Introduction: Navigating the Global Market for custom stainless steel box

In today’s competitive global market, sourcing custom stainless steel boxes presents a significant challenge for B2B buyers seeking quality, durability, and tailored solutions. Whether you’re in Nigeria or Saudi Arabia, the need for robust enclosures that meet specific industry standards is paramount. This guide offers a comprehensive exploration of custom stainless steel boxes, covering essential topics such as types, applications, supplier vetting, and cost considerations.

Understanding the nuances of custom fabrication is crucial for making informed purchasing decisions. Different industries, from pharmaceuticals to oil and gas, require distinct features and specifications in their stainless steel enclosures. This guide empowers international B2B buyers by providing insights into the latest trends in customization, material selection, and design options that can enhance operational efficiency.

Furthermore, we delve into the importance of selecting reputable suppliers who can deliver on quality and service, ensuring that your investment aligns with your business objectives. By navigating the complexities of the global market for custom stainless steel boxes, you’ll be equipped with the knowledge necessary to optimize your procurement strategies and secure the best solutions for your needs.

Understanding custom stainless steel box Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Electrical Enclosures | Designed for housing electrical components; often includes ventilation and access points | Manufacturing, pharmaceuticals, food processing | Pros: High durability, customizable; Cons: Can be costly if not optimized for design. |

| Industrial Storage Boxes | Heavy-duty construction; designed for robust storage solutions; often stackable | Warehousing, logistics, and manufacturing | Pros: Excellent space efficiency; Cons: May require specific dimensions for optimal use. |

| Walk-In Enclosures | Large enough for personnel entry; includes doors and ventilation systems | Utility and maintenance sectors | Pros: Facilitates easy access; Cons: Requires significant floor space. |

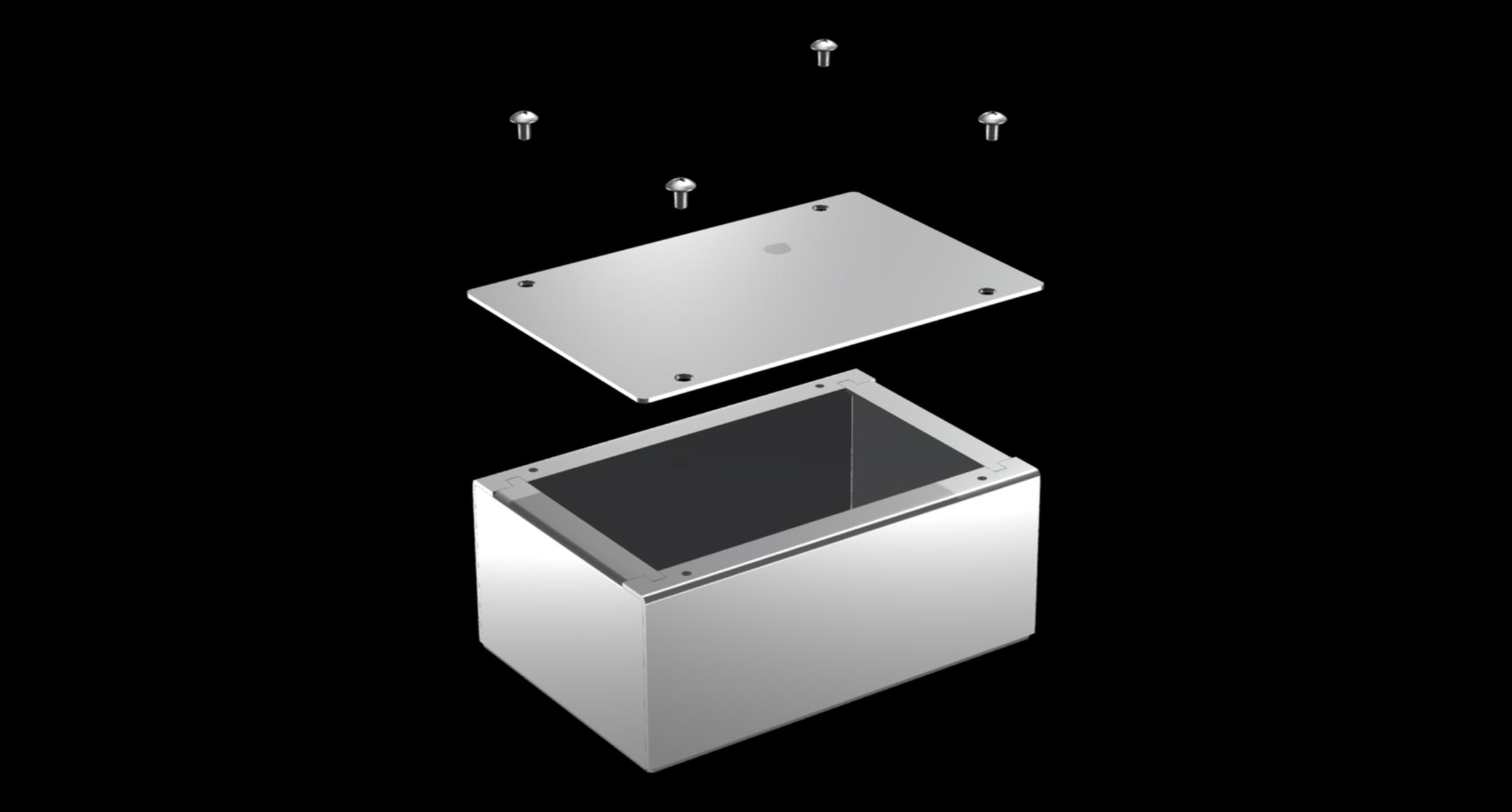

| Custom Tray Boxes | Shallow design for specific item storage; customizable dimensions and configurations | Retail display, manufacturing, and logistics | Pros: Versatile design options; Cons: Limited to lightweight items. |

| Wall-Mounted Enclosures | Space-saving design; secured to walls; options for flanged mounting | Control panels, electrical installations | Pros: Saves floor space; Cons: Installation may require additional hardware. |

What Are Custom Electrical Enclosures and Their B2B Relevance?

