Guide Contents

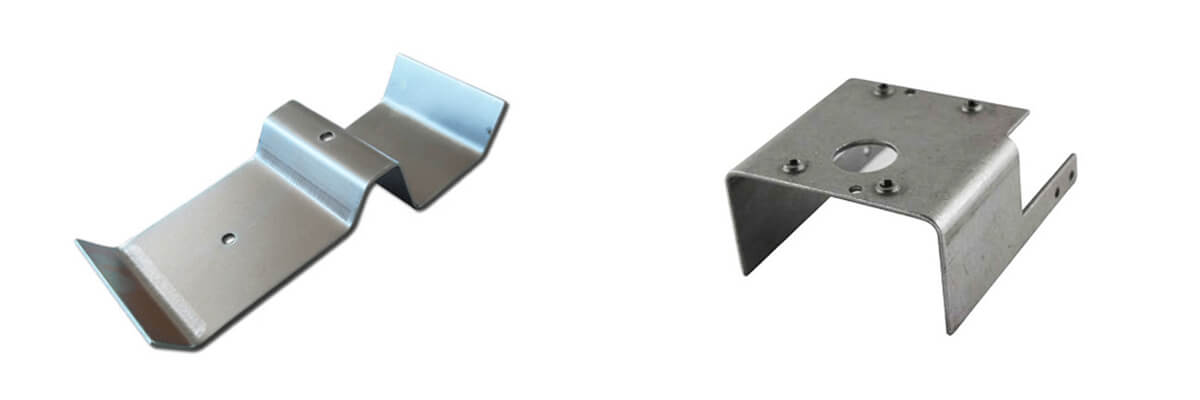

Project Insight: Custom Stainless Steel Bending

Why Speed & Precision Matter in Stainless Steel Bending

In today’s competitive product development landscape, every hour counts. Stainless steel bending must balance precision, cost, and speed to keep your innovation pipeline moving. At Honyo Prototype, we’ve redefined manufacturing with a digital-first approach that turns your designs into reality faster and more efficiently than ever before.

Real-Time Cost Transparency

Instant online quotes for stainless steel bending—see exact pricing per bend ($1–$5) based on material thickness, bend count, and tolerances

AI-driven cost analysis identifies savings opportunities, reducing expenses by up to 20% compared to traditional methods

Transparent breakdown of material costs (e.g., 1.2mm stainless steel vs. 0.8mm mild steel) with optimized pricing for your specific project

AI-Powered Precision Engineering

Automated design validation catches errors before production, preventing costly rework

CNC bending with ±0.1mm accuracy for complex enclosures, brackets, and chassis

Real-time simulation of stress points and material deformation to ensure structural integrity

72-Hour Turnaround from Design to Delivery

24/7 digital platform with automated workflow management

Same-day quotes for stainless steel projects—no waiting for manual estimations

Prototypes delivered in 72 hours, production runs in 5–7 days with integrated powder coating and welding

Your Vision, Accelerated

Partner with Honyo Prototype to transform your stainless steel designs into high-quality, cost-effective components. Our digital manufacturing ecosystem eliminates traditional bottlenecks, so you can iterate faster and bring products to market quicker.

Upload your design today and get a quote in seconds.

Honyo Capabilities & Technology

Custom Stainless Steel Bending: Precision Engineered for Your Innovation

Advanced CNC Bending Technology

Precision CNC press brakes with ±0.1° angle accuracy for stainless steel up to 3mm thickness

Laser cutting integration for burr-free edges prior to bending, ensuring clean, repeatable results

Minimum bend radius of 0.8x material thickness for tight geometries without cracking or distortion

Multi-axis bending capabilities to eliminate secondary operations for complex enclosures, brackets, and chassis

AI-Powered Instant Quoting & Optimization

Real-time instant quotes via cloud platform: Upload DXF/STEP files in <60 seconds for transparent pricing

AI-driven Design for Manufacturability (DFM) analysis to optimize bend sequences, reduce material waste, and cut costs by up to 20%

No hidden fees: Clear breakdown of material, bending, and finishing costs tailored to your stainless steel grade (304, 316, 201)

Fast turnaround: Prototypes in 3 days, production batches in 1–2 weeks with expedited options

End-to-End Quality Assurance

ISO 9001-certified processes with 100% dimensional inspection using laser measurement tools

In-process tolerance checks for critical features (e.g., flatness, angle consistency)

Seamless integration with powder coating and welding services for fully finished, ready-to-install assemblies

Scalable Production from Prototype to Scale

Seamless transition from 1 prototype to 10,000+ units with zero quality compromise

Dedicated production lines for high-volume orders, ensuring consistent throughput and on-time delivery

Real-time order tracking via our client portal for full supply chain transparency

Materials & Surface Finishes

Material Options & Finishes for Precision Stainless Steel Bending

Material Selection Guide

Choose the right material based on your application’s performance, environment, and budget needs:

Stainless Steel Grades

304: Ideal for general-purpose enclosures, brackets, and food-safe applications. Balances corrosion resistance, weldability, and cost.

316: Marine-grade strength for chemical exposure, saltwater, or medical devices. Higher molybdenum content resists pitting.

430: Cost-effective for decorative chassis or low-corrosion environments. Magnetic properties suit electromagnetic applications.

Aluminum Options

6061: High strength-to-weight ratio for structural brackets or aerospace components. Excellent fatigue resistance.

