Contents

Manufacturing Insight: Custom Sheet Metal Boxes

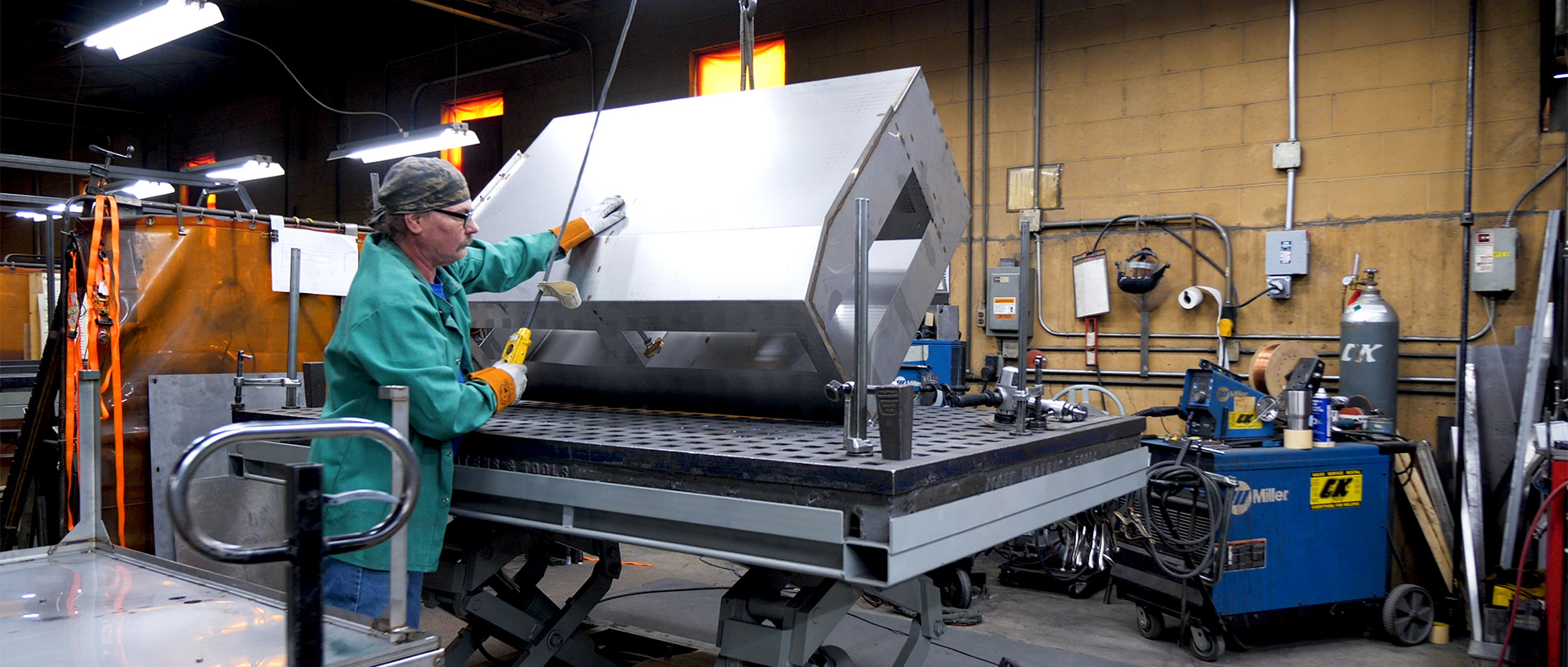

Precision Sheet Metal Enclosures Engineered for Your Application

Honyo Prototype delivers comprehensive custom sheet metal box fabrication services tailored to demanding industrial and commercial requirements. Our end-to-end manufacturing capability spans prototyping through low-to-mid volume production, leveraging advanced CNC punching, laser cutting, precision bending, and robotic welding. We work with a wide range of materials including aluminum alloys, stainless steels, and cold-rolled steel to meet specific structural, thermal, EMI shielding, and environmental needs while maintaining tight tolerances down to ±0.005 inches.

