Contents

Manufacturing Insight: Custom Stainless Steel Bending

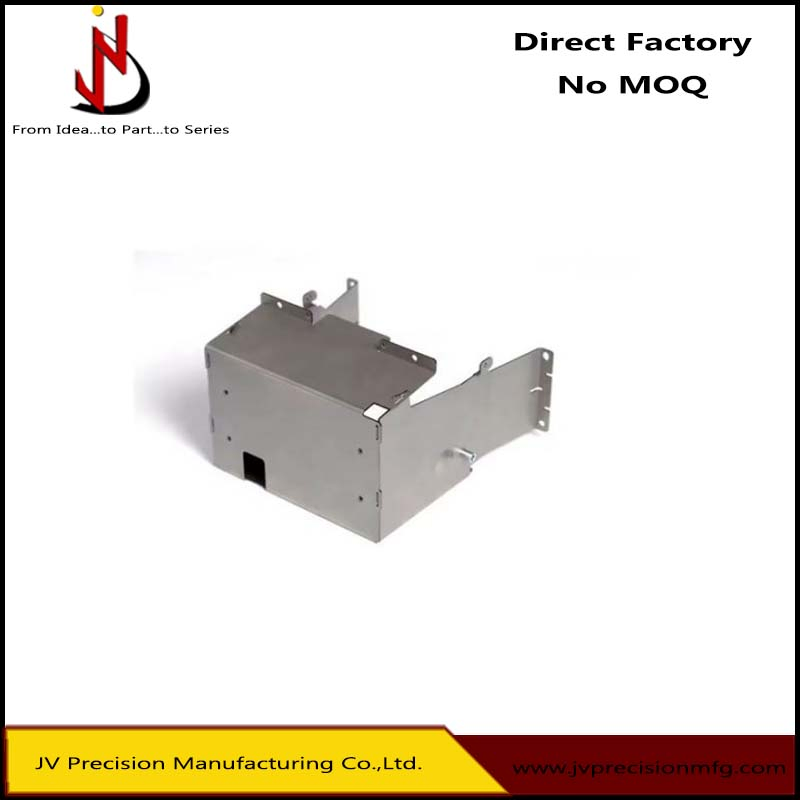

Precision Custom Stainless Steel Bending Solutions from Honyo Prototype

Honyo Prototype delivers high-precision custom stainless steel bending services engineered for demanding industrial applications. Our advanced CNC press brake fleet, featuring state-of-the-art AMADA and TRUMPF systems, ensures exceptional accuracy, repeatability, and geometric complexity for components in grades 304, 316, and other specialized alloys. We address critical challenges inherent in stainless steel fabrication—including springback control, surface integrity preservation, and tight tolerance maintenance—through optimized tooling selection, multi-axis bending strategies, and in-process metrology. Every bent component undergoes rigorous first-article inspection and batch validation per AS9102 or customer-specific requirements, guaranteeing compliance with aerospace, medical, and heavy equipment standards. This core bending capability integrates seamlessly with our full-spectrum CNC machining, laser cutting, and TIG welding services, enabling complete fabrication of complex assemblies from raw material to finished part. Accelerate your procurement cycle with Honyo’s Online Instant Quote platform, providing detailed pricing and lead time estimates for stainless steel bending projects within hours, not days, based on direct CAD file analysis and real-time machine capacity data.

Technical Capabilities

Custom stainless steel bending combined with precision 3/4/5-axis milling and turning operations enables high-complexity components with tight tolerances across a range of materials including stainless steel, aluminum, carbon steel, ABS, and nylon. While bending is typically associated with sheet or tube forming, when integrated with advanced CNC machining processes, it allows for fully finished assemblies with precise geometric features and tight dimensional control.

Below are the technical specifications relevant to custom stainless steel bending and associated precision machining capabilities:

| Parameter | Specification Details |

|---|---|

| Primary Processes | 3-axis, 4-axis, and 5-axis CNC milling, CNC turning, CNC bending (press brake/forming) |

| Material Compatibility | Stainless Steel (304, 316, 17-4 PH), Aluminum (6061, 7075), Carbon Steel (A36, 1018), ABS, Nylon (PA6, PA66) |

| Bending Capabilities | Sheet and tube bending up to 6mm (0.25″) thickness; bend angles ±0.5° accuracy |

| Milling Accuracy | ±0.005 mm (±0.0002″) for critical features; surface finishes down to 0.8 µm Ra |

| Turning Accuracy | Diameter tolerance: ±0.01 mm (±0.0004″); length tolerance: ±0.02 mm |

