Introduction: Navigating the Global Market for custom steel welding

In the ever-evolving landscape of global manufacturing, sourcing reliable custom steel welding services presents a significant challenge for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. The complexity of selecting a partner that meets both quality standards and budget constraints can be daunting. This guide aims to demystify the custom steel welding market by providing a comprehensive overview of the various types of welding services available, their applications in different industries, and essential strategies for vetting suppliers effectively.

Throughout this resource, international buyers will discover actionable insights on cost structures, timelines, and quality benchmarks that are critical for making informed purchasing decisions. We will delve into the intricacies of custom welding projects, from intricate decorative elements to robust structural components, ensuring that you understand the full spectrum of services available. Additionally, we will highlight key factors that influence pricing and quality, empowering you to negotiate effectively and establish long-term partnerships with trusted suppliers.

By equipping you with the knowledge needed to navigate this complex market, this guide aims to enhance your procurement strategy, minimize risks, and ultimately drive the success of your projects. Whether you are in Nigeria, Brazil, or any other global hub, the insights shared herein will be invaluable in your quest for high-quality custom steel welding solutions.

Understanding custom steel welding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MIG Welding | Uses a continuous wire feed; ideal for thin to medium thickness steel. | Automotive, manufacturing, and construction sectors. | Pros: Fast and versatile; Cons: Less effective for thicker materials. |

| TIG Welding | Involves a non-consumable tungsten electrode; provides high precision. | Aerospace, medical, and high-end fabrication. | Pros: Excellent for thin materials; Cons: Slower process, requires skilled labor. |

| Stick Welding | Utilizes a consumable electrode coated in flux; suitable for outdoor use. | Pipeline construction, heavy equipment repair. | Pros: Portable and effective in windy conditions; Cons: More cleanup required post-welding. |

| Flux-Cored Arc Welding | Similar to MIG but uses a tubular wire filled with flux; good for thick materials. | Heavy manufacturing and shipbuilding. | Pros: High deposition rates; Cons: Produces more smoke and requires good ventilation. |

| Submerged Arc Welding | Involves a submerged arc under granular flux; ideal for thick sections. | Large structural components and industrial applications. | Pros: High productivity and minimal cleanup; Cons: Limited to flat or horizontal positions. |

What Are the Characteristics and Suitability of MIG Welding?

MIG (Metal Inert Gas) welding is characterized by its use of a continuous wire feed as an electrode, making it suitable for welding thin to medium thickness steel. This method is particularly advantageous in high-speed production environments such as automotive and manufacturing sectors. For B2B buyers, MIG welding is a go-to choice for projects requiring versatility and efficiency. However, it may not be the best option for thicker materials, which could lead to weaker welds.

How Does TIG Welding Differ from Other Methods?

TIG (Tungsten Inert Gas) welding is distinguished by its use of a non-consumable tungsten electrode, allowing for high precision and control. This method is particularly suited for industries such as aerospace and medical fabrication, where quality and aesthetics are paramount. B2B buyers should consider TIG welding for applications involving thin materials or where detailed work is required. However, the slower process and the need for skilled labor can increase overall project costs.

What Makes Stick Welding a Practical Choice?

Stick welding, or Shielded Metal Arc Welding (SMAW), utilizes a consumable electrode coated in flux, making it ideal for outdoor applications where conditions may be less than optimal. This method is often employed in pipeline construction and heavy equipment repair due to its portability and effectiveness in windy environments. While stick welding offers the advantage of being more forgiving in adverse conditions, it does require more cleanup after the welding process, which can impact efficiency.

Why Choose Flux-Cored Arc Welding for Heavy Applications?

Flux-Cored Arc Welding (FCAW) is similar to MIG welding but uses a tubular wire filled with flux, allowing for deeper penetration and making it suitable for thicker materials. This technique is commonly used in heavy manufacturing and shipbuilding, where high deposition rates are essential. B2B buyers should note that while FCAW can produce robust welds quickly, it generates more smoke and requires good ventilation, which may necessitate additional safety measures on-site.

When Is Submerged Arc Welding the Best Option?

Submerged Arc Welding (SAW) involves creating an arc beneath a layer of granular flux, making it particularly effective for welding thick sections of steel. This method is commonly used in large structural components and industrial applications, where high productivity is crucial. B2B buyers should consider SAW for projects requiring minimal cleanup and high deposition rates, but be aware that its application is generally limited to flat or horizontal positions, which could restrict its use in certain scenarios.

Key Industrial Applications of custom steel welding

| Industry/Sector | Specific Application of custom steel welding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural Frames for Buildings | Enhanced durability and load-bearing capacity | Ensure compliance with local building codes and standards. |

| Manufacturing | Custom Machinery and Equipment | Increased efficiency and tailored solutions | Look for precision capabilities and material certifications. |

| Oil & Gas | Pipeline Fabrication | Improved safety and leak prevention | Verify experience in high-pressure welding and environmental standards. |

| Automotive | Chassis and Frame Components | Lightweight yet strong structures for performance | Assess welding techniques suitable for high-stress applications. |

| Agriculture | Farm Equipment and Machinery | Custom solutions for specific farming needs | Check for adaptability to various agricultural environments. |

How is Custom Steel Welding Applied in Construction Projects?

In the construction industry, custom steel welding is crucial for creating structural frames for buildings. This application ensures that the frameworks can withstand significant loads and environmental stresses. International buyers, particularly from regions like Africa and South America, must consider local building codes and regulations to ensure compliance. Additionally, sourcing partners should demonstrate a solid track record in timely project execution to avoid costly delays.

