the Middle East, and Europe continue to evolve, aligning sourcing strategies with market demands is vital.

Looking ahead, there is an opportunity for businesses to invest in training and resources that enhance their cutting capabilities, thereby fostering innovation and competitiveness. We encourage international buyers to engage with trusted suppliers and explore advanced cutting solutions that can elevate their operations. By prioritizing quality and efficiency, companies can secure their position in the global market and drive sustainable growth in the years to come.