Contents

Manufacturing Insight: Custom Worm Gears

Precision Custom Worm Gears: Engineered for Performance with Honyo CNC Machining

Custom worm gears present unique manufacturing challenges requiring exceptional geometric precision, stringent material properties, and controlled surface finishes to ensure optimal meshing, load capacity, and minimal backlash in critical motion systems. Standard off-the-shelf solutions often fail to meet the exacting demands of aerospace actuators, medical robotics, or industrial automation where helix accuracy and tooth profile consistency directly impact system reliability and lifespan. At Honyo Prototype, our advanced CNC machining capabilities—specifically optimized for complex helical geometries—deliver custom worm gears that consistently achieve micron-level tolerances and superior surface integrity.

Our AS9100-certified facility leverages multi-axis CNC milling and turning centers equipped with high-precision probing and in-process gauging to machine intricate worm threads from demanding materials including stainless steels, titanium alloys, and engineered plastics. Unlike conventional gear cutting methods, our CNC-based approach eliminates tooling lead times and enables rapid iteration of non-standard lead angles, variable pitch profiles, or integrated mounting features—all while maintaining strict conformance toAGMA or custom-defined quality standards. This direct digital manufacturing process ensures repeatability across prototypes through low-volume production runs, reducing total project risk.

Honyo’s technical team collaborates closely with design engineers to validate manufacturability early, addressing potential stress concentrations or assembly constraints before metal is cut. We routinely achieve critical specifications such as:

| Parameter | Typical Capability | Honyo Standard |

|---|---|---|

| Lead Accuracy | ±0.025 mm/300 mm | ±0.008 mm/300 mm |

| Surface Roughness | Ra 1.6 μm | Ra 0.4 μm |

| Tooth Profile Dev. | ±0.020 mm | ±0.005 mm |

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload your STEP or Parasolid file to receive a detailed CNC machining assessment—including lead time, material cost breakdown, and actionable DFM feedback—within minutes. No sales calls required. Experience how precision-engineered custom worm gears, backed by rigorous process control and rapid quoting, can elevate your next motion control application. Visit Honyo Prototype’s Instant Quote portal to start your project today.

