Contents

Manufacturing Insight: Custom Sheet Metal Brackets

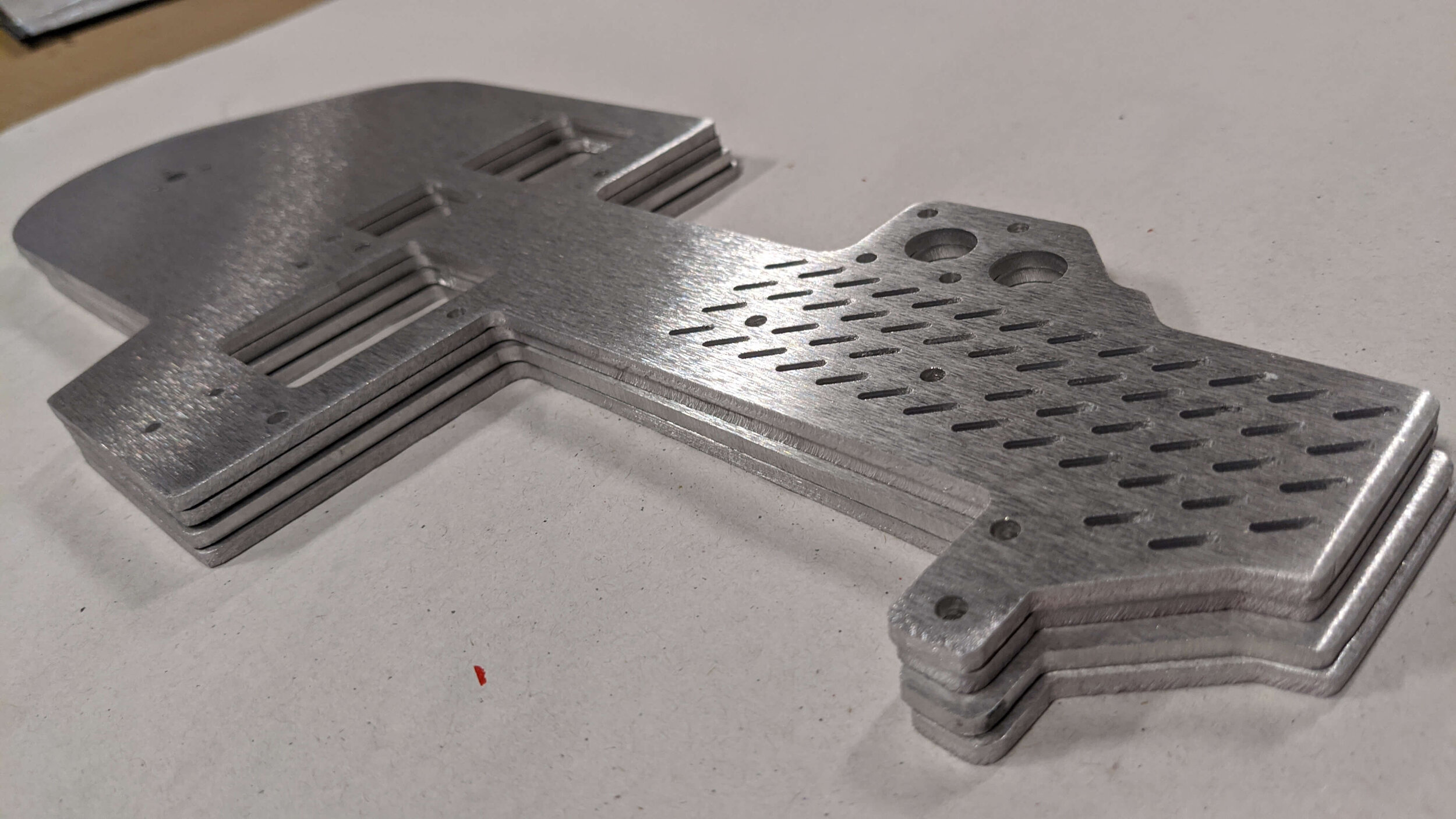

Precision Sheet Metal Brackets Engineered for Your Application

Custom sheet metal brackets serve as critical structural and functional components across aerospace, medical, industrial, and electronics sectors, where dimensional accuracy and material integrity directly impact system performance. At Honyo Prototype, our Sheet Metal Fabrication services deliver mission-critical brackets with rigorous adherence to tight tolerances, complex geometries, and demanding material specifications. Leveraging advanced fiber laser cutting, precision CNC bending, and automated welding capabilities, we transform designs from concept to certified production-ready components—ensuring repeatability from prototyping through high-volume runs.