Custom electrical enclosures are specifically engineered to protect electrical components from environmental factors. They often feature ventilation, access panels, and tailored dimensions to accommodate various equipment. Industries such as manufacturing, pharmaceuticals, and food processing rely on these enclosures for safety and compliance with regulatory standards. When purchasing, buyers should consider factors like material grade, ingress protection ratings, and customization options to ensure the enclosure meets their operational needs.

How Do Industrial Storage Boxes Serve Various Industries?

Industrial storage boxes are built to withstand heavy use, making them ideal for storing tools, parts, and other equipment in warehouses and manufacturing settings. Their robust design often allows for stacking, which maximizes storage efficiency. When selecting these boxes, buyers should evaluate the material’s strength, size options, and whether the boxes can withstand specific environmental conditions, such as moisture or chemicals.

What Are the Benefits of Walk-In Enclosures for Utility Applications?

Walk-in enclosures are designed for personnel access, making them suitable for utility and maintenance applications. They typically include doors and ventilation systems to ensure a safe working environment. These enclosures are beneficial for housing large equipment or multiple components in a single location. Buyers should consider the enclosure’s size, accessibility features, and whether it meets industry safety regulations to ensure it serves its intended purpose effectively.

Why Choose Custom Tray Boxes for Retail and Logistics?

Custom tray boxes are shallow, versatile containers designed for specific item storage, making them ideal for retail displays and logistics operations. Their customizable dimensions allow businesses to optimize space and presentation. However, they are best suited for lightweight items. Buyers should focus on the material quality, customization options, and intended use to determine the best fit for their needs.

How Do Wall-Mounted Enclosures Optimize Space in Control Panels?

Wall-mounted enclosures are an efficient solution for control panels and electrical installations, saving valuable floor space. They can be secured to walls and often come with flanged mounting options for added stability. When purchasing, buyers should assess the enclosure’s size, mounting requirements, and whether it provides adequate protection against environmental factors, ensuring it aligns with their installation requirements.

Key Industrial Applications of custom stainless steel box

| Industry/Sector | Specific Application of custom stainless steel box | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Custom enclosures for food processing equipment | Ensures compliance with hygiene standards and durability | Material grade (e.g., 304 vs. 316), surface finish, and size |

| Pharmaceutical | Storage and transport boxes for sensitive materials | Protects products from contamination and environmental factors | Regulatory compliance, custom dimensions, and sealing options |

| Oil & Gas | Enclosures for electrical and control systems | Enhances safety and protection in harsh environments | Explosion-proof features, corrosion resistance, and certification |

| Renewable Energy | Custom battery boxes for solar energy systems | Optimizes space and protects components from weather elements | Size specifications, thermal management, and material choice |

| Telecommunications | Equipment housings for network infrastructure | Provides protection against environmental damage | Customization options, IP ratings, and mounting configurations |

How is Custom Stainless Steel Box Used in the Food & Beverage Industry?

In the food and beverage sector, custom stainless steel boxes are essential for housing processing equipment, ensuring that hygiene standards are met. These enclosures protect sensitive machinery from contaminants and facilitate easy cleaning. Buyers should consider the material grade, such as SS304 for general use or SS316 for areas exposed to harsh environments, and ensure that the design complies with local food safety regulations.

What Role Does Custom Stainless Steel Box Play in the Pharmaceutical Sector?

In pharmaceuticals, custom stainless steel boxes serve as storage and transport solutions for sensitive materials, including drugs and active ingredients. These enclosures protect against contamination and maintain environmental controls, which are crucial for product integrity. Buyers must focus on regulatory compliance, custom dimensions to fit specific equipment, and sealing options to prevent exposure to external contaminants.

How Do Custom Stainless Steel Boxes Enhance Safety in the Oil & Gas Industry?

In the oil and gas industry, custom stainless steel boxes are critical for housing electrical and control systems, particularly in hazardous environments. They provide robust protection against explosions and environmental damage, ensuring operational safety. Buyers should prioritize features like explosion-proof certifications, corrosion resistance, and the ability to withstand extreme temperatures when sourcing these enclosures.

Why Are Custom Stainless Steel Boxes Important for Renewable Energy Applications?

Custom stainless steel boxes are increasingly used in renewable energy sectors, particularly for housing batteries in solar energy systems. These enclosures optimize space and protect sensitive components from weather-related damage, ensuring efficient energy storage. Buyers should consider size specifications, thermal management capabilities, and the choice of material to ensure durability and performance in varying climates.

How Do Custom Stainless Steel Boxes Support Telecommunications Infrastructure?

In telecommunications, custom stainless steel boxes provide essential protection for network infrastructure, including routers and switches. They safeguard equipment against environmental factors, ensuring uninterrupted service. Buyers must assess customization options, IP ratings for dust and water resistance, and mounting configurations to suit their specific installation needs.

