Contents

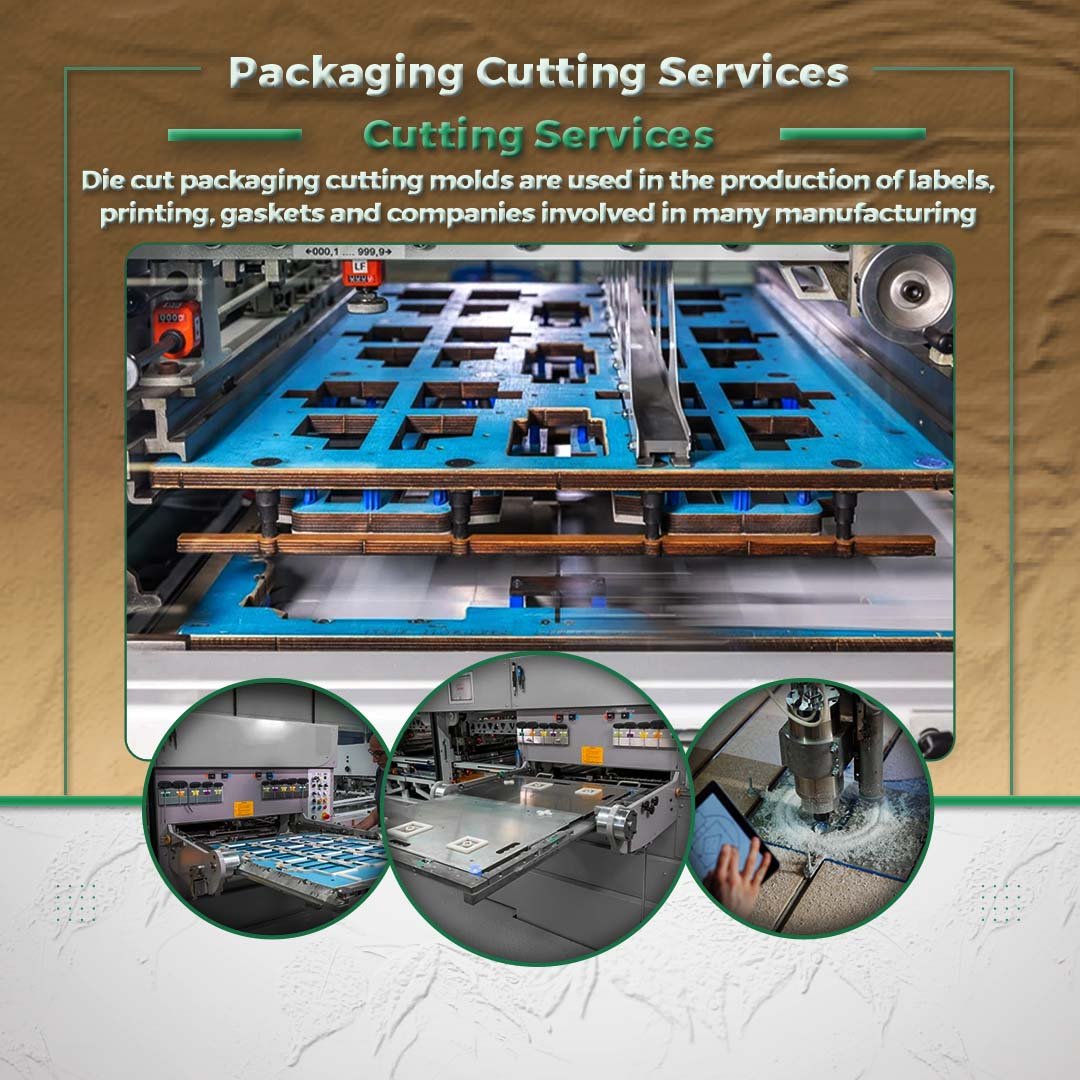

Manufacturing Insight: Cutter Services

Honyo Prototype CNC Machining Services

Honyo Prototype delivers precision-engineered CNC machining services designed to meet the exacting demands of industrial prototyping and low-volume production. Our advanced 3-, 4-, and 5-axis milling and turning capabilities ensure exceptional accuracy, repeatability, and surface finish across complex geometries. We specialize in machining a wide range of engineering-grade materials, including aluminum alloys, stainless steels, titanium, brass, and high-performance polymers, adhering to strict tolerances down to ±0.0002 inches.

Our integrated manufacturing workflow combines state-of-the-art HAAS and DMG MORI equipment with rigorous quality control protocols, including in-process CMM verification and first-article inspection reports. This ensures every component meets stringent industry standards for aerospace, medical, and industrial automation applications.

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload your CAD file, specify materials and quantities, and receive a detailed technical quotation within minutes—enabling faster decision-making and seamless transition from design to precision-machined reality.