What Role Does Custom Steel Welding Play in Manufacturing?

Manufacturers often leverage custom steel welding for fabricating specialized machinery and equipment tailored to their production processes. This approach enhances operational efficiency by providing solutions that meet specific production needs. Buyers in this sector should prioritize suppliers with precision welding capabilities and appropriate material certifications, ensuring the final products meet industry standards and quality expectations.

How is Custom Steel Welding Essential for the Oil & Gas Sector?

In the oil and gas industry, custom steel welding is vital for pipeline fabrication, where safety and integrity are paramount. High-quality welding minimizes the risk of leaks and failures, which can lead to significant environmental and financial repercussions. International buyers must evaluate suppliers based on their experience with high-pressure welding techniques and adherence to stringent environmental regulations, especially in regions with strict compliance requirements.

Why is Custom Steel Welding Important for Automotive Applications?

The automotive industry utilizes custom steel welding to produce chassis and frame components that are both lightweight and strong. This is essential for enhancing vehicle performance and fuel efficiency. When sourcing welding services, buyers should assess the welding techniques employed to ensure they are suitable for high-stress applications, which is critical for vehicle safety and durability.

How Does Custom Steel Welding Support Agricultural Equipment Manufacturing?

Custom steel welding is employed in the fabrication of farm equipment and machinery tailored to specific agricultural needs. This application allows for the development of robust and efficient tools that can withstand the rigors of farming. Buyers from regions like the Middle East and Europe should look for suppliers who can adapt their welding processes to various agricultural environments, ensuring that equipment performs reliably under different conditions.

3 Common User Pain Points for ‘custom steel welding’ & Their Solutions

Scenario 1: Delays in Project Timelines Due to Custom Specifications

The Problem: B2B buyers often face significant delays when sourcing custom steel welding services that require specific designs or intricate specifications. These delays can arise from miscommunication between the buyer and the welding service provider regarding the project’s requirements, leading to back-and-forth adjustments. In industries where timing is critical, such as construction or manufacturing, these setbacks can cascade, causing project overruns and financial strain.

The Solution: To mitigate delays, buyers should prioritize clear and detailed communication when outlining their custom welding requirements. Start with a comprehensive project brief that includes dimensions, materials, and any specific design elements. Utilizing CAD drawings or 3D models can significantly enhance clarity. Additionally, establishing a timeline with the welding contractor, including milestones for review and approval of designs, can help keep the project on track. Regular check-ins throughout the production process can also ensure that any unforeseen issues are addressed promptly, preventing delays from extending the project timeline.

Scenario 2: Inconsistent Quality Across Different Suppliers

The Problem: When sourcing custom steel welding services, inconsistency in quality can be a major pain point for buyers. Different suppliers may have varying levels of expertise, equipment, and quality control processes, leading to subpar results that fail to meet industry standards or project specifications. This inconsistency can result in costly rework, project delays, and damage to the buyer’s reputation.

The Solution: To ensure high-quality outcomes, buyers should conduct thorough due diligence when selecting a welding service provider. This includes requesting samples of previous work, reviewing certifications and industry standards they adhere to, and checking client testimonials or case studies. Establishing a strong partnership with a reliable supplier who has a proven track record can lead to more consistent quality. Implementing a quality assurance process, such as periodic inspections during the fabrication phase, can also help catch potential issues early, ensuring the final product meets the required specifications.

Scenario 3: Difficulty in Scaling Up Production

The Problem: As businesses grow, their need for custom steel welding services can increase, leading to challenges in scaling production without compromising quality or timelines. Many suppliers may not be equipped to handle larger orders efficiently, resulting in longer lead times or rushed jobs that can affect the final product’s integrity. This challenge is particularly pronounced for companies entering new markets or expanding their operations.

The Solution: Buyers looking to scale their custom welding needs should seek out suppliers that offer flexible production capabilities and have experience with high-volume orders. It’s beneficial to inquire about the supplier’s production capacity and their ability to scale operations in response to increased demand. Buyers can also consider establishing long-term contracts or partnerships with welding service providers to secure priority status during peak times. Additionally, leveraging technology such as automated welding processes can enhance production efficiency and maintain quality, ensuring that scaling up does not compromise the final output.

Strategic Material Selection Guide for custom steel welding

When selecting materials for custom steel welding, understanding the properties, advantages, limitations, and regional compliance requirements is crucial. Here, we analyze four common materials used in custom steel welding: Carbon Steel, Stainless Steel, Alloy Steel, and Aluminum. Each material has unique characteristics that influence its suitability for various applications.

What Are the Key Properties of Carbon Steel for Custom Welding?

Carbon steel is one of the most widely used materials in welding due to its excellent mechanical properties and versatility. It typically exhibits high tensile strength, good ductility, and ease of fabrication. Carbon steel can withstand moderate temperatures and pressures, making it suitable for structural applications.

Pros: Carbon steel is cost-effective and readily available, making it a preferred choice for many industries. Its durability allows it to perform well in various environments, especially in construction and manufacturing.

Cons: However, carbon steel is prone to corrosion if not properly treated. It may require protective coatings or galvanization, which can add to the overall cost.

Impact on Application: Carbon steel is compatible with a wide range of media, but its susceptibility to rust can limit its use in highly corrosive environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards such as ASTM A36 or similar. Understanding the environmental conditions is vital for selecting the appropriate grade.