3 Common User Pain Points for ‘custom stainless steel box’ & Their Solutions

Scenario 1: Navigating Material Selection for Durability

The Problem: B2B buyers often struggle with selecting the right material for custom stainless steel boxes, particularly when durability and corrosion resistance are critical. For industries such as food processing or pharmaceuticals, choosing between different grades of stainless steel (like 304 vs. 316) can be daunting. Buyers may worry about the long-term performance of their products in harsh environments, leading to costly replacements or failures.

The Solution: To overcome this challenge, start by evaluating the specific environmental conditions your stainless steel box will face. For applications involving exposure to saline or harsh chemicals, opt for 316 stainless steel, known for its superior corrosion resistance. Engage with suppliers who provide detailed specifications and have expertise in metallurgy. Request samples and conduct corrosion resistance tests to ensure the chosen material meets your operational needs. Additionally, consider working with manufacturers that offer a comprehensive consultation service to help you navigate material choices based on your specific application requirements.

Scenario 2: Ensuring Accurate Customization and Dimensions

The Problem: Many buyers find it difficult to communicate their exact specifications for custom stainless steel boxes, leading to miscommunication and errors in production. This can result in delays, increased costs, and frustration when the delivered product does not fit the intended application. The challenge is particularly pronounced in industries with strict regulatory compliance, where precise dimensions are essential.

The Solution: To mitigate this issue, buyers should invest time in creating detailed design specifications, including dimensions, tolerances, and any additional features such as mounting brackets or cable management options. Utilize CAD software to create visual representations of your requirements and share these with potential suppliers. Additionally, establish a clear communication channel with manufacturers to discuss the specifications and seek clarifications before finalizing the order. Many companies offer design assistance, which can help ensure that the dimensions and features align perfectly with your needs.

Scenario 3: Managing Lead Times and Delivery Expectations

The Problem: B2B buyers often face uncertainty regarding lead times for custom stainless steel boxes, which can disrupt project timelines and affect overall operations. This unpredictability can be exacerbated when sourcing from international suppliers, leading to potential delays in receiving critical components for projects in sectors like construction, manufacturing, or technology.

The Solution: To effectively manage lead times, start by establishing a strong relationship with your supplier. Discuss your project timelines upfront and inquire about their production schedules. Request a detailed timeline that includes key milestones, such as design approval, fabrication, and shipping. Consider building in buffer time to accommodate unexpected delays. It may also be beneficial to explore local suppliers or those with established international shipping processes to reduce transit times. Additionally, keep open lines of communication to receive regular updates on the status of your order, allowing for proactive adjustments to your project plan if necessary.

Strategic Material Selection Guide for custom stainless steel box

What Are the Key Materials for Custom Stainless Steel Boxes?

When selecting materials for custom stainless steel boxes, it’s essential to understand the properties, advantages, disadvantages, and implications for specific applications. Here, we analyze four common materials used in the fabrication of these boxes, focusing on their performance characteristics and suitability for various environments.

1. Stainless Steel 304

Key Properties:

Stainless Steel 304 is known for its excellent corrosion resistance and good mechanical properties. It can withstand temperatures up to 870°C (1600°F) and has a pressure rating suitable for various applications.

Pros & Cons:

The primary advantage of SS304 is its versatility and cost-effectiveness, making it suitable for a wide range of applications. However, it is less resistant to chloride-induced corrosion compared to other stainless steel grades, such as 316, which can be a limitation in marine or coastal environments.

Impact on Application:

This material is ideal for general-purpose applications, including food processing and storage, where hygiene and corrosion resistance are critical. However, it may not be suitable for environments with high exposure to chlorides.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN. Understanding the environmental conditions in these areas is crucial, as they may affect the longevity of SS304.

2. Stainless Steel 316

Key Properties:

Stainless Steel 316 offers superior corrosion resistance, especially against chlorides and other harsh chemicals. It can handle temperatures similar to SS304 and is often used in marine applications.

Pros & Cons:

The key advantage of SS316 is its durability in corrosive environments, making it ideal for applications in coastal or chemical processing industries. However, it comes at a higher cost compared to SS304, which could be a consideration for budget-conscious projects.

Impact on Application:

SS316 is perfect for applications where exposure to saltwater or corrosive chemicals is expected, such as in the oil and gas industry or marine environments. Its enhanced properties make it a preferred choice for long-term investments.

Considerations for International Buyers:

For buyers in Europe and South America, it’s essential to ensure compliance with international standards, as SS316 is widely recognized and specified in various industrial applications.

3. Stainless Steel 430

Key Properties:

Stainless Steel 430 is a ferritic stainless steel that offers moderate corrosion resistance and good formability. It is less expensive than austenitic grades and is suitable for applications where high corrosion resistance is not critical.

Pros & Cons:

The main advantage of SS430 is its cost-effectiveness and decent mechanical properties. However, its lower corrosion resistance makes it unsuitable for harsh environments, limiting its application scope.

Impact on Application:

SS430 is often used in indoor applications, such as kitchen equipment and appliances, where exposure to moisture is limited. It is not recommended for outdoor applications or areas with high humidity.

Considerations for International Buyers:

Buyers should be aware of the specific environments their products will face. Compliance with local standards is also essential, particularly in regions where corrosion resistance is a significant concern.

4. Powder Coated Stainless Steel

Key Properties:

Powder coating adds an extra layer of protection to stainless steel, enhancing its corrosion resistance and aesthetic appeal. The coating can withstand temperatures up to 200°C (392°F) and is available in various colors.

Pros & Cons:

The primary advantage is the enhanced durability and customization options, allowing for branding and aesthetic considerations. However, the coating can chip or scratch, which may compromise the underlying stainless steel.

Impact on Application:

Powder-coated stainless steel is suitable for both indoor and outdoor applications, providing a visually appealing finish that is resistant to fading and weathering. However, care must be taken to avoid damage to the coating.

