Contents

Manufacturing Insight: Cut Sheet Steel

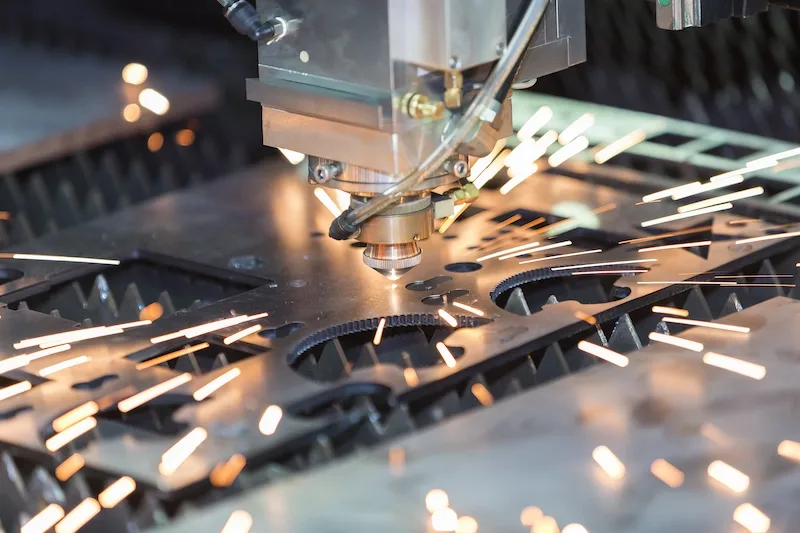

Precision Sheet Metal Fabrication: Transforming Cut Sheet Steel into Production-Ready Components

At Honyo Prototype, we specialize in high-precision sheet metal fabrication, starting with expertly cut sheet steel tailored to your exact specifications. Our integrated manufacturing capabilities encompass advanced laser, plasma, and waterjet cutting for materials ranging from mild steel and stainless steel to aluminum and specialty alloys, ensuring clean edges and tight tolerances from the first operation. Beyond cutting, we provide comprehensive secondary processes including precision forming, CNC punching, welding, hardware insertion, and finishing—all under one roof to streamline your supply chain and eliminate vendor management complexity.

What sets Honyo apart is our commitment to engineering-grade accuracy and rapid turnaround without compromising quality. Our ISO 9001-certified facility leverages state-of-the-art equipment and rigorous in-process inspections to deliver components that meet stringent industry standards for aerospace, medical, and industrial applications. Crucially, we empower your design-to-manufacturing workflow with our Online Instant Quote system, providing transparent pricing and lead times for sheet metal parts in under 60 seconds. Simply upload your STEP or DXF file, specify materials and quantities, and receive a detailed fabrication assessment—no sales calls, no delays. This digital efficiency accelerates prototyping and low-volume production, allowing you to iterate faster and bring products to market with confidence.

For cut sheet steel projects demanding precision, scalability, and seamless digital integration, Honyo Prototype delivers engineered solutions backed by decades of manufacturing expertise. Start your next project with an instant quote today.

Technical Capabilities

Technical specifications for cut sheet steel involve key parameters related to material selection, processing methods, and dimensional tolerances. Below is a detailed breakdown focused on laser cutting, bending, and welding processes for common materials used in sheet fabrication, including aluminum, steel, ABS, and nylon.

| Material | Thickness Range (mm) | Laser Cutting Compatibility | Bending Minimum Radius (inner) | Welding Process | Notes |

|---|---|---|---|---|---|

| Mild Steel | 0.5 – 25.0 | Excellent – clean cuts with CO₂ or fiber lasers | 0.8 × thickness (typical) | MIG, TIG, Spot Welding | High strength, cost-effective; requires coating for corrosion resistance |

| Stainless Steel | 0.5 – 20.0 | Excellent – minimal dross with nitrogen assist | 1.0 × thickness | TIG, MIG, Laser Welding | Good corrosion resistance; higher cost than mild steel |

| Aluminum Alloys (e.g., 5052, 6061) | 0.8 – 12.7 | Good – reflective; requires high-power fiber lasers with proper assist gas (N₂ or O₂) | 1.5 × thickness | TIG, MIG (with pulse control) | Lightweight; excellent corrosion resistance; prone to warping during welding |

| ABS (Acrylonitrile Butadiene Styrene) | 1.0 – 10.0 | Moderate – cuts cleanly with CO₂ lasers; may char edges | 2.0 × thickness | Ultrasonic, Vibration, Solvent Bonding | Thermoplastic; not weldable via traditional methods; limited heat resistance |

| Nylon (Polyamide) | 1.0 – 8.0 | Moderate – CO₂ laser cuts possible; high risk of melting or flaring | 3.0 × thickness | Hot plate, vibration, or adhesive bonding | High toughness and chemical resistance; hygroscopic; challenging to process thermally |

Laser Cutting Notes

Fiber lasers are preferred for metals (steel and aluminum) due to high precision and efficiency. CO₂ lasers are suitable for non-metallic sheets like ABS and nylon but require optimized settings to minimize thermal damage. Kerf width typically ranges from 0.1 mm to 0.3 mm depending on material and laser focus.