Our end-to-end process integrates material sourcing, fabrication, finishing, and quality validation under one roof, eliminating supply chain vulnerabilities while maintaining ISO 9001-compliant traceability. Whether you require low-volume custom brackets for R&D validation or scaled production with sub-millimeter precision, Honyo’s engineering team collaborates closely with your design specifications to optimize manufacturability and cost efficiency.

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload your STEP, DWG, or DXF file to receive a detailed, no-obligation fabrication quote in under 60 seconds—complete with lead time estimates, material cost breakdowns, and DFM feedback. This transparent, real-time quoting system eliminates procurement delays, empowering engineering and procurement teams to make data-driven decisions without waiting for manual vendor responses.

For brackets where failure is not an option, Honyo Prototype combines technical expertise with digital efficiency to deliver solutions that meet your exact functional and timeline requirements. Initiate your project with confidence through our Online Instant Quote system today.

Technical Capabilities

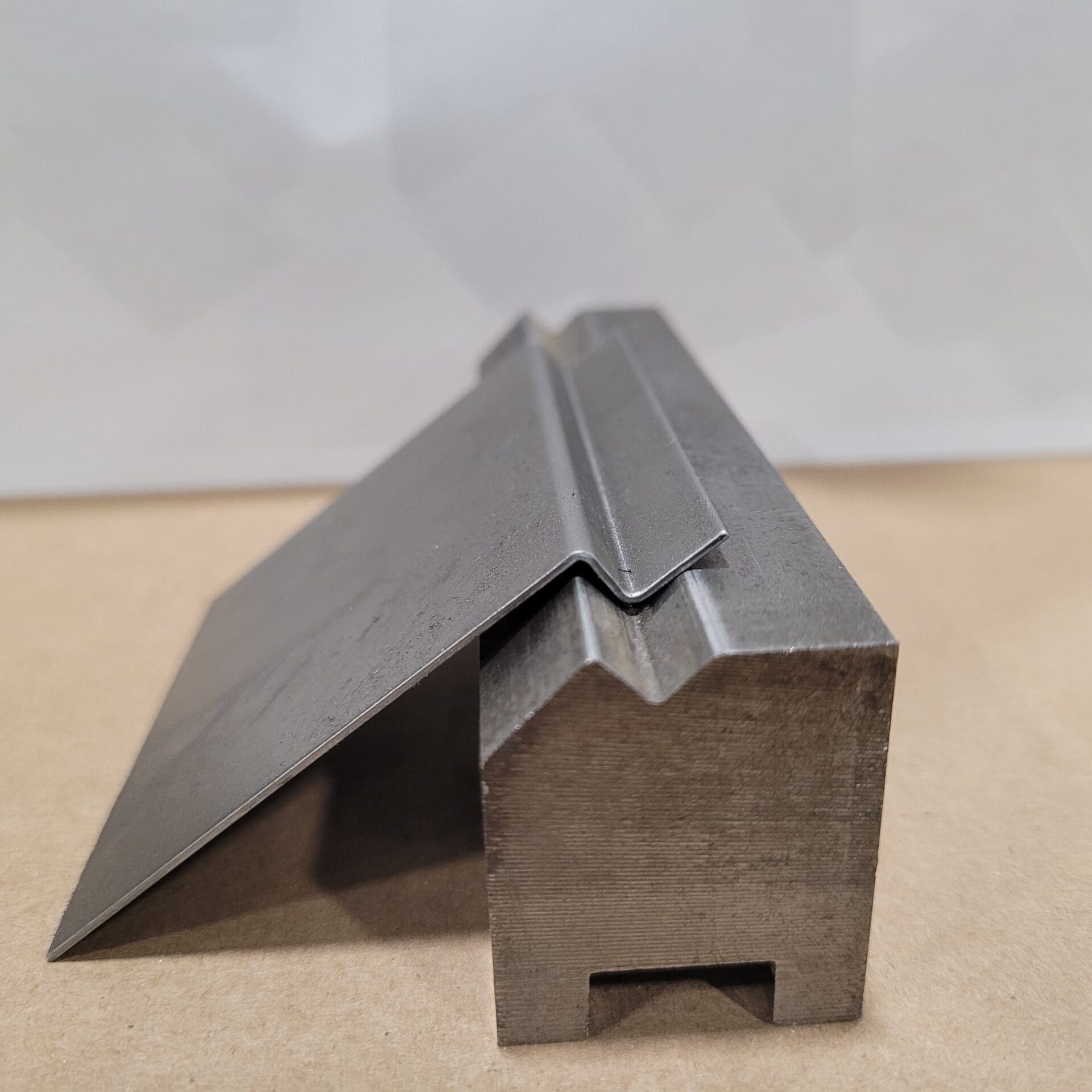

Custom sheet metal brackets are precision-engineered components commonly fabricated using laser cutting, bending, and welding processes. These operations ensure tight tolerances, structural integrity, and compatibility with various assembly requirements. While metals like aluminum and steel are standard for sheet metal fabrication, non-metallic materials such as ABS and nylon are typically machined or molded rather than processed via sheet metal techniques. Below is a detailed technical specification table outlining key parameters for each fabrication process and compatible materials.

| Parameter | Laser Cutting Specification | Bending Specification | Welding Specification | Compatible Materials |

|---|---|---|---|---|

| Process Type | Fiber or CO₂ laser cutting | CNC press braking with precision tooling | MIG, TIG, or spot welding (as applicable) | Aluminum, Steel, ABS, Nylon |