Considerations for International Buyers:

Buyers should ensure that the powder coating meets local environmental regulations, especially in regions with strict compliance requirements. Understanding the local climate can also help in selecting the right coating for durability.

Summary Table of Material Selection

| Material | Typical Use Case for custom stainless steel box | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel 304 | Food processing and storage | Versatile and cost-effective | Less resistant to chlorides | Medium |

| Stainless Steel 316 | Marine and chemical processing | Superior corrosion resistance | Higher cost compared to SS304 | High |

| Stainless Steel 430 | Indoor kitchen equipment | Cost-effective and good formability | Lower corrosion resistance | Low |

| Powder Coated Stainless Steel | Indoor/outdoor applications | Enhanced durability and aesthetic options | Coating can chip or scratch | Medium |

This guide aims to provide international B2B buyers with a comprehensive understanding of material options for custom stainless steel boxes, facilitating informed decision-making based on specific application needs and regional considerations.

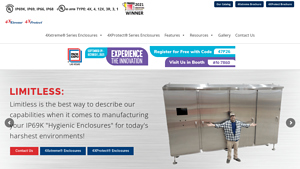

In-depth Look: Manufacturing Processes and Quality Assurance for custom stainless steel box

What Are the Main Stages of Manufacturing Custom Stainless Steel Boxes?

The manufacturing of custom stainless steel boxes involves several critical stages, ensuring that the final product meets the specific requirements of B2B buyers. Understanding these stages can help buyers make informed decisions when selecting a supplier.

Material Preparation: What Are the Key Considerations?

The first step in the manufacturing process is material preparation. Stainless steel, particularly grades such as SS304 and SS316, is commonly used due to its corrosion resistance and durability. Suppliers typically begin by sourcing high-quality raw materials from certified mills. The material is then cut to size using techniques such as laser cutting or water jet cutting, which provide precision and minimize waste.

Buyers should verify that suppliers use certified materials that conform to international standards. This can include reviewing mill test certificates and ensuring compliance with relevant industry specifications.

How Is the Forming Process Executed?

Once the material is prepared, the next stage is forming, which involves shaping the stainless steel into the desired box configuration. Common techniques include:

- Bending: Using press brakes to achieve precise angles and shapes.

- Stamping: Creating complex shapes through a die, which is efficient for high-volume production.

- Welding: Joining different sections using methods such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding, which ensure strong and durable seams.

It’s essential for buyers to inquire about the forming capabilities of their chosen manufacturers. The ability to execute intricate designs or large volumes can significantly impact the overall project timeline and costs.

What Happens During the Assembly Stage?

After forming, the assembly stage involves putting together the various components of the stainless steel box. This may include installing doors, mounting brackets, or internal panels. Quality during assembly is critical, as it affects both the functional integrity and aesthetic appeal of the final product.

Quality control checkpoints during assembly should be established to ensure that all components fit correctly and that any necessary adjustments are made promptly. Manufacturers should provide documentation of assembly procedures and any modifications made during the process.

Which Finishing Techniques Are Commonly Used?

Finishing is the final stage in the manufacturing process and plays a significant role in both the functionality and appearance of the stainless steel box. Common finishing techniques include:

- Polishing: To enhance the surface finish and provide a clean, professional look.

- Powder Coating: Adding a protective layer that can improve corrosion resistance and allow for various colors.

- Passivation: A chemical treatment that enhances corrosion resistance by removing free iron from the surface.

B2B buyers should specify their finishing requirements early in the process, as this can affect production timelines and costs. Additionally, understanding the environmental impact of finishing processes is important for compliance with international regulations.

What Quality Assurance Measures Are Essential for Custom Stainless Steel Boxes?

Quality assurance is crucial in ensuring that the custom stainless steel boxes meet both international and industry-specific standards. A robust quality management system can significantly mitigate risks associated with product defects.

Which International Standards Are Relevant?

Many manufacturers adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO 9001 ensures that the manufacturer consistently meets customer and regulatory requirements.

Additionally, industry-specific standards such as CE marking (for products sold in the European Economic Area) and API standards (for the oil and gas industry) may also apply. B2B buyers should confirm that their suppliers are compliant with these relevant standards to ensure product reliability and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints should be integrated throughout the manufacturing process to ensure that defects are caught early. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process to catch defects as they occur.

- Final Quality Control (FQC): Conducting a thorough inspection of the finished product to ensure it meets all requirements before shipping.

Buyers should request detailed QC reports from suppliers, which should outline inspection results, corrective actions taken, and any deviations from the standard.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can adopt several strategies to verify the quality control measures of their suppliers. Conducting audits is one of the most effective methods, allowing buyers to assess the manufacturer’s processes firsthand. During an audit, buyers should evaluate the supplier’s quality management system, review documentation, and inspect production facilities.

Additionally, third-party inspections can provide an unbiased assessment of the manufacturing process. Buyers should consider engaging third-party organizations that specialize in product inspections and certifications, particularly for international transactions where quality concerns may be heightened.

What Are the Unique QC Considerations for International Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Variations in regional standards, customs regulations, and import/export restrictions can impact quality assurance practices.

Understanding the local regulatory environment is crucial for compliance. Buyers should also consider the logistics of shipping and potential delays that can affect product quality, such as exposure to extreme temperatures or humidity during transit.