Technical Capabilities

Cutter Services Technical Specifications

Honyo Prototype offers precision cutter services utilizing advanced 3, 4, and 5-axis CNC milling and turning platforms to deliver high-accuracy machined components. Our capabilities are optimized for tight-tolerance applications across a range of engineering materials including aluminum, steel, ABS, and nylon. These services support rapid prototyping, bridge production, and low-volume manufacturing with consistent quality and repeatable precision.

| Parameter | Specification Detail |

|---|---|

| Machining Processes | 3-Axis CNC Milling, 4-Axis Indexed/Continuous Milling, 5-Axis Simultaneous Milling, CNC Turning (Swiss and Standard), Mill-Turn with Y-axis |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; tight tolerances down to ±0.002 mm (±0.0001″) achievable with inspection validation |

| Surface Finish | As-machined: 3.2 μm (125 μin); customizable to 0.8–1.6 μm (32–63 μin) with polishing or grinding |

| Maximum Work Envelope (Milling) | 1000 mm × 600 mm × 500 mm (X×Y×Z) for 3/4/5-axis systems; larger parts accommodated on select machines |

| Maximum Work Envelope (Turning) | Up to Ø300 mm diameter × 500 mm length (varies by machine and setup) |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Positioning Accuracy | ±0.003 mm per axis |

| Repeatability | ±0.002 mm |

| Supported Materials | Aluminum (6061, 7075, 2024), Carbon & Alloy Steel (1018, 4140, 4340), Stainless Steel (303, 304, 316), ABS (I400, Magnum 840), Nylon (6, 66, GF-filled options) |

| Coolant & Lubrication | High-pressure through-spindle coolant (metals); air cooling or mist for plastics to prevent deformation |

| Tooling System | CAT 40 / HSK-63; automatic tool changers with up to 30-tool capacity |

| Inspection & Metrology | In-process probing, CMM verification, optical comparators, micrometers, bore gauges, and surface roughness testers |

| Fixturing | Custom soft jaws, vacuum tables, modular fixturing, and tombstone setups for high-precision and batch runs |

Our machining centers are maintained to ISO 527 standards, and operators are trained in precision setup and high-accuracy programming using Mastercam, Fusion 360, and Siemens NX. Material-specific cutting strategies ensure optimal tool paths, minimizing deflection and thermal growth—especially critical when holding tight tolerances in both metallic and thermoplastic substrates.

From CAD to Part: The Process

Honyo Prototype Cutter Services Process Overview

Honyo Prototype delivers precision cutter services through a streamlined, technology-driven workflow designed for rapid prototyping and low-volume production. Our process ensures manufacturability, cost efficiency, and on-time delivery while maintaining rigorous quality standards. Below is a detailed explanation of each phase.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs automated geometry validation to check for file integrity, unit consistency, and basic manufacturability constraints. Invalid files trigger immediate feedback specifying required corrections, minimizing submission delays. All data is encrypted and stored in isolated project environments compliant with ISO 27001 standards.

AI-Powered Quoting Engine

Validated CAD models enter our proprietary AI quoting system, which analyzes geometric complexity, material requirements, tolerance specifications, and surface finish demands. The engine cross-references real-time data on machine availability, material costs, and historical production metrics to generate accurate, itemized quotes within 2 business hours. Key parameters driving cost calculations include:

| Factor | Impact on Quote | Data Source Integration |

|---|---|---|

| Feature Complexity | Higher toolpath planning time | CAM software simulation logs |

| Material Utilization | Nesting efficiency and waste reduction | ERP inventory and scrap rate history |

| Tolerance Stringency | Secondary operations or metrology needs | CMM calibration records |

| Lead Time | Machine scheduling priority | Live shop floor monitoring system |

Engineering-Driven DFM Analysis

Quotes include actionable Design for Manufacturability (DFM) feedback generated through hybrid AI and human engineering review. Our manufacturing engineers evaluate wall thickness ratios, tool access limitations, chamfer requirements, and stress concentration risks specific to CNC milling, turning, or laser cutting processes. Clients receive a formal DFM report with visual annotations and specific redesign recommendations to reduce costs by 15–30% while maintaining functional intent. This phase typically concludes within 24 hours of quote acceptance.

