Contents

Manufacturing Insight: Custom Water Jet Cutting

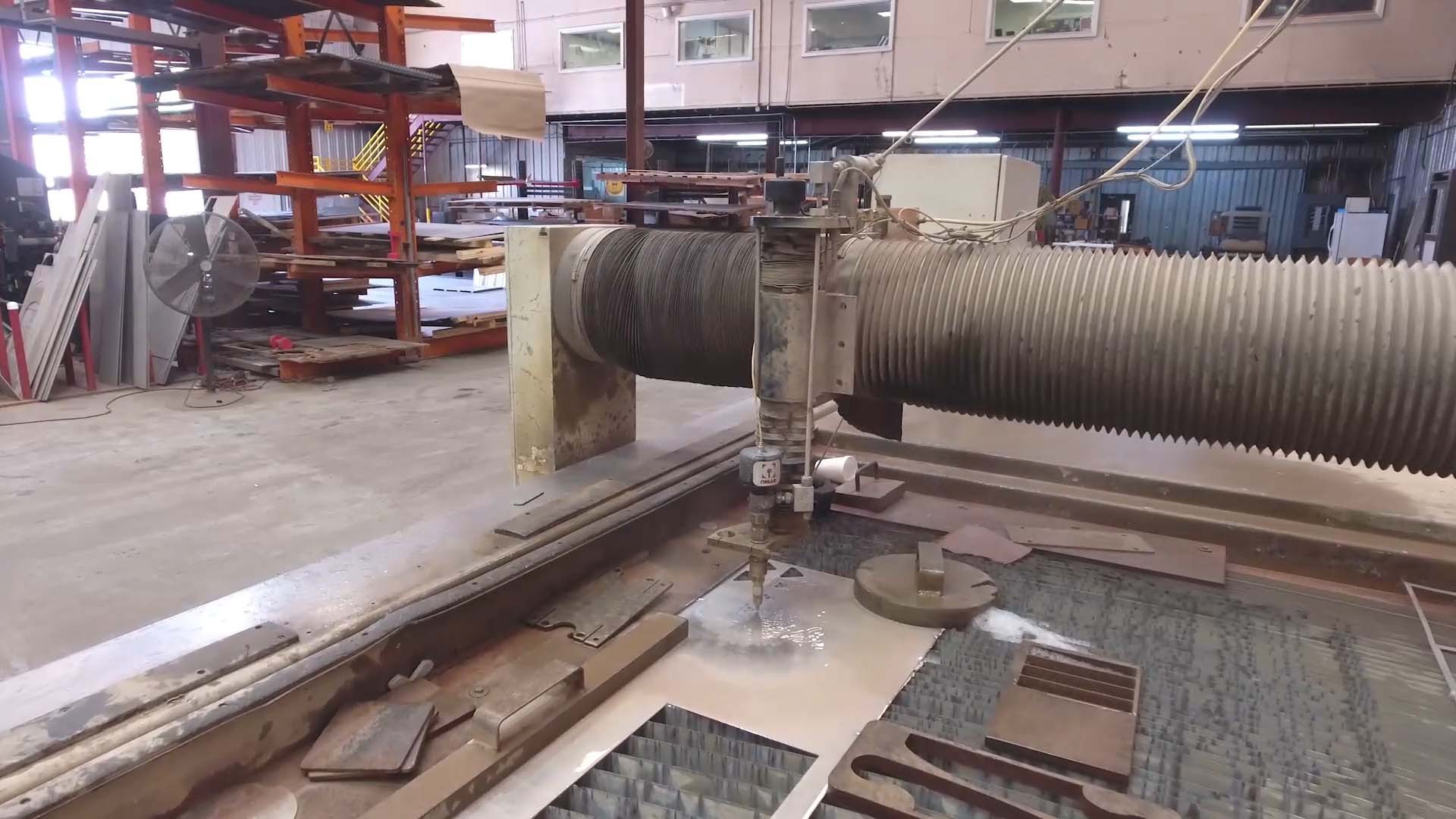

Precision Water Jet Cutting for Demanding Prototyping and Low-Volume Production

Honyo Prototype delivers advanced custom water jet cutting as a core component of our comprehensive CNC machining service portfolio, engineered specifically for rapid prototyping and specialized low-volume manufacturing. Our multi-axis abrasive water jet systems excel at processing materials traditional methods struggle with—including hardened tool steels, composites, glass, ceramics, and heat-sensitive alloys—without inducing thermal distortion, mechanical stress, or hazardous fumes. This cold-cutting capability ensures dimensional accuracy down to ±0.005 inches while maintaining material integrity, critical for validating complex geometries in aerospace, medical, and energy applications where design fidelity directly impacts performance.

Unlike conventional laser or plasma cutting, Honyo’s water jet technology handles thicknesses up to 6 inches in a single pass, enabling intricate 2D and taper-controlled 3D profiles for components that demand zero thermal-affected zones. Integrated within our end-to-end CNC workflow, water jet cutting seamlessly complements milling, turning, and EDM services, allowing us to tackle multi-process projects from raw material to finished assembly under one roof. This unified approach eliminates supplier handoffs, accelerates iteration cycles, and guarantees consistent quality control across all fabrication stages.

For immediate project feasibility assessment, Honyo’s Online Instant Quote platform provides transparent, real-time pricing and lead time estimates for water jet cutting and integrated CNC services. Simply upload your CAD file, specify material and quantity requirements, and receive a detailed manufacturing-ready quote within minutes—empowering engineering teams to make informed decisions without procurement delays.