By taking a proactive approach to understanding manufacturing processes and quality assurance measures, B2B buyers can ensure that they source high-quality custom stainless steel boxes that meet their specific needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom stainless steel box’

In the competitive landscape of B2B procurement, acquiring a custom stainless steel box demands a strategic approach. This guide provides a comprehensive checklist to ensure you cover all critical aspects when sourcing your stainless steel enclosures, helping you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications for your custom stainless steel box. Consider dimensions, material grade (e.g., SS304 or SS316), thickness, and any specific features such as mounting options or surface finishes. Having these details ready helps suppliers provide accurate quotes and reduces the likelihood of misunderstandings later in the process.

Step 2: Identify Your Application Requirements

Understand the specific application for which the stainless steel box will be used. Different environments, such as outdoor, industrial, or hygienic settings, may require varying levels of protection (e.g., IP ratings, corrosion resistance). Make a list of these requirements, as they will guide your selection of materials and designs.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your needs. Look for established manufacturers with experience in producing custom stainless steel boxes similar to your requirements. Request company profiles, product catalogs, and references from other clients, especially those in your industry or region. This step is crucial to avoid pitfalls related to quality and service.

Step 4: Verify Certifications and Compliance

Ensure that your chosen suppliers comply with relevant industry standards and certifications. Depending on your region and application, this could include ISO certifications, NEMA ratings, or UL listings. Compliance not only guarantees quality but also demonstrates the supplier’s commitment to safety and reliability.

Step 5: Request Prototypes or Samples

Before finalizing your order, ask for prototypes or samples of the custom stainless steel box. This allows you to evaluate the craftsmanship, dimensions, and overall quality of the product. Inspect the welds, finishes, and any additional features to ensure they meet your specifications and standards.

Step 6: Discuss Lead Times and Delivery Logistics

Clarify lead times with your supplier to understand how long the production and delivery will take. Discuss logistics, especially if you are importing the boxes from another country. Understanding shipping costs, potential tariffs, and delivery timelines can help you plan your project more effectively.

Step 7: Negotiate Pricing and Payment Terms

Once you have selected a supplier, engage in discussions about pricing and payment terms. Ensure that the quoted price reflects the quality and specifications of the product. Consider negotiating for better payment terms or bulk discounts, particularly if you plan on placing large or repeated orders.

By following this checklist, B2B buyers can streamline the process of sourcing custom stainless steel boxes, ensuring that they select the right product and supplier for their needs. This careful approach not only enhances the procurement process but also contributes to long-term business success.

Comprehensive Cost and Pricing Analysis for custom stainless steel box Sourcing

What Are the Key Cost Components in Sourcing Custom Stainless Steel Boxes?

Understanding the cost structure of custom stainless steel boxes is essential for international B2B buyers. The primary cost components include:

-

Materials: The type of stainless steel (such as 304 or 316) significantly affects the cost. Higher-grade materials offer better corrosion resistance and durability, which can lead to higher upfront costs but lower maintenance expenses over time.

-

Labor: The complexity of the design and the level of customization required directly influence labor costs. Skilled labor is necessary for precise fabrication and quality welding, which can increase costs.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, equipment maintenance, and facility expenses. A well-managed overhead can optimize pricing.

-

Tooling: Custom designs may necessitate specialized tools or molds. While this is often a one-time cost, it can significantly impact the initial pricing.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure that the final product meets industry standards. Implementing robust QC can add to the overall cost but is crucial for maintaining quality and reliability.

-

Logistics: Shipping and handling costs vary based on the destination, size of the order, and chosen shipping method. For international buyers, understanding Incoterms is vital to avoid unexpected freight charges.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand and supplier reputation.

How Do Price Influencers Affect Custom Stainless Steel Box Costs?

Several factors influence the pricing of custom stainless steel boxes, making it essential for buyers to consider these elements:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically lead to cost savings. Suppliers often provide discounts for larger quantities, making it advantageous to consolidate orders where possible.

-

Specifications and Customization: Unique designs or additional features (like specific dimensions or finishes) can increase costs. Buyers should balance customization needs with budget constraints.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO or UL) can elevate costs but provide assurance of product reliability. Buyers in regulated industries may find these certifications necessary.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers may charge more due to their reliability and quality assurance but may also offer better customer support.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can affect the total landed cost, including insurance and tariffs, which is especially relevant for international buyers.

What Are the Best Negotiation and Cost-Efficiency Tips for International Buyers?

When sourcing custom stainless steel boxes, international buyers can employ several strategies to enhance cost-efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and lead times. Building a good relationship with suppliers can lead to better terms and pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also long-term costs, including maintenance, durability, and potential replacement costs. A lower upfront cost may lead to higher TCO if the product is of inferior quality.

-

Leverage Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local suppliers can reduce shipping costs and lead times. It may also simplify logistics and customs processes.

-

Research Market Trends: Stay informed about market trends and material costs. Fluctuations in raw material prices can affect final pricing, so timing your purchase can lead to cost savings.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can help gauge the market rate and ensure competitive pricing. This practice also provides leverage in negotiations.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It is crucial for buyers to remember that indicative prices can vary significantly based on the aforementioned factors. Fluctuations in raw material costs, currency exchange rates, and changing market conditions can all impact final pricing. Always request detailed quotes and clarify what is included to avoid surprises.