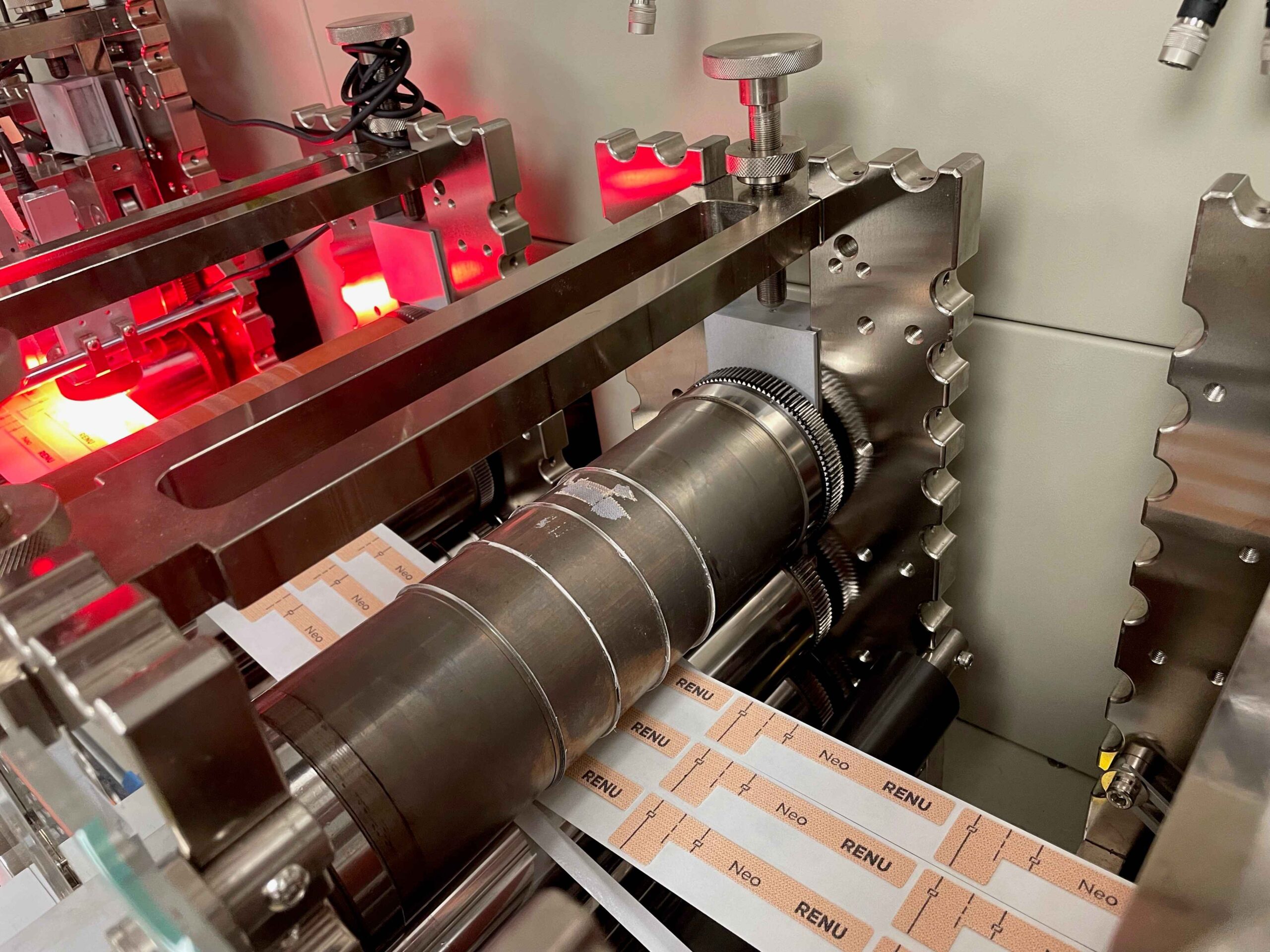

Precision Production Execution

Approved designs move to production in our climate-controlled facility housing 38 CNC machining centers (including 5-axis mills and Swiss-type lathes) and fiber laser cutters. Each job undergoes:

Material certification verification against ASTM/AMS standards

First-article inspection using calibrated CMMs and optical comparators

In-process checks at critical operation milestones

Real-time machine telemetry monitoring for thermal drift compensation

All cutter paths are validated via CAM simulation before metal cutting begins, with tool wear compensated through adaptive control systems. Production timelines adhere strictly to the quoted schedule with biweekly client progress updates.

Quality-Controlled Delivery

Completed parts undergo final inspection per AS9102 or client-specific FAI requirements. Dimensional reports, material certs, and process documentation are compiled into a digital quality package accessible via the client portal. Parts ship in ESD-safe packaging with serialized traceability tags, accompanied by a delivery confirmation email containing shipment tracking and quality documentation links. Standard delivery is 7–10 business days from DFM approval, with expedited options available for time-critical projects.

Start Your Project

For expert cutter services tailored to your manufacturing needs, contact Susan Leo at [email protected]. Our dedicated facility in Shenzhen ensures precision, efficiency, and fast turnaround times. Partner with Honyo Prototype for reliable, high-quality cutting solutions backed by advanced technology and strict quality control. Reach out today to discuss your project requirements.

Contact Information

Name: Susan Leo

Email: [email protected]

Location: Shenzhen, China

| Service Feature | Detail |

|---|---|

| Service Type | Precision Cutter Services |

| Facility Location | Shenzhen, China |

| Lead Time | Competitive, project-based |

| Materials Handled | Metals, plastics, composites |

| Customization Options | Fully customizable geometries |

Get in touch now to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.