Contents

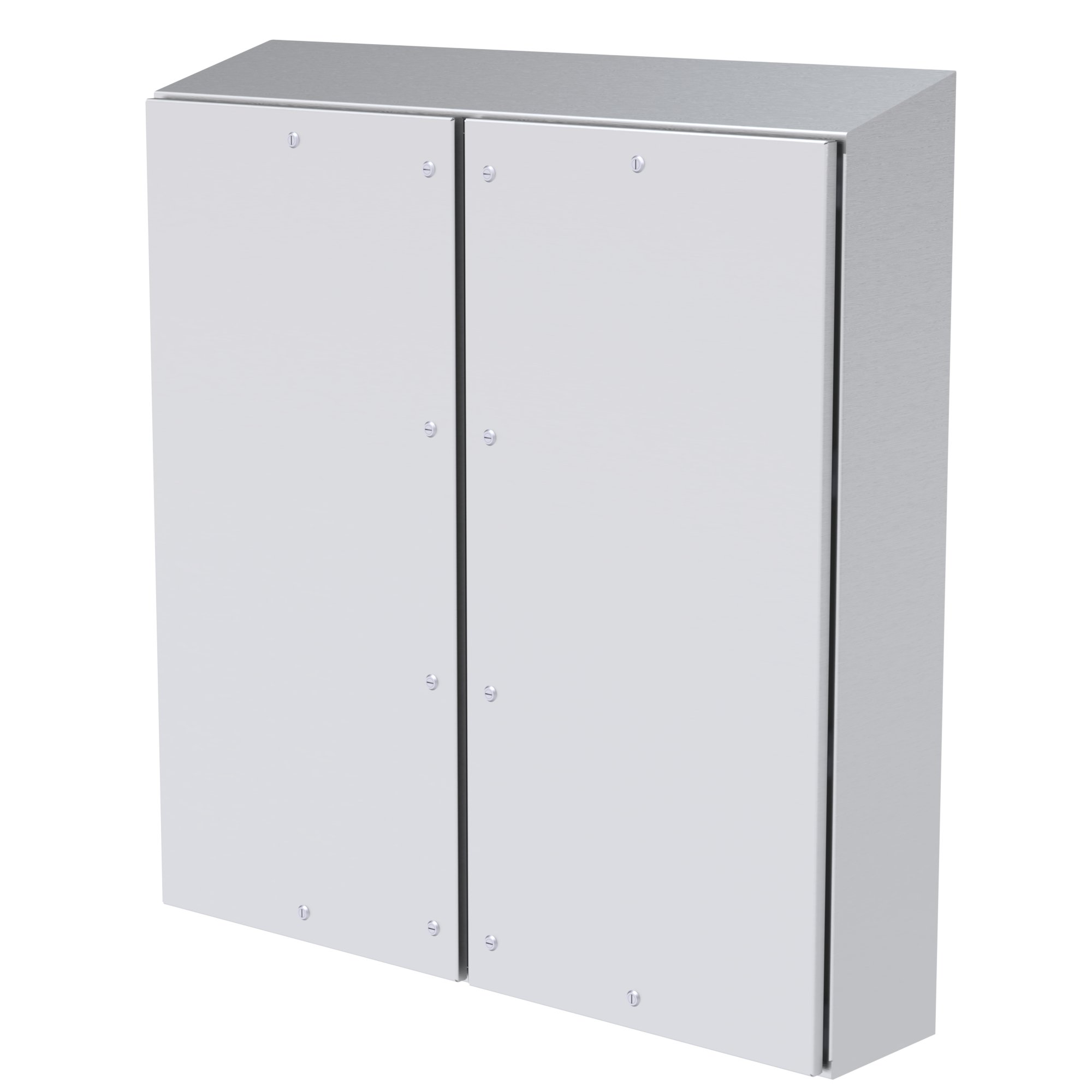

Manufacturing Insight: Custom Stainless Steel Box

Precision CNC Machining for Critical Stainless Steel Enclosures

When your application demands a custom stainless steel box that meets exact dimensional, structural, and environmental requirements, Honyo Prototype delivers engineered reliability through advanced CNC machining. Our ISO 9001-certified facility leverages multi-axis milling and turning centers to produce complex enclosures from 304, 316, and specialty stainless grades with tolerances consistently held to ±0.005mm. Unlike fabricated alternatives, CNC-machined boxes eliminate weld distortions and material weaknesses, ensuring seamless integration, superior corrosion resistance, and repeatable performance in demanding industrial, medical, or aerospace environments. Every component undergoes rigorous in-process inspection and final validation to meet stringent industry specifications.

Accelerate your prototyping or low-volume production timeline with Honyo’s Online Instant Quote system. Simply upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within minutes—no sales calls required. This direct digital workflow ensures transparency and speed from design validation to first-article delivery, empowering your engineering team to iterate faster and deploy mission-critical enclosures with confidence.

Technical Capabilities

Custom stainless steel boxes are precision-engineered enclosures commonly used in industrial, medical, and aerospace applications where durability, corrosion resistance, and dimensional accuracy are critical. These components are typically manufactured using advanced 3-axis, 4-axis, and 5-axis CNC milling processes, often combined with CNC turning for integrated features such as mounting bosses or threaded inserts. High-precision machining ensures tight tolerances down to ±0.0005″ (0.0127 mm), with surface finishes ranging from 32 to 16 μin (0.8 to 0.4 μm) Ra depending on application requirements.