Alternatives Analysis: Comparing custom stainless steel box With Other Solutions

Exploring Alternatives to Custom Stainless Steel Boxes for B2B Applications

In the realm of industrial solutions, the choice of materials and designs can significantly affect operational efficiency and cost-effectiveness. Custom stainless steel boxes are popular due to their durability and corrosion resistance, making them ideal for various applications. However, it is essential for B2B buyers to explore alternative solutions that may offer similar benefits tailored to specific needs. Below, we compare custom stainless steel boxes with two viable alternatives: aluminum enclosures and plastic enclosures.

| Comparison Aspect | Custom Stainless Steel Box | Aluminum Enclosures | Plastic Enclosures |

|---|---|---|---|

| Performance | High durability and strength; excellent resistance to corrosion and heat. | Good strength and corrosion resistance; lighter than steel. | Adequate for low-stress environments; lower strength and durability. |

| Cost | Generally higher due to material and fabrication costs. | Moderate cost; typically less expensive than stainless steel. | Lowest cost; ideal for budget-sensitive projects. |

| Ease of Implementation | Requires skilled labor for fabrication and assembly. | Easier to fabricate; can be cut and assembled with standard tools. | Very easy to work with; often comes pre-assembled. |

| Maintenance | Low maintenance; resistant to rust and wear. | Moderate maintenance; may require protective coatings. | Low maintenance; susceptible to UV degradation over time. |

| Best Use Case | Harsh environments (e.g., food processing, chemical plants). | General-purpose applications; suitable for indoor and outdoor use. | Lightweight applications; ideal for non-critical environments. |

What Are the Pros and Cons of Aluminum Enclosures Compared to Custom Stainless Steel Boxes?

Aluminum enclosures present a lightweight alternative to custom stainless steel boxes. They are easier to fabricate and can be cost-effective, making them suitable for a range of applications. However, while aluminum has good corrosion resistance, it does not match the durability of stainless steel in extreme environments. For industries that require robust protection against harsh conditions, aluminum may fall short.

How Do Plastic Enclosures Compare to Custom Stainless Steel Boxes?

Plastic enclosures offer the most budget-friendly option among alternatives. They are lightweight and easy to handle, often coming pre-assembled, which simplifies installation. However, plastic lacks the durability and heat resistance of metal options, making it less suitable for applications involving heavy machinery or exposure to harsh chemicals. While they are ideal for low-stress environments, they may not provide the long-term reliability required in more demanding settings.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right enclosure solution, B2B buyers should consider the specific demands of their application. Factors such as environmental conditions, required durability, budget constraints, and installation complexity will guide the decision-making process. For industries dealing with extreme temperatures or corrosive substances, custom stainless steel boxes are typically the best choice. Conversely, if cost and weight are primary concerns, aluminum or plastic enclosures may suffice. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for custom stainless steel box

What Are the Essential Technical Properties of a Custom Stainless Steel Box?

When considering a custom stainless steel box, understanding its technical properties is crucial for ensuring that the product meets specific application requirements. Here are some key specifications to consider:

1. Material Grade

The most commonly used grades for stainless steel boxes are 304 and 316. Grade 304 is known for its excellent corrosion resistance and is typically used in general applications. Grade 316 offers enhanced corrosion resistance, particularly in marine environments, making it ideal for industries like oil and gas. Choosing the right material grade is essential for durability and longevity, impacting maintenance costs and overall performance.

2. Thickness

The thickness of the stainless steel, typically measured in millimeters (mm), ranges from 1.2 mm to 3.0 mm or more, depending on the application. Thicker materials provide better structural integrity and are more suitable for heavy-duty applications. Selecting the appropriate thickness is vital for the box’s strength and resistance to deformation under load.

3. Tolerance

Tolerance refers to the permissible limit of variation in dimensions and is crucial for ensuring that the custom box fits perfectly in its intended application. Common tolerances for stainless steel fabrication range from ±0.5 mm to ±1.0 mm. Precise tolerances are essential for components that require a tight fit, which can affect functionality and safety.

4. Surface Finish

The surface finish of a stainless steel box can significantly impact its aesthetic appeal and resistance to corrosion. Common finishes include brushed, polished, and powder-coated. A polished finish enhances appearance and corrosion resistance, while powder coating can provide additional color options and protect against wear. Selecting the right finish is critical for both functional and aesthetic considerations.

5. Welding Quality

The quality of welds in a stainless steel box is a critical factor for structural integrity and appearance. Welds should be smooth and polished to prevent corrosion and ensure that the box is aesthetically pleasing. High-quality welding techniques reduce the risk of failures in harsh environments, making this an important consideration in the design process.

6. IP Ratings

Ingress Protection (IP) ratings indicate the level of protection against dust and water. For instance, an IP65 rating signifies that the enclosure is dust-tight and can withstand water jets. Understanding the required IP rating is essential for applications in environments exposed to moisture or contaminants, ensuring the longevity and reliability of the box.

What Are Common Trade Terms Related to Custom Stainless Steel Boxes?

Familiarity with industry-specific jargon can facilitate smoother negotiations and collaborations. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of stainless steel boxes, an OEM may supply custom solutions designed to fit specific machinery or equipment, highlighting the importance of sourcing from reputable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their operational needs to avoid excess stock or insufficient supplies.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Providing detailed specifications in an RFQ helps suppliers deliver accurate quotes, ensuring that the buyer can make informed decisions based on costs and capabilities.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping responsibilities, risk transfer, and cost allocation, impacting overall project budgeting and logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Knowing the lead time is critical for project planning and inventory management. Buyers should consider lead times when coordinating with suppliers to ensure timely delivery in alignment with project schedules.

6. Customization Capabilities

This term refers to a manufacturer’s ability to tailor products to specific requirements, including dimensions, materials, and features. Understanding a supplier’s customization capabilities helps buyers ensure that their unique needs are met, resulting in a more effective and satisfactory product.

