Contents

Manufacturing Insight: Custom Sheet Metal Ductwork

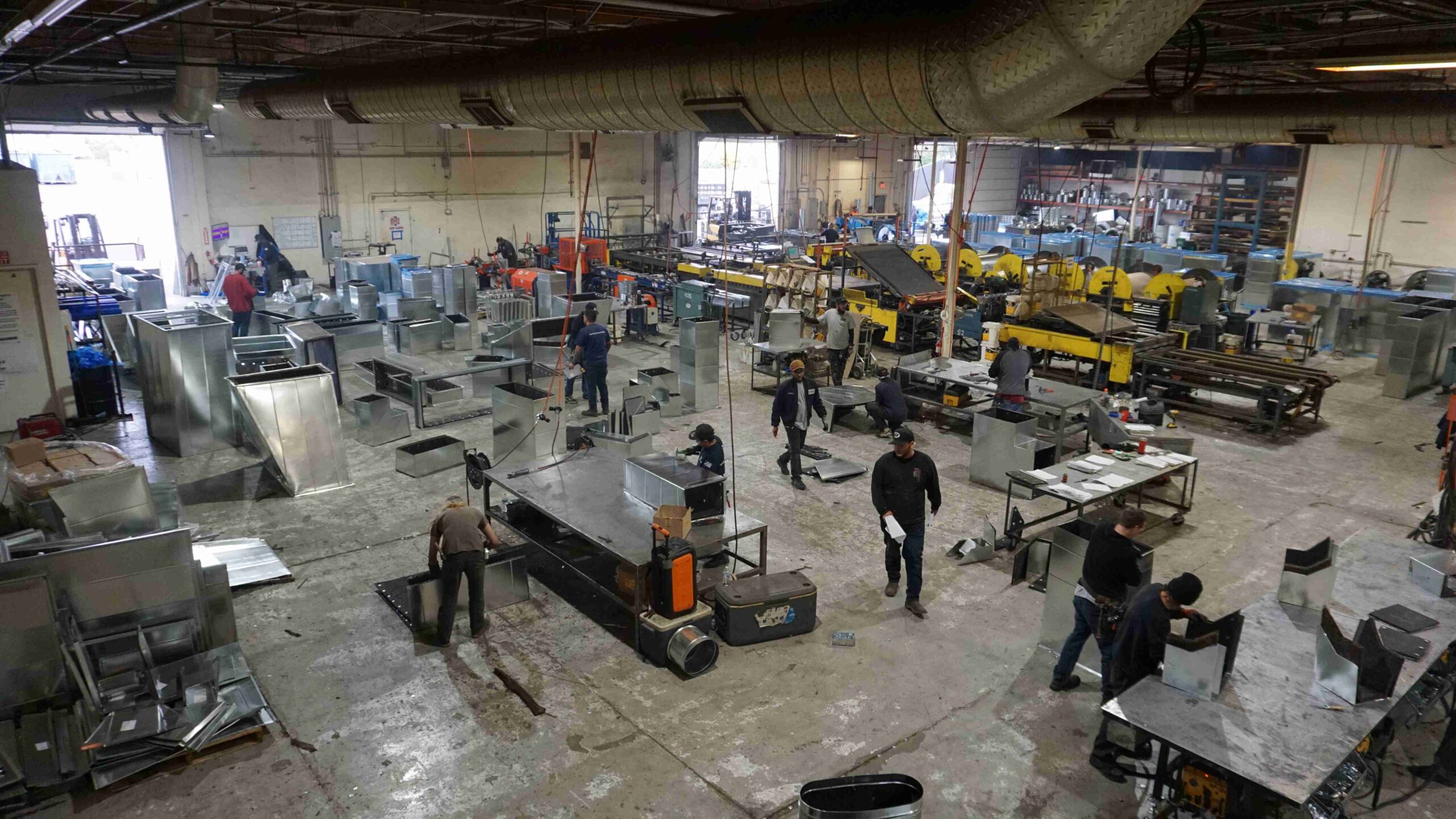

Custom Sheet Metal Ductwork Solutions

Honyo Prototype delivers precision-engineered custom sheet metal ductwork for demanding industrial, commercial, and HVAC applications where airflow integrity, dimensional accuracy, and material performance are non-negotiable. Our advanced sheet metal fabrication capabilities ensure leak-tight seams, optimal aerodynamic profiles, and strict adherence to project specifications—from complex transitions and plenums to custom exhaust systems.

Leveraging state-of-the-art laser cutting, CNC press braking, and robotic welding, we consistently achieve tolerances down to ±0.005 inches across materials including galvanized steel, stainless steel (304/316), and aluminum alloys. Every duct assembly undergoes rigorous QA checks per ASHRAE standards to guarantee structural resilience and compliance with project requirements. Accelerate your project timeline with Honyo’s Online Instant Quote platform, providing detailed pricing and lead time estimates within minutes—no manual RFQ delays. Submit your DXF/DWG files today to validate manufacturability and receive actionable data for seamless integration into your build schedule.

Technical Capabilities

Custom sheet metal ductwork is engineered for precise airflow management in HVAC, industrial ventilation, and specialized process applications. Fabrication involves advanced processes including laser cutting for accuracy, CNC bending for tight tolerances, and welding for structural integrity and leak-resistant joints. Below are the technical specifications related to fabrication processes and compatible materials.