While the primary material is stainless steel (e.g., 304, 316, 17-4 PH), similar machining capabilities apply to other materials including aluminum, carbon steel, ABS, and nylon—each selected based on environmental exposure, mechanical needs, and cost targets. Multi-axis milling allows for complex geometries, undercuts, and precision-machined sealing surfaces without the need for extensive post-processing.

Below is a comparison of technical capabilities across common materials used in the production of custom precision-machined enclosures:

| Feature | Stainless Steel (304/316) | Aluminum (6061-T6) | Carbon Steel (1018) | ABS (Thermoplastic) | Nylon (PA6/PA66) |

|---|---|---|---|---|---|

| Machining Process | 3/4/5-Axis Milling, CNC Turning | 3/4/5-Axis Milling, CNC Turning | 3/4/5-Axis Milling, CNC Turning | 3/4-Axis Milling | 3/4-Axis Milling |

| Typical Tolerance | ±0.0005″ (0.0127 mm) | ±0.0005″ (0.0127 mm) | ±0.001″ (0.0254 mm) | ±0.002″ (0.0508 mm) | ±0.002″ (0.0508 mm) |

| Surface Finish (Ra) | 16–32 μin (0.4–0.8 μm) | 16–32 μin (0.4–0.8 μm) | 32 μin (0.8 μm) | 63–125 μin (1.6–3.2 μm) | 63–125 μin (1.6–3.2 μm) |

| Corrosion Resistance | Excellent | Good (anodized) | Poor (requires plating) | Good | Good (moisture sensitive) |

| Typical Applications | Medical, Marine, Food & Beverage | Aerospace, Enclosures | Industrial Frames | Prototypes, Jigs | Wear Components, Insulators |

| Max Part Size (Typical) | 24″ x 36″ x 18″ | 48″ x 96″ x 24″ | 48″ x 96″ x 24″ | 48″ x 96″ x 12″ | 48″ x 96″ x 12″ |

| Secondary Operations | Passivation, CIP, Laser Etch | Anodizing, PEM Inserts | Plating, Painting | Vapor Polishing, Dyeing | Machining, Annealing |

All parts are inspected using CMM (Coordinate Measuring Machine), optical comparators, or laser scanning to ensure compliance with engineering drawings and GD&T specifications. First article inspection (FAI) and PPAP documentation are available upon request for production runs.

From CAD to Part: The Process

Honyo Prototype Custom Stainless Steel Box Manufacturing Process

Our end-to-end workflow for custom stainless steel enclosures ensures precision, efficiency, and technical compliance. The process begins when a client uploads a 3D CAD model via our secure customer portal. We accept STEP, IGES, SolidWorks, and Parasolid formats, with automatic validation for geometric integrity and unit consistency. Invalid submissions trigger immediate feedback for correction, minimizing client-side delays.

The validated CAD model enters our AI-powered quoting engine. This system analyzes 150+ parameters including material grade (e.g., 304 vs. 316 stainless steel), wall thickness, tolerances, surface finish requirements, and geometric complexity. It cross-references real-time data on raw material costs, machine utilization, and labor rates to generate a technically accurate quote within 90 minutes. Crucially, the AI flags potential cost drivers such as sub-2mm internal radii or non-standard hole patterns that impact manufacturability.

Following quote acceptance, our DFM (Design for Manufacturability) phase commences. Senior manufacturing engineers conduct a dual-path review:

First, the AI system performs automated tolerance stack analysis and identifies features requiring secondary operations (e.g., deep drawn sections needing annealing).

Second, a human engineer verifies AI findings and assesses weld seam placement, grain direction for brushed finishes, and fixture requirements for repeatable bending. Clients receive a collaborative DFM report with actionable recommendations—such as adjusting bend radii to match available tooling—reducing production risks by 40% on average.

Production leverages our integrated digital workflow. Laser cutting uses 4kW fiber lasers with ±0.1mm positional accuracy, followed by CNC press braking with real-time springback compensation. Welding employs TIG for critical seams and MIG for structural joints, all per AWS D1.6 standards. Post-fabrication, parts undergo passivation per ASTM A967 and dimensional validation via CMM against the original CAD. For enclosures requiring IP ratings, we perform helium leak testing at this stage.

Delivery includes serialized tracking from our Ningbo facility. Standard lead times vary based on complexity, as shown below:

| Complexity Tier | Typical Lead Time | Key Variables |

|---|---|---|

| Tier 1: Simple box (≤5 bends, no welds) | 7–10 business days | Material availability, anodizing queue |

| Tier 2: Moderate (welded seams, tapped holes) | 12–15 business days | Weld certification requirements, surface finish |

| Tier 3: Complex (EMI shielding, gasket channels) | 18–22 business days | Custom tooling, multi-stage finishing |

All shipments include first-article inspection reports, material certs, and a digital twin of the as-built part for client verification. This closed-loop process ensures stainless steel enclosures meet ISO 2768-mK tolerances while maintaining full traceability from CAD to delivery.

Start Your Project

Looking for a custom stainless steel enclosure built to your exact specifications? Honyo Prototype delivers precision-manufactured stainless steel boxes tailored to your project requirements. From design support to rapid prototyping and low-volume production, our in-house capabilities in Shenzhen ensure high quality, fast turnaround, and full traceability.

Contact Susan Leo today to discuss your custom solution.

Email: [email protected]

Our manufacturing facility is based in Shenzhen, China, providing scalable production with international quality standards. Let us support your next project with expert engineering and reliable delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.