| Material Thickness Range | 0.5 mm – 25 mm (Aluminum: up to 20 mm; Steel: up to 25 mm) | 0.8 mm – 12 mm (optimal for clean bends) | 1.0 mm – 10 mm (minimum thickness for weld integrity) | Varies by material |

| Tolerance | ±0.1 mm (laser cut features) | ±0.2° angular tolerance, ±0.2 mm linear | ±0.5 mm (weld distortion controlled via fixturing) | Material-dependent |

| Edge Quality | Smooth, burr-minimized cut; optional deburring | Clean, crack-free bends with controlled bend radii | Smooth weld beads; post-weld grinding available | Aluminum, Steel |

| Minimum Feature Size | Hole diameter ≥ material thickness; slot width ≥ 1.0 mm | Flange length ≥ 3× material thickness | Weld seam length ≥ 6 mm for strength | Aluminum, Steel |

| Bend Radius | Typically 1× material thickness (standard tooling) | Custom tooling available for tighter radii | N/A | Aluminum, Steel |

| Surface Finish Options | As-cut, anodized (Al), powder coated, zinc-plated (Steel) | Painted, powder coated, or bare metal | Post-weld finishing: grinding, sanding, coating | Aluminum, Steel |

| Material Notes | Aluminum 5052, 6061-T6; Steel: CRCA, HRCA, or Stainless 304 | Avoid bending across grain for improved strength | Weld only conductive, weldable materials | ABS and Nylon not suitable for laser cutting or welding in sheet metal context |

| Process Limitations | ABS and Nylon not suitable (melting, poor edge quality) | Non-metallics not bendable via press brake in sheet format | ABS and Nylon cannot be welded using MIG/TIG; require adhesives or mechanical fastening | ABS and Nylon limited to machining/molding |

Note: ABS and Nylon are included for reference but are not compatible with standard sheet metal processes such as laser cutting, bending, or welding. These polymers are typically fabricated using CNC machining, routing, or injection molding. For hybrid assemblies, brackets in aluminum or steel can be designed to integrate with plastic components via fasteners or inserts.