Technical Capabilities

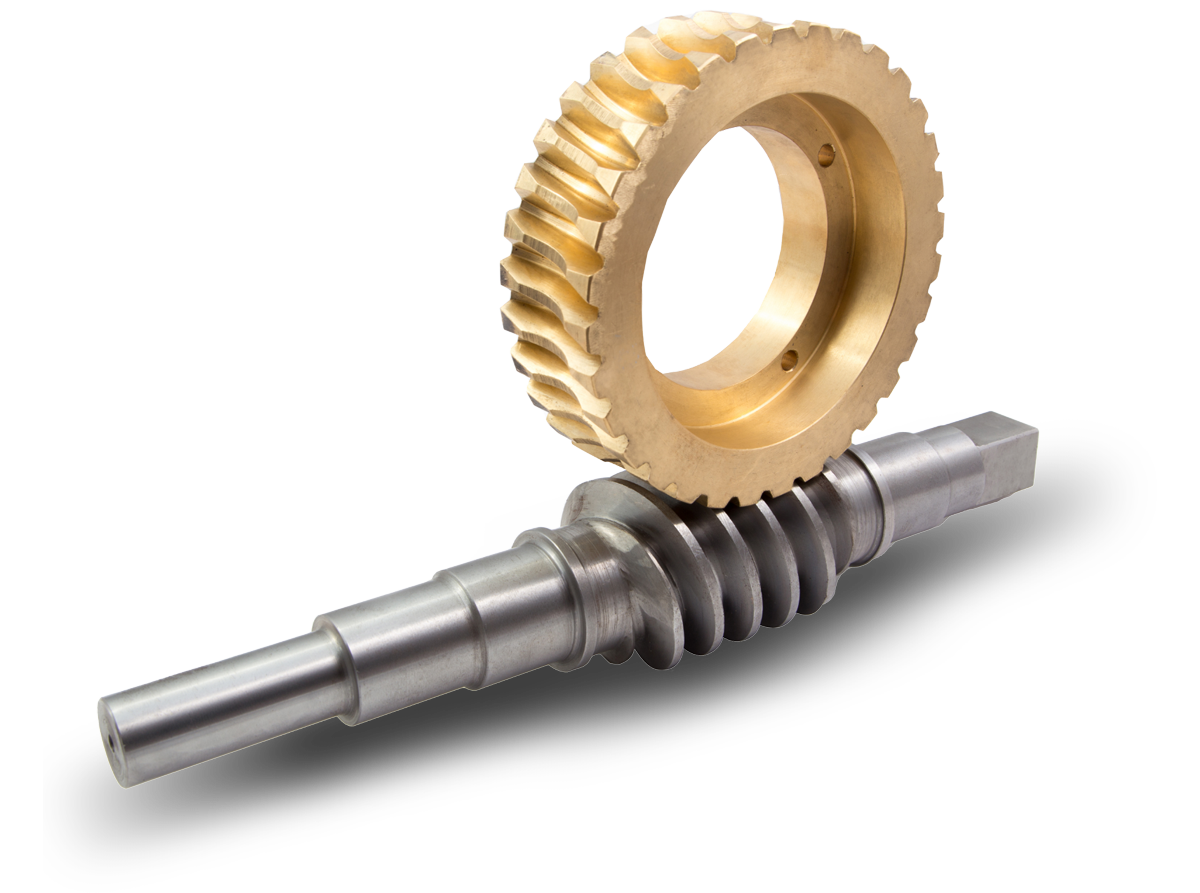

Custom worm gears are precision-engineered components designed for high-performance motion transmission in compact spaces. At Honyo Prototype, we specialize in manufacturing custom worm gears using advanced 3-, 4-, and 5-axis CNC milling and turning processes, ensuring exceptional accuracy and surface finish. Our capabilities support tight tolerances down to ±0.002 mm, critical for smooth meshing and long service life in high-load or high-precision applications.

We work with a range of engineering-grade materials including aluminum, steel, ABS, and nylon, allowing for optimized performance across diverse operational environments—whether requiring high strength, corrosion resistance, or lightweight and low-friction characteristics.

Below is a summary of technical specifications for custom worm gears manufactured via multi-axis CNC processes:

| Parameter | Specification Details |

|---|---|

| Manufacturing Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning; multi-task machining |

| Tolerance Capability | ±0.002 mm (tight tolerance achievable on lead, pitch diameter, and tooth profile) |

| Surface Finish | As low as Ra 0.4 µm (polished finishes available upon request) |

| Materials Available | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 304/316), ABS, Nylon (PA6, PA66) |

| Module Range | 0.5 to 5 mm (customizable based on application) |

| Lead Accuracy | ±0.005 mm per revolution (achievable with 5-axis precision machining) |

| Maximum Outer Diameter | Up to 300 mm (dependent on material and machine setup) |

| Tooth Profile Options | Involute, Archimedes, or custom profiles per design requirements |

| Secondary Operations | Heat treatment (for steel), anodizing (aluminum), stress relieving, precision grinding |

| Quality Control | CMM inspection, gear metrology, first-article inspection (FAI), GD&T compliance |

All custom worm gears are produced to meet application-specific torque, speed, and efficiency requirements. Material selection directly influences wear resistance, lubrication needs, and compatibility with mating worm wheels. For example, steel worms paired with bronze or nylon worm wheels are common in high-torque systems, while all-polymer configurations suit lightweight, low-noise applications.

Honyo Prototype ensures full traceability and documentation, supporting industries such as robotics, aerospace, medical devices, and industrial automation where reliability and precision are paramount.

From CAD to Part: The Process

Honyo Prototype executes custom worm gear manufacturing through a rigorously controlled digital workflow designed for precision, efficiency, and engineering collaboration. Our process eliminates traditional quotation delays while ensuring manufacturability and performance compliance from initial design to delivered component.

CAD Upload and Initial Submission

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. The system validates file integrity and extracts critical geometric parameters including lead angle, axial module, tooth profile, number of starts, pitch diameter, and face width. Material specifications and functional requirements documented within the CAD metadata or supplementary RFQ forms are automatically linked to the project dossier. All data undergoes immediate encryption per ISO 27001 standards to protect intellectual property.