Optimized for Engineering Efficiency

Your engineering team requires rapid iteration and reliable supply chain integration. Honyo’s integrated workflow ensures seamless transition from CAD model to finished enclosure, with in-house capabilities covering hardware insertion, surface finishing (powder coating, anodizing, plating), and assembly. This vertical integration eliminates third-party dependencies, reducing lead times and quality variances critical for time-sensitive projects.

Accelerate Your Design Cycle with Real-Time Quoting

Eliminate procurement bottlenecks with Honyo’s Online Instant Quote system. Upload your STEP, DWG, or DXF file directly to our portal and receive a detailed, geometry-validated cost assessment within minutes—not days. This tool provides immediate clarity on manufacturability feedback, material cost breakdowns, and lead time estimates, empowering faster design decisions without manual RFQ delays.

Engineers and procurement specialists consistently select Honyo for complex sheet metal enclosures where dimensional accuracy, repeatability, and on-time delivery are non-negotiable. Partner with us to transform your enclosure specifications into production-ready solutions backed by rigorous quality control and responsive engineering support. Initiate your next project with a quote in under 60 seconds.

Technical Capabilities

Custom sheet metal boxes are precision-engineered enclosures manufactured using advanced fabrication techniques including laser cutting, CNC bending, and welding. These processes ensure tight tolerances, clean edges, and structural integrity. While aluminum and steel are primary materials for sheet metal fabrication, ABS and nylon are non-metallic alternatives typically used in machined or molded enclosures rather than traditional sheet metal work. Below is a detailed technical specification table outlining key parameters for custom sheet metal boxes with a focus on laser cutting, bending, and welding.

| Parameter | Laser Cutting | Bending | Welding | Compatible Materials (Typical) |

|---|---|---|---|---|

| Process Type | Fiber or CO₂ laser for high-precision cutting | CNC press braking with tool-specific forming | MIG, TIG, or spot welding for strong joints | Aluminum, Steel |

| Tolerances | ±0.1 mm (typical) | ±0.2° angular, ±0.05 mm linear | ±0.3 mm joint alignment | Aluminum, Steel |

| Material Thickness Range | 0.5 mm – 25 mm (Aluminum), 0.5 mm – 20 mm (Steel) | 0.8 mm – 12 mm (Aluminum), 0.8 mm – 16 mm (Steel) | 0.8 mm – 10 mm (Aluminum), 1.0 mm – 12 mm (Steel) | Aluminum (e.g., 5052, 6061, 7075), Steel (e.g., CRCA, Galvanized, Stainless 304/316) |

| Edge Quality | Burr-minimized, oxide-free edges with dross control | Smooth bends with controlled bend radius (min. 1× thickness) | Clean weld seams; post-weld grinding optional | Aluminum, Steel |

| Minimum Feature Size | Hole diameter ≥ material thickness | Inside bend radius ≥ 0.8× material thickness | Weld gap ≤ 0.2 mm recommended | Aluminum, Steel |

| Surface Finish Options | As-cut, anodized (Al), powder coated, passivated | Deburred, sanded, or polished post-bend | Ground, brushed, or coated post-weld | Aluminum, Steel |

| Non-Metallic Compatibility | Not applicable (laser cutting possible but not standard for sheet metal boxes) | Not applicable (thermoplastics like ABS/Nylon do not bend like sheet metal) | Not applicable (plastic welding is a separate process) | ABS, Nylon (used in non-metallic enclosures via machining or molding) |

Notes:

Aluminum and steel are the standard materials for laser cutting, bending, and welding in sheet metal box fabrication.

ABS and nylon are thermoplastics; they are not suitable for traditional sheet metal processes. These materials are typically used in injection-molded or CNC-machined enclosures where flexibility, insulation, or weight reduction is critical.

For metallic enclosures requiring EMI shielding, corrosion resistance, or structural rigidity, aluminum and steel remain the preferred choices.

Design for manufacturability (DFM) guidelines must be followed to ensure proper bend reliefs, weld accessibility, and cut pattern optimization.