Key Material Capabilities

| Material Category | Examples | Max Thickness | Tolerance Range |

|————————|———————————–|—————|———————|

| Metals | Titanium, Inconel, Tool Steel | 6.0 in | ±0.005 in – ±0.010 in |

| Composites | Carbon Fiber, Kevlar, G10 | 4.0 in | ±0.008 in |

| Ceramics/Glass | Alumina, Borosilicate, Tempered | 1.5 in | ±0.010 in |

| Plastics | UHMW, PEEK, Acrylic | 3.0 in | ±0.005 in |

Accelerate your next prototype with Honyo’s precision water jet cutting—where material versatility meets rapid turnaround. Initiate your project instantly via our Online Instant Quote system and experience seamless integration from concept to certified component.

Technical Capabilities

Custom water jet cutting is a high-precision manufacturing process that utilizes a high-pressure stream of water, often mixed with abrasive particles, to cut through a wide range of materials. When integrated with multi-axis motion control systems (3-axis, 4-axis, and 5-axis configurations), water jet cutting achieves complex geometries and tight tolerance features typically associated with milling and turning operations—without introducing heat-affected zones or mechanical stress.

This hybrid approach combines the cold-cutting advantage of water jet technology with the precision kinematics of multi-axis CNC platforms, enabling intricate 3D contouring and beveled edge preparation. While traditionally used for 2D profiling, advanced 5-axis water jet systems now support dynamic tilting heads for taper compensation, angular cuts, and 3D part shaping—offering capabilities that rival or complement traditional subtractive methods.

The process supports a broad material spectrum, including Aluminum, Steel, ABS, and Nylon, with tight tolerances typically held within ±0.005″ (0.127 mm), and down to ±0.001″ (0.025 mm) in optimal conditions with secondary finishing.