AI-Assisted Quotation Generation

Proprietary AI algorithms analyze the CAD geometry against our production database of 12,000+ qualified worm gear builds. The system evaluates material utilization, machine time estimates across 5-axis milling and CNC hobbing centers, heat treatment complexity, and inspection protocols. Within 90 minutes, clients receive a technically validated quote detailing unit cost, lead time, and recommended material grades (e.g., 4140 chrome-moly,青铜 C93200 bronze, or PEEK polymer). Crucially, this is not an automated price-only output—the AI flags geometric anomalies requiring engineering review, triggering direct SME consultation before finalization.

Engineering-Led DFM Analysis

Every design undergoes mandatory Design for Manufacturability review by our worm gear specialists. This phase identifies critical manufacturability constraints including:

Minimum root fillet radii versus cutter clearance

Lead angle feasibility for thread milling

Tooth profile deviations affecting backlash

Material hardness versus required surface finish

DFM feedback is delivered within 24 business hours as actionable engineering recommendations. Key assessment categories include:

| DFM Category | Critical Parameters Evaluated | Typical Resolution Pathway |

|---|---|---|

| Geometry | Undercuts, thin rims, non-standard leads | Suggest profile modifications |

| Material Selection | Hardness vs. wear resistance, lubrication needs | Propose certified alloys/alternatives |

| Tolerances | Runout specs vs. achievable AGMA Q10-Q12 standards | Negotiate functional vs. nominal specs |

| Assembly Interface | Shaft bore fit, thrust collar alignment | Adjust GD&T callouts |

This collaborative phase often involves real-time video reviews with the client’s design team to optimize performance without compromising function.

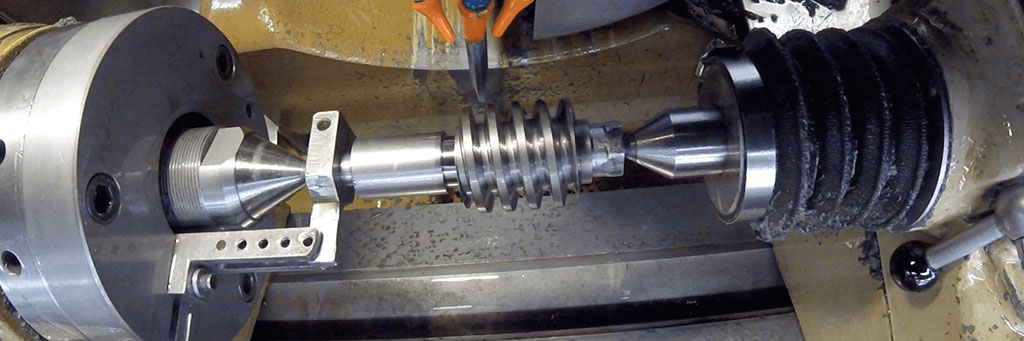

Precision Production Execution

Approved designs enter production using dedicated worm gear manufacturing cells. Key process controls include:

CNC thread milling with Renishaw probing for lead accuracy verification

In-process CMM checks of pitch diameter and tooth thickness at 25% intervals

Case hardening (where specified) with post-heat-treatment stress relief

Final inspection using gear analyzers measuring total composite error per AGMA 2015-1 standard

All worm gears undergo 100% functional testing with mating worm wheels to validate transmission efficiency and noise levels before shipment.

Traceable Delivery and Documentation

Completed components ship with full traceability documentation including heat-treated material certs, first-article inspection reports, and process validation records. We utilize climate-controlled logistics partners for critical shipments, providing real-time GPS tracking. Standard lead time from CAD approval to delivery is 15-22 business days for single-start steel worms up to 250mm diameter, with expedited options available for qualified geometries. Every shipment includes a digital twin package with as-manufactured 3D scan data for client verification against original CAD.

Start Your Project

Looking for custom worm gears engineered to your exact specifications? Honyo Prototype delivers precision-manufactured components with fast turnaround times. Our advanced production capabilities and strict quality control ensure reliable performance for demanding applications.

All products are manufactured at our Shenzhen factory, where skilled technicians oversee every stage of production. Whether you need a single prototype or low-volume production runs, we provide tailored solutions with consistent accuracy.

Contact Susan Leo today to discuss your project requirements. Email at [email protected] for a prompt response and technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.