From CAD to Part: The Process

Honyo Prototype Custom Sheet Metal Bracket Production Process

Our end-to-end workflow for custom sheet metal brackets ensures precision, efficiency, and transparency from initial design to final delivery. The process is structured to minimize lead times while maintaining rigorous quality standards, specifically optimized for low-to-mid volume prototyping and bridge production.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, DWG, or native formats like SolidWorks) via our secure customer portal. Our system automatically validates file integrity, checks for unit consistency, and confirms geometric completeness. Incomplete or non-manufacturable geometries trigger immediate client alerts with specific error diagnostics, preventing downstream delays. All uploaded designs are timestamped and assigned a unique project ID for traceability.

AI-Powered Quoting Engine

Validated CAD files enter our proprietary parametric quoting system, which analyzes over 50 manufacturability and cost drivers in under 90 seconds. The AI engine evaluates material utilization, bend complexity, hardware integration points, secondary operations (e.g., tapping, welding), and surface finish requirements against real-time material costs and machine capacity. Crucially, this is not a black-box solution: every AI-generated quote undergoes review by a dedicated manufacturing engineer who verifies feasibility and adjusts parameters for edge cases (e.g., exotic alloys or extreme tolerances). Clients receive a detailed quote breakdown including material grade options, estimated lead time, and actionable DFM suggestions.

Engineering-Led DFM Analysis

Upon quote acceptance, senior manufacturing engineers conduct a formal Design for Manufacturability (DFM) review. This phase focuses on eliminating cost drivers while preserving functional intent. Key optimization areas include:

| Parameter | Standard Check | Honyo Enhancement |

|---|---|---|

| Bend Radius | Confirms ≥ material thickness | Recommends optimal radii for tooling reduction |

| Hole Placement | Verifies edge/corner distances | Proposes nest-friendly patterns for laser cutting |

| Tolerances | Flags unrealistic GD&T | Substitutes cost-effective alternatives |

| Material Selection | Validates grade vs. application | Suggests cost-optimized alternatives (e.g., 5052 vs. 6061) |

Clients receive a formal DFM report within 24 hours, with collaborative revision tools to approve changes or discuss trade-offs. This stage typically reduces production costs by 15–30% through geometry simplifications and process optimizations.

Precision Production Execution

Approved designs move to our climate-controlled production floor. Brackets are manufactured using:

Laser Cutting: Amada LC series with ±0.1mm positional accuracy for complex contours

Bending: CNC press brakes (Trumf/Tajima) with co-ordinate measuring machine (CMM) verified tooling

Finishing: In-house deburring, powder coating (AAMA 2604 compliant), or anodizing based on specifications

All critical dimensions undergo first-article inspection per AS9102 standards, with real-time SPC data logged to the client portal. High-mix production lines enable lot sizes from 1 to 500 units without retooling delays.

Quality-Controlled Delivery

Final brackets undergo 100% visual inspection and batch sampling for dimensional compliance (per ISO 2768-mK). Packaging is customized for application requirements—static-shielded for electronics or kitted for assembly lines. We manage logistics via DHL/FedEx with temperature-controlled options for sensitive finishes, providing real-time shipment tracking. Every order includes a digital quality dossier with inspection reports, material certifications, and process validation records. Standard lead time is 7–10 business days from DFM sign-off, with expedited 72-hour options for prototypes.

This integrated process leverages automation for speed while retaining engineering oversight at critical decision points, ensuring brackets meet functional requirements without compromising manufacturability. Clients retain full visibility through our portal, with direct engineer access for technical queries at any stage.

Start Your Project

Looking for custom sheet metal brackets tailored to your exact specifications? Honyo Prototype delivers precision-manufactured components from our Shenzhen factory, ensuring fast turnaround and consistent quality.

Contact Susan Leo today to discuss your project requirements. Email [email protected] for a prompt response and expert engineering support.

| Feature | Detail |

|---|---|

| Material Options | Steel, Stainless Steel, Aluminum, Galvanized |

| Processes | Laser Cutting, CNC Punching, Bending, Welding |

| Finishes | Powder Coating, Anodizing, Plating, Passivation |

| Tolerances | ±0.1 mm typical |

| Location | Shenzhen, China |

Partner with a trusted manufacturer for low to medium volume production runs with scalable capacity. Let Honyo Prototype be your solution for reliable, high-precision sheet metal brackets.

Reach out to Susan Leo at [email protected] to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.