By grasping these essential properties and trade terminologies, B2B buyers can make informed decisions when sourcing custom stainless steel boxes, leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the custom stainless steel box Sector

What Are the Current Market Dynamics and Key Trends in the Custom Stainless Steel Box Sector?

The custom stainless steel box market is witnessing robust growth driven by increasing demand across various industries such as food processing, pharmaceuticals, oil and gas, and telecommunications. Key global drivers include the rise in industrial automation, stringent safety regulations, and the need for durable and corrosion-resistant materials. As industries become more globalized, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly sourcing custom solutions that meet specific operational needs.

Emerging technologies such as advanced manufacturing techniques, including laser cutting and 3D printing, are revolutionizing the customization process, allowing for greater precision and reduced lead times. Buyers can now configure their products online, selecting from a range of specifications, materials, and finishes. This shift towards digitalization not only streamlines the ordering process but also enhances transparency and collaboration between manufacturers and buyers.

Sourcing trends are evolving, with buyers prioritizing suppliers that offer not just competitive pricing but also flexibility in production and delivery schedules. The rise of e-commerce platforms is facilitating easier access to suppliers worldwide, making it imperative for buyers to evaluate vendor capabilities and certifications carefully. As markets in Nigeria and Saudi Arabia continue to develop, the demand for tailored stainless steel solutions is expected to grow, necessitating suppliers to adapt their offerings to meet regional requirements effectively.

How Can Sustainability and Ethical Sourcing Impact the Custom Stainless Steel Box Market?

Sustainability and ethical sourcing are becoming increasingly pivotal in the custom stainless steel box sector. Environmental impact considerations are driving companies to adopt more sustainable practices throughout their supply chains. Buyers are now more aware of the ecological footprint associated with manufacturing processes, prompting a shift towards suppliers that prioritize eco-friendly materials and production methods.

The use of recycled stainless steel and eco-certifications can significantly enhance a company’s reputation and appeal to environmentally conscious consumers. Moreover, ethical sourcing ensures that materials are procured responsibly, minimizing the exploitation of labor and resources. Buyers should seek suppliers that demonstrate compliance with international standards for sustainability, such as ISO 14001, which highlights effective environmental management systems.

Incorporating green certifications not only aligns with corporate social responsibility (CSR) goals but also opens up new market opportunities, particularly in regions where environmental regulations are tightening. By choosing suppliers that prioritize sustainability, businesses can mitigate risks associated with supply chain disruptions and enhance their brand image in an increasingly competitive marketplace.

What Has Been the Evolution of the Custom Stainless Steel Box Industry?

The custom stainless steel box industry has evolved significantly over the past few decades. Initially, the market was dominated by traditional fabrication methods, which often resulted in longer lead times and limited customization options. However, advancements in technology and manufacturing processes have transformed the landscape.

The introduction of computer-aided design (CAD) and computer numerical control (CNC) machining has allowed for higher precision and efficiency in production. As a result, manufacturers can now offer a wider range of sizes and configurations tailored to specific client needs. The rise of e-commerce and digital platforms has further facilitated this evolution, enabling buyers to interact directly with manufacturers and configure products according to their specifications.

Today, the industry continues to innovate, focusing on enhancing product functionality and aesthetic appeal while prioritizing sustainability and ethical practices. As the global market expands, the ability to adapt to changing consumer demands and environmental standards will be crucial for success in the custom stainless steel box sector.

Frequently Asked Questions (FAQs) for B2B Buyers of custom stainless steel box

-

How do I determine the right specifications for a custom stainless steel box?

To identify the appropriate specifications for your custom stainless steel box, start by assessing the intended use and environment. Consider the dimensions, material grade (commonly SS304 or SS316 for enhanced corrosion resistance), thickness, and surface finish. Utilizing online configuration tools can facilitate this process, allowing you to input specific measurements and receive instant pricing. Engaging with suppliers for expert advice can also clarify which options best meet your operational requirements. -

What is the best material for a custom stainless steel box?

The optimal material for a custom stainless steel box typically depends on the application. Stainless steel 304 is widely used for general purposes due to its excellent corrosion resistance and affordability. For harsher environments, such as marine or chemical applications, stainless steel 316 is recommended due to its superior resistance to pitting and corrosion. Always evaluate the environmental factors and required durability before making a decision. -

What customization options are available for stainless steel boxes?

Customization options for stainless steel boxes are extensive. Buyers can select dimensions, wall thickness, interior configurations, and finishing styles such as powder coating or brushed finishes. Additional features may include mounting options, door types (hinged, sliding), and internal accessories like shelves or partitions. Collaborating closely with manufacturers during the design phase ensures that all specific needs are met. -

What is the minimum order quantity (MOQ) for custom stainless steel boxes?

Minimum order quantities (MOQs) for custom stainless steel boxes vary by manufacturer and can depend on the complexity of the design. Typically, MOQs can range from 10 to 100 units. It’s essential to discuss your requirements directly with potential suppliers, as some may offer lower MOQs for standard designs, while custom designs might necessitate higher quantities to justify production costs. -

How can I vet suppliers for custom stainless steel boxes?

Vetting suppliers is crucial to ensure quality and reliability. Start by researching their experience and reputation in the industry, looking for customer reviews and case studies. Verify their certifications, such as ISO or other quality management standards. Request samples of previous work to assess craftsmanship and quality. Additionally, consider their communication responsiveness and willingness to engage in the design process, which can indicate their commitment to customer satisfaction. -

What payment terms should I expect when ordering custom stainless steel boxes?