5052: Superior formability for complex bends in lightweight enclosures (e.g., consumer electronics housings).

Copper & Alloys

Pure Copper: Unmatched thermal/electrical conductivity for EMI shielding or heat sinks. Requires specialized handling due to softness.

Surface Finish Solutions

Enhance durability, aesthetics, and functionality with precision finishes:

Powder Coating: UV-resistant, scratch-proof color options for outdoor enclosures.

Passivation: Removes surface contaminants; critical for medical/food-grade stainless steel parts.

Mirror/Satin Polishing: Premium visual finish for visible components (e.g., architectural panels).

Anodizing: Hardened surface with color customization for aluminum parts.

Electroplating: Nickel or chrome plating for conductivity and corrosion resistance on copper/steel.

Optimize with AI-Powered Precision

Upload your CAD file today for instant, transparent pricing—no manual quotes, no delays. Our AI-driven platform:

Real-Time Cost Analysis: Instantly breaks down material costs (e.g., 1.2mm 316 stainless steel bends at ~$3.50/bend vs. 0.8mm mild steel at $1.80/bend) and predicts bending complexity fees.

Smart Material Recommendations: Automatically suggests optimal grades (e.g., 304 for standard enclosures, 316 for coastal projects) based on your design’s environmental and mechanical requirements.

5–7 Day Standard Turnaround: Automated workflows eliminate tooling costs and delays—prototypes ship in 72 hours for urgent needs.

Zero Guesswork: Engineered for cost efficiency. For brackets, chassis, or enclosures, our system cross-references material properties with production data to maximize durability while minimizing waste.

Innovate faster, not harder: Honyo Prototype’s platform turns complex material decisions into one-click solutions—so you ship better parts, faster.

From Quote to Part: Our Process

How It Works: From CAD to Part in Days, Not Weeks

Honyo Prototype’s AI-driven platform transforms your design into precision stainless steel parts with seamless transparency and speed—no more guesswork or delays. Perfect for hardware startups and product engineers creating enclosures, brackets, and chassis.

1. Upload Your CAD File

Supported Formats: DXF, STEP, DWG, IGES (drag-and-drop simplicity with automatic file validation)

Instant Compatibility Check: Our system flags formatting issues in seconds—no technical expertise required

No File Size Limits: Handle complex geometries effortlessly for enclosures, brackets, or custom chassis

2. Get Instant AI-Powered Quote

Real-Time Pricing: AI analyzes material thickness, bend count, precision requirements, and stainless steel grade (e.g., 304/316) for accurate costs

Transparent Breakdown: See itemized fees per bend ($1–$5), material adjustments, and processing costs—no hidden charges

Speed: Quote generated in seconds, not days—optimize your budget before committing

3. Proactive DFM Analysis

AI-Powered Design Optimization: Identifies potential issues like insufficient bend radii, material stress points, or tooling conflicts before production

Actionable Recommendations: Receive cost-saving tweaks (e.g., reducing bend angles or adjusting flange lengths) to cut expenses by up to 20% while maintaining strength

Collaborative Refinement: Iterate with our engineering team via a shared dashboard—no back-and-forth emails

4. Rapid Production & Delivery

Precision CNC Bending: ±0.1mm tolerances with automated tool calibration for stainless steel’s high-strength demands

End-to-End Quality Control: Laser verification at every stage—no compromises on accuracy or surface finish

Trackable Turnaround: Most orders ship in 3–5 business days with real-time shipment tracking—faster than traditional suppliers by 50%+

Start Your Project with Honyo

Start Your Project with Honyo: Precision Stainless Steel Bending, Simplified

At Honyo Prototype, we transform complex stainless steel bending challenges into seamless, cost-effective solutions. Our AI-driven platform and Shenzhen-based manufacturing hub deliver precision parts with unprecedented speed and transparency — so you can focus on innovation, not logistics.

AI-Powered Instant Quote in Seconds

Upload your DXF/STEP file → real-time pricing in <10 seconds

Dynamic cost breakdown: per-bend rates ($1–$5), material thickness adjustments, precision tiers

Transparent pricing with no hidden fees — see exactly what you’re paying for

Engineered for Cost Efficiency

Optimized CNC tooling for stainless steel (0.8mm–6mm) reduces costs by up to 30% vs traditional methods

Strategic material selection guidance (e.g., 1.2mm SS vs 0.8mm mild steel cost differences)

Integrated laser cutting + bending workflows minimize secondary operations and rework

3-Day Prototype to Production Turnaround

Shenzhen/Dongguan facilities enable 24/7 production with 72-hour lead times for prototypes

Scalable from 1 to 10,000+ units without retooling costs

ISO-certified quality control at every stage — zero compromise on precision

Why Partner with Honyo? Founder-Led Expertise

Susan Leo (Founder) brings 15+ years in precision sheet metal fabrication and innovation

End-to-end service: laser cutting, welding, powder coating — one partner, one quote

Cost-effective solutions for enclosures, brackets, and chassis — 30% lower total project costs vs industry averages

Ready to Build? Get Your Quote Today

Email: [email protected]

Phone: +86 139 2843 8620

Visit us: Shenzhen/Dongguan facilities (open for tours by appointment)

Innovate with confidence. Let’s build what’s next — faster, smarter, and for less.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.