How Does Stainless Steel Compare in Terms of Performance?

Stainless steel is known for its superior corrosion resistance, making it ideal for applications exposed to moisture or harsh chemicals. It maintains strength at elevated temperatures and is often used in food processing, pharmaceuticals, and marine environments.

Pros: The key advantage of stainless steel is its longevity and low maintenance requirements. It is also aesthetically pleasing, which is important for architectural applications.

Cons: The primary disadvantage is the higher cost compared to carbon steel. Additionally, welding stainless steel requires specialized techniques to prevent issues like distortion and discoloration.

Impact on Application: Stainless steel is compatible with a variety of media, including corrosive substances, making it suitable for industries that require stringent hygiene standards.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM A240 or EN 10088. In regions like the Middle East, where humidity is high, stainless steel is often preferred for its durability.

What Are the Benefits and Limitations of Alloy Steel?

Alloy steel is engineered to enhance specific properties, such as strength, toughness, and wear resistance. Common alloying elements include chromium, nickel, and molybdenum, which improve performance in demanding applications.

Pros: The key advantage of alloy steel is its ability to withstand extreme conditions, making it suitable for heavy machinery and automotive components.

Cons: The complexity of manufacturing alloy steel can lead to higher costs. Additionally, the welding process may require preheating and post-weld heat treatment to prevent cracking.

Impact on Application: Alloy steel is often used in industries where high strength and toughness are critical, such as oil and gas, mining, and construction.

Considerations for International Buyers: Compliance with international standards like ASTM A572 or JIS G3106 is essential. Buyers in regions like Brazil should assess the availability of specific alloys to ensure timely project execution.

Is Aluminum a Viable Option for Custom Steel Welding?

Aluminum is increasingly used in welding applications due to its lightweight and corrosion-resistant properties. It is often used in aerospace, automotive, and construction industries where weight reduction is crucial.

Pros: The primary advantage of aluminum is its excellent strength-to-weight ratio and resistance to corrosion, which reduces the need for protective coatings.

Cons: However, aluminum can be more expensive than steel and requires specialized welding techniques, such as TIG welding, to achieve strong joints.

Impact on Application: Aluminum is compatible with various media but may not be suitable for high-temperature applications due to its lower melting point compared to steel.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221. In regions like Europe, where lightweight construction is favored, aluminum is often a preferred material.

Summary Table of Material Selection for Custom Steel Welding

| Material | Typical Use Case for custom steel welding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural beams, frames | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Food processing, marine applications | Superior corrosion resistance | Higher cost, requires special welding | High |

| Alloy Steel | Heavy machinery, automotive components | High strength and toughness | Higher manufacturing complexity | Medium |

| Aluminum | Aerospace, automotive, lightweight structures | Lightweight and corrosion-resistant | More expensive, requires specialized welding | High |

This guide should assist international B2B buyers in making informed decisions regarding material selection for custom steel welding projects, considering both performance and regional compliance factors.

In-depth Look: Manufacturing Processes and Quality Assurance for custom steel welding

What Are the Main Stages of Manufacturing Custom Steel Welding?

The manufacturing process for custom steel welding involves several key stages that ensure the final product meets the required specifications and quality standards. Understanding these stages is crucial for B2B buyers, particularly those in diverse markets like Africa, South America, the Middle East, and Europe.

Material Preparation: How Is Steel Readied for Welding?

The first stage of the manufacturing process is material preparation. This involves selecting the appropriate type and grade of steel based on project requirements. Common materials include carbon steel, stainless steel, and alloy steel, each chosen for their specific properties, such as strength, corrosion resistance, and weldability.

Once the material is selected, it undergoes cutting, which can be performed using various methods such as laser cutting, plasma cutting, or traditional sawing. Following this, the edges of the steel pieces are cleaned to remove any contaminants, rust, or grease that could affect the quality of the weld. This cleaning process is essential to ensure a strong bond during welding.

Forming: What Techniques Are Used to Shape Steel?

After preparation, the next step is forming. This stage involves shaping the steel into the desired configuration through processes such as bending, rolling, or stamping. Advanced techniques like CNC machining may also be employed for complex geometries, ensuring precision and repeatability.

Forming is critical as it sets the foundation for how the components will fit together during the assembly phase. Proper forming techniques reduce the likelihood of defects and minimize the need for rework, which can lead to delays and increased costs.

Assembly: How Are Components Joined Together?

The assembly phase is where the actual welding takes place. Various welding techniques are employed, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding, depending on the materials and the specific application. Each technique has its advantages; for instance, TIG welding is often preferred for its precision, while MIG welding is favored for speed and efficiency.

During assembly, proper alignment of components is crucial to ensure structural integrity. Welding is conducted in a controlled environment, often using jigs and fixtures to maintain accuracy. This stage may also involve additional processes such as bolting or riveting, depending on the design requirements.

Finishing: What Post-Weld Treatments Are Common?

The finishing stage involves several processes that enhance the durability and aesthetics of the welded components. Common finishing techniques include grinding, polishing, and applying protective coatings such as paint, powder coating, or galvanization. These treatments protect against corrosion and wear, extending the life of the product.

Additionally, finishing processes may involve further inspections to verify that the welds meet visual and structural standards. This is especially important for projects requiring aesthetic considerations, such as ornamental steel fabrication.

What Quality Control Measures Are Essential for Custom Steel Welding?

