Contents

Manufacturing Insight: Cut Stainless Steel

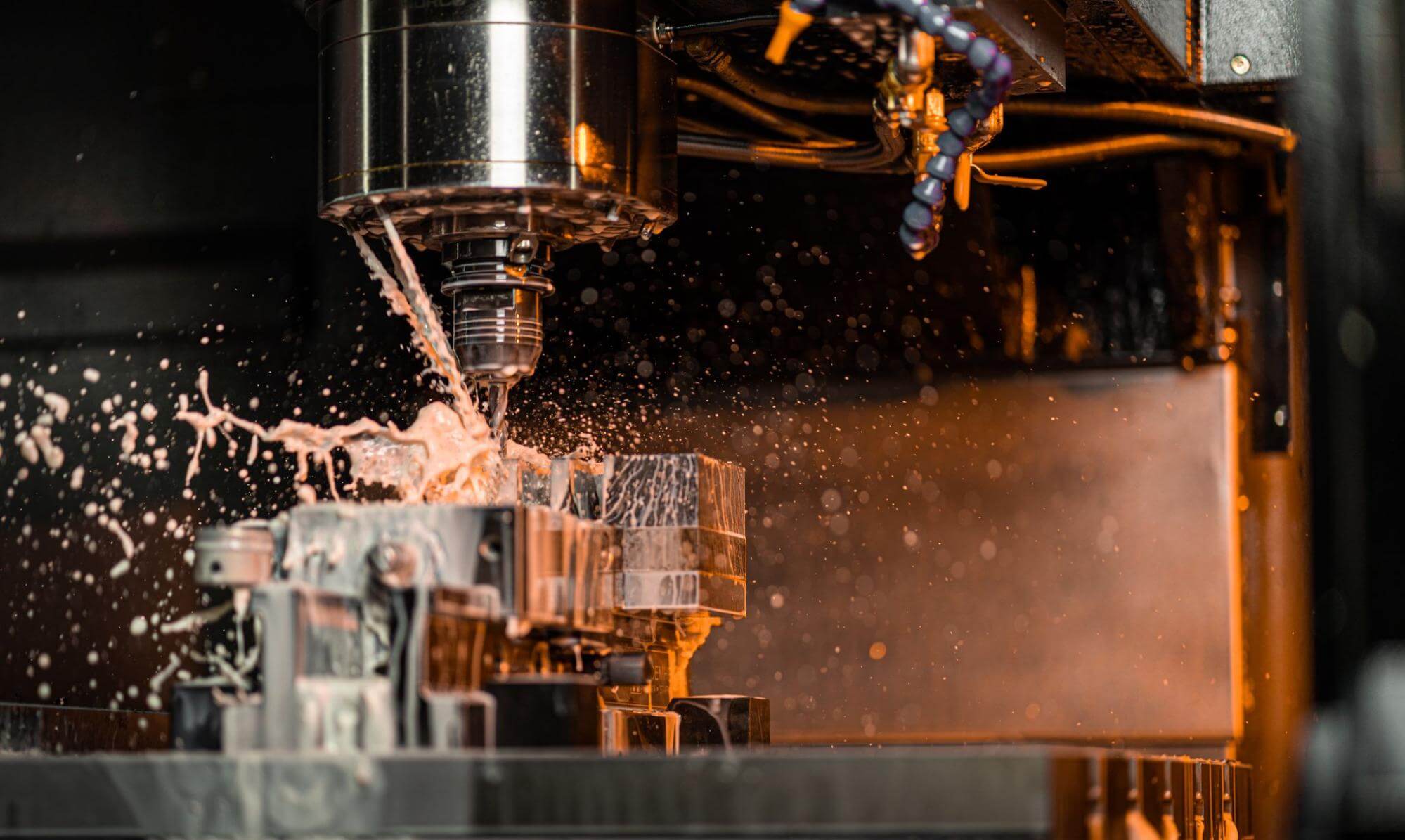

Precision CNC Machining for Stainless Steel Components

Stainless steel remains a critical material choice for demanding applications across aerospace, medical, and industrial sectors due to its exceptional corrosion resistance, strength, and biocompatibility. However, its propensity for work hardening, thermal conductivity challenges, and stringent tolerance requirements demand specialized machining expertise. At Honyo Prototype, our advanced CNC milling and turning centers are optimized specifically for stainless alloys including 304, 316, 17-4 PH, and custom grades, ensuring consistent part integrity and dimensional accuracy down to ±0.0002 inches.

We eliminate traditional quoting delays with our proprietary Online Instant Quote platform, allowing engineers to upload CAD files and receive detailed pricing, lead time estimates, and manufacturability feedback within minutes—not days. This accelerates prototyping and low-volume production cycles while maintaining rigorous quality control through in-process inspections and post-machining validation. Partner with Honyo to transform complex stainless steel designs into mission-critical components with uncompromised precision and responsiveness.