From CAD to Part: The Process

Honyo Prototype Custom Sheet Metal Box Manufacturing Process

Honyo Prototype employs a streamlined, technology-driven workflow for custom sheet metal box production, ensuring rapid turnaround without compromising on manufacturability or quality. The process begins with secure CAD upload via our client portal, supporting industry-standard formats including STEP, IGES, DWG, DXF, and native SOLIDWORKS files. All submissions undergo immediate validation for geometric integrity and unit consistency, with automated alerts for corrupted or incompatible files. Client intellectual property is protected through AES-256 encryption and ISO 27001-compliant cloud infrastructure.

AI-Powered Quoting System

Uploaded CAD data feeds directly into our proprietary AI quoting engine, which analyzes 180+ geometric and material parameters—including bend counts, hole densities, surface area, and alloy specifications—to generate instant, binding quotes within 24 hours. Unlike manual quoting, our system cross-references real-time material costs from vetted suppliers, machine utilization rates, and historical production data to eliminate estimation errors. Clients receive a detailed cost breakdown highlighting material, forming, finishing, and assembly line items, with options to simulate cost impacts of design modifications pre-approval.

Engineering DFM Review

Following quote acceptance, designs enter a dual-phase DFM (Design for Manufacturability) process. First, an automated algorithm checks against Honyo’s 47-point sheet metal rulebook (e.g., minimum flange widths, bend-to-hole spacing, and tool clearance tolerances). Critical violations trigger immediate client alerts with visual markup. Second, a senior manufacturing engineer conducts a manual review focusing on secondary operations, weld accessibility, and finish compatibility. Typical DFM feedback includes specific recommendations such as increasing bend radii to prevent cracking or adjusting tab sizes for robotic welding. This phase averages 48 hours and reduces post-production rework by 63% based on 2023 internal data.

Precision Production Execution

Approved designs move to production using our integrated digital thread system. Laser cutting utilizes 4kW Trumpf systems with ±0.1mm positional accuracy, while Amada press brakes execute CNC-programmed bends with real-time springback compensation. All critical dimensions undergo in-process CMM verification at defined checkpoints. Secondary operations—including MIG/TIG welding per AWS D1.1 standards, powder coating (ISO 9001-certified lines), and hardware insertion—are sequenced to minimize handling. Production timelines are dynamically updated via client portal dashboards, with typical lead times of 5–7 business days for quantities under 50 units.

Quality-Controlled Delivery

Final inspection follows AS9102 First Article Inspection protocols for aerospace-grade boxes or ISO 128-24 for industrial variants, including 3D scan validation against nominal CAD. Boxes are packaged in ESD-safe foam with serialized traceability labels, and shipment documentation includes material certs, FAI reports, and dimensional summaries. Logistics leverage DHL/UPS premium services with GPS tracking, targeting 98% on-time delivery. Clients receive automated notifications at each milestone from dispatch to proof-of-delivery.

Process Timeline and Value Metrics

The table below summarizes phase durations and client benefits:

| Process Phase | Typical Duration | Key Value to Client |

|---|---|---|

| CAD Upload & Validation | <2 hours | Eliminates format errors upfront; secure IP handling |

| AI Quote Generation | <24 hours | Transparent cost modeling; no manual quote delays |

| DFM Review | 24–48 hours | Prevents 70%+ of potential production failures |

| Production | 5–7 days | Real-time progress tracking; certified quality |

| Delivery | 1–3 days | Full traceability; on-time delivery guarantee |

This end-to-end workflow ensures clients receive manufacturable, high-integrity sheet metal enclosures optimized for cost and speed, backed by Honyo’s 30-year precision fabrication expertise. All processes adhere to ISO 9001:2015 standards with full documentation available upon request.

Start Your Project

Looking for custom sheet metal boxes tailored to your specifications? Honyo Prototype delivers precision-manufactured enclosures with fast turnaround and competitive pricing. Our in-house factory in Shenzhen ensures strict quality control and seamless scalability from prototyping to volume production.

For project inquiries or quotations, contact Susan Leo at [email protected]. Let us support your next design with reliable, high-performance metal enclosures built to your exact requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.