Quality assurance is a critical aspect of the custom steel welding process, ensuring that the final products meet international standards and customer expectations. A robust quality control (QC) framework involves several checkpoints and testing methods.

What International Standards Should B2B Buyers Consider?

For B2B buyers, understanding the relevant international standards is essential. ISO 9001 is the most widely recognized quality management system standard, focusing on meeting customer requirements and enhancing satisfaction. Additionally, industry-specific standards such as CE marking for products sold in Europe, and API (American Petroleum Institute) standards for oil and gas applications, may apply depending on the project.

These certifications indicate that the manufacturing processes and quality management systems are aligned with international best practices, providing assurance to buyers regarding the reliability and safety of the products.

What Are the Key Quality Control Checkpoints in Manufacturing?

The QC process typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial inspection assesses raw materials upon arrival at the manufacturing facility, ensuring they meet specified requirements.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are performed to monitor key parameters such as weld quality, dimensions, and alignment. This helps identify and rectify issues before the final product is completed.

-

Final Quality Control (FQC): Once production is complete, a comprehensive inspection is conducted to ensure the product meets all specifications. This may include visual inspections, dimensional checks, and non-destructive testing methods such as ultrasonic testing or x-ray inspection to detect internal defects.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, verifying a supplier’s quality assurance practices is crucial. Here are several methods to ensure that suppliers maintain high QC standards:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control measures, and overall compliance with industry standards.

-

Quality Assurance Reports: Requesting detailed QC reports can provide insights into the supplier’s performance metrics, including defect rates and corrective actions taken for any issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality management system and product conformity to specifications.

What Are the Unique QC Considerations for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, and the Middle East, should be aware of specific QC nuances. This includes understanding local regulations and standards that may differ from international norms. For example, certain countries may require additional certifications or testing methods for imported goods.

Furthermore, cultural differences in business practices can influence the supplier’s approach to quality assurance. Establishing clear communication channels and expectations from the outset can help mitigate misunderstandings and ensure alignment on quality standards.

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for custom steel welding is essential for B2B buyers. By focusing on these elements, buyers can make informed decisions that enhance their supply chain effectiveness and ensure the delivery of high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom steel welding’

In the competitive landscape of custom steel welding, making informed decisions is crucial for B2B buyers. This checklist will guide you through the essential steps to ensure you select the right supplier for your custom welding needs, optimizing both quality and cost-effectiveness.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of your project, including dimensions, material types, and any specific welding processes needed. This step is essential because well-defined specifications help suppliers provide accurate quotes and timelines. Additionally, consider including tolerances and any industry standards that must be met.

- Material Type: Specify whether you require stainless steel, carbon steel, or alloy materials.

- Welding Process: Identify if you need MIG, TIG, or another welding method.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in custom steel welding. Look for companies with a solid reputation and a portfolio that aligns with your project requirements. This step is vital to ensure you find reliable partners who can deliver quality work.

- Online Reviews: Check platforms like Google and industry-specific forums for feedback.

- Case Studies: Review past projects to assess their capabilities and experience.

Step 3: Evaluate Supplier Certifications

Confirm that potential suppliers hold relevant certifications, such as ISO 9001 or AWS certifications. These certifications are indicators of quality management and adherence to industry standards, ensuring that you are partnering with a capable and compliant supplier.

- Quality Assurance: Inquire about their quality control processes.

- Safety Standards: Ensure they comply with safety regulations in your region.

Step 4: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotes that outline all costs involved, including materials, labor, and any additional services. This step is crucial for budgeting and allows you to compare offers transparently.

- Breakdown of Costs: Ensure the quote includes a breakdown of material and labor costs.

- Timeline: Verify the estimated completion time for your project.

Step 5: Visit the Supplier’s Facility

If possible, visit the supplier’s facility to evaluate their equipment, technology, and working conditions. This step provides insight into their operational capabilities and quality control measures, helping you assess if they can meet your project requirements.

- Equipment Condition: Check for modern and well-maintained machinery.

- Work Environment: Observe safety protocols and worker conditions.

Step 6: Discuss Communication and Support

Establish clear communication channels and support structures with your chosen supplier. Effective communication is key to a successful partnership, especially when managing timelines and addressing any issues that may arise during the project.

- Point of Contact: Identify a dedicated project manager or contact person.

- Regular Updates: Agree on the frequency and format of progress updates.

Step 7: Negotiate Terms and Finalize the Contract

Before finalizing your partnership, negotiate terms that protect your interests, including payment schedules, delivery timelines, and warranty conditions. A well-structured contract mitigates risks and ensures that both parties are aligned on expectations.

- Payment Terms: Consider milestone payments based on project phases.

- Warranties: Specify warranties for materials and workmanship.

By following these steps, B2B buyers can effectively navigate the sourcing process for custom steel welding, ensuring they select a supplier that meets their quality, budget, and timeline needs.

Comprehensive Cost and Pricing Analysis for custom steel welding Sourcing

What Are the Key Cost Components in Custom Steel Welding?

Understanding the cost structure of custom steel welding is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of steel significantly influence costs. For instance, high-grade stainless steel or specialty alloys may incur higher prices than standard carbon steel. Buyers should consider sourcing from local suppliers to mitigate transportation costs.

-

Labor: Skilled labor is essential in welding processes. Labor costs can vary based on the region and the expertise required. In areas with a shortage of skilled workers, such as parts of Africa and South America, labor costs may be higher.