| Parameter | Specification / Capability |

|---|---|

| Cutting Method | High-pressure abrasive water jet (up to 90,000 psi) with multi-axis CNC motion control |

| Axis Configuration | 3-axis (X, Y, Z), 4-axis (with rotational A or B axis), 5-axis (full spatial articulation) |

| Tolerance Capability | ±0.005″ (0.127 mm) standard; ±0.001″ (0.025 mm) with calibration and fine tuning |

| Material Compatibility | Aluminum, Steel (mild and stainless), ABS, Nylon, composites, plastics, and exotic alloys |

| Max Material Thickness | Up to 6″ (152 mm) for steel; up to 8″ (203 mm) for softer materials like ABS and Nylon |

| Cut Angle Range (5-axis) | Up to ±45° for bevels and taper compensation |

| Surface Finish | As-cut finish: 250–350 μin Ra; can be improved with secondary processes |

| Edge Quality | No heat-affected zone (HAZ); minimal burr; stress-free cutting |

| Lead Times | Rapid prototyping: 3–7 days; production runs scalable based on complexity |

| Typical Applications | Aerospace components, jigs and fixtures, medical device parts, complex brackets |

This capability is ideal for clients requiring tight-tolerance, complex geometry parts in materials sensitive to thermal distortion, offering a cold alternative to laser or plasma cutting while achieving near-milled precision.

From CAD to Part: The Process

Honyo Prototype executes custom water jet cutting through a streamlined, technology-integrated workflow designed for precision, speed, and manufacturability assurance. The process begins when a client uploads their CAD file via our secure customer portal. Supported formats include DXF, DWG, STEP, and IGES, with immediate system validation for geometric integrity and unit consistency to prevent downstream errors.

The uploaded CAD data feeds into our proprietary quoting engine, which generates an algorithm-driven cost and lead time estimate within two business hours. This system—marketed as AI Quote—analyzes part geometry, material requirements, nesting efficiency, and machine availability against real-time production capacity and material inventory. It is critical to clarify this is not generative AI but a rules-based expert system incorporating decades of shop floor data on kerf width, taper compensation, and motion path optimization. The quoted price explicitly includes all secondary operations such as edge deburring or protective coating if specified.

Following quote acceptance, the Design for Manufacturability (DFM) phase commences. Honyo engineers conduct a mandatory technical review focusing on water jet-specific constraints: minimum feature size (typically 1x material thickness), internal corner radii (avoiding sharp internal corners below 0.06″), and structural stability of narrow sections. We provide actionable feedback via marked-up PDFs within 24 hours, suggesting modifications to reduce machining time—such as consolidating nested parts or adjusting tolerances from ±0.005″ to ±0.010″ where functionally permissible. Client approval of the DFM report is required before production release.

Production leverages our fleet of 5-axis abrasive water jet systems with 90,000 PSI pumps and 0.04″ diameter nozzles. Key operational parameters are strictly controlled as follows:

| Material Category | Max Thickness | Typical Tolerance | Common Applications |

|---|---|---|---|

| Metals (Steel, Aluminum, Titanium) | 8.0 inches | ±0.005 inches | Aerospace brackets, hydraulic manifolds |

| Composites & Plastics | 6.0 inches | ±0.008 inches | Insulators, marine components |

| Stone & Glass | 4.0 inches | ±0.015 inches | Architectural elements, display fixtures |

All parts undergo in-process verification via CMM spot checks at 20% production intervals, with final inspection against the original CAD model using optical comparators. Nesting software dynamically groups client orders to minimize material waste, and we maintain certified material traceability for aerospace and medical clients. Parts are packaged in anti-corrosive VCI paper with serialized labels matching the delivery manifest.

Delivery occurs via client-specified carriers with real-time shipment tracking. Standard lead time is 3-5 business days from DFM approval, with expedited 24-hour options for simple geometries under 24″ x 24″. Honyo retains full process documentation—including pump pressure logs, abrasive consumption records, and inspection reports—for 24 months, ensuring complete auditability for regulated industries. This end-to-end control guarantees first-article compliance without requiring minimum order quantities.

Start Your Project

Looking for precision custom water jet cutting services? Honyo Prototype offers high-accuracy cutting for a wide range of materials, ideal for prototypes and low-volume production. Our advanced water jet technology ensures clean, burr-free edges without heat-affected zones—perfect for metals, plastics, composites, and more.

With our manufacturing facility located in Shenzhen, we provide fast turnaround and reliable support for clients across industries including aerospace, automotive, and industrial equipment.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.