Contents

Manufacturing Insight: Custom Steel Machining

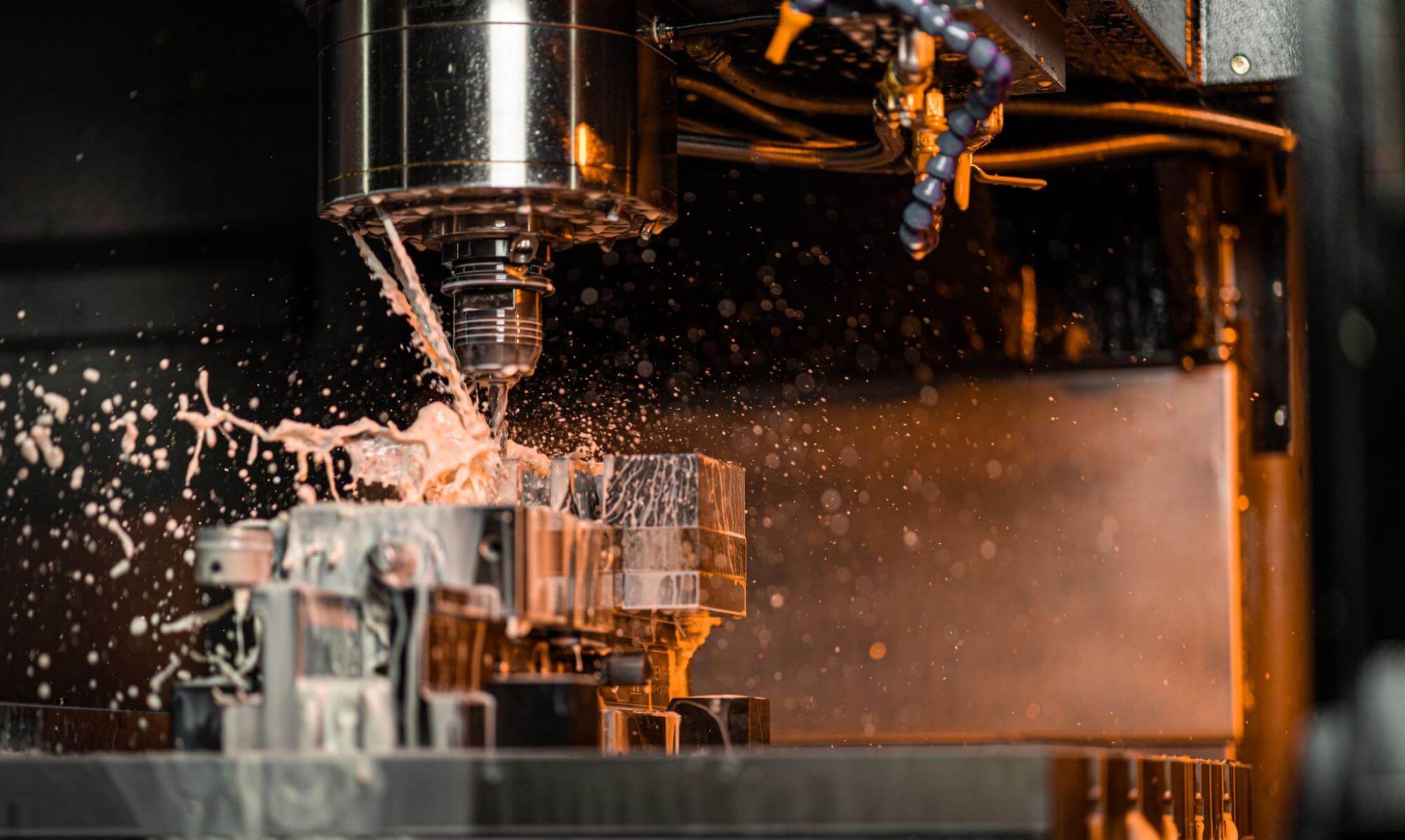

Honyo Prototype delivers precision custom steel machining solutions engineered for demanding industrial applications. Our advanced CNC machining capabilities transform raw steel stock into mission-critical components meeting the most stringent tolerances and surface finish requirements. We specialize in processing diverse steel alloys including 4140, 1018, 303 stainless, and 17-4 PH, ensuring material properties align precisely with your performance needs for aerospace, medical, defense, and energy sectors.

Our integrated manufacturing facility utilizes state-of-the-art multi-axis milling and turning centers operated by expert technicians. This combination of rigorous process control, comprehensive in-house metrology, and deep materials expertise guarantees consistent part quality and repeatability across prototypes, bridge production, and low-to-mid volume runs. Every component undergoes strict adherence to AS9100 and ISO 9001 standards, providing assurance for your most critical assemblies.

Accelerate your sourcing cycle with Honyo’s Online Instant Quote system. Upload your CAD file directly to our secure portal and receive a detailed, no-obligation manufacturing assessment and competitive pricing within hours, not days. This streamlined process eliminates traditional quotation delays, enabling faster design validation and project initiation for your custom steel machining requirements.