-

Manufacturing Overhead: This includes facility costs, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, thereby affecting the overall pricing structure.

-

Tooling: Custom tooling may be necessary for specific projects, which can add to the initial costs. However, investing in durable tooling can lead to cost savings over time by enhancing production efficiency.

-

Quality Control (QC): Ensuring that the final product meets specified standards requires an investment in quality control measures. This can include testing and inspection processes that ensure compliance with industry certifications.

-

Logistics: Transportation costs for raw materials and finished products can significantly impact pricing. Buyers should negotiate Incoterms to define responsibilities for logistics, which can affect the total cost of ownership.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the margin expectations within different regions can help buyers negotiate better deals.

How Do Price Influencers Affect Custom Steel Welding Costs?

Several factors can influence the price of custom steel welding services:

-

Volume and Minimum Order Quantities (MOQ): Higher volumes often lead to lower per-unit costs. Suppliers may provide discounts for bulk orders, making it advantageous for buyers to consolidate their purchasing.

-

Specifications and Customization: Unique specifications or custom designs typically incur additional costs. Buyers should provide detailed drawings and specifications to receive accurate quotes.

-

Materials and Quality Certifications: The choice of materials and the availability of certifications (e.g., ISO, ASTM) can affect pricing. Suppliers with recognized certifications may charge a premium, reflecting the quality assurance processes they adhere to.

-

Supplier Factors: The supplier’s location, reputation, and experience can influence pricing. Established suppliers may command higher prices due to their reliability and proven track record.

-

Incoterms: The chosen Incoterms can significantly impact the total cost. For example, selecting “FOB” (Free on Board) may shift more transportation costs onto the buyer compared to “CIF” (Cost, Insurance, and Freight), where the supplier covers these expenses.

What Tips Can Help B2B Buyers Negotiate Better Prices for Custom Steel Welding?

To ensure cost-efficiency in sourcing custom steel welding services, buyers should consider the following tips:

-

Negotiate with Multiple Suppliers: Engaging with several suppliers can provide leverage during negotiations. Obtaining multiple quotes allows buyers to compare pricing and services.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the initial price, consider the entire lifecycle cost of the product, including maintenance, durability, and potential rework.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import/export tariffs, and local market conditions that may affect pricing. Buyers from Africa and South America should pay particular attention to these aspects to avoid unexpected costs.

-

Leverage Technology: Utilize online platforms for instant pricing and comparisons. Some suppliers offer tools for uploading designs and receiving quotes, streamlining the sourcing process.

-

Build Long-Term Relationships: Establishing a strong relationship with a supplier can lead to more favorable pricing in the long run. Loyalty often results in better service and pricing adjustments.

Conclusion: What Should Buyers Remember About Pricing in Custom Steel Welding?

It is essential for buyers to approach custom steel welding sourcing with a comprehensive understanding of cost components and price influencers. By leveraging negotiation strategies and evaluating total costs, businesses can secure better deals that align with their project needs. Always remember that indicative prices are subject to change based on market conditions, material availability, and supplier capabilities.

Alternatives Analysis: Comparing custom steel welding With Other Solutions

Understanding Alternatives to Custom Steel Welding

When considering custom steel welding for a project, it is essential to explore alternative solutions that may also meet your needs. Various methods exist for metal fabrication, each with its advantages and disadvantages. By comparing custom steel welding with alternatives like custom sheet metal fabrication and 3D metal printing, buyers can make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Custom Steel Welding | Custom Sheet Metal Fabrication | 3D Metal Printing |

|---|---|---|---|

| Performance | High strength and durability, suitable for complex structures. | Good for precision parts, limited to sheet thickness. | High precision, complex geometries possible. |

| Cost | Higher initial costs due to labor and materials. | Generally lower, especially for bulk orders. | Costly for large parts but economical for small batches. |

| Ease of Implementation | Requires skilled labor and setup time. | Quick turnaround with automated processes. | Requires specialized equipment and knowledge. |

| Maintenance | Regular inspection needed for integrity. | Minimal maintenance, easier to replace parts. | Limited maintenance but depends on material used. |

| Best Use Case | Structural components, heavy-duty applications. | Enclosures, brackets, and lighter structures. | Prototyping, complex designs, and low-volume production. |

Detailed Breakdown of Alternatives

Custom Sheet Metal Fabrication

Custom sheet metal fabrication involves cutting, bending, and assembling metal sheets into desired shapes and sizes. This method is particularly advantageous for creating enclosures, brackets, and other components that do not require the same structural strength as welded components. One of the primary benefits is cost-effectiveness, especially for large quantities, as the process can be highly automated. However, it is limited by the thickness of the sheets used and may not be suitable for heavy-duty applications where high strength is critical.

3D Metal Printing

3D metal printing, also known as additive manufacturing, creates parts layer by layer from a digital model. This technology allows for the production of highly complex geometries that would be difficult or impossible to achieve with traditional methods. It is particularly useful for prototyping and low-volume production runs. However, the initial investment in 3D printing equipment can be high, and the costs per unit can escalate for larger parts. Moreover, the mechanical properties of printed parts may not match those produced through traditional welding techniques, making it less suitable for structural applications.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate solution for your project depends on various factors, including project specifications, budget constraints, and desired lead times. Custom steel welding is ideal for applications requiring high strength and durability, while custom sheet metal fabrication offers a cost-effective solution for lighter components. For projects needing complex designs or rapid prototyping, 3D metal printing may be the best fit. By assessing the specific requirements and constraints of your project, you can choose the method that aligns best with your operational goals and budgetary considerations.