Payment terms for custom stainless steel boxes can vary significantly among suppliers. Many manufacturers require a deposit (typically 30% to 50%) upfront, with the balance due upon completion or delivery. It’s advisable to clarify these terms upfront and explore options such as letter of credit or escrow services for larger orders to mitigate risks. Understanding the payment structure helps in budgeting and ensures transparency throughout the transaction. -

What quality assurance processes should be in place for custom stainless steel boxes?

Quality assurance processes are vital in manufacturing custom stainless steel boxes. Reputable suppliers should implement strict quality control measures, including material inspection, dimensional checks, and weld integrity assessments. Request information about their QA protocols, such as testing procedures or certifications, to ensure that the products meet industry standards and your specific requirements. -

How do logistics and shipping work for international orders of custom stainless steel boxes?

Logistics for international orders involve several steps, including production timelines, packaging, and shipping methods. Confirm with your supplier about their shipping capabilities and any partnerships with freight forwarders. Discuss potential customs duties, tariffs, and the estimated delivery timeframe to avoid unexpected delays. Establishing clear communication regarding these logistics ensures a smooth procurement process and timely delivery of your custom products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Custom Stainless Steel Box Manufacturers & Suppliers List

1. MetalsCut4U – Custom Fabricated Metal Trays and Boxes

Domain: metalscut4u.com

Registered: 2015 (10 years)

Introduction: Custom fabricated metal tray or box made from aluminum, stainless steel, or carbon steel. Customers can configure their tray box online in four simple steps: selecting the sheet metal type, surface, thickness, and entering individual measurements. The sheet metal calculator provides pricing based on the chosen options. The product is customizable in size and shape, allowing for specific dimensions…

2. Takachi – Custom Stainless Steel Enclosures

Domain: takachi-enclosure.com

Registered: 2011 (14 years)

Introduction: SHEET METAL STAINLESS STEEL BOXES – Custom sized stainless steel enclosures available in various series: 1. MBS series: Simple structure, dimensions W&D: 50-500mm, H: 20-250mm. 2. MBSF series: Wallmount flange, dimensions W&D: 50-500mm, H: 20-250mm. 3. MCGS series: Shockproof with corner guards, dimensions W: 50-500mm, D: 50-400mm, H: 20-250mm. 4. TCS series: Stainless steel sheet cover, dimension…

3. Andrews Fabrication – Custom Stainless Steel Enclosures

Domain: andrewsfabrication.com

Registered: 2008 (17 years)

Introduction: Custom stainless steel enclosures designed to exact specifications. Options include any size, indoor or outdoor use, and materials such as stainless steel, aluminum, or powder-coated mild steel. Numerous configurations available with various door, interior, back panel, flush or surface mounting options. Types of enclosures offered: Custom Enclosures, Aluminum Enclosures, Stainless Steel Enclosures…

4. Polycase – Metal Enclosures for Electronics

Domain: polycase.com

Registered: 1996 (29 years)

Introduction: Metal enclosures for electronics available in diecast aluminum, extruded aluminum, carbon steel, and stainless steel. Features include EMI shielding, waterproof options, and various sizes and styles. Key factors for selection: material properties, NEMA/IP ratings, mounting hardware, off-the-shelf vs. custom fabrication, and customization options. Examples of products include: EX-50 (Extruded Alumi…

5. 4Xxtreme® – Custom Stainless Steel Enclosures

Domain: 4xxtreme.com

Registered: 2014 (11 years)

Introduction: Custom Stainless Enclosures, Inc. manufactures and supplies custom stainless steel electrical enclosures for various industries including food & dairy, pharmaceutical, oil & gas, and wastewater. Key product lines include 4Xxtreme® Enclosures and 4XProtect® Enclosures. The 4Xxtreme® series includes various enclosure types such as Single Door Enclosures, Flanged Single Door Enclosures, Sequester Fla…

6. Affordable Custom Metal Box Fabrication

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Metal box fabrication, 3mm thick, suitable for housing a 700VA Toroid transformer and 2 server-grade power supplies. Budget: $100 max for the case, with a previous quote of $600 for aluminum fabrication. Seeking affordable options for custom design, considering manufacturability and potential use of flanges instead of welding.

7. Enclosure Manufacturers – Metal Boxes & Electrical Cabinets

Domain: enclosuremanufacturers.com

Registered: 2001 (24 years)

Introduction: Metal boxes are fabrications designed to provide shelter, store, or enclose various objects, specifically electrical components. They include aluminum enclosures, stainless steel enclosures, and various electrical cabinets. Key features include:

– Versatile shapes: rounded, circular, cylindrical, and standard geometric designs (rectangles and squares).

– Manufacturing techniques: metal stamping,…

Strategic Sourcing Conclusion and Outlook for custom stainless steel box

In navigating the landscape of custom stainless steel boxes, strategic sourcing emerges as a vital component for international B2B buyers. The ability to specify material types, dimensions, and finishes allows businesses to tailor solutions that meet their unique operational requirements. With manufacturers offering advanced customization options, including various grades of stainless steel and additional features like powder coating, buyers can ensure durability and compliance with industry standards.

Moreover, establishing strong partnerships with suppliers can lead to improved supply chain efficiency and cost savings. Whether sourcing for industries such as food processing, pharmaceuticals, or electronics, understanding the nuances of supplier capabilities and product specifications is essential.

As we look to the future, the demand for custom stainless steel solutions is expected to grow, driven by an increasing focus on quality and sustainability. International buyers from regions such as Africa, South America, the Middle East, and Europe should seize this opportunity to leverage strategic sourcing practices. Engage with suppliers who not only meet your specifications but also align with your long-term business goals. Start exploring your options today and position your business for success in this evolving market.