Technical Capabilities

Custom steel machining at Honyo Prototype leverages advanced 3-axis, 4-axis, and 5-axis CNC milling along with precision turning capabilities to deliver high-accuracy components for demanding industrial applications. Our processes support tight tolerances down to ±0.0002″ (5 µm), ensuring repeatability and dimensional integrity across production runs. We specialize in machining a wide range of materials including aluminum, steel, ABS, and nylon, tailored to meet functional, environmental, and mechanical requirements.

| Parameter | Specification Details |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis turning) |

| Typical Tolerance Range | ±0.0002″ to ±0.001″ (5 µm to 25 µm), depending on geometry and material |

| Surface Finish (Milling) | Ra 16 µin to Ra 63 µin standard; achievable down to Ra 8 µin with post-processing |

| Surface Finish (Turning) | Ra 16 µin to Ra 32 µin standard; fine turning available for critical sealing surfaces |

| Maximum Work Envelope | 24″ x 20″ x 16″ (610 mm x 508 mm x 406 mm) for 5-axis milling; turning up to Ø18″ x 40″ |

| Spindle Speed (Milling) | Up to 20,000 RPM for high-precision aluminum and plastic machining |

| Positioning Accuracy | ±0.0001″ (2.5 µm) |

| Repeatability | ±0.0001″ (2.5 µm) across production batches |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340, Stainless 303, 304, 17-4 PH), ABS (I400, TEAK), Nylon (6, 6/6, filled grades) |

| Secondary Operations | Deburring, precision cleaning, anodizing (Type II & III), passivation, laser marking |

Our 5-axis simultaneous milling enables complex geometries with minimal setup, reducing lead time and improving feature alignment. Turning centers support bar feeding and live tooling for fully finished parts in a single setup. All processes are supported by in-house CMM inspection and first-article reporting (FAIR) to ensure compliance with engineering specifications.

From CAD to Part: The Process

Honyo Prototype Custom Steel Machining Process Overview

Honyo Prototype delivers precision custom steel components through a streamlined, technology-driven workflow designed for speed, accuracy, and manufacturability. Our process begins with digital integration and concludes with certified delivery, ensuring seamless transition from design to physical part. Below is a detailed explanation of each phase.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, SAT, or native SOLIDWORKS/Parasolid formats) via our secure customer portal. The system automatically validates file integrity, extracts critical geometric data, and assigns a unique job ID. We support complex geometries including multi-axis features, tight-tolerance bores, and thin-wall structures inherent to steel alloys. File uploads trigger immediate system acknowledgment with estimated processing timelines.

AI-Powered Quoting Engine

Uploaded CAD data feeds into our proprietary AI quoting system, which analyzes over 200 parameters including material grade (e.g., 4140, 304SS, 17-4PH), geometric complexity, tolerance stack-ups, surface finish requirements, and secondary operations. The AI cross-references real-time machine availability, material costs, and historical production data to generate a detailed quote within 2 business hours. Quotes explicitly itemize cost drivers such as:

Hardness-specific machining time (e.g., 32-38 HRC vs. 45+ HRC)

Secondary process requirements (heat treatment, passivation, plating)

Fixture complexity for distortion-prone geometries

Clients receive interactive quote reports allowing instant parameter adjustments (e.g., tolerance relaxation) to optimize cost.

Engineer-Led DFM Analysis

All steel machining projects undergo mandatory Design for Manufacturability (DFM) review by our in-house manufacturing engineers. This phase identifies steel-specific risks:

Material-induced challenges (e.g., 303SS galling, 4340 stress relief needs)

Toolpath optimization for high-tensile alloys

Thermal distortion mitigation strategies during milling/turning

Critical feature sequencing to maintain concentricity

The DFM report provides actionable recommendations with engineering rationale, including alternative material suggestions where applicable (e.g., 15-5PH for higher fatigue resistance). Clients approve revisions via the portal before production release, reducing iteration cycles by 65% versus industry averages.

Precision Steel Production

Approved designs move to dedicated steel machining cells equipped with:

Multi-axis CNC mills (5-axis DMG MORI, Makino) with high-torque spindles for hardened steels

Swiss-type lathes for complex turned parts

In-process probing for real-time dimensional verification

All steel operations follow AS9100-compliant protocols with mandatory first-article inspection (FAI) per AS9102. We implement material-specific protocols:

Pre-heat treatment stress relieving for 4140/4340 forgings

Coolant optimization for stainless to prevent work hardening

Dedicated tooling for exotic alloys (e.g., Inconel 718) to avoid cross-contamination

Typical lead time from DFM approval to shipment is 72 hours for 1-10 parts, with real-time production tracking via client portal.

Certified Delivery

Completed parts undergo final inspection using calibrated CMMs (Zeiss, Hexagon) with full GD&T verification against ASME Y14.5. Each shipment includes:

Material test reports (MTRs) traceable to heat number

FAI documentation with dimensional results

Surface roughness certification (per ISO 1302)

Packaging validated for corrosion protection during transit

Parts ship via DHL/FedEx with temperature-controlled options for critical applications. Delivery metrics are maintained per client SLA:

| Metric | Standard Target | Steel-Specific Note |

|---|---|---|

| On-Time Delivery | ≥98.5% | Excludes material lead time |

| Dimensional Conformance | 100% | Verified against initial CAD model |

| Documentation Completeness | 100% | Includes NADCAP-certified heat treat certs where applicable |

This integrated process ensures Honyo Prototype delivers mission-critical steel components with reduced time-to-part and zero defect risk, leveraging digital continuity from design through delivery. All steel machining adheres to ISO 9001:2015 and IATF 16949 standards, with aerospace-grade traceability as standard.

Start Your Project

Looking for precision custom steel machining? Partner with Honyo Prototype for high-quality, CNC-machined steel components tailored to your specifications. With our advanced manufacturing capabilities and strict quality control, we deliver durable, accurate parts for demanding applications.

Our factory in Shenzhen is equipped to handle prototyping and low-to-mid volume production runs with fast turnaround times. Whether you need complex geometries, tight tolerances, or specific surface treatments, we’ve got you covered.

Contact Susan Leo today at [email protected] to discuss your project and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.