Essential Technical Properties and Trade Terminology for custom steel welding

What Are the Key Technical Properties in Custom Steel Welding?

When engaging in custom steel welding, understanding the essential technical properties is critical for ensuring project success and meeting industry standards. Here are some key specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the classification of steel based on its chemical composition and mechanical properties. Common grades include A36 for structural steel and 304 or 316 for stainless steel. Selecting the appropriate material grade is vital as it directly affects the strength, durability, and corrosion resistance of the finished product. Buyers should ensure that the material grade aligns with the intended application and environmental conditions.

2. Tolerance

Tolerance is the allowable variation in dimensions of a welded component. It is crucial for ensuring that parts fit together correctly during assembly. Common tolerances in welding can range from ±0.1 mm to ±5 mm, depending on the complexity and precision required. Understanding tolerance levels helps buyers specify their needs accurately and minimizes costly rework or project delays.

3. Weld Type

The type of weld (e.g., MIG, TIG, stick) is significant as it influences the strength and appearance of the welded joint. Each method has its advantages; for instance, TIG welding offers high precision, while MIG welding is faster and suitable for thicker materials. Knowing the suitable weld type for a specific application is essential for achieving desired structural integrity and aesthetics.

4. Finish

The finish of a welded product can impact both functionality and appearance. Common finishes include powder coating, galvanizing, or polishing. A proper finish protects against corrosion and wear, contributing to the longevity of the product. Buyers should consider the environmental exposure and aesthetic requirements when specifying finishes.

5. Heat Treatment

Heat treatment processes like annealing or quenching can enhance the mechanical properties of steel, such as hardness and ductility. These treatments are particularly important for applications requiring high strength or resistance to wear. Buyers must communicate any heat treatment needs to ensure the final product meets performance expectations.

What Are Common Trade Terms Used in Custom Steel Welding?

Familiarity with industry terminology can streamline communication and enhance understanding between buyers and suppliers. Here are several common trade terms used in custom steel welding:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom steel welding, buyers might work directly with OEMs to ensure that the welded components meet specific standards and specifications required for their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it affects budgeting and inventory management. Understanding MOQ helps in making informed purchasing decisions, especially for custom projects where quantities may vary.

3. RFQ (Request for Quote)

An RFQ is a document used by buyers to request pricing and terms from suppliers for specific products or services. It typically includes details such as material specifications, quantities, and delivery timelines. Submitting an RFQ helps buyers compare options and negotiate better terms.

4. Incoterms

Incoterms (International Commercial Terms) are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding Incoterms is essential for buyers involved in cross-border transactions to ensure compliance and mitigate risks.

5. Lead Time

Lead time refers to the period between placing an order and the delivery of the finished product. It includes manufacturing time, processing time, and shipping. Buyers should consider lead time when planning projects to ensure timely delivery and avoid operational delays.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions, foster effective communication with suppliers, and ultimately enhance the success of their custom steel welding projects.

Navigating Market Dynamics and Sourcing Trends in the custom steel welding Sector

What Are the Key Market Dynamics and Trends in the Custom Steel Welding Sector?

The custom steel welding sector is experiencing significant transformation driven by globalization, technological advancements, and evolving buyer expectations. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can provide high-quality custom solutions with quick turnaround times. The demand for rapid prototyping and shorter lead times is on the rise, fueled by the need for businesses to adapt swiftly to market changes and customer needs. Digital platforms facilitating instant pricing and order tracking are becoming essential tools for buyers, enabling them to streamline their procurement processes.

Sourcing trends are also shifting towards greater transparency and collaboration. Buyers are looking for suppliers who can provide detailed insights into their production processes and capabilities. This trend is particularly pronounced in regions such as Nigeria and Brazil, where local suppliers are gaining traction by offering customized solutions that cater to specific industrial requirements. Furthermore, the integration of advanced technologies like automation and AI in manufacturing processes is enhancing efficiency and precision in custom welding, making it easier for companies to meet diverse customer demands.

How Is Sustainability Shaping the Custom Steel Welding Landscape?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the custom steel welding sector. The environmental impact of steel production and welding processes has prompted businesses to seek suppliers who prioritize sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and waste reduction initiatives. Buyers are increasingly favoring suppliers who have ‘green’ certifications, such as ISO 14001, which demonstrate a commitment to environmental management and sustainability.

Ethical supply chains are also gaining importance as companies recognize the need to ensure fair labor practices and responsible sourcing of materials. This is particularly relevant for international buyers from regions like the Middle East and Africa, where there is a growing emphasis on social responsibility. By prioritizing suppliers who adhere to ethical sourcing standards, businesses can enhance their brand reputation and meet the expectations of environmentally conscious consumers.

What Historical Developments Have Shaped the Custom Steel Welding Sector?

The evolution of the custom steel welding sector can be traced back to the industrial revolution, which marked a significant turning point in manufacturing practices. Initial welding techniques were rudimentary, relying on manual labor and basic tools. However, advancements in technology, such as the introduction of electric arc welding in the early 20th century, revolutionized the industry, allowing for greater precision and efficiency.

As industries expanded globally, the demand for custom welding solutions surged, leading to the establishment of specialized firms that could cater to diverse needs across various sectors. Today, the focus has shifted towards not only enhancing production capabilities but also integrating sustainability and ethical considerations into the fabric of the industry. This historical context underscores the importance of adaptability and innovation in meeting the ever-changing demands of international B2B buyers in the custom steel welding sector.