Fabrication Process Specifications

| Process | Technical Capability | Tolerance / Accuracy | Material Compatibility | Notes |

|---|---|---|---|---|

| Laser Cutting | High-precision 2D profiling of sheet metal components using CO₂ or fiber laser systems | ±0.1 mm (0.004 in) | Aluminum, Steel, ABS (limited), Nylon (limited) | ABS and Nylon require specialized lasers; typically not recommended due to melting and outgassing risks |

| CNC Bending | Automated press braking using CNC-controlled tooling for accurate angle formation | ±0.25° angular, ±0.2 mm linear | Aluminum, Steel | Not suitable for ABS or Nylon due to low rigidity and thermal sensitivity |

| Welding | MIG, TIG, or spot welding for seam and joint joining | Penetration depth: 80–100% of base metal | Aluminum (TIG/MIG), Steel (MIG/Spot) | ABS and Nylon are not weldable via conventional methods; require solvent or ultrasonic joining |

Material Properties and Ductwork Suitability

| Material | Thickness Range (Typical) | Formability | Heat Resistance | Joining Method | Application Suitability |

|---|---|---|---|---|---|

| Aluminum | 0.8 – 6.0 mm | Excellent | High (up to 400°C) | TIG/MIG welding, riveting | Corrosion-resistant ducts, cleanrooms, marine |

| Steel | 0.7 – 8.0 mm | Excellent | High (up to 500°C) | MIG/spot welding, fastening | Industrial HVAC, high-temperature exhaust systems |

| ABS | 1.0 – 5.0 mm (sheet) | Good | Low (≤80°C) | Solvent bonding, mechanical | Low-pressure ventilation; not for high-temp service |

| Nylon | 1.0 – 4.0 mm (sheet) | Moderate | Moderate (≤120°C) | Ultrasonic welding, fasteners | Chemical-resistant ducting; limited structural use |

Notes on Material Selection

Aluminum and steel are primary materials for durable, high-performance ductwork requiring laser cutting, bending, and welding.

ABS and nylon are thermoplastics used in specialized corrosive or low-weight applications but are incompatible with standard sheet metal welding and high-heat processes.

Laser cutting of plastics requires controlled environments due to fumes and edge quality concerns.

CNC bending is limited to ductile metals; thermoplastics require thermoforming instead.

From CAD to Part: The Process

Honyo Prototype Custom Sheet Metal Ductwork Process Overview

Honyo Prototype executes custom sheet metal ductwork through a rigorously defined, technology-enhanced workflow designed for precision, efficiency, and manufacturability. Our process begins with structured digital input and concludes with validated delivery, ensuring alignment with client specifications and industry standards.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, DWG, or native SolidWorks formats) via our secure customer portal. We validate file integrity, coordinate systems, and geometric completeness. Incomplete or non-standard files trigger immediate automated feedback to the client, minimizing downstream delays. All geometry, material specifications, and critical tolerances are extracted for downstream systems.

AI-Powered Quoting Engine

Uploaded CAD data feeds directly into our proprietary AI quoting system, which analyzes over 200 geometric and material parameters. The AI cross-references real-time material costs, machine utilization rates, historical production data, and regional logistics variables to generate an accurate cost and lead time estimate within 4 business hours. Complex geometries or non-standard materials trigger escalation to a human estimator for nuanced review, ensuring quotes reflect true manufacturability constraints.

Design for Manufacturability (DFM) Analysis

All designs undergo mandatory DFM review by our senior sheet metal engineering team. This phase identifies potential fabrication conflicts such as suboptimal bend radii, inadequate flange widths, weld accessibility issues, or tolerance stack-ups. We provide actionable feedback via annotated PDF markups or scheduled engineering calls, proposing modifications to enhance producibility without compromising functional requirements. Typical DFM adjustments include optimizing bend sequences, suggesting alternative joint methods (e.g., hemmed seams vs. welding), or material thickness recommendations. Client approval is required before proceeding.

Precision Production Execution

Approved designs move to production using our integrated digital workflow. Laser cutting achieves ±0.1mm positional accuracy on materials up to 6mm thick, while CNC press brakes execute bends to ±0.5° angular tolerance. All welds comply with AWS D1.3 structural steel standards, with robotic welding deployed for repetitive joints. In-process quality checks occur at three stages: post-cutting, post-forming, and post-welding. Dimensional verification uses calibrated CMMs or optical comparators against the original CAD model, with first-article inspection reports provided upon request.

Quality-Controlled Delivery

Final assemblies undergo leak testing per SMACNA standards where specified, followed by protective packaging with edge guards and desiccants for moisture-sensitive finishes. Each shipment includes a traceability package: serialized material certs, FAIR documentation, dimensional reports, and a digital as-built model. Delivery logistics are managed through our certified carrier network, with real-time shipment tracking accessible via the client portal. All deliveries include a quality sign-off from our production lead engineer, confirming adherence to the approved DFM and original specifications.

This closed-loop process ensures that every ductwork component meets stringent performance and dimensional requirements while optimizing cost and timeline predictability. Honyo’s integration of AI-driven quoting with deep engineering oversight eliminates common prototyping pitfalls, delivering production-ready ductwork on schedule.

Start Your Project

Looking for custom sheet metal ductwork solutions? Partner with Honyo Prototype for precision fabrication and reliable delivery. Our manufacturing facility in Shenzhen offers advanced capabilities in sheet metal forming, welding, and finishing tailored to your specifications.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.