| Tight Tolerance Features | Positional tolerances: ±0.01 mm; concentricity: <0.02 mm; flatness: <0.05 mm over 100 mm |

| Max Work Envelope (Milling) | 5-axis: 1200 x 800 x 600 mm; 4-axis: 1000 x 600 x 500 mm; 3-axis: 1500 x 1000 x 600 mm |

| Max Turning Diameter | 300 mm; max length: 600 mm |

| Secondary Finishing | Deburring, passivation (stainless), anodizing (aluminum), polishing, laser marking |

| Quality Control | CMM inspection, optical comparators, laser micrometers; ISO 2768 medium accuracy standard or tighter |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (based on complexity and volume) |

Note: While ABS and nylon are not suitable for bending in the same manner as metals, these thermoplastics are often machined using the same 3/4/5-axis platforms to produce complementary components in assemblies involving bent stainless steel parts. Machining of plastics follows optimized feeds/speeds and fixturing to prevent deformation.

Honyo Prototype supports end-to-end manufacturing from design validation to tight-tolerance production, ensuring material integrity and geometric precision across both metallic and non-metallic elements in complex builds.

From CAD to Part: The Process

Honyo Prototype executes custom stainless steel bending through a rigorously defined five-stage workflow designed for precision, efficiency, and manufacturability assurance. This integrated process leverages digital tools and engineering expertise to minimize lead times while ensuring component quality and cost-effectiveness for industrial clients.

The process initiates with secure CAD file upload via our customer portal. Clients submit native or neutral format files including STEP AP203/AP214, IGES, Parasolid, or native SOLIDWORKS formats. All uploads undergo immediate AES-256 encryption and are isolated within project-specific secure directories to protect intellectual property. Our system validates geometric integrity and unit consistency before advancing to the next phase.

An AI-powered quoting engine then generates a preliminary cost and lead time estimate within 2 business hours. This system analyzes over 15 million historical bending parameters including material grade (304, 316, 430 etc.), thickness, bend radius, angular tolerances, and geometric complexity against real-time machine availability and material costs. The AI cross-references our proprietary database of stainless steel springback characteristics and tooling requirements to establish baseline feasibility before human review. Clients receive an interactive quote portal showing cost drivers and configurable lead time options.

All projects subsequently undergo mandatory Design for Manufacturability (DFM) review by our senior bending engineers. This critical phase identifies and resolves stainless steel-specific challenges including:

Springback compensation requirements based on alloy grade and temper condition

Grain direction orientation relative to bend lines to prevent cracking

Minimum flange length validation against tooling constraints

Surface protection protocols to avoid marred finishes

Tooling compatibility assessment for tight radii or complex geometries

During DFM, engineers collaborate with clients through our secure portal to propose optimized solutions. Typical adjustments include minor feature relocation to eliminate secondary operations or bend sequence modifications to maintain flatness tolerances. Only after DFM sign-off does the project advance to production.

Production occurs in our climate-controlled bending facility utilizing CNC press brakes with capacities from 30 to 300 tons and bed lengths up to 3100mm. For stainless steel components, we implement:

Polished tooling sets to prevent surface scratching

In-process laser verification of bend angles after each operation

Dedicated workstations to avoid carbon steel cross-contamination

Real-time springback adjustment via machine-integrated strain gauges

Critical dimensions undergo first-article inspection using CMMs with 0.001mm resolution, with full FAI reports available upon request. All components are deburred using non-marring techniques appropriate for specified surface finishes.

Final delivery includes kitted components with protective film intact, packaged in anti-corrosive VCI paper within custom-designed crates. Shipping documentation contains material test reports, process validation data, and dimensional conformance certificates. Standard lead time from DFM approval to shipment is 7-12 business days for single-bend components, with complex geometries typically requiring 10-15 days. Expedited options with guaranteed 72-hour production windows are available for qualified projects.

This structured workflow ensures stainless steel bending projects meet ASME Y14.5 GD&T standards while maintaining material integrity and surface quality requirements critical for aerospace, medical, and semiconductor applications.

Start Your Project

Looking for precision custom stainless steel bending? Honyo Prototype delivers high-quality, made-to-order metal fabrication with tight tolerances and fast turnaround. Our manufacturing facility in Shenzhen is equipped to handle complex bending requirements for prototyping and low-to-mid volume production.

Contact Susan Leo today to discuss your project specifications and get a competitive quote. Email us at [email protected] and leverage our expertise in custom stainless steel solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.