Frequently Asked Questions (FAQs) for B2B Buyers of custom steel welding

-

How do I evaluate a custom steel welding supplier?

When evaluating a custom steel welding supplier, consider their experience, certifications, and portfolio of past projects. Look for suppliers who have expertise in your specific industry or application, as well as positive testimonials from previous clients. Request detailed information about their welding techniques, materials used, and quality assurance processes. Additionally, assess their ability to meet deadlines and budget constraints. A visit to their facility can also provide insights into their operational capabilities and safety standards. -

What are the common materials used in custom steel welding?

Custom steel welding typically involves a variety of materials, including carbon steel, stainless steel, and aluminum. Carbon steel is favored for its strength and cost-effectiveness, making it ideal for structural applications. Stainless steel, known for its corrosion resistance, is preferred for projects requiring durability in harsh environments. Aluminum offers lightweight properties and is often used in applications where weight reduction is crucial. Discuss material options with your supplier to find the best fit for your specific project requirements. -

What customization options are available for my welding project?

Customization options in welding projects can include specific dimensions, shapes, and finishes tailored to your needs. Many suppliers offer services like CNC machining, bending, and finishing processes such as powder coating or anodizing. It’s important to clearly communicate your design specifications and functional requirements to the supplier. Some companies may also provide design assistance, helping you optimize the product for manufacturability and performance while ensuring compliance with industry standards. -

What are the minimum order quantities (MOQ) for custom steel welding?

Minimum order quantities (MOQ) for custom steel welding can vary significantly by supplier and project complexity. Some suppliers may accept small orders, especially for prototypes or one-off projects, while others may have higher MOQs to justify production costs. It’s advisable to discuss your specific needs with potential suppliers to understand their policies on MOQs. This discussion can also lead to negotiations on pricing and lead times based on your order size. -

What payment terms should I expect when sourcing custom steel welding services?

Payment terms for custom steel welding services can vary widely between suppliers. Common arrangements include upfront deposits, progress payments tied to project milestones, and net payment terms upon project completion. It’s essential to clarify these terms upfront to avoid misunderstandings later. Some suppliers may also offer financing options or discounts for early payments. Always ensure that the payment terms align with your cash flow and project timelines. -

How do I ensure quality assurance in my custom steel welding project?

Quality assurance in custom steel welding projects can be ensured through rigorous inspection protocols and certifications. Inquire about the supplier’s quality control processes, such as non-destructive testing and material certifications. Suppliers should also adhere to industry standards like ISO 9001 or AWS (American Welding Society) certifications. Regular communication and progress updates during the project can help identify potential quality issues early, allowing for timely adjustments. -

What logistics considerations should I keep in mind for international shipping of welded products?

When sourcing custom steel welding services internationally, logistics considerations are crucial. Assess the supplier’s ability to handle export documentation, compliance with international shipping regulations, and customs clearance processes. Discuss shipping options and costs, including freight insurance, to ensure your products arrive safely and on time. Additionally, consider the supplier’s location in relation to shipping ports to minimize transit times and costs. -

How can I manage communication effectively with my overseas welding supplier?

Effective communication with an overseas welding supplier is vital for project success. Utilize clear and concise language, avoiding jargon that may lead to misunderstandings. Establish regular check-in schedules via email or video calls to discuss project progress and address any concerns. Use project management tools to share documents and updates in real-time. Time zone differences should also be considered when scheduling meetings to ensure timely responses and collaboration throughout the project lifecycle.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Custom Steel Welding Manufacturers & Suppliers List

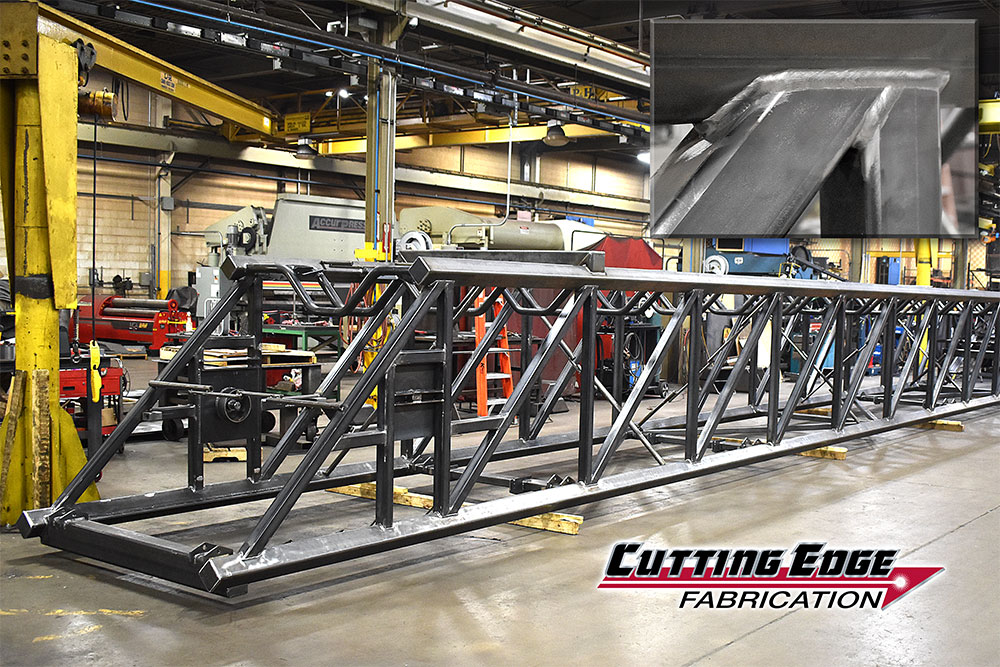

1. Swanton Welding – Custom Steel Fabrication Services

Domain: swantonweld.com

Registered: 2001 (24 years)