Technical Capabilities

Technical Specifications for Precision Cut Stainless Steel Components

Honyo Prototype delivers high-precision machined stainless steel components using advanced 3, 4, and 5-axis CNC milling and turning processes. Our capabilities support tight tolerance requirements and complex geometries across a range of engineering materials, including stainless steel, aluminum, carbon steel, ABS, and nylon. Below is a detailed breakdown of technical specifications and material compatibility.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Multi-axis) |

| Material – Stainless Steel | 303, 304, 304L, 316, 316L, 17-4 PH, 410, 416, 440C (Austenitic, Martensitic, Precipitation Hardening) |

| Material – Aluminum | 6061-T6, 7075-T6, 2024-T3, 5052, 6082 (High strength-to-weight ratio, excellent machinability) |

| Material – Steel | 1018, 1045, 4140, 4340, A36 (Low to medium carbon and alloy steels for structural applications) |

| Material – Plastics | ABS (Acrylonitrile Butadiene Styrene), Nylon 6, Nylon 6/6, POM (Delrin) – machined for non-metallic, wear-resistant components |

| Tolerance Range | ±0.005 mm (±0.0002″) for critical dimensions; tight control down to ±0.0025 mm (±0.0001″) with inspection |

| Surface Finish | As-machined: 3.2–1.6 µm (125–63 µin); Optional polishing, passivation, or coating available |

| Max Work Envelope (Milling) | 5-Axis: 1000 x 800 x 600 mm; 3-Axis: 1200 x 750 x 500 mm |

| Max Turning Diameter | 300 mm; Max Length: 600 mm (Swiss-type turning available for small, high-precision parts) |

| Positioning Accuracy | ±0.002 mm per axis (laser-calibrated machines) |

| Repeatability | ±0.003 mm across production runs |

| Inspection Equipment | CMM (Coordinate Measuring Machine), Optical Comparators, Micrometers, Calipers, Thread Gauges |

| Secondary Operations | Deburring, Tapping, Heat Treatment, Anodizing (Al), Passivation (SS), Laser Marking |

All stainless steel components are machined with optimized toolpaths to minimize work hardening and ensure dimensional stability. Multi-axis milling enables single-setup machining of complex 3D contours, reducing cumulative error and improving geometric accuracy. Turning operations are ideal for cylindrical or rotational parts requiring concentricity and fine surface finishes.

For hybrid assemblies, we support integration of machined stainless steel with aluminum brackets, ABS enclosures, or nylon bushings, ensuring material compatibility and long-term performance.

From CAD to Part: The Process

Honyo Prototype executes stainless steel cutting through a rigorously controlled digital workflow designed for precision, efficiency, and material integrity. Our process begins when a customer uploads a native CAD file (STEP, IGES, or native SolidWorks) to our secure portal. The geometry, material specification (e.g., 304L, 316L), and critical tolerances are immediately parsed by our AI-powered quoting engine. This system cross-references historical production data, real-time machine availability, and stainless-specific parameters such as thermal conductivity and chromium oxide layer behavior to generate an accurate cost and lead time estimate within minutes. The AI explicitly accounts for stainless steel challenges including heat-affected zone minimization and dross prevention during laser cutting.

Following customer approval of the AI-generated quote, the design enters our mandatory Design for Manufacturability (DFM) phase. A senior manufacturing engineer conducts a thorough review focused on stainless steel properties. This includes verifying kerf compensation for fiber laser cutting (typically 0.1–0.2mm), assessing potential warpage from thermal stress in thin sections (<1mm), confirming minimum hole diameters relative to material thickness, and evaluating edge quality requirements against ANSI B46.1 standards. Any geometric features risking micro-cracking during high-speed cutting—such as acute internal corners or nested contours—are flagged with specific revision recommendations. Customer collaboration is required to resolve DFM findings before proceeding.

Approved designs advance to production where stainless steel sheets undergo stringent material verification. Mill certificates are validated against ASTM A240 specifications, and material thickness is confirmed via ultrasonic gauge measurement. Cutting occurs on our IPG fiber laser systems (max 4kW) with nitrogen assist gas to prevent oxidation and ensure burr-free edges; parameters are dynamically adjusted per grade (e.g., 316L requires 15% slower cutting speed than 304 at 2mm thickness). All parts undergo in-process CMM inspection at critical stages, with surface roughness verified to Ra ≤ 1.6µm. Post-cut, parts receive citric acid passivation per ASTM A967 to restore the chromium oxide layer, followed by ultrasonic cleaning to eliminate ferrous contamination.

Final quality validation includes full First Article Inspection per AS9102, with dimensional reports traceable to NIST standards. Parts are packaged in VCI paper with desiccant inside static-shielded containers rated IP67, preventing corrosion during transit. Our integrated MES system provides real-time shipment tracking, with delivery typically occurring within 5–7 business days after DFM sign-off for standard orders. This closed-loop process ensures stainless steel components meet aerospace, medical, and semiconductor industry requirements for corrosion resistance and dimensional accuracy.

Key stainless steel cutting parameters we optimize:

| Parameter | Typical Range for Stainless Steel | Critical Consideration |

|---|---|---|

| Laser Power | 1–4 kW | Higher power for >6mm thickness |

| Assist Gas | Nitrogen (99.995% purity) | Prevents oxide formation on cut edge |

| Cutting Speed | 0.5–3.5 m/min | Grade-dependent (316L slower than 304) |

| Kerf Width | 0.1–0.25 mm | Compensated in CAD model |

| Surface Roughness | Ra 0.8–1.6 µm | Verified via profilometer |

Start Your Project

Need precision-cut stainless steel for your next project? Honyo Prototype delivers high-quality, accurate cuts using advanced manufacturing techniques, ensuring consistency and durability for demanding applications.

Our factory in Shenzhen offers fast turnaround times and strict quality control, ideal for prototypes and low-to-mid volume production runs.

Contact Susan Leo today to request a quote or discuss your specifications.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.