Bending Considerations

Minimum bend radius is critical to avoid cracking or weakening at the bend line. Springback must be compensated in tooling design, especially for aluminum and nylon. Bend allowances and K-factors vary by material and are used in flat pattern development.

Welding Guidelines

Metal welding requires proper joint preparation and shielding gas to prevent oxidation. Aluminum demands precise heat control due to high thermal conductivity and low melting point relative to steel. Plastics like ABS and nylon are joined using non-fusion methods; traditional arc welding is not applicable.

This data supports process planning for prototyping and low-to-mid volume manufacturing at Honyo Prototype, ensuring dimensional accuracy and structural integrity across diverse material options.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Cutting Process Overview

Our end-to-end digital manufacturing workflow for precision sheet steel cutting integrates advanced automation with engineering expertise to ensure rapid, cost-effective production. Below is a detailed technical breakdown of each stage, specifically for laser, plasma, and waterjet cutting of sheet steel components.

Upload CAD

Customers initiate the process by uploading native or neutral CAD files (STEP, IGES, DXF, DWG) via our secure web portal. Our system validates file integrity, confirms units (mm/inch), and extracts critical geometric data including part轮廓, hole patterns, and bend lines. We support thickness ranges from 0.5 mm to 25 mm across common grades (e.g., A36, 304SS, 5052-Al, though steel-specific). File acceptance triggers immediate geometric analysis for manufacturability flags.

AI-Powered Quoting

Within 15 minutes, our proprietary AI engine generates a detailed quote using real-time shop floor data. The algorithm factors material cost (current scrap-indexed pricing), machine hourly rates, nesting efficiency, and secondary operations. Unlike manual quoting, it identifies potential cost drivers such as excessive kerf loss in intricate contours or suboptimal material utilization. Quotes include explicit lead times (typically 3-7 days for 1-50 parts) and highlight design elements impacting cost, such as tolerances tighter than ±0.1 mm or features requiring secondary finishing.

Engineered DFM Analysis

All designs undergo mandatory Design for Manufacturability review by our sheet metal specialists. This phase resolves conflicts between design intent and production realities. Key validation checks include:

| DFM Parameter | Standard Checkpoint | Honyo Threshold |

|---|---|---|

| Minimum Hole Diameter | Material thickness ratio | ≥ 1.0x thickness |

| Kerf Clearance | Internal feature separation | ≥ 0.5 mm + kerf width |

| Nesting Efficiency | Material utilization | ≥ 85% (target 92%) |

| Tolerance Feasibility | GD&T vs. process capability | Cpk ≥ 1.33 achievable |

The DFM report provides actionable recommendations—such as adjusting fillet radii to prevent dross adhesion in plasma cutting or consolidating features to reduce pierce points—with no obligation to proceed. 95% of first-time designs pass with minor suggestions.

Precision Production

Approved designs move to production on our automated cutting cells. We deploy Bystronic laser systems (6 kW fiber), Hypertherm plasma, and OMAX waterjets based on material grade and thickness. Each job receives:

Dynamic nesting via SigmaNEST software to maximize yield

First-article inspection against CAD using FARO Arm CMM

In-process monitoring for kerf width consistency (±0.05 mm)

Deburring per ISO 1302 surface roughness requirements

All parts are serialized and tracked through our MES for full traceability from coil to shipment.

Guaranteed Delivery

Completed orders undergo final QA per AS9102 standards before kitting. We ship globally via DHL/FedEx with real-time tracking, including material certs and FAI reports. For JIT customers, we offer consignment inventory at our Shenzhen facility with 48-hour pull capability. Standard lead time is 5 business days from DFM approval for quantities under 100 parts, with expedited 72-hour options available.

This integrated workflow reduces time-to-part by 40% versus traditional vendors while maintaining ±0.1 mm positional accuracy. Request a CAD upload link to experience our zero-commitment quoting engine or contact our applications team for material-specific capability data sheets. No minimum order quantity applies.

Start Your Project

For custom cut sheet steel solutions, contact Susan Leo at [email protected]. Our manufacturing facility in Shenzhen ensures precision cutting, fast turnaround, and consistent quality for prototyping and low-volume production needs. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.