Introduction: Swanton Welding offers a range of custom steel fabrication services including: 1. Custom Metal Fabrication 2. Structural Steel Fabrication 3. Custom Welding Services 4. Sheet Metal Fabrication 5. Heavy Fabrication 6. Rolling & Forming 7. Painting & Blasting. They have three state-of-the-art facilities and provide in-house services to minimize errors and ensure quality control, monitored by a Certi…

2. Morrison Welding – Steel Fabrication Solutions

Domain: morrisonwelding.com

Registered: 2000 (25 years)

Introduction: This company, Morrison Welding – Steel Fabrication Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. ATWF Inc – Custom Metal Fabrication & Welding Services

Domain: atwf-inc.com

Registered: 1998 (27 years)

Introduction: Custom Metal Fabrication and Welding services including:

– Engineering Services

– Laser Cutting Services (sheets up to 60 x 120 inches, thickness up to 1 inch)

– Precision Metal Fabrication

– Powder Coating

– Prototyping (same-day to 5-day turnaround)

– Welding & Finishing Services

– Inspection Services (ISO 9001 certified)

Materials used:

– Stainless Steel

– Aluminum

– Carbon Steel

– Inconel

– Co…

4. SendCutSend – Custom Sheet Metal Fabrication

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services including laser cutting, CNC routing, waterjet cutting, anodizing, bending & forming, countersinking, dimple forming, hardware insertion, plating, powder coating, tapping, tumbling, and deburring. They provide instant pricing for custom parts uploaded in STEP, DXF, or EPS formats, with no minimum quantities and free US shipping on orders o…

5. Standard Welding – Custom Fabricated Metal Solutions

Domain: stdwelding.com

Registered: 2002 (23 years)

Introduction: Standard Welding sells raw materials cut or sheared to size, full-lengths, sheets, and plates. All products are custom fabricated items not found on store shelves. They specialize in prototype and made-to-order items, working with mild steel, stainless steel, and aluminum. Services include CNC Oxy Fuel Burning (up to 4″ thick plate), CNC Plasma Cutting, Shearing (up to 1/2″ plate, 10′-0″ long), Pr…

6. Custom Metal Work – Gym Equipment Stoppers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom metal work services for small pieces, specifically for gym equipment. The user is looking for two small metal pieces designed as stoppers for rollers on a power rack, made from rectangular tubes (1.5×3 inches) and circular tubes (1 inch diameter). Recommendations include local fabricators and welding services in Birmingham and Redditch, such as Iron King, Ian Whitaker Productions, DJ Steel,…

7. Minerva Welding – Custom Metal Fabrication Services

Domain: minervawelding.com

Registered: 2003 (22 years)

Introduction: Custom Metal Fabrication Services in Wooster, OH; Precision Custom Manufacturing; Specializes in custom metal fabrication for businesses; Industries served: automotive, construction, manufacturing; Capabilities include: precision welding, fabrication of stainless steel, carbon steel, and aluminum; Advanced fitting and welding techniques: MIG, TIG, stick welding; Services: sheet metal & plate rolli…

8. Profab TX – Custom Welding & Steel Fabrication

Domain: profabtx.com

Registered: 2018 (7 years)

Introduction: Custom Welding & Steel Fabrication services in Odessa, TX. Services include: precision metalwork, custom welding, ornamental gates, staircases, doors, railings, outdoor structures, and more. Welding services offered: Tig Welding, Mig Welding, Custom Welding, Laser Welding. Metal fabrication capabilities include: Stainless Steel Fabrication, Carbon Steel Fabrication, Sheet Metal Fabrication, Alumin…

Strategic Sourcing Conclusion and Outlook for custom steel welding

What Are the Key Takeaways for B2B Buyers in Custom Steel Welding?

In the dynamic landscape of custom steel welding, strategic sourcing emerges as a pivotal element for success. Buyers should prioritize partnerships with experienced fabricators who demonstrate a strong commitment to quality and timely project execution. The ability to access a diverse range of materials and specialized services—such as precision cutting and post-processing—can significantly enhance project outcomes, ensuring that specifications are met while maintaining budget constraints.

How Can Strategic Sourcing Enhance Your Business Operations?

Investing in strategic sourcing not only streamlines procurement processes but also fosters long-term relationships with suppliers who understand your unique needs. This approach allows businesses to mitigate risks associated with supply chain disruptions, especially in regions like Africa, South America, the Middle East, and Europe, where market conditions can fluctuate. By collaborating with reputable welding partners, buyers can leverage local expertise and global standards, facilitating smoother operations and superior product quality.

What’s Next for International B2B Buyers in Custom Steel Welding?

As you navigate the complexities of sourcing custom steel welding solutions, consider taking proactive steps to engage with suppliers who align with your operational goals. Embrace the opportunity to innovate and enhance your projects through strategic partnerships. The future of custom steel welding holds immense potential—position your business to capitalize on these opportunities by fostering connections that drive efficiency and excellence in fabrication.